ASTM C1332-18

(Practice)Standard Practice for Measurement of Ultrasonic Attenuation Coefficients of Advanced Ceramics by Pulse-Echo Contact Technique

Standard Practice for Measurement of Ultrasonic Attenuation Coefficients of Advanced Ceramics by Pulse-Echo Contact Technique

SIGNIFICANCE AND USE

5.1 This practice is useful for characterizing material microstructure or measuring variations in microstructure that occur because of material processing conditions and thermal, mechanical, or chemical exposure (3). When applied to monolithic or composite ceramics, the procedure should reveal microstructural gradients due to density, porosity, and grain variations. This practice may also be applied to polycrystalline metals to assess variations in grain size, porosity, and multiphase constituents.

5.2 This practice is useful for measuring and comparing microstructural variations among different samples of the same material or for sensing and measuring subtle microstructural variations within a given sample.

5.3 This practice is useful for mapping variations in the attenuation coefficient and the attenuation spectrum as they pertain to variations in the microstructure and associated properties of monolithic ceramics, ceramic composites and metals.

5.4 This practice is useful for establishing a reference database for comparing materials and for calibrating ultrasonic attenuation measurement equipment.

5.5 This practice is not recommended for highly attenuating monolithics or composites that are thick, highly porous, or that have rough or highly textured surfaces. For these materials Practice E664/E664M may be appropriate. Guide E1495/E1495M is recommended for assessing attenuation differences among composite plates and laminates that may exhibit, for example, pervasive matrix porosity or matrix crazing in addition to having complex fiber architectures or thermomechanical degradation (3). The proposed ASTM Standard Practice for Measuring Ultrasonic Velocity in Advanced Ceramics (C1331) is recommended for characterizing monolithic ceramics with significant porosity or porosity variations (4).

SCOPE

1.1 This practice describes a procedure for measurement of ultrasonic attenuation coefficients for advanced structural ceramic materials. The procedure is based on a broadband buffered piezoelectric probe used in the pulse-echo contact mode and emitting either longitudinal or shear waves. The primary objective of this practice is materials characterization.

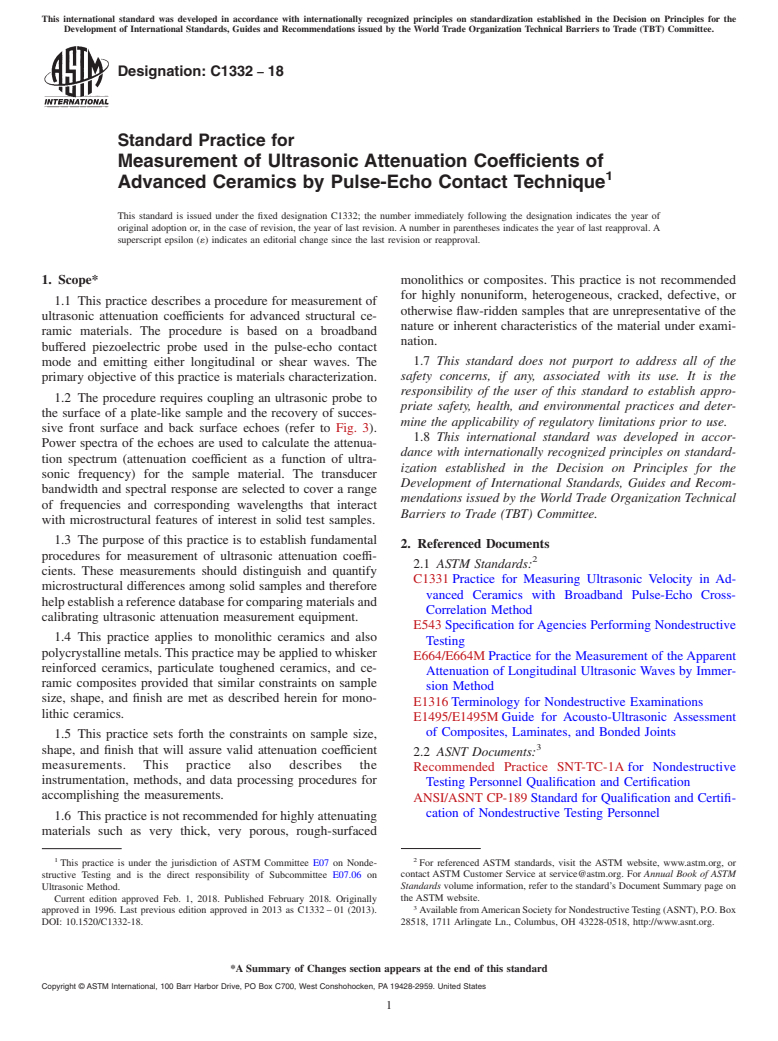

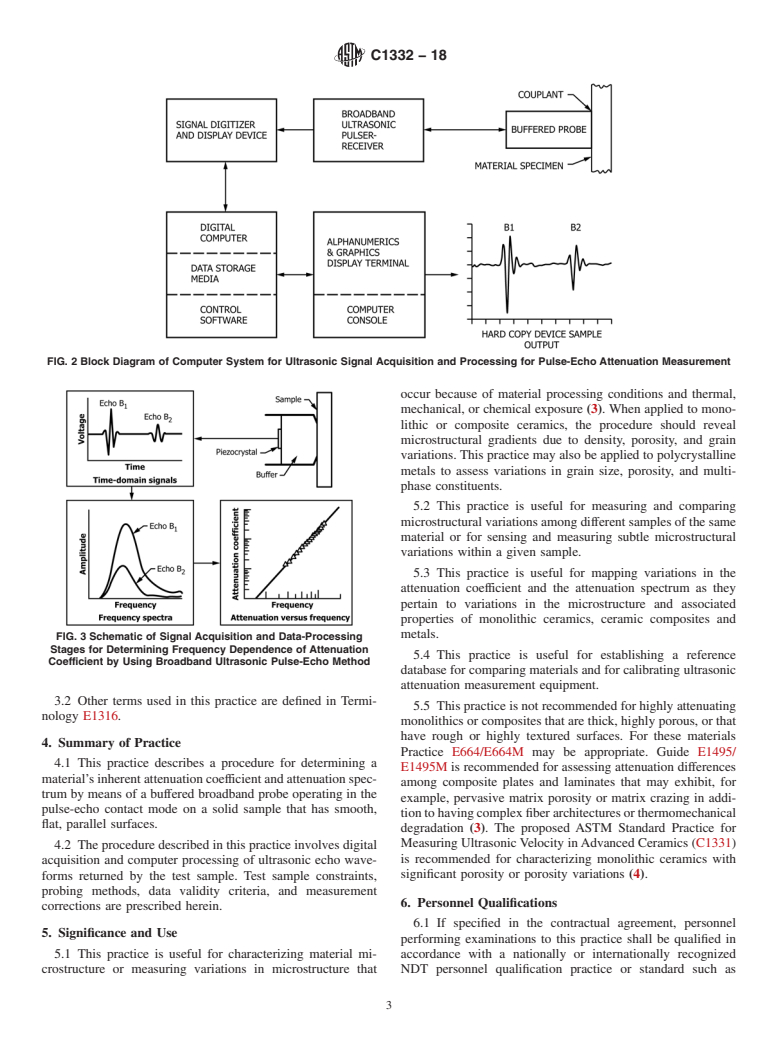

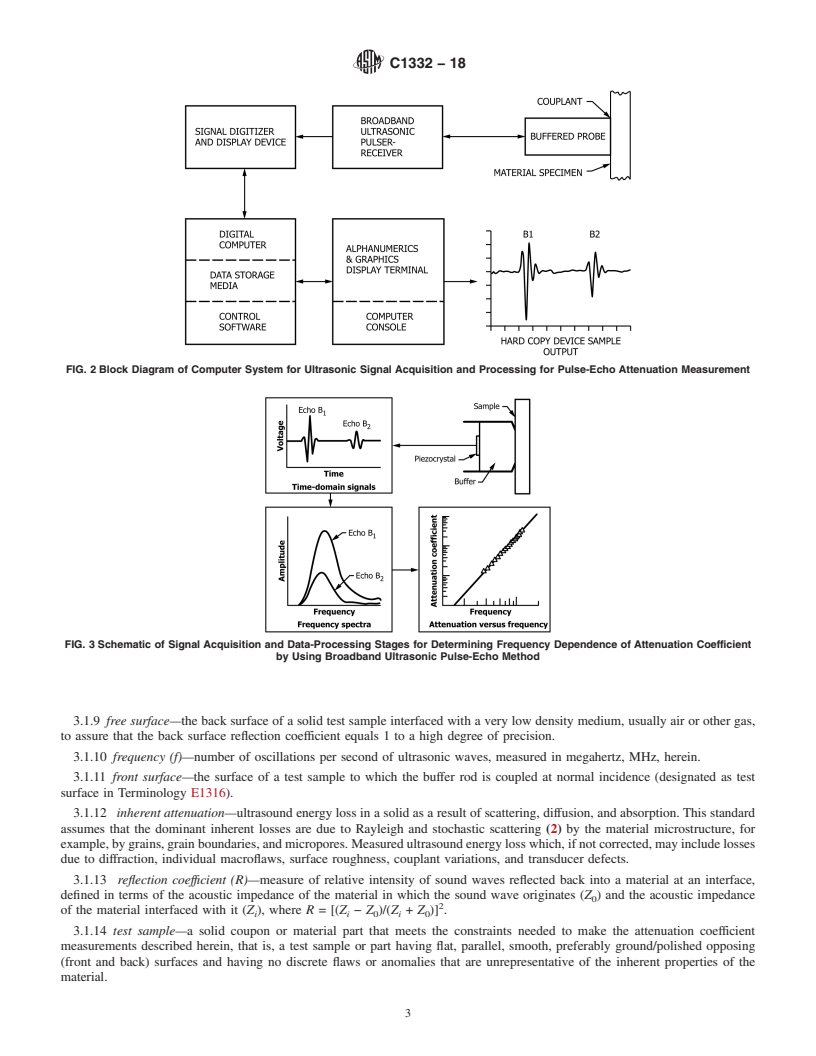

1.2 The procedure requires coupling an ultrasonic probe to the surface of a plate-like sample and the recovery of successive front surface and back surface echoes (refer to Fig. 3). Power spectra of the echoes are used to calculate the attenuation spectrum (attenuation coefficient as a function of ultrasonic frequency) for the sample material. The transducer bandwidth and spectral response are selected to cover a range of frequencies and corresponding wavelengths that interact with microstructural features of interest in solid test samples.

1.3 The purpose of this practice is to establish fundamental procedures for measurement of ultrasonic attenuation coefficients. These measurements should distinguish and quantify microstructural differences among solid samples and therefore help establish a reference database for comparing materials and calibrating ultrasonic attenuation measurement equipment.

1.4 This practice applies to monolithic ceramics and also polycrystalline metals. This practice may be applied to whisker reinforced ceramics, particulate toughened ceramics, and ceramic composites provided that similar constraints on sample size, shape, and finish are met as described herein for monolithic ceramics.

1.5 This practice sets forth the constraints on sample size, shape, and finish that will assure valid attenuation coefficient measurements. This practice also describes the instrumentation, methods, and data processing procedures for accomplishing the measurements.

1.6 This practice is not recommended for highly attenuating materials such as very thick, very porous, rough-surfaced monolithics or composites. This practice is not recommended for highly nonuniform, heterogeneous, cracked, defective, or otherwise flaw-r...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1332 − 18

Standard Practice for

Measurement of Ultrasonic Attenuation Coefficients of

1

Advanced Ceramics by Pulse-Echo Contact Technique

This standard is issued under the fixed designation C1332; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* monolithics or composites. This practice is not recommended

for highly nonuniform, heterogeneous, cracked, defective, or

1.1 This practice describes a procedure for measurement of

otherwise flaw-ridden samples that are unrepresentative of the

ultrasonic attenuation coefficients for advanced structural ce-

nature or inherent characteristics of the material under exami-

ramic materials. The procedure is based on a broadband

nation.

buffered piezoelectric probe used in the pulse-echo contact

1.7 This standard does not purport to address all of the

mode and emitting either longitudinal or shear waves. The

safety concerns, if any, associated with its use. It is the

primary objective of this practice is materials characterization.

responsibility of the user of this standard to establish appro-

1.2 The procedure requires coupling an ultrasonic probe to

priate safety, health, and environmental practices and deter-

the surface of a plate-like sample and the recovery of succes-

mine the applicability of regulatory limitations prior to use.

sive front surface and back surface echoes (refer to Fig. 3).

1.8 This international standard was developed in accor-

Power spectra of the echoes are used to calculate the attenua-

dance with internationally recognized principles on standard-

tion spectrum (attenuation coefficient as a function of ultra-

ization established in the Decision on Principles for the

sonic frequency) for the sample material. The transducer

Development of International Standards, Guides and Recom-

bandwidth and spectral response are selected to cover a range

mendations issued by the World Trade Organization Technical

of frequencies and corresponding wavelengths that interact

Barriers to Trade (TBT) Committee.

with microstructural features of interest in solid test samples.

1.3 The purpose of this practice is to establish fundamental

2. Referenced Documents

procedures for measurement of ultrasonic attenuation coeffi-

2

2.1 ASTM Standards:

cients. These measurements should distinguish and quantify

C1331Practice for Measuring Ultrasonic Velocity in Ad-

microstructural differences among solid samples and therefore

vanced Ceramics with Broadband Pulse-Echo Cross-

helpestablishareferencedatabaseforcomparingmaterialsand

Correlation Method

calibrating ultrasonic attenuation measurement equipment.

E543Specification forAgencies Performing Nondestructive

1.4 This practice applies to monolithic ceramics and also

Testing

polycrystallinemetals.Thispracticemaybeappliedtowhisker

E664/E664MPractice for the Measurement of theApparent

reinforced ceramics, particulate toughened ceramics, and ce-

Attenuation of Longitudinal Ultrasonic Waves by Immer-

ramic composites provided that similar constraints on sample

sion Method

size, shape, and finish are met as described herein for mono-

E1316Terminology for Nondestructive Examinations

lithic ceramics.

E1495/E1495MGuide for Acousto-Ultrasonic Assessment

of Composites, Laminates, and Bonded Joints

1.5 This practice sets forth the constraints on sample size,

3

shape, and finish that will assure valid attenuation coefficient

2.2 ASNT Documents:

measurements. This practice also describes the

Recommended Practice SNT-TC-1A for Nondestructive

instrumentation, methods, and data processing procedures for

Testing Personnel Qualification and Certification

accomplishing the measurements.

ANSI/ASNT CP-189Standard for Qualification and Certifi-

cation of Nondestructive Testing Personnel

1.6 Thispracticeisnotrecommendedforhighlyattenuating

materials such as very thick, very porous, rough-surfaced

1 2

This practice is under the jurisdiction of ASTM Committee E07 on Nonde- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

structive Testing and is the direct responsibility of Subcommittee E07.06 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Ultrasonic Method. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Feb. 1, 2018. Published February 2018. Originally the ASTM website.

3

approved in 1996. Last previous edition approved in 2013 as C1332–01 (2013). AvailablefromAmericanSo

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1332 − 01 (Reapproved 2013) C1332 − 18

Standard Test Method Practice for

Measurement of Ultrasonic Attenuation Coefficients of

1

Advanced Ceramics by Pulse-Echo Contact Technique

This standard is issued under the fixed designation C1332; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method practice describes a procedure for measurement of ultrasonic attenuation coefficients for advanced

structural ceramic materials. The procedure is based on a broadband buffered piezoelectric probe used in the pulse-echo contact

mode and emitting either longitudinal or shear waves. The primary objective of this test method practice is materials

characterization.

1.2 The procedure requires coupling an ultrasonic probe to the surface of a plate-like sample and the recovery of successive

front surface and back surface echoes. echoes (refer to Fig. 3). Power spectra of the echoes are used to calculate the attenuation

spectrum (attenuation coefficient as a function of ultrasonic frequency) for the sample material. The transducer bandwidth and

spectral response are selected to cover a range of frequencies and corresponding wavelengths that interact with microstructural

features of interest in solid test samples.

1.3 The purpose of this test method practice is to establish fundamental procedures for measurement of ultrasonic attenuation

coefficients. These measurements should distinguish and quantify microstructural differences among solid samples and therefore

help establish a reference database for comparing materials and calibrating ultrasonic attenuation measurement equipment.

1.4 This test method practice applies to monolithic ceramics and also polycrystalline metals. This test method practice may be

applied to whisker reinforced ceramics, particulate toughened ceramics, and ceramic composites provided that similar constraints

on sample size, shape, and finish are met as described herein for monolithic ceramics.

1.5 This test method practice sets forth the constraints on sample size, shape, and finish that will assure valid attenuation

coefficient measurements. This test method practice also describes the instrumentation, methods, and data processing procedures

for accomplishing the measurements.

1.6 This test method practice is not recommended for highly attenuating materials such as very thick, very porous,

rough-surfaced monolithics or composites. This test method practice is not recommended for highly nonuniform, heterogeneous,

cracked, defective, or otherwise flaw-ridden samples that are unrepresentative of the nature or inherent characteristics of the

material under examination.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C1331 Practice for Measuring Ultrasonic Velocity in Advanced Ceramics with Broadband Pulse-Echo Cross-Correlation Method

E543 Specification for Agencies Performing Nondestructive Testing

1

This test method practice is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.06 on

Ultrasonic Method.

Current edition approved Feb. 1, 2013Feb. 1, 2018. Published April 2013February 2018. Originally approved in 1996. Last previous edition approved in 20072013 as

C1332C1332 – 01 (2013).– 01 (2007). DOI: 10.1520/C1332-01R13. DOI: 10.1520/C1332-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.