ASTM B804-02(2024)

(Specification)Standard Specification for UNS N08367 and UNS N08926 Welded Pipe

Standard Specification for UNS N08367 and UNS N08926 Welded Pipe

ABSTRACT

This guide covers UNS N08367 and UNS N08926 welded pipe for general corrosion applications. The joints of the specimens shall be double or single welded and full penetration welded made. The welds shall be made either manually or automatically by an electric process involving the deposition of filler metal according to the class specified. The weld surface on either side of the weld shall be flush with the base plate. The contour of the reinforcement shall be reasonably smooth and free of irregularities. The deposited metal shall be fused uniformly into the plate surface. Transverse tension tests shall be made across the welded joint to assure that it must have the same minimum ultimate tensile strength as the specified minimum ultimate tensile strength of the plate. Transverse guided weld bend test shall be used to check cracks or other imperfections. The pipe shall be furnished with smooth ends, free of burrs and injurious defects and shall have a workmanlike finish.

SCOPE

1.1 This specification covers UNS N08367 and UNS N08926 welded pipe for general corrosion applications. (Although no restrictions are placed on the sizes of pipe that may be furnished under this specification, commercial practice is commonly limited to sizes not less than 8 in. nominal diameter.)

1.2 Six classes of pipe are covered as follows:

1.2.1 Class 1 pipe shall be double welded by processes employing filler metal in all passes and shall be completely radiographed.

1.2.2 Class 2 pipe shall be double welded by processes employing filler metal in all passes. No radiography is required.

1.2.3 Class 3 pipe shall be double welded by processes employing filler metal in all passes except the inside root weld may be made without the addition of filler metal. Welds are to be completely radiographed.

1.2.4 Class 4 pipe shall be double welded by processes employing filler metal in all passes except the inside root weld may be made without the addition of filler metal. No radiography is required.

1.2.5 Class 5 pipe shall be single welded by processes employing filler metal in all passes except that the pass exposed to the inside pipe surface may be made without the addition of filler metal. Welds are to be completely radiographed.

1.2.6 Class 6 pipe shall be single welded by processes employing filler metal in all passes except that the pass exposed to the inside pipe surface may be made without the addition of filler metal. No radiography is required.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 13, of this standard: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Safety Data Sheet (SDS) for this product/material as provided by the manufacturer, to establish appropriate safety, health, and environmental practices, and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B804 − 02 (Reapproved 2024)

Standard Specification for

UNS N08367 and UNS N08926 Welded Pipe

This standard is issued under the fixed designation B804; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope dard does not purport to address all of the safety concerns, if

any, associated with its use. It is the responsibility of the user

1.1 This specification covers UNS N08367 and UNS

of this standard to become familiar with all hazards including

N08926 welded pipe for general corrosion applications. (Al-

those identified in the appropriate Safety Data Sheet (SDS) for

though no restrictions are placed on the sizes of pipe that may

this product/material as provided by the manufacturer, to

be furnished under this specification, commercial practice is

establish appropriate safety, health, and environmental

commonly limited to sizes not less than 8 in. nominal diam-

practices, and determine the applicability of regulatory limi-

eter.)

tations prior to use.

1.2 Six classes of pipe are covered as follows:

1.5 This international standard was developed in accor-

1.2.1 Class 1 pipe shall be double welded by processes

dance with internationally recognized principles on standard-

employing filler metal in all passes and shall be completely

ization established in the Decision on Principles for the

radiographed.

Development of International Standards, Guides and Recom-

1.2.2 Class 2 pipe shall be double welded by processes

mendations issued by the World Trade Organization Technical

employing filler metal in all passes. No radiography is re-

Barriers to Trade (TBT) Committee.

quired.

1.2.3 Class 3 pipe shall be double welded by processes 2. Referenced Documents

employing filler metal in all passes except the inside root weld 2

2.1 ASTM Standards:

may be made without the addition of filler metal. Welds are to

A262 Practices for Detecting Susceptibility to Intergranular

be completely radiographed.

Attack in Austenitic Stainless Steels

1.2.4 Class 4 pipe shall be double welded by processes

A370 Test Methods and Definitions for Mechanical Testing

employing filler metal in all passes except the inside root weld

of Steel Products

may be made without the addition of filler metal. No radiog-

B625 Specification for Ni-Fe-Cr-Mo-Cu-N Low-Carbon

raphy is required.

Alloy, Ni-Fe-Cr-Si Alloy, Cr-Ni-Fe-N Low-Carbon Alloy,

1.2.5 Class 5 pipe shall be single welded by processes

Fe-Ni-Cr-Mo-Cu-N Alloy, and Ni-Fe-Cr-Mo-N Alloy

employing filler metal in all passes except that the pass

Plate, Sheet, and Strip

exposed to the inside pipe surface may be made without the

B688 Specification for Chromium-Nickel-Molybdenum-

addition of filler metal. Welds are to be completely radio-

Iron Plate, Sheet, and Strip

graphed.

B880 Specification for General Requirements for Chemical

1.2.6 Class 6 pipe shall be single welded by processes

Check Analysis Limits for Nickel, Nickel Alloys and

employing filler metal in all passes except that the pass

Cobalt Alloys

exposed to the inside pipe surface may be made without the

B899 Terminology Relating to Non-ferrous Metals and Al-

addition of filler metal. No radiography is required.

loys

1.3 The values stated in inch-pound units are to be regarded E8/E8M Test Methods for Tension Testing of Metallic Ma-

as standard. The values given in parentheses are mathematical terials

conversions to SI units that are provided for information only E29 Practice for Using Significant Digits in Test Data to

and are not considered standard. Determine Conformance with Specifications

E38 Methods for Chemical Analysis of Nickel-Chromium

1.4 The following safety hazards caveat pertains only to the

and Nickel-Chromium-Iron Alloys (Withdrawn 1989)

test methods portion, Section 13, of this standard: This stan-

1 2

This specification is under the jurisdiction of ASTM Committee B02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

B02.07 on Refined Nickel and Cobalt and Their Alloys. Standards volume information, refer to the standard s Document Summary page on

Current edition approved April 1, 2024. Published May 2024. Originally the ASTM website.

approved in 1989. Last previous edition approved in 2018 as B804 – 02 (2018). The last approved version of this historical standard is referenced on

DOI: 10.1520/B0804-02R24. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B804 − 02 (2024)

E354 Test Methods for Chemical Analysis of High- 5.2.3 The weld surface on either side of the weld shall be

Temperature, Electrical, Magnetic, and Other Similar Iron, flush with the base plate or shall have a reasonably uniform

Nickel, and Cobalt Alloys crown, not to exceed ⁄8 in. (3.2 mm). Any weld reinforcement

E1019 Test Methods for Determination of Carbon, Sulfur, may be removed at the manufacturer’s option or by agreement

Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt between the manufacturer and purchaser. The contour of the

Alloys by Various Combustion and Inert Gas Fusion reinforcement shall be reasonably smooth and free of irregu-

Techniques larities. The deposited metal shall be fused uniformly into the

E1473 Test Methods for Chemical Analysis of Nickel, plate surface. No concavity of contour is permitted unless the

Cobalt, and High-Temperature Alloys resulting thickness of weld metal is equal to or greater than the

minimum thickness of the adjacent base metal.

2.2 ASME Boiler and Pressure Vessel Code:

5.2.4 Weld defects shall be repaired by removal to sound

Section VIII, Division 1 Rules for Construction of Pressure

metal and rewelding. Subsequent heat treatment and inspection

Vessels

shall be as required on the original welds.

Section IX Qualification Standard for Welding and Brazing

Procedures, Welders, Brazers, and Welding and Brazing

5.3 Heat Treatment—The recommended heat treatment shall

Operators

consist of heating to a minimum temperature of 2025 °F for

UNS N08367 and 2012 °F for UNS N08926 followed by

2.3 American Welding Society Standards:

quenching in water or rapidly cooling by other means.

AWS A5.11 Nickel and Nickel Alloy Covered Welded Elec-

trodes

6. Chemical Composition

AWS A5.14 Nickel and Nickel Alloy Bare Welding Rods

and Electrodes

6.1 The chemical composition of the pipe shall conform to

the requirements in Table 1 of Specification B688 for UNS

3. Terminology

N08367 and Table 1 of Specification B625 for UNS N08926.

3.1 Terms defined in Terminology B899 shall apply unless

6.2 The alloy content of the deposited weld metal shall

otherwise defined in this standard.

conform to that required for the plate or the welding electrodes

as shown in Specification AWS A5.11 for ENiCrMo-3,

4. Ordering Information

ENiCrMo-4, and ENiCrMo-10 or AWS A5.14 for ERNiCrMo-

4.1 It is the responsibility of the purchaser to specify all

10, ERNiCrMo-3, and ERNiCrMo-4.

requirements that are necessary for material ordered under this

6.3 If product analysis is made of the plate or weld metal by

specification. Examples of such requirements include, but are

the purchaser, the chemical composition thus determined shall

not limited to, the following:

conform to the requirements specified in 6.1 and 6.2 subject to

4.1.1 Quantity (feet or number of lengths),

the permissible tolerances in Specification B880.

4.1.2 Class (see 1.2),

4.1.3 Size (outside diameter and minimum wall thickness),

7. Mechanical Properties and Other Requirements

4.1.4 Length (specific or random),

7.1 Mechanical Properties:

4.1.5 ASTM specification number,

7.1.1 The mechanical properties of the plate shall be in

4.1.6 Authorization for repair of plate defects by welding

accordance with Table 1. Tension tests made by the plate

without prior approval if such is intended (see 9.4),

manufacturer shall qualify the plate material.

4.1.7 Circumferential weld permissibility (see 8.3.2), and

7.1.2 Transverse tension tests taken across the welded joint

4.1.8 Supplementary requirements.

shall have the same minimum ultimate tensile strength as the

specified minimum ultimate tensile strength of the plate.

5. Materials and Manufacture

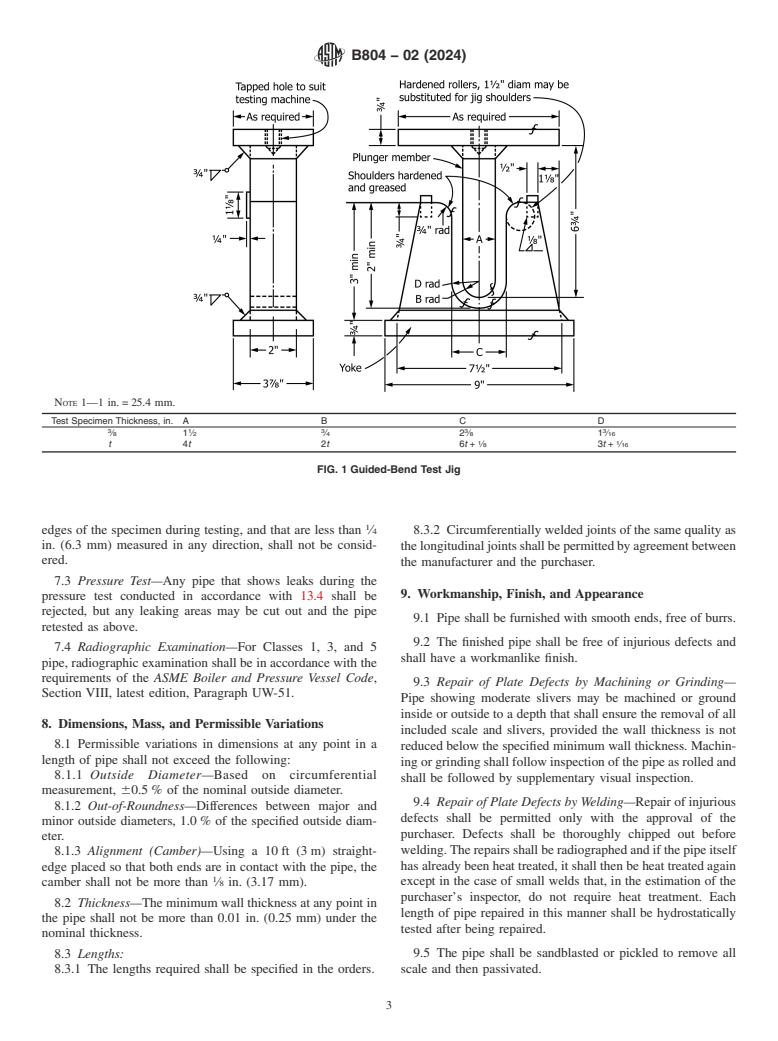

7.2 Transverse Guided Weld Bend Test Requirements—

5.1 Materials—The starting material shall conform to the

Bends made in accordance with Fig. 1 shall be acceptable if no

requirements of Specification B688 for UNS N08367 and

cracks or other imperfections exceeding ⁄8 in. (3.2 mm) in any

Specification B625 for UNS N08926.

direction are present in the weld metal or between the weld and

5.2 Manufacture:

the pipe metal after bending. Cracks that originate along the

5.2.1 The joints shall be double or single welded, full

penetration welds made in accordance with ASME Boiler and

Pressure Vessel Code, Section IX.

5.2.2 The welds shall be made either manually or automati-

TABLE 1 Mechanical Property Requirements

cally by an electric process involving the deposition of filler

Elongation

Tensile Strength, min Yield Strength, min

metal according to the class specified.

in 2 in. or

Gage

50.8 mm,

ksi MPa ksi MPa

min, %

UNS # ⁄16 100 690 45 310 30

Available from American Society of Mechanical Engineers (ASME), ASME

N08367

International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

> ⁄16 95 655 45 310 30

www.asme.org.

UNS 94 650 43 295 35

Available from American Welding Society (AWS), 550 NW LeJeune Rd., N08926

Miami, FL 33126, http://www.aws.org.

B804 − 02 (2024)

NOTE 1—1 in. = 25.4 mm.

Test Specimen Thickness, in. A B C D

3 1 3 3 3

⁄8 1 ⁄2 ⁄4 2 ⁄8 1 ⁄16

1 1

t 4t 2t 6t + ⁄8 3t + ⁄16

FIG. 1 Guided-Bend Test Jig

edges of the specimen during testing, and that are less than ⁄4 8.3.2 Circumferentially welded joints of the same quality as

in. (

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.