ASTM D4938-89(2007)

(Test Method)Standard Test Method for Erosion Testing of Antifouling Paints Using High Velocity Water

Standard Test Method for Erosion Testing of Antifouling Paints Using High Velocity Water

SIGNIFICANCE AND USE

This test method is intended to measure the erosion rates of ablative antifouling paint systems exposed to flowing water at velocities designed to subject the paint system to shear stresses experienced in service.

Measurement of erosion rates are necessary to help in the assessment of ablative antifouling paint film thicknesses required for fouling control between scheduled drydockings of ships, in the selection of materials, in producing quality assurance, and in understanding the performance mechanism.

The test data is intended to serve as a guide for predicting the service life of ablative antifouling paints in order to calculate the necessary paint thickness to fit specified deployment cycles. Erosion rates of antifouling paints in service will vary depending on such factors as: berthing location, geographic area of operation, salinity, pH, and temperature of seawater. It should also be recognized that some areas of the ship are subject to different erosion rates.

The degree of correlation between results obtained from this test method and shipboard service has not been determined.

SCOPE

1.1 This test method covers the determination of erosion rates for marine antifouling paint systems immersed in flowing natural seawater.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4938 −89(Reapproved2007)

Standard Test Method for

Erosion Testing of Antifouling Paints Using High Velocity

Water

This standard is issued under the fixed designation D4938; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Test Method

3.1 Steel panels coated with the antifouling paint system

1.1 This test method covers the determination of erosion

under evaluation are positioned in a high velocity water

ratesformarineantifoulingpaintsystemsimmersedinflowing

channel, similar to the type shown in Figs. 1-3, parallel to the

natural seawater.

path of the flowing water.

1.2 This standard does not purport to address all of the

3.2 Exposure conditions shall include at least one series of

safety concerns, if any, associated with its use. It is the

test panels evaluated at the standard water velocity of 12 m/s

responsibility of the user of this standard to establish appro-

and shall specify the length of time, temperature, salinity, and

priate safety and health practices and determine the applica-

pH.Additionalvelocitiesmaybeconductedatthediscretionof

bility of regulatory limitations prior to use. For a specific

the customer.

hazard statement, see Section 7.

3.3 Color photographs and coating thickness measurements

2. Referenced Documents

shallbetakenpriortoexposure,atspecifiedtimeintervals,and

repeated at the end of the test for comparison purposes.

2.1 ASTM Standards:

A569/A569M Specification for Steel, Carbon (0.15

4. Significance and Use

Maximum,Percent),Hot-RolledSheetandStripCommer-

cial (Withdrawn 2000)

4.1 Thistestmethodisintendedtomeasuretheerosionrates

D823Practices for Producing Films of Uniform Thickness

of ablative antifouling paint systems exposed to flowing water

of Paint, Varnish, and Related Products on Test Panels

at velocities designed to subject the paint system to shear

D1889Test Method for Turbidity of Water (Withdrawn

stresses experienced in service.

2007)

4.2 Measurement of erosion rates are necessary to help in

D2200Practice for Use of Pictorial Surface Preparation

the assessment of ablative antifouling paint film thicknesses

Standards and Guides for Painting Steel Surfaces

required for fouling control between scheduled drydockings of

2.2 U.S. Military Specifications:

ships, in the selection of materials, in producing quality

MIL-P-24441Paint, Epoxy-Polyamide

assurance, and in understanding the performance mechanism.

DOD-P-24647Paint, Antifouling, Ship Hull (Metric)

4.3 The test data is intended to serve as a guide for

DOD-P-24655Paint, Underwater Hull, Anticorrosion (Met-

predictingtheservicelifeofablativeantifoulingpaintsinorder

ric)

to calculate the necessary paint thickness to fit specified

deployment cycles. Erosion rates of antifouling paints in

service will vary depending on such factors as: berthing

This test method is under the jurisdiction of ASTM Committee D01 on Paint

location, geographic area of operation, salinity, pH, and tem-

and Related Coatings, Materials, andApplications and is the direct responsibility of

perature of seawater. It should also be recognized that some

Subcommittee D01.45 on Marine Coatings.

areas of the ship are subject to different erosion rates.

Current edition approved June 1, 2007. Published August 2007. Originally

approved in 1989. Last previous edition approved in 2002 as D4938-89(2002).

4.4 Thedegreeofcorrelationbetweenresultsobtainedfrom

DOI: 10.1520/D4938-89R07.

this test method and shipboard service has not been deter-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

mined.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 5. Apparatus

The last approved version of this historical standard is referenced on

www.astm.org.

5.1 Water Channel:

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

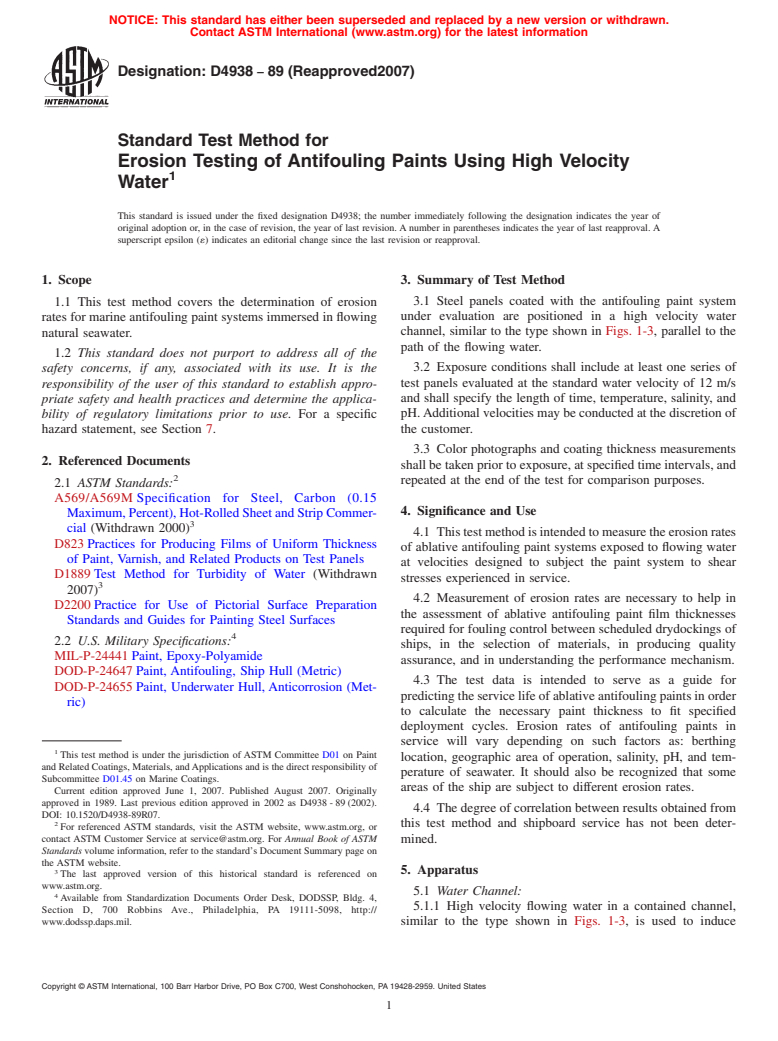

5.1.1 High velocity flowing water in a contained channel,

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

www.dodssp.daps.mil. similar to the type shown in Figs. 1-3, is used to induce

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4938−89(2007)

FIG. 1 High Velocity Flow Channel

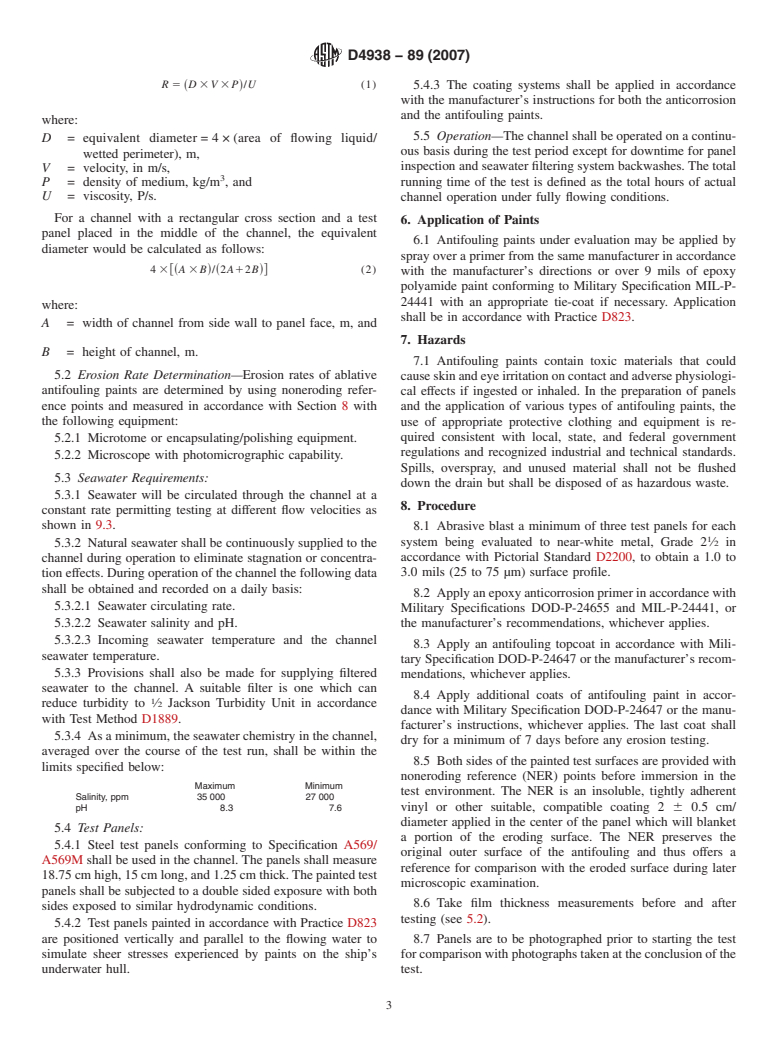

FIG. 2 Simplified Schematic of Flow Channel

W, mm Velocity, m/s

50 18

hydrodynamic shear stresses on painted panels to determine

60 15

erosion rates of ablative antifouling paints.

75 12

100 9

5.1.2 The basic apparatus consists of a four-walled channel,

150 6

rectangular in cross section, through which natural seawater

300 3

flows at varying linear velocities to simulate ships’ speeds.

5.1.3 All wetted materials supplying seawater to and within FIG. 3 Cross-Section View of Test Panel Mounted in Flow Chan-

nel (Low Velocity Section)

thechannelshallbenonmetallicwiththefollowingexceptions:

5.1.3.1 Channel circulating pump impellers.

5.1.3.2 Thermowells. channel shall provide flow with fully formed turbulent charac-

5.1.3.3 Channel flow orifice plate. teristics. A minimum Reynolds number of 1000000 shall be

5.1.4 One section of the channel shall permit testing of the achieved in each velocity test section. The Reynolds number,

panels at a standard test velocity of 12 m/s.All sections of the R, is calculated as follows:

D4938−89(2007)

R 5 D 3V 3P /U (1) 5.4.3 The coating systems shall be applied in accordance

~ !

with the manufacturer’s instructions for both the anticorrosion

and the antifouling paints.

where:

5.5 Operation—Thechannelshallbeoperatedonacontinu-

D = equivalent diameter=4× (area of flowing liquid/

ous basis during the test period except for downtime for panel

wetted perimeter), m,

inspection and seawater filtering system backwashes.The total

V = velocity, in m/s,

P = density of medium, kg/m , and running time of the test is defined as the total hours of actual

U = viscosity, P/s. channel operation under fully flowing conditions.

For a channel with a rectangular cross section and a test

6. Application of Paints

panel placed in the middle of the channel, the equivalent

6.1 Antifouling paints under evaluation may be applied by

diameter would be calculated as follows:

spray over a primer from the same manufacturer in accordance

4 3 A 3B / 2A12B (2)

@~ ! ~ !#

with the manufacturer’s directions or over 9 mils of epoxy

polyamide paint conforming to Military Specification MIL-P-

24441 with an appropriate tie-coat if necessary. Application

where:

shall be in accordance with Practice D823.

A = width of channel from side wall to panel face, m, and

7. Hazards

B = height of channel, m.

7.1 Antifouling paints contain toxic materials that could

5.2 Erosion Rate Determination—Erosion rates of ablative

cause

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.