ASTM B474/B474M-19(2023)

(Specification)Standard Specification for Electric Fusion Welded Nickel and Nickel Alloy Pipe

Standard Specification for Electric Fusion Welded Nickel and Nickel Alloy Pipe

ABSTRACT

This specification covers electric fusion welded pipe suitable for high-temperature or corrosive service. The pipes are designated into five classes namely Class 1, Class 2, Class 3, Class 4 and Class 5, according to how they are to be welded. The joints shall be full penetration double-welded or single-welded butt joints employing fusion welding processes. The furnished pipe shall undergo heat treatment and a chemical analysis shall be employed for both plate and weld. Each pipe shall be subjected to transverse tension test, transverse guided weld bend test and hydrostatic pressure test.

SCOPE

1.1 This specification covers electric fusion welded pipe suitable for high-temperature or corrosive service as listed in Table 1. (Although no restrictions are placed on the sizes of pipe that may be furnished under this specification, commercial practice is commonly limited to sizes not less than 8 in. [203 mm] nominal diameter.)

1.2 Five classes of pipe are covered as follows:

1.2.1 Class 1—Pipe shall be double welded by processes employing filler metal in all passes and shall be completely radiographed.

1.2.2 Class 2—Pipe shall be double welded by processes employing filler metal in all passes. No radiography is required.

1.2.3 Class 3—Pipe shall be single welded by processes employing filler metal in all passes and shall be completely radiographed.

1.2.4 Class 4—Same as Class 3 except that the weld pass exposed to the inside pipe surface may be made without the addition of filler metal.

1.2.5 Class 5—Pipe shall be double welded by processes employing filler metal in all passes and shall be spot radiographed.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Safety Data Sheet (SDS) for this product/material as provided by the manufacturer, to establish appropriate safety, health, and environmental practices, and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B474/B474M − 19 (Reapproved 2023)

Standard Specification for

Electric Fusion Welded Nickel and Nickel Alloy Pipe

This standard is issued under the fixed designation B474/B474M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope and environmental practices, and determine the applicability

of regulatory limitations prior to use.

1.1 This specification covers electric fusion welded pipe

1.5 This international standard was developed in accor-

suitable for high-temperature or corrosive service as listed in

dance with internationally recognized principles on standard-

Table 1. (Although no restrictions are placed on the sizes of

ization established in the Decision on Principles for the

pipe that may be furnished under this specification, commercial

practice is commonly limited to sizes not less than 8 in. [203 Development of International Standards, Guides and Recom-

mm] nominal diameter.) mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.2 Five classes of pipe are covered as follows:

1.2.1 Class 1—Pipe shall be double welded by processes

2. Referenced Documents

employing filler metal in all passes and shall be completely

radiographed.

2.1 ASTM Standards:

1.2.2 Class 2—Pipe shall be double welded by processes

A262 Practices for Detecting Susceptibility to Intergranular

employing filler metal in all passes. No radiography is re-

Attack in Austenitic Stainless Steels

quired.

A370 Test Methods and Definitions for Mechanical Testing

1.2.3 Class 3—Pipe shall be single welded by processes

of Steel Products

employing filler metal in all passes and shall be completely

B127 Specification for Nickel-Copper Alloy Plate, Sheet,

radiographed.

and Strip

1.2.4 Class 4—Same as Class 3 except that the weld pass

B162 Specification for Nickel Plate, Sheet, and Strip

exposed to the inside pipe surface may be made without the

B168 Specification for Nickel-Chromium-Aluminum Alloys

addition of filler metal.

(UNS N06699), Nickel-Chromium-Iron Alloys (UNS

1.2.5 Class 5—Pipe shall be double welded by processes

N06600, N06601, N06603, N06690, N06693, N06025,

employing filler metal in all passes and shall be spot radio-

N06045, and N06696), Nickel-Chromium-Cobalt-

graphed.

Molybdenum Alloy (UNS N06617), Nickel-Iron-

1.3 The values stated in either SI units or inch-pound units

Chromium-Tungsten Alloy (UNS N06674), and

are to be regarded separately as standard. The values stated in

B333 Specification for Nickel-Molybdenum Alloy Plate,

each system are not necessarily exact equivalents; therefore, to

Sheet, and Strip

ensure conformance with the standard, each system shall be

B424 Specification for Nickel-Iron-Chromium-

used independently of the other, and values from the two

Molybdenum-Copper Alloys Plate, Sheet, and Strip

systems shall not be combined.

B435 Specification for Heat and Corrosion Resistant High

1.4 This standard does not purport to address all of the

Temperature Alloy Plate, Sheet, and Strip

safety concerns, if any, associated with its use. It is the

B443 Specification for Nickel-Chromium-Molybdenum-

responsibility of the user of this standard to become familiar

Columbium Alloy and Nickel-Chromium-Molybdenum-

with all hazards including those identified in the appropriate

Silicon Alloy Plate, Sheet, and Strip

Safety Data Sheet (SDS) for this product/material as provided

B463 Specification for UNS N08020 Alloy Plate, Sheet, and

by the manufacturer, to establish appropriate safety, health,

Strip

B536 Specification for Nickel-Iron-Chromium-Silicon Al-

loys Plate, Sheet, and Strip

This specification is under the jurisdiction of ASTM Committee B02 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.07 on Refined Nickel and Cobalt and Their Alloys.

Current edition approved Nov. 1, 2023. Published November 2023. Originally

approved in 1968. Last previous edition approved in 2019 as B474/B474M – 19. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/B0474_B474M-19R23. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Designation established in accordance with ASTM E527 and SAE J 1086, Standards volume information, refer to the standard’s Document Summary page on

Practice for Numbering Metals and Alloys (UNS). the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B474/B474M − 19 (2023)

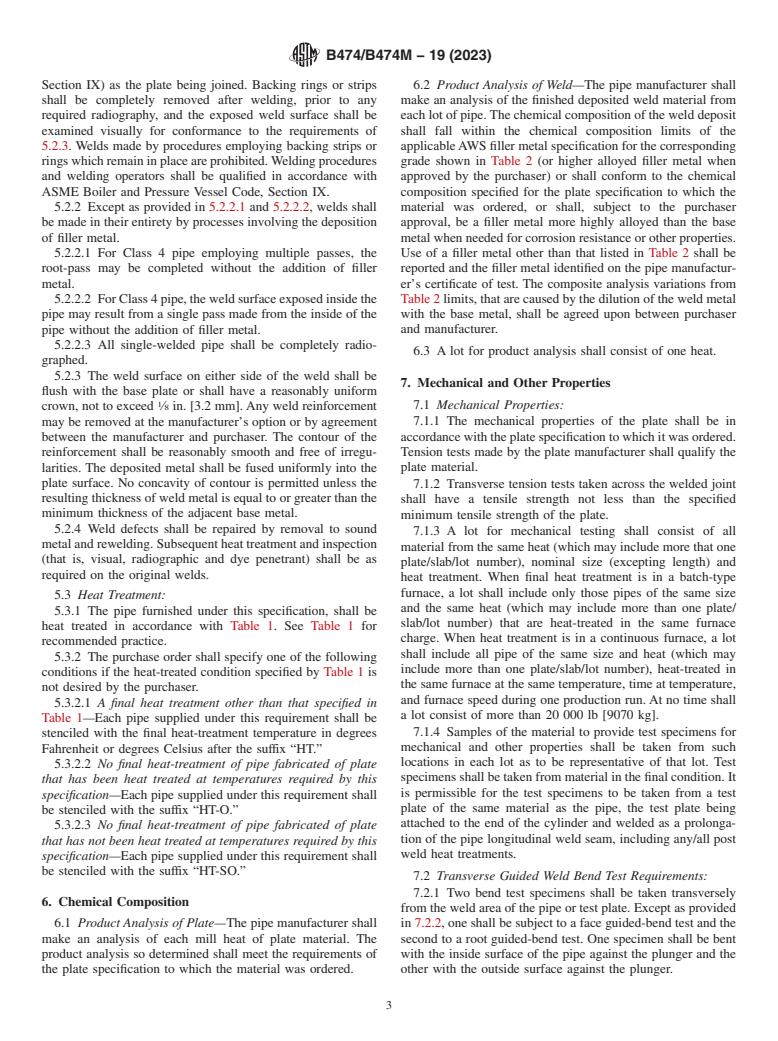

TABLE 1 Recommended Heat Treatment

A,B

PWHT

Alloy UNS Designation Quench

Deg. F. [Deg. C]

200 (Ni) N02200 1650-1700 [900 to 928] Rapid Air/water

201 (Low C) N02201 1650-1700 [900 to 928] Rapid Air/water

400 (Ni-Cu) N04400 1650-1700 [900 to 928] Rapid Air/water

C

X (Ni-Cr-Mo-Fe) N06002 2150 [1177] Rapid Air/water

D C

C22 (Low C-Ni-Mo-Cr) N06022 2050-[1120] Rapid Air/water

D C

G30 (Ni-Cr-Fe-Mo-Cu) N06030 2150 [1177] Rapid Air/water

D B

C2000 (Ni-Cr-Mo-Cu) N06200 2075-2125 [1135-1163] Rapid Air/water

D B

230 (Ni-Cr-W-Mo) N06230 2150-2250 [177-1232] Rapid Air/water

600 (Ni-Cr-Fe) N06600 1800-1850 [983 to 1010] Rapid Air/water

E

601 (Ni-Cr-Fe-Al) N06601 1600-1650 [874 to 900] Rapid Air/water

C

625 (Ni-Cr-Mo-Cb) Grade 1 N06625 1600 [871] Rapid Air/water

C

625 (Ni-Cr-Mo-Cb) Grade 2 N06625 2000 [1093] Rapid Air/water

D B

G3 (Ni-Cr-Fe-Mo-Cu) N06985 2100-2150 [1147 to 1177] Rapid Air/water

Alloy 20 (Cr-Ni-Fe-Mo-Cu-Cb) N08020 1700-1850 [927 to 1010] Rapid Air/water

E

825 (Ni-Fe-Cr-Mo-Cu) N08825 1700-1800 [930 to 980] Rapid Air/water

C

C276 (Low C-Ni-Mo-Cr) N10276 2050 [1121] Rapid Air/water

C

B2 (Ni-Mo) N10665 1950 [1065] Rapid Air/water

D C

B3 (Ni-Mo) N10675 1950 [1065] Rapid Air/water

A

Recommended temperatures—Different temperatures may be selected by either the purchaser or the manufacturer.

B

Set temperatures, ±25 °F [±14 °C].

C

Minimum set temperature.

D

Registered Trademark of Haynes International.

E

Heat treatment is highly dependent on intended service temperature — consult material manufacturer for specific heat treatments for end use temperature.

B575 Specification for Low-Carbon Nickel-Chromium- 3. Terminology

Molybdenum, Low-Carbon Nickel-Chromium-

3.1 Terms defined in Terminology B899 shall apply unless

Molybdenum-Copper, Low-Carbon Nickel-Chromium-

otherwise defined in this standard.

Molybdenum-Tantalum, Low-Carbon Nickel-Chromium-

Molybdenum-Tungsten, and Low-Carbon Nickel-

4. Ordering Information

Molybdenum-Chromium Alloy Plate, Sheet, and Strip

4.1 It is the responsibility of the purchaser to specify all

B582 Specification for Nickel-Chromium-Iron-

requirements that are necessary for material ordered under this

Molybdenum-Copper Alloy Plate, Sheet, and Strip

specification. Examples of such requirements include, but are

B880 Specification for General Requirements for Chemical

not limited to, the following:

Check Analysis Limits for Nickel, Nickel Alloys and

4.1.1 Quantity (feet, metres, or number of lengths),

Cobalt Alloys

4.1.2 Name of material or UNS number (electric-fusion-

B899 Terminology Relating to Non-ferrous Metals and Al-

welded pipe),

loys

4.1.3 Alloy (Table 1),

E8/E8M Test Methods for Tension Testing of Metallic Ma-

4.1.4 Class (see 1.2),

terials

4.1.5 Size (outside diameter and minimum wall thickness),

E29 Practice for Using Significant Digits in Test Data to

4.1.6 Length (specific or random),

Determine Conformance with Specifications

4.1.7 ASTM designation and year of issue,

E1473 Test Methods for Chemical Analysis of Nickel,

4.1.8 Authorization for repair of plate defects by welding

Cobalt, and High-Temperature Alloys

without prior approval if such is intended (see 9.4),

2.2 American Society of Mechanical Engineers Standard:

4.1.9 Circumferential weld permissibility (see 8.3.2), and

ASME Boiler and Pressure Vessel Code, Section IX and

4.1.10 Supplementary requirements.

Section VIII, Div. 1

2.3 American Welding Society Standards:

5. Materials and Manufacture

A5.4 Corrosion-Resisting Chromium and Chromium Nickel

5.1 Materials—The plate material shall conform to the

Steel Covered Welding Electrodes

requirements of the appropriate raw material specification

A5.9 Corrosion-Resisting Chromium and Chromium Nickel

listed in 2.1.

Steel Welding Rods and Bare Electrodes

5.2 Welding:

A5.11 Nickel and Nickel Alloy Covered Welded Electrodes

5.2.1 The joints shall be full penetration double-welded or

A5.14 Nickel and Nickel Alloy Bare Welding Rods and

single-welded butt joints employing fusion welding processes

Electrodes

as defined under “Definitions,” ASME Boiler and Pressure

Vessel Code, Section IX. This specification makes no provision

Available from American Society of Mechanical Engineers (ASME), ASME

for any difference in weld quality requirements regardless of

International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

the weld joint type employed (single or double) in making the

www.asme.org.

weld. Where backing rings or strips are employed, the ring or

Available from American Welding Society (AWS), 550 NW LeJeune Rd.,

Miami, FL 33126, http://www.aws.org. strip material shall be of the same P-number (Table QW-422 of

B474/B474M − 19 (2023)

Section IX) as the plate being joined. Backing rings or strips 6.2 Product Analysis of Weld—The pipe manufacturer shall

shall be completely removed after welding, prior to any make an analysis of the finished deposited weld material from

required radiography, and the exposed weld surface shall be each lot of pipe. The chemical composition of the weld deposit

examined visually for conformance to the requirements of shall fall within the chemical composition limits of the

5.2.3. Welds made by procedures employing backing strips or applicable AWS filler metal specification for the corresponding

rings which remain in place are prohibited. Welding procedures grade shown in Table 2 (or higher alloyed filler metal when

and welding operators shall be qualified in accordance with approved by the purchaser) or shall conform to the chemical

ASME Boiler and Pressure Vessel Code, Section IX. composition specified for the plate specification to which the

5.2.2 Except as provided in 5.2.2.1 and 5.2.2.2, welds shall material was ordered, or shall, subject to the purchaser

be made in their entirety by processes involving the deposition approval, be a filler metal more highly alloyed than the base

of filler metal. metal when needed for corrosion resistance or other properties.

5.2.2.1 For Class 4 pipe employing multiple passes, the Use of a filler metal other than that listed in Table 2 shall be

root-pass may be completed without the addition of filler reported and the filler metal identified on the pipe manufactur-

metal. er’s certificate of test. The composite analysis variations from

5.2.2.2 For Class 4 pipe, the weld surface exposed inside the Table 2 limits, that are caused by the dilution of the weld metal

with the base metal, shall be agreed upon between purchaser

pipe may result from a single pass made from the inside of the

pipe without the addition of filler metal. and manufacturer.

5.2.2.3 All single-welded pipe shall be completely radio-

6.3 A lot for product analysis shall consist of one heat.

graphed.

5.2.3 The weld surface on either side of the weld shall be

7. Mechanical and Other Properties

flush with the base plate or shall have a reasonably uniform

7.1 Mechanical Properties:

crown, not to exceed ⁄8 in. [3.2 mm]. Any weld reinforcement

may be removed at the manufacturer’s option or by agreement 7.1.1 The mechanical properties of the plate shall be in

between the manufacturer and purchaser. The contour of the accordance with the plate specification to which it was ordered.

reinforcement shall be reasonably smooth and free of irregu- Tension tests made by the plate manufacturer shall qualify the

plate material.

larities. The deposited metal shall be fused uniformly into the

plate surface. No concavity of contour is permitted unless the

7.1.2 Transverse tension tests taken across the welded joint

resulting thickness of weld metal is equal to or greater than the

shall have a tensile strength not less than the specified

minimum thickness of the adjacent base metal.

minimum tensile strength of the plate.

5.2.4 Weld defects shall be repaired by removal to sound

7.1.3 A lot for mechanical testing shall consist of all

metal and rewelding. Subsequent heat treatment and inspection

material from the same heat (which may include more that one

(that is, visual, radiographic and dye penetrant) shall be as

plate/slab/lot number), nominal size (excepting length) and

required on the original welds.

heat treatment. When final heat treatment is in a batch-type

furnace, a lot shall include only those pipes of the same size

5.3 Heat Treatment:

and the same heat (which may include more than one plate/

5.3.1 The pipe furnished under this specification, shall be

slab/lot number) that are heat-treated in the same furnace

heat treated in accordance with Table 1. See Table 1 for

charge. When heat treatment is in a continuous furnace, a lot

recommended practice.

shall include all pipe of the same size and heat (which may

5.3.2 The purchase order shall specify one of the following

include more than one plate/slab/lot number), heat-treated in

conditions if the heat-treated condition specified by Table 1 is

the same furnace at the same temperature, time at temperature,

not desired by the purchaser.

and furnace speed during one production run. At no time shall

5.3.2.1 A final heat treatment other than that specified in

a lot consist of more than 20 000 lb [9070 kg].

Table 1—Each pipe supplied under this requirement shall be

7.1.4 Samples of the material to provide test specimens for

stenciled with the final heat-treatment temperature in degrees

mechanical and other properties shall be taken from such

Fahrenheit or degrees Celsius after the suffix “HT.”

locations in each lot as to be representative of that lot. Test

5.3.2.2 No final heat-treatment of pipe fabricated of plate

specimens shall be taken from material in the final condition. It

that has been heat treated at temperatures required by this

is permissible for the test specimens to be taken from a test

specification—Each pipe supplied under this requirement shall

plate of the same material as the pipe, the test plate being

be stenciled with the suffix “HT-O.”

attached to the end of the cylinder and we

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.