ASTM D2581-09

(Specification)Standard Specification for Polybutylene (PB) Plastics Molding and Extrusion Materials (Withdrawn 2018)

Standard Specification for Polybutylene (PB) Plastics Molding and Extrusion Materials (Withdrawn 2018)

ABSTRACT

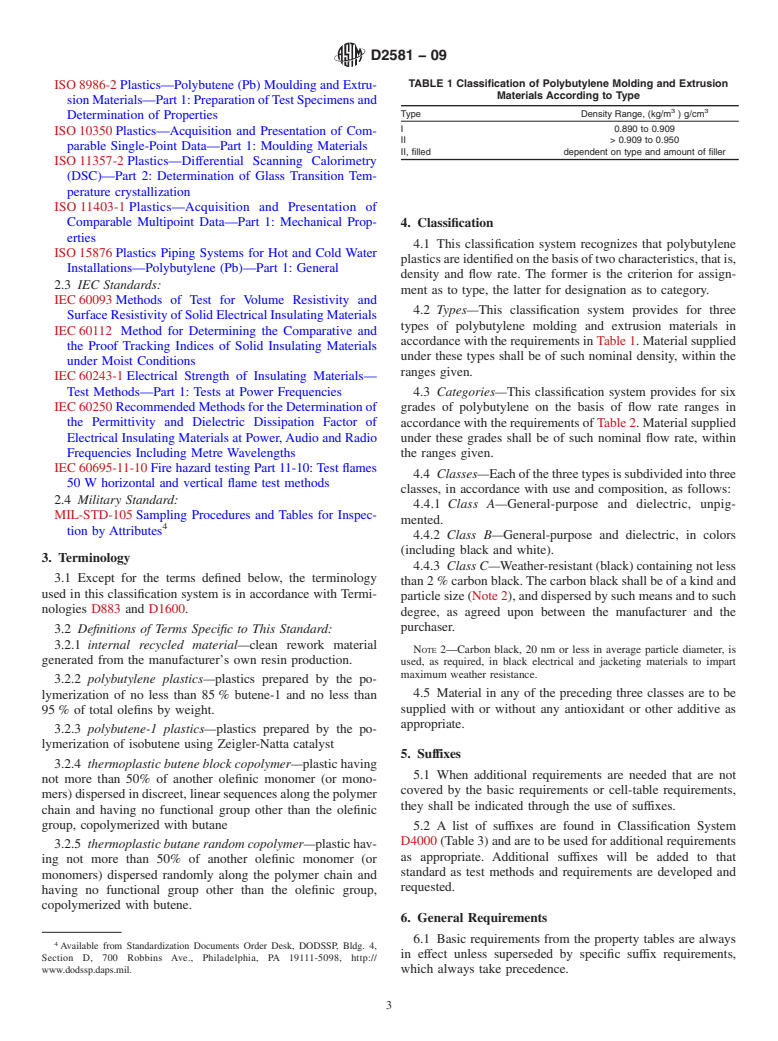

This classification system covers polybutylene plastics materials suitable for molding and extrusion that allows the material to be recycled. This system recognizes that polybutylene plastics are identified on the basis of two characteristics which are density and flow rate. The former is the criterion for assignment as to type of material which are Type I, Type II, and Type II that is colored and filled. The latter for designation as to categories and classes which are class A for general purpose and dielectric and is unpigmented, Class B also for general purpose and dielectric in black and white and Class C which is weather resistant, color black and containing not less than a certain percentage of carbon black.. The properties in this classification system shall be determined in accordance to test methods specified regarding its density, flow rate, tensile properties and carbon black content. Tensile properties include tensile strength, yield strength, and elongation at break.

SCOPE

1.1 This classification system covers polybutylene plastics materials suitable for molding and extrusion.

1.2 This classification system is applicable to all butene homopolymers and to copolymers of butene with a maximum content of other 1-olefinic monomers of less than 50 % and with a content of non-olefinic monomers with functional groups up to a maximum of 1 %.

1.3 This classification system allows for the use of those polybutylene plastic materials that are to be recycled, reconstituted, and reground, provided the following conditions are met:

1.3.1 The requirements as stated in this classification system and other guideline pertaining to these materials are met, and

1.3.2 The material has not been modified in any way to alter its conformance to water contact regulations or other similar requirements.

1.4 The proportions of recycled, reconstituted, and regrind material used, as well as the nature and the amount of any contaminant, cannot be practically covered in this classification system. It is the responsibility of the supplier and buyer of recycled, reconstituted, and regrind materials to ensure compliance.

1.5 The properties included in this classification system are those required to characterize and classify the specific product. Other properties are necessary to identify particular characteristics important to specialized applications. These are specified by using suffixes as given in Section 5. Properties shall be selected in such a manner that consistency of different lots or shipments is assured. The tests involved in this classification system are intended to provide information for identifying materials in accordance with types and categories. It is not the function of this classification system to provide specific engineering data for design purposes.

1.6 This classification system and subsequent line callout (specification) are intended to provide a means of calling out plastic materials used in the fabrication of end items or parts. It is not intended for the selection of materials. Material selection is to be made by those having expertise in the plastic field after careful consideration of the design and the performance required of the part, the environment to which it will be exposed, the fabrication process to be employed, the costs involved, and the inherent properties of the material other than those covered by this standard.

1.7 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

Note 1—This standard, ISO 8986-1, and ISO 8986-2 address the same subject matter, but differ in technical content.

1.8 The following precautionary caveat pertains only to the test methods portion, Section 11, of this classification system: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety an...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2581 −09

Standard Classification System for

1

Polybutylene (PB) Plastics Molding and Extrusion Materials

This standard is issued under the fixed designation D2581; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* plastic materials used in the fabrication of end items or parts.

It is not intended for the selection of materials. Material

1.1 This classification system covers polybutylene plastics

selection is to be made by those having expertise in the plastic

materials suitable for molding and extrusion.

field after careful consideration of the design and the perfor-

1.2 This classification system is applicable to all butene

mancerequiredofthepart,theenvironmenttowhichitwillbe

homopolymers and to copolymers of butene with a maximum

exposed, the fabrication process to be employed, the costs

content of other 1-olefinic monomers of less than 50% and

involved, and the inherent properties of the material other than

with a content of non-olefinic monomers with functional

those covered by this standard.

groups up to a maximum of 1%.

1.7 The values stated in SI units are to be regarded as the

1.3 This classification system allows for the use of those

standard. The values given in parentheses are for information

polybutylene plastic materials that are to be recycled,

only.

reconstituted, and reground, provided the following conditions

NOTE 1—This standard, ISO8986-1, and ISO8986-2 address the same

are met:

subject matter, but differ in technical content.

1.3.1 Therequirementsasstatedinthisclassificationsystem

1.8 The following precautionary caveat pertains only to the

and other guideline pertaining to these materials are met, and

test methods portion, Section 11, of this classification system:

1.3.2 Thematerialhasnotbeenmodifiedinanywaytoalter

This standard does not purport to address all of the safety

its conformance to water contact regulations or other similar

concerns, if any, associated with its use. It is the responsibility

requirements.

of the user of this standard to establish appropriate safety and

1.4 The proportions of recycled, reconstituted, and regrind

health practices and determine the applicability of regulatory

material used, as well as the nature and the amount of any

limitations prior to use.

contaminant,cannotbepracticallycoveredinthisclassification

system. It is the responsibility of the supplier and buyer of

2. Referenced Documents

recycled, reconstituted, and regrind materials to ensure com-

2

2.1 ASTM Standards:

pliance.

C177Test Method for Steady-State Heat Flux Measure-

1.5 The properties included in this classification system are

ments and Thermal Transmission Properties by Means of

thoserequiredtocharacterizeandclassifythespecificproduct.

the Guarded-Hot-Plate Apparatus

Other properties are necessary to identify particular character-

D149Test Method for Dielectric Breakdown Voltage and

isticsimportanttospecializedapplications.Thesearespecified

DielectricStrengthofSolidElectricalInsulatingMaterials

by using suffixes as given in Section 5. Properties shall be

at Commercial Power Frequencies

selected in such a manner that consistency of different lots or

D150Test Methods forAC Loss Characteristics and Permit-

shipments is assured. The tests involved in this classification

tivity (Dielectric Constant) of Solid Electrical Insulation

system are intended to provide information for identifying

D257Test Methods for DC Resistance or Conductance of

materials in accordance with types and categories. It is not the

Insulating Materials

function of this classification system to provide specific engi-

D495Test Method for High-Voltage, Low-Current, DryArc

neering data for design purposes.

Resistance of Solid Electrical Insulation

D543Practices for Evaluating the Resistance of Plastics to

1.6 This classification system and subsequent line callout

Chemical Reagents

(specification) are intended to provide a means of calling out

D570Test Method for Water Absorption of Plastics

1

ThisclassificationsystemisunderthejurisdictionofASTMCommitteeD20on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

2

Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 1, 2009. Published August 2009. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1967. Last previous edition approved in 2002 as D2581-02. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D2581-09. the ASTM website.

*A Summary of Changes section appears at the end of this standa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.