ASTM D6357-00a

(Test Method)Test Methods for Determination of Trace Elements in Coal, Coke, & Combustion Residues from Coal Utilization Processes by Inductively Coupled Plasma Atomic Emission, Inductively Coupled Plasma Mass, & Graphite Furnace Atomic Absorption Spectrometry

Test Methods for Determination of Trace Elements in Coal, Coke, & Combustion Residues from Coal Utilization Processes by Inductively Coupled Plasma Atomic Emission, Inductively Coupled Plasma Mass, & Graphite Furnace Atomic Absorption Spectrometry

SCOPE

1.1 These test methods pertain to the determination of antimony, arsenic, beryllium, cadmium, chromium, cobalt, copper, lead, manganese, molybdenum,nickel, vanadium, and zinc is in coal and coke. These test methods can also be used for the analysis of residues from coal combustion processes.

Note 1-These test methods may be applicable to the determination of other trace elements.

1.2 The values stated in SI units shall be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6357 – 00a

Standard Test Methods for

Determination of Trace Elements in Coal, Coke, and

Combustion Residues from Coal Utilization Processes by

Inductively Coupled Plasma Atomic Emission Spectrometry,

Inductively Coupled Plasma Mass Spectrometry, and

Graphite Furnace Atomic Absorption Spectrometry

This standard is issued under the fixed designation D 6357; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other Documents:

EPA/600/4-91/010 Methods for the Determination of Met-

1.1 These test methods pertain to the determination of

als in Environmental Samples

antimony, arsenic, beryllium, cadmium, chromium, cobalt,

copper, lead, manganese, molybdenum, nickel, vanadium, and

3. Terminology

zinc in coal and coke. These test methods can also be used for

3.1 Definitions—Definitions applicable to these test meth-

the analysis of residues from coal combustion processes.

ods are listed in Terminology D 121.

NOTE 1—These test methods may be applicable to the determination of

other trace elements.

4. Summary of Test Method

1.2 The values stated in SI units shall be regarded as the 4.1 The coal or coke to be analyzed is ashed under con-

standard.

trolled conditions, digested by a mixture of aqua-regia and

1.3 This standard does not purport to address all of the hydrofluoric acid, and finally dissolved in 1 % nitric acid.

safety concerns, if any, associated with its use. It is the

Combustion residues are digested on an as-received basis. The

responsibility of the user of this standard to establish appro- concentration of individual trace elements is determined by

priate safety and health practices and determine the applica-

either inductively coupled atomic emission spectrometry (IC-

bility of regulatory limitations prior to use. PAES) or inductively coupled plasma mass spectrometry

(ICPMS). Selected elements that occur at concentrations below

2. Referenced Documents

the detection limits of ICPAES can be quantitatively analyzed

2.1 ASTM Standards:

by graphite furnace atomic absorption spectrometry (GFAA).

D 121 Terminology of Coal and Coke

5. Significance and Use

D 346 Practice for Collection and Preparation of Coke

Samples for Laboratory Analysis 5.1 Coal contains several elements whose individual con-

D 1193 Specification for Reagent Water

centrations are generally less than 0.01 %. These elements are

D 2013 Method of Preparing Coal Samples for Analysis commonly and collectively referred to as trace elements. These

D 3173 Test Method for Moisture in the Analysis Sample of

elements primarily occur as part of the mineral matter in coal.

Coal and Coke The potential release of certain trace elements from coal

D 3180 Practice for Calculating Coal and Coke Analyses

combustion sources has become an environmental concern.

from As-Determined to Different Bases 5.2 The ash prepared in accordance with these provisional

D 4621 Guide for Accountability and Quality Control in the

test methods quantitatively retains the elements listed in 1.1

Coal Analysis Laboratory and is representative of their concentrations in the coal or coke.

D 5142 Test Methods for Proximate Analysis of the Analy-

6. Apparatus

sis Sample of Coal and Coke by Instrumental Procedures

6.1 Inductively Coupled Plasma Atomic Emission Spectrom-

eter (ICPAES)—The spectrometer system may be either simul-

taneous or sequential, vacuum or purged, but must include

These test methods are under the jurisdiction of ASTM Committee D05 on Coal

and Coke and are the direct responsibility of Subcommittee D05.29 on Major

computer-controlled background correction.

Elements in Ash and Trace Elements of Coal.

Current edition approved Oct. 10, 2000. Published January 2001. Originally

published as PS 52 - 96. Last previous edition D 6357 - 00.

2 4

Annual Book of ASTM Standards, Vol 05.06. Available from Superintendent of Documents, U.S. Printing Office, Washing-

Annual Book of ASTM Standards, Vol 11.01. ton, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6357 – 00a

NOTE 2—A matrix modifier is used to minimize GFAA interference

6.1.1 Argon Gas Supply—High purity (99.99 %).

effects by selective volatilization of either the analyte or the matrix

6.1.2 Mass Flow Controllers—A mass-flow controller to

components. Other matrix modifiers such as nickel nitrate or palladium

regulate the nebulizer gas is required. Mass flow controllers on

nitrate can be used. The analyst should compare modifiers to establish

the intermediate and outer torch gas flows are recommended.

optimum performance as outlined in 10.1.

6.2 Inductively Coupled Plasma Mass Spectrometer

7.7 Blank Solutions—All of the test methods in this stan-

(ICPMS)—The spectrometer system must be capable of scan-

dard require two types of blank solutions. A calibration blank

ning the mass range of the elements to be analyzed.

that is used to establish the analytical calibration curve and a

6.2.1 Argon Gas Supply, high purity (99.99 %).

method blank which is used to evaluate possible contamination

6.2.2 The use of a variable speed peristaltic pump for

and assess spectral background.

delivering sample solution to the nebulizer, a mass-flow

7.7.1 Calibration Blank—A 1 % nitric acid solution. When

controller on the gas supply to the nebulizer, and a water-

using matrix modifiers of GFAA, the calibration blank shall

cooled spray chamber are highly recommended.

also contain the same equivalent concentration.

6.3 Atomic Absorption Spectrometer with Graphite Furnace

7.7.2 Method Blank—Consists of all the reagents in the

(GFAA), having background correction capable of removing

same volumes as used in preparing the samples. The method

nonspecific absorbance.

blank shall be processed through the entire sample digestion

6.3.1 Single-Element Hollow Cathode or Single-Element

scheme.

Electrodeless Discharge Lamps.

6.3.2 Single-Output Device, capable of recording and evalu-

8. Analysis Sample

ating peak area and peak shape.

8.1 Samples of coal and coke shall be prepared in accor-

6.3.3 Pyrolytic Coated Graphite Tubes and Platforms.

dance with Method D 2013 or Practice D 346.

6.3.4 Argon Gas Supply, high purity (99.99 %).

8.2 Standard practices for the sampling and preparation of

6.3.5 Autosampler—Although not specifically required, the

residues from coal utilization processes have not been estab-

use of an autosampler is highly recommended.

lished. Some of these materials are highly abrasive. The use of

6.4 Muffle Furnace, with temperature control and with air

high speed pulverizers for size reduction shall be avoided. The

circulation as specified in 9.1.

use of jaw crushers followed by final preparation in an agate

6.5 Analytical Balance, capable of weighing to 0.1 mg.

mortar and pestle is recommended to prevent contamination of

6.6 Teflon Beakers, 100- or 200-mL capacity.

the sample.

6.7 Hot Plate, capable of regulating temperature between 90

8.3 Analyze separate test portions for moisture content in

to 150°C.

accordance with Test Methods D 3173 and D 5142 so that

6.8 Volumetric Flasks, 100- and 10-mL capacity.

calculations to other bases can be made.

6.9 HDPE Bottles, 100-mL capacity.

9. Procedure

6.10 Crucibles, 50-mL quartz or high silica.

9.1 Ashing—Weigh to the nearest 0.1 mg enough of the coal

7. Reagents

or coke sample that will yield approximately 0.5 g of ash into

an open 50-mL quartz or high-silica crucible. Place the crucible

7.1 Purity of Reagents—All acids used in these test methods

in a cold muffle furnace. Adjust the temperature control so that

must be trace metal purity grade or equivalent. Redistilled

the furnace reaches a temperature of 300°C in 1 h and then

acids are acceptable.

500°C in the second hour. Maintain the furnace temperature at

7.2 Purity of Water—The purity of the water used in these

500°C for a minimum of 2 h, stirring the sample occasionally.

test methods shall be equivalent to ASTM Type II reagent

Ashing is complete when no visible evidence of carbonaceous

water of Specification D 1193.

material remains. Cool the samples to room temperature under

7.3 Aqua Regia Solution—Mix one part concentrated nitric

conditions that minimize the absorption of water. Grind the ash

acid (HNO , sp. gr. 1.42) and three parts concentrated hydro-

to pass a 150-μm (No. 100) U.S.A. standard sieve in an agate

chloric acid (HCl, sp. gr. 1.9).

mortar then reignite at 500°C for 1 h. Cool the ash and store in

7.4 Hydrofluoric Acid—Concentrated (HF, sp. gr. 1.15).

a desiccator. Determine the percentage of ash by analyzing

7.5 ICP Calibration Standards—Aqueous multielement so-

under the same conditions a separate portion of the analysis

lutions made up in 1 % HNO are used for calibration of

sample.

ICPAES and ICPMS systems. The standards may be purchased

or prepared from high-purity grade chemicals or metals.

NOTE 3—If all the ash from 9.1 is quantitatively transferred for

7.5.1 GFAA Stock Standard Solution (1000 ppm)—Single- digestion in 9.2, it is not necessary to sieve and grind the ash. Results from

11.2.3, 12.3, or 13.1.3.8 are then ppm of the element in the as-determined

element standards either purchased or prepared from high-

sample.

purity grade chemicals or metals.

7.5.2 GFAA Intermediate Stock Standard Solution (1 9.2 Dissolution—Weigh 0.2000 to 0.5000 g of the thor-

ppm)—Add 0.1 mL of stock standard solution (7.5.1) and 1 mL

oughly blended ash prepared according to 9.1 into a 100- or

of concentrated nitric acid to a 100-mL volumetric flask. Dilute 200-mL Teflon beaker. Add 20 mL of aqua regia and 20 mL of

to volume with water.

concentrated hydrofluoric acid to the beaker. Place the beaker

7.6 Magnesium Nitrate Solution—Matrix modifier (see on a hot plate that has been adjusted to 130 to 150°C. Heat the

Note 2), (106–g/L Mg(NO ) 6H O) for the determination of mixture to dryness, but do not bake. After the solution has

3 2 2

arsenic and antimony, equivalent to 10 000-ppm magnesium. evaporated, rinse the beaker walls with deionized water and

D 6357 – 00a

heat this solution to dryness, again being careful not to bake the 11.2 Calibration Procedure—Calibrate the instrument ac-

sample. Remove the beaker from the hot plate and cool to room cording to the procedure recommended by the manufacturer

temperature. Add 1 mL of concentrated nitric acid and 20 mL using a calibration blank and aqueous multielement standards

of deionized water to the beaker. Heat the contents on a hot made up in 1 % trace metal grade HNO . All calibration

plate at 90 to 100°C until the sample is in solution. If a residue solutions must also contain an internal standard (see Note 5).

remains after1hof heating, it may be ignored. The trace Records for all calibrations must be in accordance with Guide

elements are considered to be quantitatively extracted at this D 4621.

point. Remove the beaker from the hot plate and allow the

NOTE 5—An internal standard is needed to compensate for:

solution to cool to room temperature. Transfer the cool solution

1. Differences in physical properties (such as viscosity) between the

to a 100-mL volumetric flask and dilute to volume with

calibration standard and the test samples and

deionized water. If the solution is not to be analyzed immedi-

2. Drift caused by thermal changes in the laboratory which will affect

the instrument optics.

ately, transfer to a HDPE bottle to avoid adsorption of lead

An appropriate internal standard element should:

during storage. Prepare a method blank (7.7.2) with each batch

(i) not be naturally present in the test samples in appreciable concen-

of samples to be analyzed.

trations,

NOTE 4—To minimize contamination, clean laboratory ware in a 1:1 (ii) not present spectral interferences with any analyte,

solution of HNO followed by a 1:1 solution of HCl then rinse thoroughly (iii) be a strong emitter so that its relative concentration can be kept

with deionized water. low, and

(iv) be as chemically similar to the analyte as possible.

10. Analysis

11.2.1 Initial Calibration Verification—Before analyzing

10.1 Because of the differences between various makes and

test samples, analyze the method blank and verify the proper

models of instruments, all instrumental operating instructions

calibration of the instrument by analyzing a reference material

cannot be provided. Instead, the analyst shall refer to the

that has traceability to an internationally recognized certifying

instructions provided by the manufacturer of the particular

agency such as NIST. Results for the reference material must

instrument. Sensitivity, instrumental detection limit, linear

be within the stated uncertainty limits or the calibration

dynamic range, interference effects, and appropriate back-

procedure must be repeated.

ground correction shall be investigated and established for each

11.2.2 Periodic Calibration Verification and

individual analyte on that particular instrument.

Recalibration—In accordance with Guide D 4621, analyze a

control sample such as NIST on a periodic basis. Results

11. Test Method A—Inductively Coupled Plasma Atomic

obtained for the control sample must be within 10 % of the

Emission Spectroscopy

stated value or all results obtained since the last successful

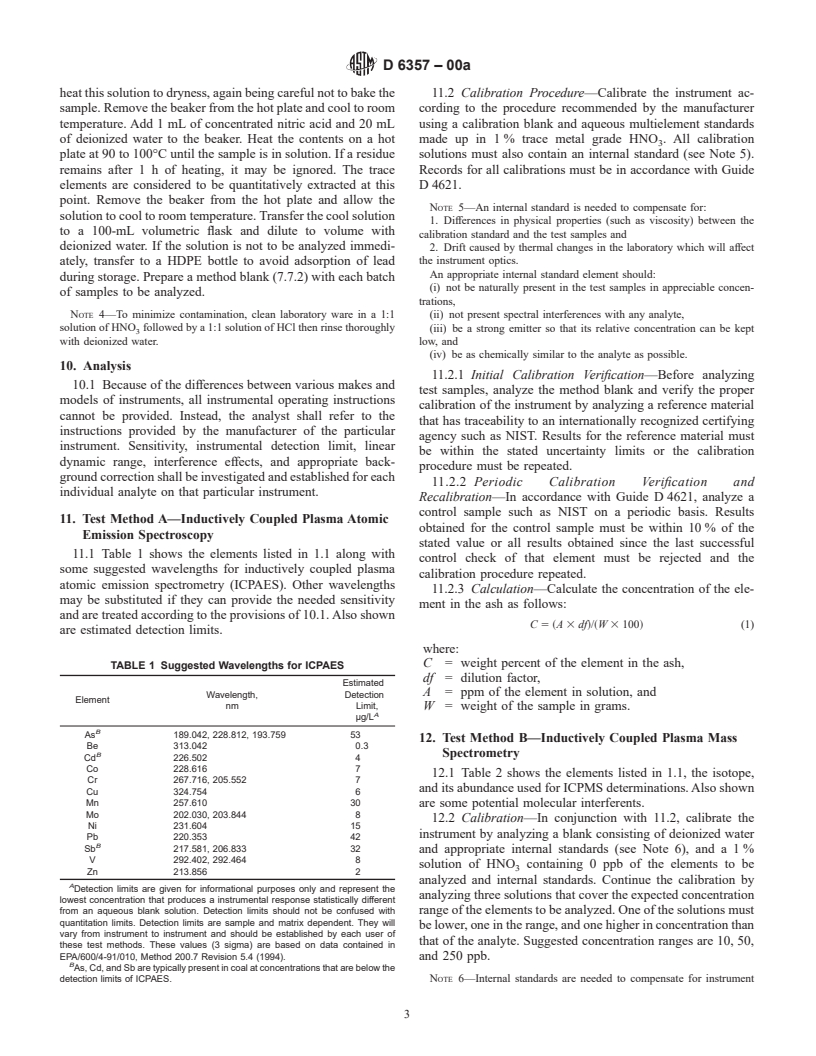

11.1 Table 1 shows the elements listed in 1.1 along with

control check of that element must be rejected and the

some suggested wavelengths for inductively coupled plasma

calibration procedure repeated.

atomic emission spectrometry (ICPAES). Other wavelengths

11.2.3 Calculation—Calculate the concentration of the ele-

may be substituted if they can provide the needed sensitivity

ment in the ash as follows:

and are treated according to the provisions of 10.1. Also shown

C 5 A 3 df!/ W 3 100! (1)

~ ~

are estimated detection limits.

where:

C = weight percent of the element in the ash,

TABLE 1 Suggested Wavelengths for ICPAES

df = dilution factor,

Estimated

A = ppm of the element in solution, and

Wavelength, Detection

Element

nm Limit,

W = weight of the sample in grams.

A

μg/L

B

As 189.042, 228.812, 193.759 53

12. Test Method B—Inductively Coupled Plasma Mass

Be 313.042 0.3

B Spectrometry

Cd 226.502 4

Co 228.616 7

12.1 Table 2 shows the elements listed in 1.1, the isotope,

Cr 267.716, 205.552 7

and its abundance used for ICPMS determinations. Also shown

Cu 324.754 6

Mn 257.610 30

are some potential molecular interferents.

Mo 202.030, 203.844 8

12.2 Calibration—In conjunction with 11.2, calibrate the

Ni 231.604 15

instrument by analyzing a b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.