ASTM B756-00(2006)

(Specification)Standard Specification for Nickel-Chromium-Molybdenum-Tungsten Alloy (UNS N06110) Rod and Bar

Standard Specification for Nickel-Chromium-Molybdenum-Tungsten Alloy (UNS N06110) Rod and Bar

ABSTRACT

This specification covers UNS N06110 nickel-chromium-molybdenum-tungsten alloy hot-worked rods and bars and cold-worked rods. The chemical compositions and mechanical properties of the materials should conform to the requirements in this specification.

SCOPE

1.1 This specification covers nickel-chromium-molybdenum-tungsten (UNS N06110) in the form of hot-worked rod and bar and cold-worked rod in the conditions shown in Table 1.

1.2 The values stated in inch-pound units are to be regarded as the standards. The SI units in parentheses are provided for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B756 – 00 (Reapproved 2006)

Standard Specification for

Nickel-Chromium-Molybdenum-Tungsten Alloy (UNS

N06110) Rod and Bar

This standard is issued under the fixed designation B756; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

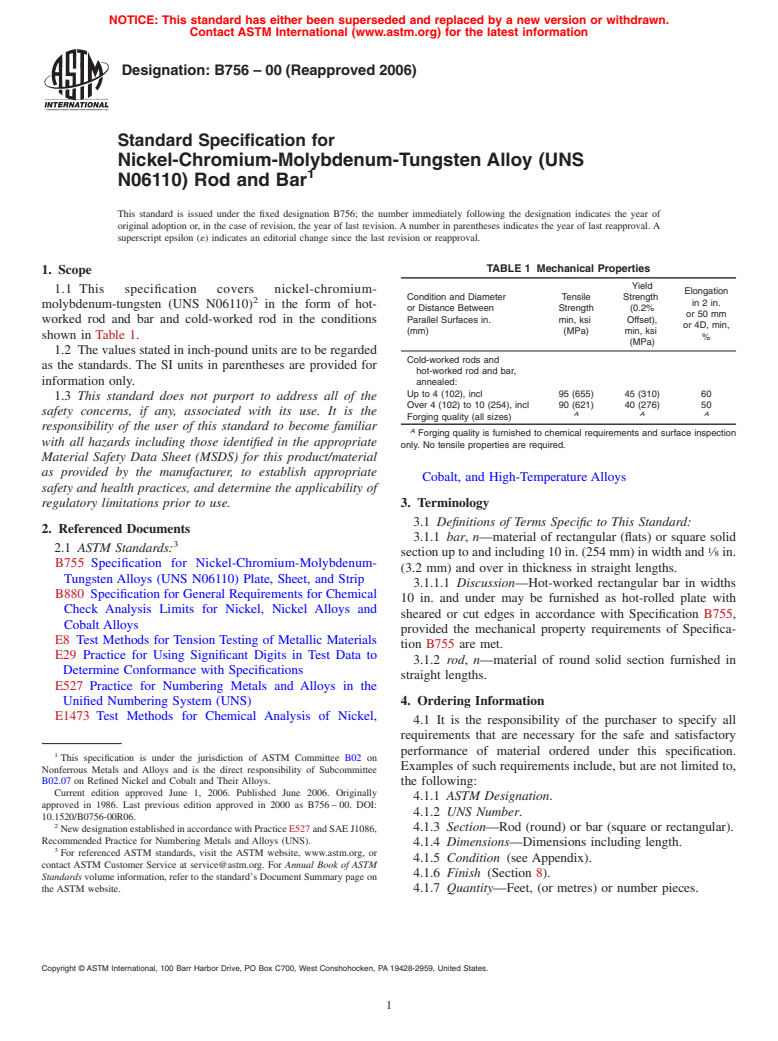

TABLE 1 Mechanical Properties

1. Scope

Yield

1.1 This specification covers nickel-chromium-

Elongation

Condition and Diameter Tensile Strength

in2in.

molybdenum-tungsten (UNS N06110) in the form of hot-

or Distance Between Strength (0.2%

or 50 mm

worked rod and bar and cold-worked rod in the conditions Parallel Surfaces in. min, ksi Offset),

or 4D, min,

(mm) (MPa) min, ksi

shown in Table 1.

%

(MPa)

1.2 The values stated in inch-pound units are to be regarded

Cold-worked rods and

as the standards. The SI units in parentheses are provided for

hot-worked rod and bar,

information only.

annealed:

Up to 4 (102), incl 95 (655) 45 (310) 60

1.3 This standard does not purport to address all of the

Over 4 (102) to 10 (254), incl 90 (621) 40 (276) 50

safety concerns, if any, associated with its use. It is the

AA A

Forging quality (all sizes)

responsibility of the user of this standard to become familiar

A

Forging quality is furnished to chemical requirements and surface inspection

with all hazards including those identified in the appropriate

only. No tensile properties are required.

Material Safety Data Sheet (MSDS) for this product/material

as provided by the manufacturer, to establish appropriate

Cobalt, and High-Temperature Alloys

safety and health practices, and determine the applicability of

regulatory limitations prior to use. 3. Terminology

3.1 Definitions of Terms Specific to This Standard:

2. Referenced Documents

3.1.1 bar, n—material of rectangular (flats) or square solid

2.1 ASTM Standards:

section up to and including 10 in. (254 mm) in width and ⁄8 in.

B755 Specification for Nickel-Chromium-Molybdenum-

(3.2 mm) and over in thickness in straight lengths.

Tungsten Alloys (UNS N06110) Plate, Sheet, and Strip

3.1.1.1 Discussion—Hot-worked rectangular bar in widths

B880 Specification for General Requirements for Chemical

10 in. and under may be furnished as hot-rolled plate with

Check Analysis Limits for Nickel, Nickel Alloys and

sheared or cut edges in accordance with Specification B755,

Cobalt Alloys

provided the mechanical property requirements of Specifica-

E8 Test Methods for Tension Testing of Metallic Materials

tion B755 are met.

E29 Practice for Using Significant Digits in Test Data to

3.1.2 rod, n—material of round solid section furnished in

Determine Conformance with Specifications

straight lengths.

E527 Practice for Numbering Metals and Alloys in the

Unified Numbering System (UNS) 4. Ordering Information

E1473 Test Methods for Chemical Analysis of Nickel,

4.1 It is the responsibility of the purchaser to specify all

requirements that are necessary for the safe and satisfactory

performance of material ordered under this specification.

This specification is under the jurisdiction of ASTM Committee B02 on

Examples of such requirements include, but are not limited to,

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.07 on Refined Nickel and Cobalt and Their Alloys. the following:

Current edition approved June 1, 2006. Published June 2006. Originally

4.1.1 ASTM Designation.

approved in 1986. Last previous edition approved in 2000 as B756 – 00. DOI:

4.1.2 UNS Number.

10.1520/B0756-00R06.

4.1.3 Section—Rod (round) or bar (square or rectangular).

New designation established in accordance with Practice E527 and SAE J1086,

Recommended Practice for Numbering Metals and Alloys (UNS).

4.1.4 Dimensions—Dimensions including length.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1.5 Condition (see Appendix).

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1.6 Finish (Section 8).

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 4.1.7 Quantity—Feet, (or metres) or number pieces.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B756 – 00 (2006)

TABLE 3 Permissible Variations in Diameter of Cold-Worked Rod

4.1.8 Certification—State if certification is required (see

Section 15). Permissible Variations from Specified

Specified Dimensions,

Dimension, in. (mm)

4.1.9 Samples for Product (Check) Analysis—State

in. (mm)

+−

whether samples for product (check) analysis should be fur-

1 3

nished (see 5.2). ⁄16 (1.6) to ⁄16 (4.8), excl 0 0.002 (0.05)

3 1

⁄16 (4.8) to ⁄2 (12.7), excl 0 0.003 (0.08)

4.1.10 Purchaser Inspection (see Section 13)—If purchaser

1 15

⁄2 (12.7) to ⁄16 (23.8), incl 0.001 (0.03) 0.002 (0.05)

wishes to witness test or inspection of material at place of

15 15

Over ⁄16 (23.8) to 1 ⁄16 0.0015 (0.04) 0.003 (0.08)

manufacture, the purchase order must so state indicating which (49.2), incl

15 1

Over 1 ⁄16 (49.2) to 2 ⁄2 (63.5), 0.002 (0.05) 0.004 (0.10)

test or inspections are to be witnessed.

incl

5. Chemical Composition

5.1 The material shall conform to the composition limits

TABLE 4 Permissible Variations in Diameter or Distance

specified in Table 2.

Between Parallel Surfaces of Hot-Worked Rod and Bar

5.2 If a product (check) analysis is performed by the

Permissible Variations from

purchaser, the material shall conform to the product (check)

A Specified Dimensions, in. (mm)

Specified Dimension, in. (mm)

analysis variations in accordance with Specification B880.

+−

Rod and bar, hot-worked:

6. Mechanical and Other Properties

1 (25.4) and under 0.016 (0.41) 0.016 (0.41)

6.1 Mechanical Properties—The material shall conform to Over 1 (25.4) to 2 (50.8), incl 0.031 (0.79) 0.016 (0.41)

Over 2 (50.8) to 4 (101.6), incl 0.047 (1.19) 0.031 (0.79)

the mechanical properties specified in Table 1.

Over 4 (101.6) 0.125 (3.18) 0.063 (1.60)

Rod, rough-turned or ground:

7. Dimensions and Permissible Variations

Under 1 (25.4) 0.005 (0.13) 0.005 (0.13)

1 (25.4) and over 0.031 (0.79) 0

7.1 Diameter, Thickness, or Width—The permissible varia-

B

Forging quantity rod:

tionsfromthespecifieddimensionsofcoldworkedrodshallbe

Under 1 (25.4) 0.005 (0.13) 0.005 (0.13)

as prescribed in Table 3, and of hot-worked rod and bar as

1 (25.4) and over 0.031 (0.79) 0

prescribed in Table 4. A

Dimensionsapplytodiameterofrods,todistancebetweenparallelsurfacesof

squares, and separately to width and thickness of rectangles.

7.2 Out-of-Round—Hot-worked rods and cold-worked rods

B

Spot grinding is permitted to remove minor surface imperfections. The depth

(except forging quality) all sizes, in straight lengths, shall not

of these spot ground areas shall not exceed 3 % of the diameter of the rod.

be out-of-round by more than one half the total permissible

variations in diameter shown inTable 3 andTable 4, except for

hot-worked rods ⁄2 in. (12.7 mm) in diameter and under, which

7.4.1 Rods and bars ordered to random or nominal lengths

may be out-of-round by the total permissible variations in

will be furnished with either cropped or saw-cut ends; material

diameter shown in Table 4.

ordered to cut lengths will be furnished with square saw-cut or

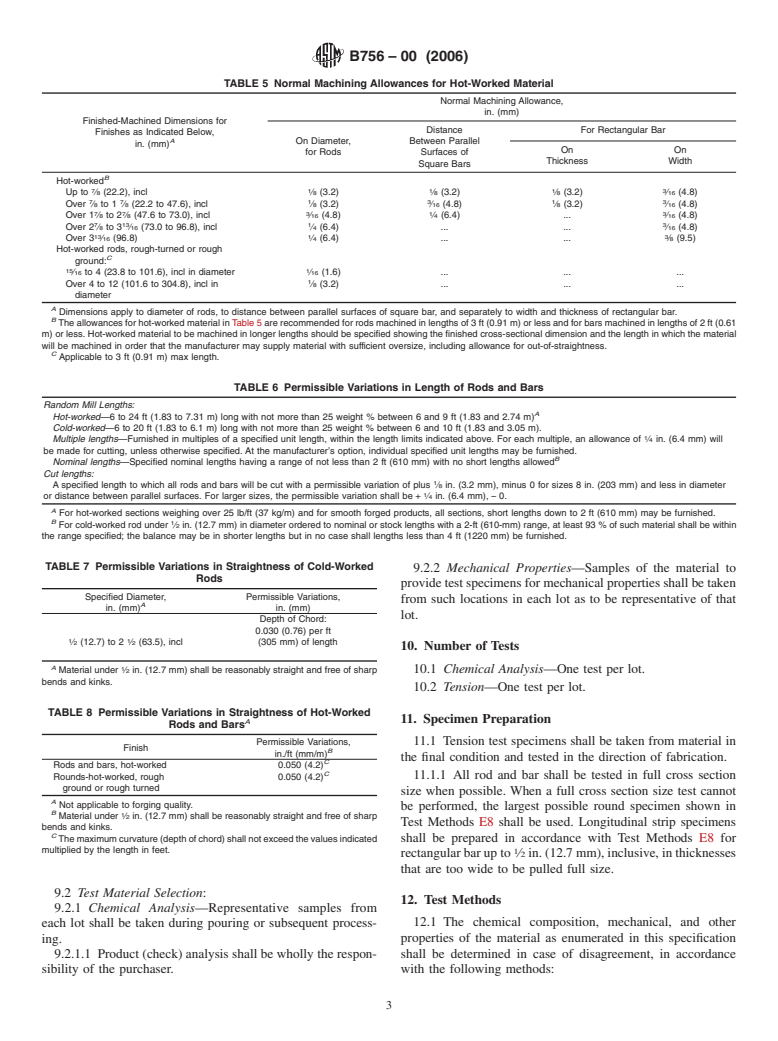

7.3 Machining Allowances for Hot-Worked Materials—

machined ends.

When the surfaces of hot-worked products are to be machined,

7.5 Straightness:

the allowances prescribed in Table 5 are recommended for

7.5.1 The permissible variations in straightness of cold-

normal machining operations.

worked rod as determined by the departure from straightness

7.4 Length—The permissible variations in length of cold-

shall be as prescribed in Table 7.

worked and hot-worked rod and bar shall be as prescribed in

Table 6. 7.5.2 The permissible variations in straightness of hot-

worked rod and bar as determined by the departure from

TABLE 2 Chemical Requirements

straightness shall be as specified in Table 8.

Composition

Element Limits,

8. Workmanship, Finish, and Appearance

%

8.1 The material shall be uniform in quality and condition,

C 0.15 max

Mn 1.0 max

smooth, commercially straight or flat, and free of injurious

Si 1.0 max

imperfections.

P 0.015 max

S 0.015 max

Cr 28.0 min

9. Sampling

33.0 max

Cb 1.0 max

9.1 Lot Definition:

Co (if determined) 1.0 max

9.1.1 A lot for chemical analysis shall consist of one heat.

Mo 9.0 min

12.0 max

9.1.2 Alot for mechanical properties testing shall consist of

Fe 1.0 max

all material from the same heat, nominal diameter or thickness,

Al 1.0 max

Ti 1.0 max and condition.

W 1.0 min

9.1.2.1 Where material cannot be identified by heat, a lot

4.0 max

A

shall consist of not more than 500 lb (227 kg) of material in the

Ni 51.0 min

Cu 0.50 max

same size and condition except that a single piece weighing

A

Element shall be determined arithmetically by difference. over 500 lb shall be considered as one lot.

B756 – 00 (2006)

TABLE 5 Normal Machining Allowances for Hot-Worked Material

Normal Machining Allowance,

in. (mm)

Finished-Machined Dimensions for

Distance For Rectangular Bar

Finishes as Indicated Below,

A

On Diameter, Between Parallel

in. (mm)

On On

for Rods Surfaces of

Thickness Width

Square Bars

B

Hot-worked

7 1 1 1 3

Up to ⁄8 (22.2), incl ⁄8 (3.2) ⁄8 (3.2) ⁄8 (3.2) ⁄16 (4.8)

7 7 1 3 1 3

Over ⁄8 to 1 ⁄8 (22.2 to 47.6), incl ⁄8 (3.2) ⁄16 (4.8) ⁄8 (3.2) ⁄16 (4.8)

7 7 3 1 3

Over 1 ⁄8 to 2 ⁄8 (47.6 to 73.0), incl ⁄16 (4.8) ⁄4 (6.4) . ⁄16 (4.8)

7 13 1 3

Over 2 ⁄8 to 3 ⁄16 (73.0 to 96.8), incl ⁄

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.