ASTM F948-94(2011)

(Test Method)Standard Test Method for Time-to-Failure of Plastic Piping Systems and Components Under Constant Internal Pressure With Flow (Withdrawn 2018)

Standard Test Method for Time-to-Failure of Plastic Piping Systems and Components Under Constant Internal Pressure With Flow (Withdrawn 2018)

SIGNIFICANCE AND USE

The data obtained by this test method are useful for establishing pressure, or hoop stress where applicable, versus failure-time relationships, under independently controlled internal and external environments that simulate actual anticipated product end-use conditions, from which the design basis (DB) for piping products or materials, or both, can be determined. (Refer to Test Method D2837 and Practice D2992, and Appendix X1 of this test method.)

Note 3—Reference to design basis (DB) in this test method refers to the hydrostatic design basis (HDB) for material in straight hollow cylindrical shapes where hoop stress can be easily calculated, or is based on applied pressure design basis (PDB) for complex-shaped products or systems where complex stress fields seriously prohibit the use of hoop stress.

In order to characterize plastics as piping products, it is necessary to establish the stress-to-rupture-time, or pressure-to-rupture-time relationships over two or more logarithmic decades of time (hours) within controlled environmental parameters. Because of the nature of the test and specimens employed, no single line can adequately represent the data. Therefore, the confidence limits should be established.

Results obtained at one set of environmental conditions should not be used for other conditions, except that higher temperature data can be used for a design basis assignment for lower application temperatures, provided that it can be demonstrated that the application conditions present a less stringent environment. The design basis should be determined for each specific plastic material and each different set of environmental constraints. Design and processing can significantly affect the long-term performance of piping products, and therefore should be taken into consideration during any evaluation (see Appendix X2).

Specimens used must be representative of the piping product or material under evaluation (see Appendix X2).

SCOPE

1.1 This test method covers the determination of the time-to-failure of plastic piping products under constant internal pressure and flow.

1.2 This test method provides a method of characterizing plastics in the form of pipe, components, and systems under any reasonable combination of internal and external temperatures and environments, under the procedures described.

1.3 This test method can be used to characterize the tested plastic materials or products, or both, on the basis of pressure-, or stress-rupture data developed under the conditions prescribed.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the determination of the time-to-failure of plastic piping products under constant internal pressure and flow.

Formerly under the jurisdiction of Committee F17 on Plastic Piping Systems, this test method was withdrawn in February 2018. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F948 − 94 (Reapproved 2011)

Standard Test Method for

Time-to-Failure of Plastic Piping Systems and Components

1

Under Constant Internal Pressure With Flow

ThisstandardisissuedunderthefixeddesignationF948;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2992 Practice for Obtaining Hydrostatic or Pressure De-

sign Basis for “Fiberglass” (Glass-Fiber-Reinforced

1.1 This test method covers the determination of the time-

Thermosetting-Resin) Pipe and Fittings

to-failure of plastic piping products under constant internal

D3567 Practice for Determining Dimensions of “Fiberglass”

pressure and flow.

(Glass-Fiber-Reinforced Thermosetting Resin) Pipe and

1.2 This test method provides a method of characterizing

Fittings

plastics in the form of pipe, components, and systems under

E177 Practice for Use of the Terms Precision and Bias in

any reasonable combination of internal and external tempera-

ASTM Test Methods

tures and environments, under the procedures described.

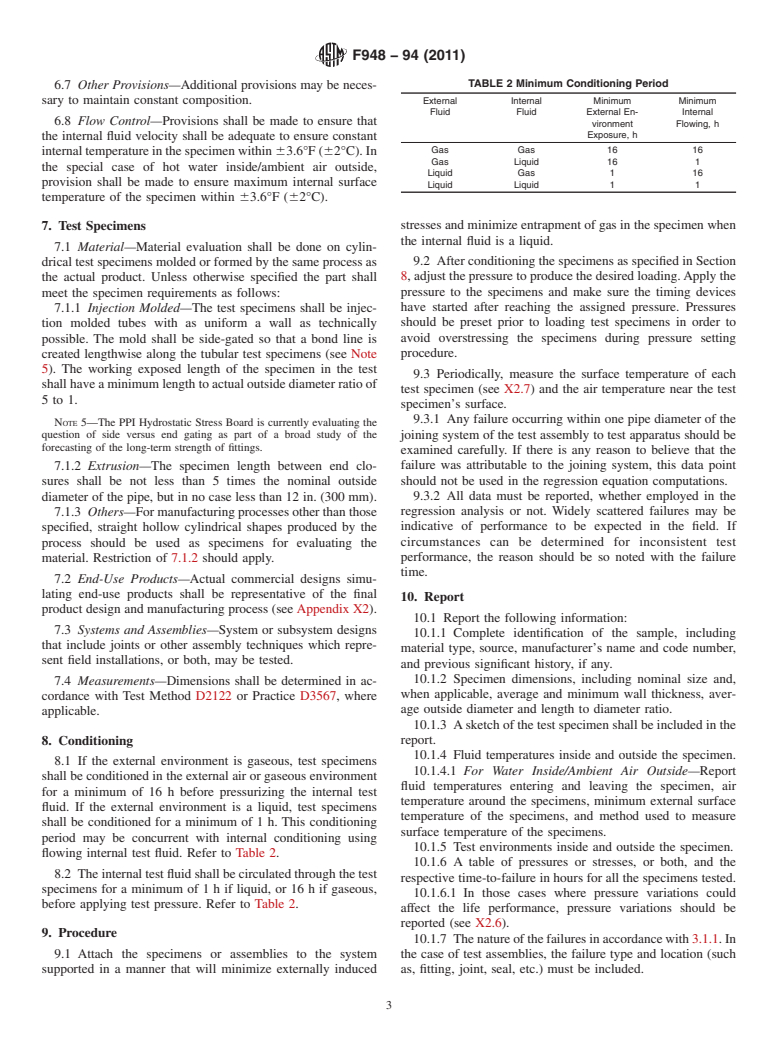

2.2 PPI Documents:

1.3 This test method can be used to characterize the tested

TR-2 Policies and Procedures for the Listing ofThermoplas-

plastic materials or products, or both, on the basis of pressure-,

tic Pipe, Fittings, and Fixture Materials When Evaluated

3

or stress-rupture data developed under the conditions pre-

Under Constant Internal Pressure With Flow

scribed.

TR-3 Policies and Procedures for Developing Recom-

mended Hydrostatic Design Stresses for Thermoplastic

1.4 The values stated in inch-pound units are to be regarded

3

Pipe Materials

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

3. Terminology

and are not considered standard.

3.1 Definitions:

1.5 This standard does not purport to address all of the

3.1.1 failure—bursting, cracking, splitting, or weeping

safety concerns, if any, associated with its use. It is the

(seepage of test fluid through the wall of the product) during

responsibility of the user of this standard to establish appro-

the test, which results in the inability of the specimen to

priate safety and health practices and determine the applica-

maintain pressure or contain the internal test fluid, shall

bility of regulatory limitations prior to use.

constitute failure of the test specimen. Failure may sometimes

occur by ballooning, an excessive extension leading to struc-

2. Referenced Documents

tural failure. When failure occurs by ballooning the degree of

2

2.1 ASTM Standards:

distension should be recorded. Assemblies may also fail to

D543 Practices for Evaluating the Resistance of Plastics to

joint leakage or separation.

Chemical Reagents

NOTE 1—Overall distension, which results from creep caused by

D2122 Test Method for Determining Dimensions of Ther-

long-term stress, is not considered to be a ballooning failure.

moplastic Pipe and Fittings

3.1.2 hoop stress—the tensile stress in the wall of the piping

D2837 Test Method for Obtaining Hydrostatic Design Basis

product in the circumferential direction due to internal pres-

forThermoplasticPipeMaterialsorPressureDesignBasis

sure. Units will be reported as pounds per square inch (psi) or

for Thermoplastic Pipe Products

mega pascals (MPa). Hoop stress will be calculated by the

following ISO equation:

1

This test method is under the jurisdiction of ASTM Committee F17 on Plastic

S 5 P ~D 2 t!/2t

Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test

Methods.

where:

Current edition approved Aug. 1, 2011. Published August 2011. Originally

S = hoop stress, psi (MPa),

approvedin1985.Lastpreviouseditionapprovedin2006asF948 – 94(2006).DOI:

10.1520/F0948-94R11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from Plastics Pipe Institute (PPI), 105 Decker Court, Suite 825,

the ASTM website. Irving, TX 75062, http://www.plasticpipe.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F948 − 94 (2011)

onstratedthattheapplicationconditionspresentalessstringent

D = average outside diameter, in. (mm),

environment. The design basis should be determined for each

P = internal pressure, psig (MPag), and

specificplasticmaterialandeachdifferentsetofenvironmental

t = mimimum wall thickness in. (mm).

NOTE 2—Hoop stress should only be determined on straight hollow constraints

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.