ASTM D187-08

(Test Method)Standard Test Method for Burning Quality of Kerosine

Standard Test Method for Burning Quality of Kerosine

SIGNIFICANCE AND USE

Since the information provided by this test method is largely qualitative in nature, specific limits covering the following characteristics are required in referring to this test method in specifications for kerosine:

Duration of the test: 16 h is understood, if not otherwise specified;

Permissible change in flame shape and dimensions during the test;

Description of the acceptable appearance of the chimney deposit.

SCOPE

1.1 This test method covers the qualitative determination of the burning properties of kerosine to be used for illuminating purposes. (Warning—Combustible. Vapor harmful.)

Note 1—The corresponding Energy Institute (IP) test method is IP 10 which features a quantitative evaluation of the wick-char-forming tendencies of the kerosine, whereas Test Method D 187 features a qualitative performance evaluation of the kerosine. Both test methods subject the kerosine to somewhat more severe operating conditions than would be experienced in typical designated applications.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements appear throughout the test method.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D187 − 08

StandardTest Method for

1

Burning Quality of Kerosine

This standard is issued under the fixed designation D187; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

4

1. Scope* 2.3 Other Document:

Formulas for Denatured Alcohol and Rum Treasury Dept.,

1.1 This test method covers the qualitative determination of

U. S. Bureau of Alcohol, Tobacco, and Firearms, Publi-

the burning properties of kerosine to be used for illuminating

cation No. 368

purposes. (Warning—Combustible. Vapor harmful.)

NOTE 1—The corresponding Energy Institute (IP) test method is IP 10 3. Summary of Test Method

which features a quantitative evaluation of the wick-char-forming tenden-

3.1 The kerosine sample is burned for 16 h in a specified

cies of the kerosine, whereas Test Method D187 features a qualitative

lamp under specified conditions. The average rate of burning,

performance evaluation of the kerosine. Both test methods subject the

kerosine to somewhat more severe operating conditions than would be

the change in the shape of the flame, and the density and color

experienced in typical designated applications.

of the chimney deposit are reported.

1.2 The values stated in SI units are to be regarded as

4. Significance and Use

standard. No other units of measurement are included in this

standard.

4.1 Since the information provided by this test method is

largely qualitative in nature, specific limits covering the

1.3 This standard does not purport to address all of the

following characteristics are required in referring to this test

safety concerns, if any, associated with its use. It is the

method in specifications for kerosine:

responsibility of the user of this standard to establish appro-

4.1.1 Duration of the test: 16 h is understood, if not

priate safety and health practices and determine the applica-

otherwise specified;

bility of regulatory limitations prior to use. Specific warning

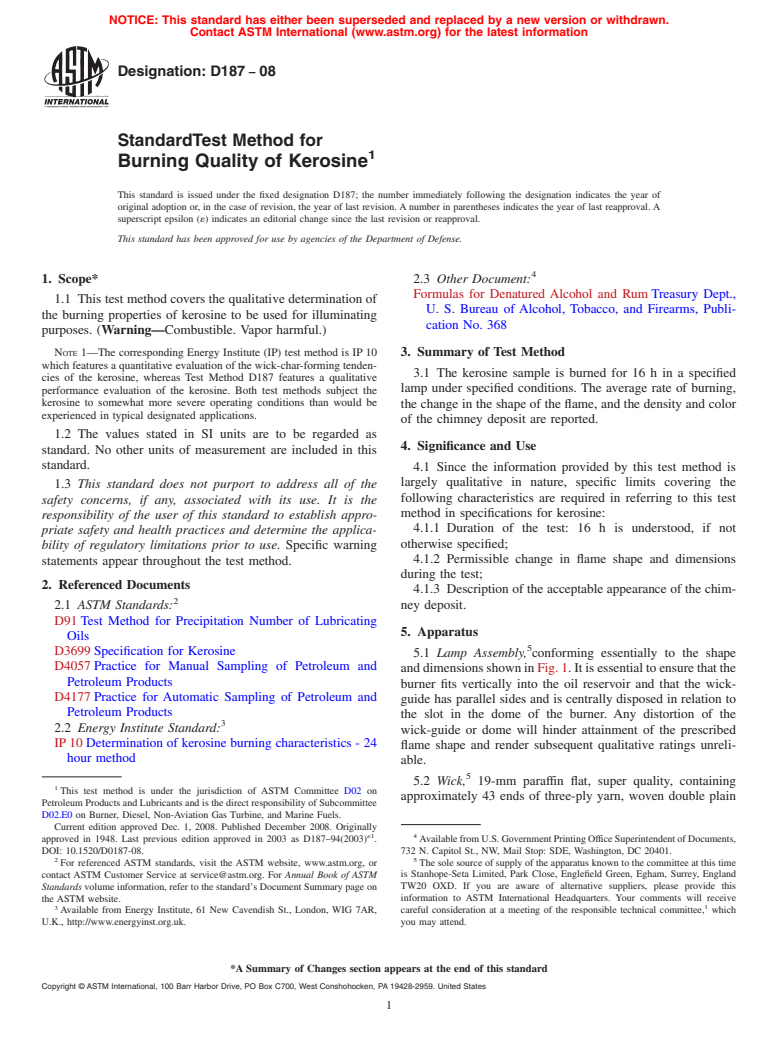

4.1.2 Permissible change in flame shape and dimensions

statements appear throughout the test method.

during the test;

2. Referenced Documents

4.1.3 Description of the acceptable appearance of the chim-

2

2.1 ASTM Standards: ney deposit.

D91 Test Method for Precipitation Number of Lubricating

5. Apparatus

Oils

5

D3699 Specification for Kerosine

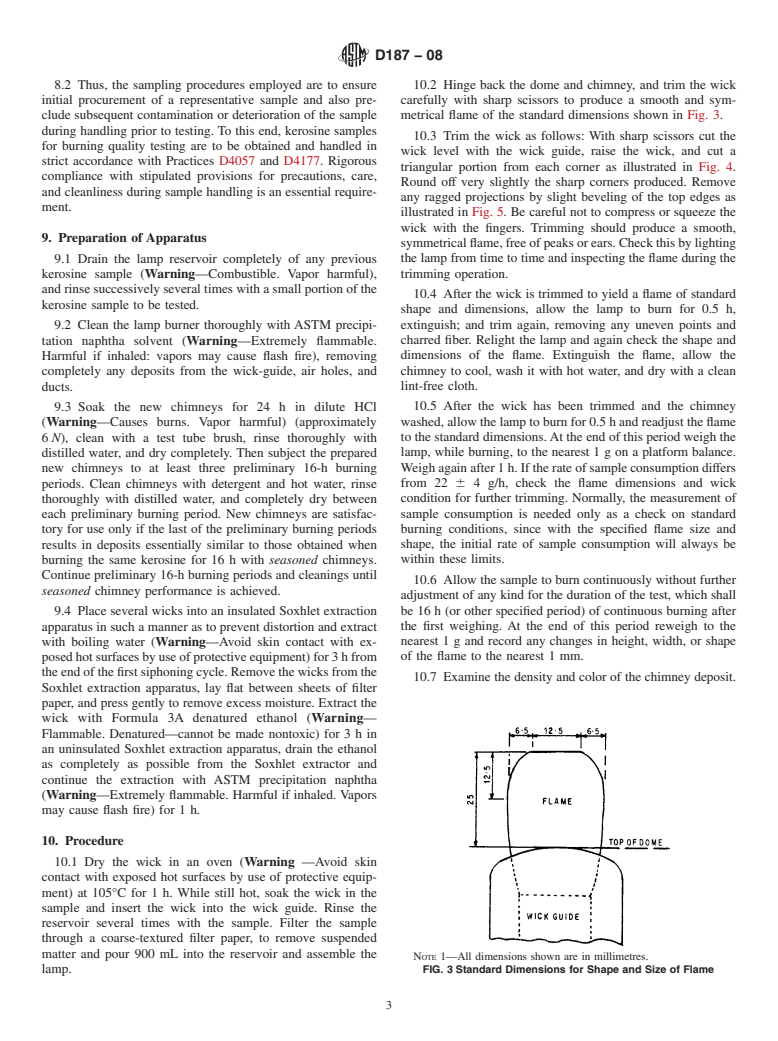

5.1 Lamp Assembly, conforming essentially to the shape

D4057 Practice for Manual Sampling of Petroleum and

anddimensionsshowninFig.1.Itisessentialtoensurethatthe

Petroleum Products

burner fits vertically into the oil reservoir and that the wick-

D4177 Practice for Automatic Sampling of Petroleum and

guide has parallel sides and is centrally disposed in relation to

Petroleum Products

the slot in the dome of the burner. Any distortion of the

3

2.2 Energy Institute Standard:

wick-guide or dome will hinder attainment of the prescribed

IP 10 Determination of kerosine burning characteristics - 24

flame shape and render subsequent qualitative ratings unreli-

hour method

able.

5

5.2 Wick, 19-mm paraffin flat, super quality, containing

1

This test method is under the jurisdiction of ASTM Committee D02 on

approximately 43 ends of three-ply yarn, woven double plain

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.E0 on Burner, Diesel, Non-Aviation Gas Turbine, and Marine Fuels.

Current edition approved Dec. 1, 2008. Published December 2008. Originally

´1

4

approved in 1948. Last previous edition approved in 2003 as D187–94(2003) . AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

DOI: 10.1520/D0187-08. 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

2 5

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The sole source of supply of the apparatus known to the committee at this time

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM is Stanhope-Seta Limited, Park Close, Englefield Green, Egham, Surrey, England

Standards volume information, refer to the standard’s Document Summary page on TW20 OXD. If you are aware of alternative suppliers, please provide this

the ASTM website. information to ASTM International Headquarters. Your comments will receive

1

3

Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR, careful consideration at a meeting of the responsible technical committee, which

U.K., http://www.energyinst.org.uk. you may attend.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-29

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

´1

Designation:D187–94 (Reapproved 2003) Designation:D187–08

Standard Test Method for

1

Burning Quality of Kerosine

This standard is issued under the fixed designation D 187; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Warning notes were editorially moved into text in November 2003.

1. Scope*

1.1 This test method covers the qualitative determination of the burning properties of kerosine to be used for illuminating

purposes. (Warning—Combustible. Vapor harmful.)

NOTE 1—The corresponding Energy Institute of Petroleum (IP) test method is IP10 which features a quantitative evaluation of the wick-char-forming

tendencies of the kerosine, whereas Test Method D 187 features a qualitative performance evaluation of the kerosine. Both test methods subject the

kerosine to somewhat more severe operating conditions than would be experienced in typical designated applications.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific warning statements appear throughout the test method.

2. Referenced Documents

2

2.1 ASTM Standards:

D91 Test Method for Precipitation Number of Lubricating Oils

D 3699 Specification for Kerosine

D 4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D 4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

3

2.2 Energy Institute Standard:

IP 10 Determination of kerosine burning characteristics - 24 hour method

4

2.3 Other Document:

Formulas for Denatured Alcohol and Rum, Treasury Dept., U. S. Bureau of Alcohol, Tobacco, and Firearms, Publication No.

368

3. Summary of Test Method

3.1 The kerosine sample is burned for 16 h in a specified lamp under specified conditions. The average rate of burning, the

change in the shape of the flame, and the density and color of the chimney deposit are reported.

4. Significance and Use

4.1 Since the information provided by this test method is largely qualitative in nature, specific limits covering the following

characteristics are required in referring to this test method in specifications for kerosine:

4.1.1 Duration of the test: 16 h is understood, if not otherwise specified;

4.1.2 Permissible change in flame shape and dimensions during the test;

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.E0.01

on Burner, Diesel, Non-Aviation Gas Turbine, and Marine Fuel Oils. Burner Fuels.

Current edition approved Nov.Dec. 1, 2003.2008. Published November 2003.December 2008. Originally approved in 1948. Last previous edition approved in 19992003

´1

as D187–94 (1999).D 187–94(2003) .

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

3

Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR, U.K., http://www.energyinst.org.uk.

4

The sole source of supply of the apparatus known to the committee at this time is Stanhope-Seta Limited, Park Close, Englefield Green, Egham, Surrey, England TW20

OXD. If you are aware of alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at

a meeting of the responsible technical committee, which you may attend.

4

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

´1

Designation:D187–94 (Reapproved 2003) Designation:D187–08

Standard Test Method for

1

Burning Quality of Kerosine

This standard is issued under the fixed designation D 187; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Warning notes were editorially moved into text in November 2003.

1. Scope*

1.1 This test method covers the qualitative determination of the burning properties of kerosine to be used for illuminating

purposes. (Warning—Combustible. Vapor harmful.)

NOTE 1—The corresponding Energy Institute of Petroleum (IP) test method is IP10 which features a quantitative evaluation of the wick-char-forming

tendencies of the kerosine, whereas Test Method D 187 features a qualitative performance evaluation of the kerosine. Both test methods subject the

kerosine to somewhat more severe operating conditions than would be experienced in typical designated applications.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific warning statements appear throughout the test method.

2. Referenced Documents

2

2.1 ASTM Standards:

D91 Test Method for Precipitation Number of Lubricating Oils

D 3699 Specification for Kerosine

D 4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D 4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

3

2.2 Energy Institute Standard:

IP 10 Determination of kerosine burning characteristics - 24 hour method

4

2.3 Other Document:

Formulas for Denatured Alcohol and Rum, Treasury Dept., U. S. Bureau of Alcohol, Tobacco, and Firearms, Publication No.

368

3. Summary of Test Method

3.1 The kerosine sample is burned for 16 h in a specified lamp under specified conditions. The average rate of burning, the

change in the shape of the flame, and the density and color of the chimney deposit are reported.

4. Significance and Use

4.1 Since the information provided by this test method is largely qualitative in nature, specific limits covering the following

characteristics are required in referring to this test method in specifications for kerosine:

4.1.1 Duration of the test: 16 h is understood, if not otherwise specified;

4.1.2 Permissible change in flame shape and dimensions during the test;

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.E0.01

on Burner, Diesel, Non-Aviation Gas Turbine, and Marine Fuel Oils. Burner Fuels.

Current edition approved Nov.Dec. 1, 2003.2008. Published November 2003.December 2008. Originally approved in 1948. Last previous edition approved in 19992003

´1

as D187–94 (1999).D 187–94(2003) .

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

3

Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR, U.K., http://www.energyinst.org.uk.

4

The sole source of supply of the apparatus known to the committee at this time is Stanhope-Seta Limited, Park Close, Englefield Green, Egham, Surrey, England TW20

OXD. If you are aware of alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at

a meeting of the responsible technical committee, which you may attend.

4

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.