ASTM D6087-08

(Test Method)Standard Test Method for Evaluating Asphalt-Covered Concrete Bridge Decks Using Ground Penetrating Radar

Standard Test Method for Evaluating Asphalt-Covered Concrete Bridge Decks Using Ground Penetrating Radar

SIGNIFICANCE AND USE

This test method provides information on the condition of concrete bridge decks overlaid with asphaltic concrete without necessitating removal of the overlay, or other destructive procedures.

This test method also provides information on the condition of bridge decks without overlays and with portland cement concrete overlays.

A systematic approach to bridge deck rehabilitation requires considerable data on the condition of the decks. In the past, data has been collected using the traditional methods of visual inspection supplemented by physical testing and coring. Such methods have proven to be tedious, expensive, and of limited accuracy. Consequently, GPR provides a mechanism to rapidly survey bridges in an efficient, non-destructive manner.

Information on the condition of asphalt-covered concrete bridge decks is needed to estimate bridge deck condition for maintenance and rehabilitation, to provide cost-effective information necessary for rehabilitation contracts.

GPR is currently the only non-destructive method that can evaluate bridge deck condition on bridge decks containing an asphalt overlay.

SCOPE

1.1 This test method covers several ground penetrating radar (GPR) evaluation procedures that can be used to evaluate the condition of concrete bridge decks overlaid with asphaltic concrete wearing surfaces. These procedures can also be used for bridge decks overlaid with portland cement concrete and for bridge decks without an overlay. Specifically, this test method predicts the presence or absence of concrete or rebar deterioration at or above the level of the top layer of reinforcing bar.

1.2 Deterioration in concrete bridge decks is manifested by the corrosion of embedded reinforcement or the decomposition of concrete, or both. The most serious form of deterioration is that which is caused by corrosion of embedded reinforcement. Corrosion may be initiated by deicing salts, used for snow and ice control in the winter months, penetrating the concrete. In arid climates, the corrosion can be initiated by chloride ions contained in the mix ingredients. Deterioration may also be initiated by the intrusion of water and aggravated by subsequent freeze/thaw cycles causing damage to the concrete and subsequent debonding of the reinforcing steel with the surrounding compromised concrete.

1.2.1 As the reinforcing steel corrodes, it expands and creates a crack or subsurface fracture plane in the concrete at or just above the level of the reinforcement. The fracture plane, or delamination, may be localized or may extend over a substantial area, especially if the concrete cover to the reinforcement is small. It is not uncommon for more than one delamination to occur on different planes between the concrete surface and the reinforcing steel. Delaminations are not visible on the concrete surface. However, if repairs are not made, the delaminations progress to open spalls and, with continued corrosion, eventually affect the structural integrity of the deck.

1.2.2 The portion of concrete contaminated with excessive chlorides is generally structurally deficient compared with non-contaminated concrete. Additionally, the chloride-contaminated concrete provides a pathway for the chloride ions to initiate corrosion of the reinforcing steel. It is therefore of particular interest in bridge deck condition investigations to locate not only the areas of active reinforcement corrosion, but also areas of chloride-contaminated and otherwise deteriorated concrete.

1.3 This test method may not be suitable for evaluating bridges with delaminations that are localized over the diameter of the reinforcement, or for those bridges that have cathodic protection (coke breeze as cathode) installed on the bridge or for which a conductive aggregate has been used in the asphalt (that is, blast furnace slag). This is because metals are perfect reflectors of electromagnetic waves, since the wave impedances for metal...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6087 − 08

StandardTest Method for

Evaluating Asphalt-Covered Concrete Bridge Decks Using

1

Ground Penetrating Radar

This standard is issued under the fixed designation D6087; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope non-contaminated concrete. Additionally, the chloride-

contaminatedconcreteprovidesapathwayforthechlorideions

1.1 This test method covers several ground penetrating

to initiate corrosion of the reinforcing steel. It is therefore of

radar(GPR)evaluationproceduresthatcanbeusedtoevaluate

particular interest in bridge deck condition investigations to

the condition of concrete bridge decks overlaid with asphaltic

locate not only the areas of active reinforcement corrosion, but

concrete wearing surfaces. These procedures can also be used

also areas of chloride-contaminated and otherwise deteriorated

for bridge decks overlaid with portland cement concrete and

concrete.

for bridge decks without an overlay. Specifically, this test

method predicts the presence or absence of concrete or rebar 1.3 This test method may not be suitable for evaluating

deterioration at or above the level of the top layer of reinforc- bridgeswithdelaminationsthatarelocalizedoverthediameter

ing bar. of the reinforcement, or for those bridges that have cathodic

protection (coke breeze as cathode) installed on the bridge or

1.2 Deterioration in concrete bridge decks is manifested by

for which a conductive aggregate has been used in the asphalt

thecorrosionofembeddedreinforcementorthedecomposition

(that is, blast furnace slag). This is because metals are perfect

of concrete, or both. The most serious form of deterioration is

reflectors of electromagnetic waves, since the wave imped-

that which is caused by corrosion of embedded reinforcement.

ances for metals are zero.

Corrosion may be initiated by deicing salts, used for snow and

ice control in the winter months, penetrating the concrete. In 1.4 A precision and bias statement has not been developed

at this time. Therefore, this standard should not be used for

arid climates, the corrosion can be initiated by chloride ions

contained in the mix ingredients. Deterioration may also be acceptance or rejection of a material for purchasing purposes.

initiated by the intrusion of water and aggravated by subse-

1.5 The values stated in SI units are to be regarded as the

quent freeze/thaw cycles causing damage to the concrete and

standard. The inch-pound units given in parentheses are for

subsequent debonding of the reinforcing steel with the sur-

information only.

rounding compromised concrete.

1.6 This standard does not purport to address all of the

1.2.1 As the reinforcing steel corrodes, it expands and

safety concerns, if any, associated with its use. It is the

creates a crack or subsurface fracture plane in the concrete at

responsibility of the user of this standard to establish appro-

orjustabovethelevelofthereinforcement.Thefractureplane,

priate safety and health practices and determine the applica-

or delamination, may be localized or may extend over a

bility of regulatory limitations prior to use. Specific precau-

substantial area, especially if the concrete cover to the rein-

tionary statements are given in Section 5.

forcement is small. It is not uncommon for more than one

delamination to occur on different planes between the concrete

2. Summary of Test Method

surface and the reinforcing steel. Delaminations are not visible

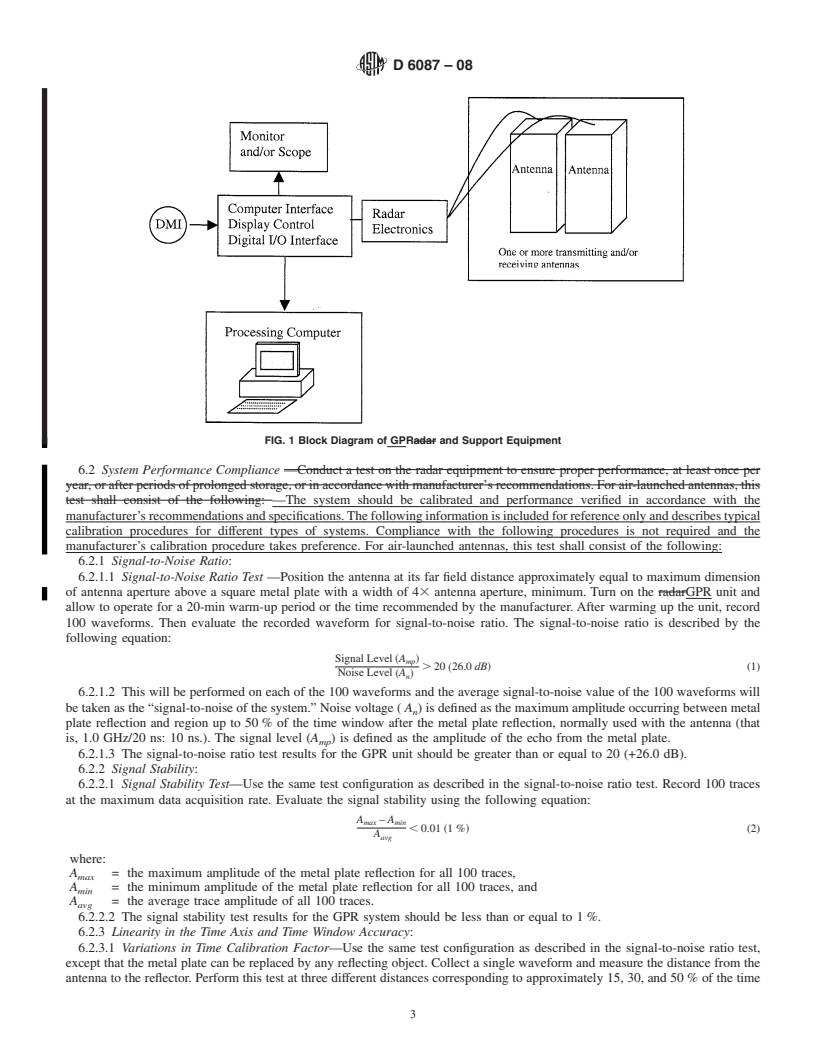

2.1 The data collection equipment consists of a short-pulse

on the concrete surface. However, if repairs are not made, the

GPR device, data acquisition device, recording device, and

delaminations progress to open spalls and, with continued

data processing and interpretation equipment. The user makes

corrosion, eventually affect the structural integrity of the deck.

repeated passes with the data collection equipment in a

1.2.2 The portion of concrete contaminated with excessive

direction parallel or perpendicular to the centerline across a

chlorides is generally structurally deficient compared with

bridge deck at specified locations. Bridge deck condition is

quantified based on the data obtained.

3. Significance and Use

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.32 on

3.1 This test method provides information on the condition

Bridges and Structures.

of concrete bridge decks overlaid with asphaltic concrete

CurrenteditionapprovedJuly1,2008.PublishedJuly2008.Originallyapproved

without necessitating removal of the overlay, or other d

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D6087–07 Designation:D6087–08

Standard Test Method for

Evaluating Asphalt-Covered Concrete Bridge Decks Using

1

Ground Penetrating Radar

This standard is issued under the fixed designation D 6087; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1This test method covers several radar evaluation procedures that can be used to evaluate the condition of concrete bridge

decks overlaid with asphaltic concrete wearing surfaces. Specifically, this test method predicts the presence or absence of concrete

or rebar deterioration at or above the level of the top layer of reinforcing bar.

1.2Deterioration in concrete bridge decks is manifested by the corrosion of embedded reinforcement or the decomposition of

concrete, or both. The most serious form of deterioration is that which is caused by corrosion of embedded reinforcement.

Corrosionisinitiatedbydeicingsalts,usedforsnowandicecontrolinthewintermonths,penetratingtheconcrete.Inaridclimates,

the corrosion can be initiated by chloride ions contained in the mix ingredients.

1.1 This test method covers several ground penetrating radar (GPR) evaluation procedures that can be used to evaluate the

condition of concrete bridge decks overlaid with asphaltic concrete wearing surfaces.These procedures can also be used for bridge

decks overlaid with portland cement concrete and for bridge decks without an overlay. Specifically, this test method predicts the

presence or absence of concrete or rebar deterioration at or above the level of the top layer of reinforcing bar.

1.2 Deterioration in concrete bridge decks is manifested by the corrosion of embedded reinforcement or the decomposition of

concrete, or both. The most serious form of deterioration is that which is caused by corrosion of embedded reinforcement.

Corrosion may be initiated by deicing salts, used for snow and ice control in the winter months, penetrating the concrete. In arid

climates, the corrosion can be initiated by chloride ions contained in the mix ingredients. Deterioration may also be initiated by

the intrusion of water and aggravated by subsequent freeze/thaw cycles causing damage to the concrete and subsequent debonding

of the reinforcing steel with the surrounding compromised concrete.

1.2.1 Asthereinforcingsteelcorrodes,itexpandsandcreatesacrackorsubsurfacefractureplaneintheconcreteatorjustabove

the level of the reinforcement. The fracture plane, or delamination, may be localized or may extend over a substantial area,

especially if the concrete cover to the reinforcement is small. It is not uncommon for more than one delamination to occur on

different planes between the concrete surface and the reinforcing steel. Delaminations are not visible on the concrete surface.

However, if repairs are not made, the delaminations progress to open spalls and, with continued corrosion, eventually affect the

structural integrity of the deck.

1.2.2 The portion of concrete contaminated with excessive chlorides is generally structurally deficient compared with

non-contaminated concrete. Additionally, the chloride-contaminated concrete provides a pathway for the chloride ions to initiate

corrosion of the reinforcing steel. It is therefore of particular interest in bridge deck condition investigations to locate not only the

areas of active reinforcement corrosion, but also areas of chloride-contaminated and otherwise deteriorated concrete.

1.3 This test method may not be suitable for evaluating bridges with delaminations that are localized over the diameter of the

reinforcement, or for those bridges that have cathodic protection (coke breeze as cathode) installed on the bridge or for which a

conductive aggregate has been used in the asphalt (that is, blast furnace slag). This is because metals are perfect reflectors of

electromagnetic waves, since the wave impedances for metals are zero.

1.4The values stated in SI units are to be regarded as the standard.The inch-pound units given in parentheses are for information

only.

1.5

1.4 A precision and bias statement has not been developed at this time. Therefore, this standard should not be used for

acceptance or rejection of a material for purchasing purposes.

1.5 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for

in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.