ASTM D187-94(2003)e1

(Test Method)Standard Test Method for Burning Quality of Kerosine

Standard Test Method for Burning Quality of Kerosine

SIGNIFICANCE AND USE

Since the information provided by this test method is largely qualitative in nature, specific limits covering the following characteristics are required in referring to this test method in specifications for kerosine:

4.1.1 Duration of the test: 16 h is understood, if not otherwise specified;

4.1.2 Permissible change in flame shape and dimensions during the test;

4.1.3 Description of the acceptable appearance of the chimney deposit.

SCOPE

1.1 This test method covers the qualitative determination of the burning properties of kerosine to be used for illuminating purposes. (Warning—Combustible. Vapor harmful.)

Note 1—The corresponding Institute of Petroleum (IP) test method is IP 10 which features a quantitative evaluation of the wick-char-forming tendencies of the kerosine, whereas Test Method D 187 features a qualitative performance evaluation of the kerosine. Both test methods subject the kerosine to somewhat more severe operating conditions than would be experienced in typical designated applications.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements appear throughout the test method.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation:D187–94 (Reapproved 2003)

Standard Test Method for

Burning Quality of Kerosine

This standard is issued under the fixed designation D 187; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Warning notes were editorially moved into text in November 2003.

1. Scope 3. Summary of Test Method

1.1 This test method covers the qualitative determination of 3.1 The kerosine sample is burned for 16 h in a specified

the burning properties of kerosine to be used for illuminating lamp under specified conditions. The average rate of burning,

purposes. (Warning—Combustible. Vapor harmful.) the change in the shape of the flame, and the density and color

of the chimney deposit are reported.

NOTE 1—The corresponding Institute of Petroleum (IP) test method is

IP 10 which features a quantitative evaluation of the wick-char-forming

4. Significance and Use

tendencies of the kerosine, whereas Test Method D 187 features a

4.1 Since the information provided by this test method is

qualitative performance evaluation of the kerosine. Both test methods

subject the kerosine to somewhat more severe operating conditions than largely qualitative in nature, specific limits covering the

would be experienced in typical designated applications.

following characteristics are required in referring to this test

method in specifications for kerosine:

1.2 This standard does not purport to address all of the

4.1.1 Duration of the test: 16 h is understood, if not

safety concerns, if any, associated with its use. It is the

otherwise specified;

responsibility of the user of this standard to establish appro-

4.1.2 Permissible change in flame shape and dimensions

priate safety and health practices and determine the applica-

during the test;

bility of regulatory limitations prior to use. Specific warning

4.1.3 Description of the acceptable appearance of the chim-

statements appear throughout the test method.

ney deposit.

2. Referenced Documents

5. Apparatus

2.1 ASTM Standards:

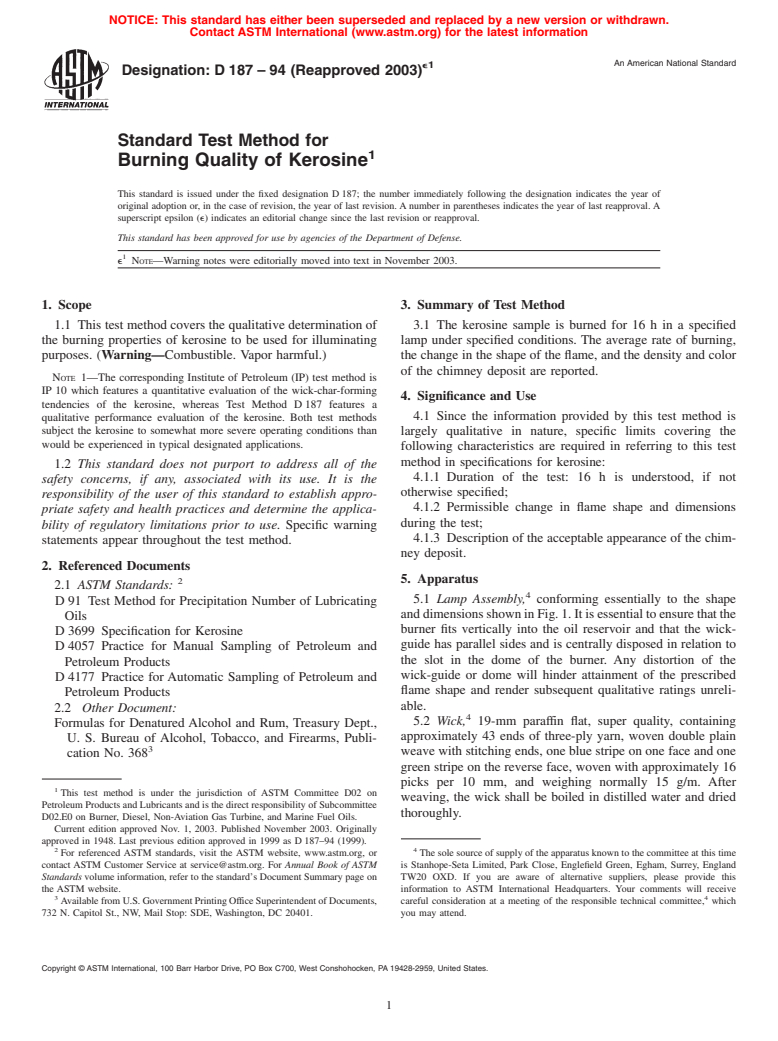

5.1 Lamp Assembly, conforming essentially to the shape

D 91 Test Method for Precipitation Number of Lubricating

anddimensionsshowninFig.1.Itisessentialtoensurethatthe

Oils

burner fits vertically into the oil reservoir and that the wick-

D 3699 Specification for Kerosine

guide has parallel sides and is centrally disposed in relation to

D 4057 Practice for Manual Sampling of Petroleum and

the slot in the dome of the burner. Any distortion of the

Petroleum Products

wick-guide or dome will hinder attainment of the prescribed

D 4177 Practice for Automatic Sampling of Petroleum and

flame shape and render subsequent qualitative ratings unreli-

Petroleum Products

able.

2.2 Other Document:

5.2 Wick, 19-mm paraffin flat, super quality, containing

Formulas for Denatured Alcohol and Rum, Treasury Dept.,

approximately 43 ends of three-ply yarn, woven double plain

U. S. Bureau of Alcohol, Tobacco, and Firearms, Publi-

weave with stitching ends, one blue stripe on one face and one

cation No. 368

green stripe on the reverse face, woven with approximately 16

picks per 10 mm, and weighing normally 15 g/m. After

This test method is under the jurisdiction of ASTM Committee D02 on

weaving, the wick shall be boiled in distilled water and dried

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

thoroughly.

D02.E0 on Burner, Diesel, Non-Aviation Gas Turbine, and Marine Fuel Oils.

Current edition approved Nov. 1, 2003. Published November 2003. Originally

approved in 1948. Last previous edition approved in 1999 as D 187–94 (1999).

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The sole source of supply of the apparatus known to the committee at this time

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM is Stanhope-Seta Limited, Park Close, Englefield Green, Egham, Surrey, England

Standards volume information, refer to the standard’s Document Summary page on TW20 OXD. If you are aware of alternative suppliers, please provide this

the ASTM website. information to ASTM International Headquarters. Your comments will receive

3 4

AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments, careful consideration at a meeting of the responsible technical committee, which

732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401. you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D187–94 (2003)

FIG. 2 Sight Gage

7. Hazards

7.1 Specific Safety Hazards:

7.1.1 Formula 3A Denatured Ethanol—(Warning—

Flammable. Denatured—cannot be made nontoxic.)

7.1.2 Hydrochloric Acid—Dilute 6 N.(Warning—Causes

burns. Vapor harmful.)

7.1.3 Kerosine—(Warning—Combustible. Vapor harmful.)

7.1.4 Precipitation Naphtha—(Warning—Extremely flam-

mable. Harmful if inhaled. Vapors may cause flash fire.)

7.2 Technical Precautions:

7.2.1 Test Room—It is desirable to dedicate a suitable room

for the exclusive conduct of kerosine burning tests. However,

kerosine burning tests can be conducted in any part of a room

that is adequately ventilated and reasonably free of drafts.

When necessary, the test lamp should be surrounded with a

suitable circular shield to protect from drafts. The circular

shield is to be constructed of draft-proof material of about 600

mm diameter and height.

7.2.2 Lamp Location—Place the test lamps at least 300 mm

NOTE—All dimensions shown are in millimetres. Except where other-

apart and 300 mm from any wall or other obstruction.

wise indicated, the tolerance for chimney dimensions is 61 mm.

7.2.3 Test Temperature—Maintain test room temperature

FIG. 1 Test Lamp

above 15°C and allow the temperature of the kerosine to

approach equilibrium room temperature within at least 5°C.

5.2.1 The wick shall then be made into rolls and left for

8. Sampling

seven days before it is cut into 200-mm lengths. The lengths

shall then be packed into suitable containers. The ash of the

8.1 The fundamental objective of sampling is to obtain a

wick shall not exceed 0.4 weight %.

sample for testing purposes that is truly representative of the

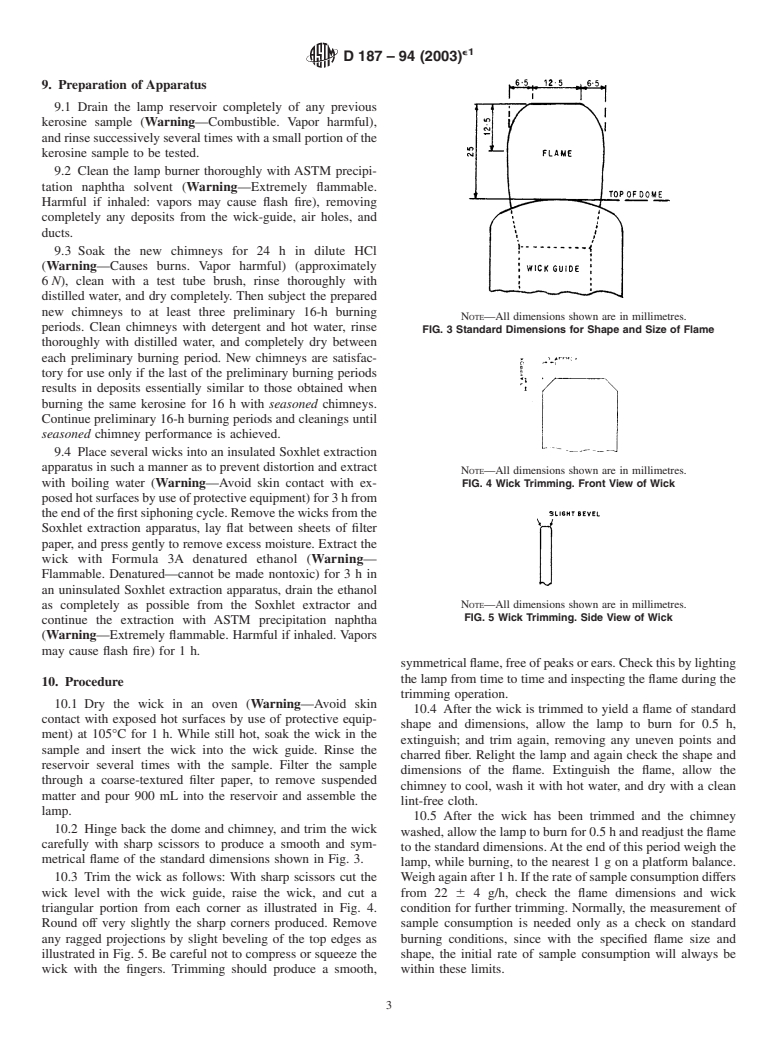

5.3 Sight Gage —A suitable flame-size measuring device,

entire quantity of a given bulk product tank, batch, shipment,

accurate to 1 mm. The sight gage shown in Fig. 2 is

and so forth, at the time and place of sampling.

satisfactory.

8.2 Thus, the sampling procedures employed are to ensure

initial procurement of a representative sample and also pre-

6. Reagents and Materials

clude subsequent contamination or deterioration of the sample

6.1 Formula 3A Denatured Ethanol—See Formulas for during handling prior to testing. To this end, kerosine samples

Denatured Alcohol and Rum. for burning quality testing are to be obtained and handled in

6.2 Hydrochloric Acid, Dilute (approximately 6 N). strict accordance with Practices D 4057 and D 4177. Rigorous

6.3 Kerosine—See Specification D 3699. compliance with stipulated provisions for precautions, care,

6.4 Precipitation Naphtha—See Reagent section in Test and cleanliness during sample handling is an essential require-

Method D 91. ment.

e1

D187–94 (2003)

9. Preparation of Apparatus

9.1 Drain the lamp reservoir completely of any previous

kerosine sample (Warning—Combustible. Vapor harmful),

and rinse successively several times with a small portion of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.