ASTM D1710-15(2021)

(Specification)Standard Specification for Extruded Polytetrafluoroethylene (PTFE) Rod, Heavy Walled Tubing and Basic Shapes

Standard Specification for Extruded Polytetrafluoroethylene (PTFE) Rod, Heavy Walled Tubing and Basic Shapes

ABSTRACT

This specification covers the testing and requirements of extruded and compression molded polytetrafluoroethylene (PTFE) rods and heavy-walled tubing manufactured from virgin or reprocessed PTFE resin. Covered here are three types of PTFE fluorocarbon materials as follows: Type I (premium), materials having maximum physical and electrical properties to meet rigid requirements; Type II (general purpose), materials having properties required of general electrical, mechanical, and chemical applications; and Type III, materials for noncritical chemical, electrical, and mechanical applications. These types are further subdivided into two grades, and even further into four classes as appropriate. Sampled specimens shall be appropriately tested on the following: workmanship and appearance (color, finish, and internal defects); specific gravity; tensile strength and elongation; dielectric strength; dimensional stability; and melting point.

SCOPE

1.1 This specification covers extruded polytetrafluoroethylene (PTFE) rod, heavy-walled tubing, and basic shapes manufactured from the PTFE resin of Specification D4894 and reprocessed PTFE resin (as defined in Guide D7209).

1.2 The specification covers all sizes of rod, tubing, and basic shapes with a wall thickness of 1.6 mm (1/16 in.) or greater. These materials must be made wholly from PTFE and produced in accordance with good commercial ram extrusion practices.

Note 1: This specification and ISO/DIS 13000-1 (1997) and ISO/DIS 13000-2 (1997) differ in approach, however, data obtained using either are technically equivalent.

Note 2: For compression molded PTFE materials, see Specification D3294. Material that can be certified to Specification D3294 may be substituted for Specification D1710, however the reverse in not true.

1.3 The values stated in SI units, as detailed in IEEE/ASTM SI 10 are to be regarded as the standard. The inch-pound units given in parentheses are provided for information only.

1.4 The following precautionary caveat pertains to the test methods portion, Section 12, only of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1710 −15 (Reapproved 2021)

Standard Specification for

Extruded Polytetrafluoroethylene (PTFE) Rod, Heavy Walled

Tubing and Basic Shapes

This standard is issued under the fixed designation D1710; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This specification covers extruded polytetrafluoroethyl-

D149Test Method for Dielectric Breakdown Voltage and

ene (PTFE) rod, heavy-walled tubing, and basic shapes manu-

DielectricStrengthofSolidElectricalInsulatingMaterials

factured from the PTFE resin of Specification D4894 and

at Commercial Power Frequencies

reprocessed PTFE resin (as defined in Guide D7209).

D374Test Methods for Thickness of Solid Electrical Insu-

1.2 The specification covers all sizes of rod, tubing, and

lation (Metric) D0374_D0374M

basic shapes with a wall thickness of 1.6 mm ( ⁄16 in.) or

D618Practice for Conditioning Plastics for Testing

greater. These materials must be made wholly from PTFE and

D792Test Methods for Density and Specific Gravity (Rela-

produced in accordance with good commercial ram extrusion

tive Density) of Plastics by Displacement

practices.

D883Terminology Relating to Plastics

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

NOTE 1—This specification and ISO/DIS 13000-1 (1997) and ISO/DIS

tics

13000-2(1997)differinapproach,however,dataobtainedusingeitherare

D3892Practice for Packaging/Packing of Plastics

technically equivalent.

D4894 Specification for Polytetrafluoroethylene (PTFE)

NOTE 2—For compression molded PTFE materials, see Specification

D3294. Material that can be certified to Specification D3294 may be Granular Molding and Ram Extrusion Materials

substituted for Specification D1710, however the reverse in not true.

D5740Guide for Writing Material Standards in the Classi-

fication Format

1.3 ThevaluesstatedinSIunits,asdetailedinIEEE/ASTM

D5947Test Methods for Physical Dimensions of Solid

SI 10 are to be regarded as the standard. The inch-pound units

Plastics Specimens

given in parentheses are provided for information only.

D7209Guide for Waste Reduction, Resource Recovery, and

1.4 The following precautionary caveat pertains to the test

UseofRecycledPolymericMaterialsandProducts(With-

methods portion, Section 12, only of this specification: This

drawn 2015)

standard does not purport to address all of the safety concerns,

E94Guide for Radiographic Examination Using Industrial

if any, associated with its use. It is the responsibility of the user

Radiographic Film

of this standard to establish appropriate safety, health, and

IEEE/ASTM SI 10Standard for the Use of the International

environmental practices and determine the applicability of

System of Units (SI): The Modern Metric System

regulatory limitations prior to use.

2.2 ISO Standards:

1.5 This international standard was developed in accor-

ISO 13000-1 (2005) Plastics—Polytetrafluoroethylene

dance with internationally recognized principles on standard-

(PTFE) Semi-Finished Products, Part 1: Basis for Speci-

ization established in the Decision on Principles for the

fication

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1 3

This specification is under the jurisdiction of ASTM Committee D20 on The last approved version of this historical standard is referenced on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic www.astm.org.

Materials. Available from ASTM International, 100 Barr Harbor Drive, West

Current edition approved Oct. 1, 2021. Published October 2021. Originally Conshohocken, PA 19428.

approved in 1960. Last previous edition approved in 2015 as D1710-15. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/D1710-15R21. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1710 − 15 (2021)

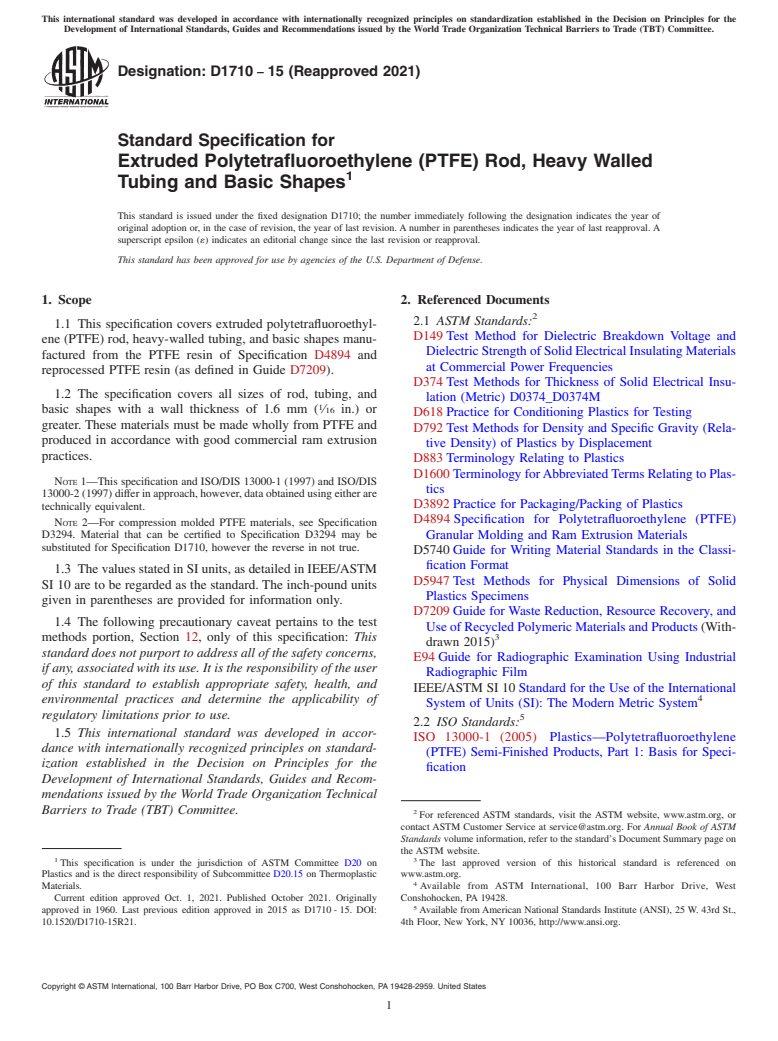

TABLE 1 Detail Requirements of Extruded Rod

Type I Type II Type III

A A A

Rod Diameter, in. Rod Diameter, in. Rod Diameter, in.

Properties

1 1 1

under ⁄2 to over under ⁄2 to over under ⁄2 to over

1 1 1 1 1 1 1 1 1

⁄2 1 ⁄2 1 ⁄2 ⁄2 1 ⁄2 1 ⁄2 ⁄2 1 ⁄2 1 ⁄2

Specific gravity, min 2.14 2.15 2.15 2.14 2.15 2.15 2.12 2.13 2.14

Tensile strength, min, MPa 13.8 14.5 15.2 13.8 14.5 15.2 9.7 10.3 11.0

(psi) (2000) (2100) (2200) (2000) (2100) (2200) (1400) (1500) (1600)

Elongation at Break, min,% 150 175 200 100 125 150 50 75 75

Dielectric strength, min, V/mil 700 750 750 . . . . . .

B

Dimensional stability, max, %

Length 1.5 1.5 . 1.5 1.5 . 3.0 3.0 .

Diameter 0.5 0.5 . 0.5 0.5 . 1.0 1.0 .

A

1 in. = 25.4 mm.

B

This requirement applies only to rod of Classes B and D that is under 25.4 mm (1 in.) in diameter. Values for larger sizes shall be as agreed upon by manufacture and

buyer or manufacture stating material was stress relieved after manufacture of extruded rod.

ISO 13000-2 (2005) Plastics—Polytetrafluoroethylene that type, grade, and class. A comma is used as the separator

(PTFE) Semi-Finished Products, Part 2: Preparation of between the standard number and the type. Separators are not

Test Specimen and Determination of Properties needed between the type, grade, and class. A provision for

special notes is included so that other information can be

3. Terminology

provided when required. An example would be to specify the

3.1 Definitions: dimensiontolerancesforeachsizeofrod,heavy-walledtubing,

or basic shape. When special notes are used, they shall be

3.1.1 Definitions are in accordance with Terminology D883

unless otherwise specified. preceded by a comma.

3.1.2 lot, n—one production run or a uniform blend of two

4.3 The types are further subdivided into two grades:

or more production runs.

4.3.1 Grade 1—Made only from virgin resin.

4.3.2 Grade 2—Made using reprocessed resin.

3.2 Abbreviations—Abbreviations are in accordance with

Terminology D1600. PTFE is the acronym for polytetrafluo-

4.4 The grades are further subdivided into four classes:

roethylene.

4.4.1 Class A—Rod, heavy-walled tubing, or basic shape

having normal dimensional stability.

4. Classification

4.4.2 Class B—Rod, heavy-walled tubing, or basic shape

4.1 This specification covers three types of PTFE rod,

meeting the dimensional stability requirements of Table 1.

heavy-walled tubing, and basic shapes. They are as follows:

4.4.3 Class C—Same as Class A, but, in addition, com-

4.1.1 Type I, Premium—Atypeofrod,heavy-walledtubing,

pletely examined for internal defects.

or basic shape requiring both maximum physical and electrical

4.4.4 Class D—Same as Class B, but, in addition, com-

properties to meet rigid requirements.

pletely examined for internal defects.

4.1.2 Type II, Non-electrical Premium—A type of rod,

heavy-walled tubing, or basic shape requiring physical 5. Materials and Manufacture

properties, but no electrical requirements.

5.1 The rod, heavy-walled tubing, or basic shapes from

4.1.3 Type III—Atype of rod, heavy-walled tubing, or basic

Types I, II, III, and IV shall be made from non-pigmented

shape for non-critical chemical, electrical, and mechanical

PTFE as free of foreign matter as commercially practical.

applications.

4.1.4 Type IV—Atype of rod, heavy-walled tubing, or basic

6. General Requirements

shapeforchemical,electrical,andmechanicalapplications,not

6.1 The rod, heavy-walled tubing, or basic shapes covered

requiring physical property testing as described forTypes I, II,

by this specification shall meet the mechanical and electrical

and III, in Tables 1 and 2.

requirements specified in Table 1 when tested by the methods

NOTE3—TypeIandTypeIIareGrade1(VirginResin)andTypeIIIand given in Section 12. The heavy-walled tubing covered by this

Type IV are Grade 2 (Reprocessed Resin).

specification shall meet the mechanical and electrical require-

ments in Table 2 when tested by the methods given in Section

4.2 A one-line system is used to specify materials covered

12.

by this specification. The system uses predefined cells to refer

to specific aspects of this specification, illustrated as follows:

7. Dimensions, Mass, and Permissible Variations

Specification

Standard Number Type Grade Class Special

7.1 The dimensions and tolerances of heavy-walled tubing

Block notes

shall be in accordance with Table 3. Measurements shall be

made in accordance with Method A of Test Methods D374 or

Example: Specification D1710–08 1 1 A

Test Method D5947.

4.2.1 For this example, the line callout would be Specifica-

tion D1710–08, 11 A, and would specify that a rod, heavy- 7.2 For rod and heavy-walled tubing, it is necessary to

walledtubing,orbasicshapehasallofthepropertieslistedfor center-less-grindtheoutsidediameterforrodandheavy-walled

D1710 − 15 (2021)

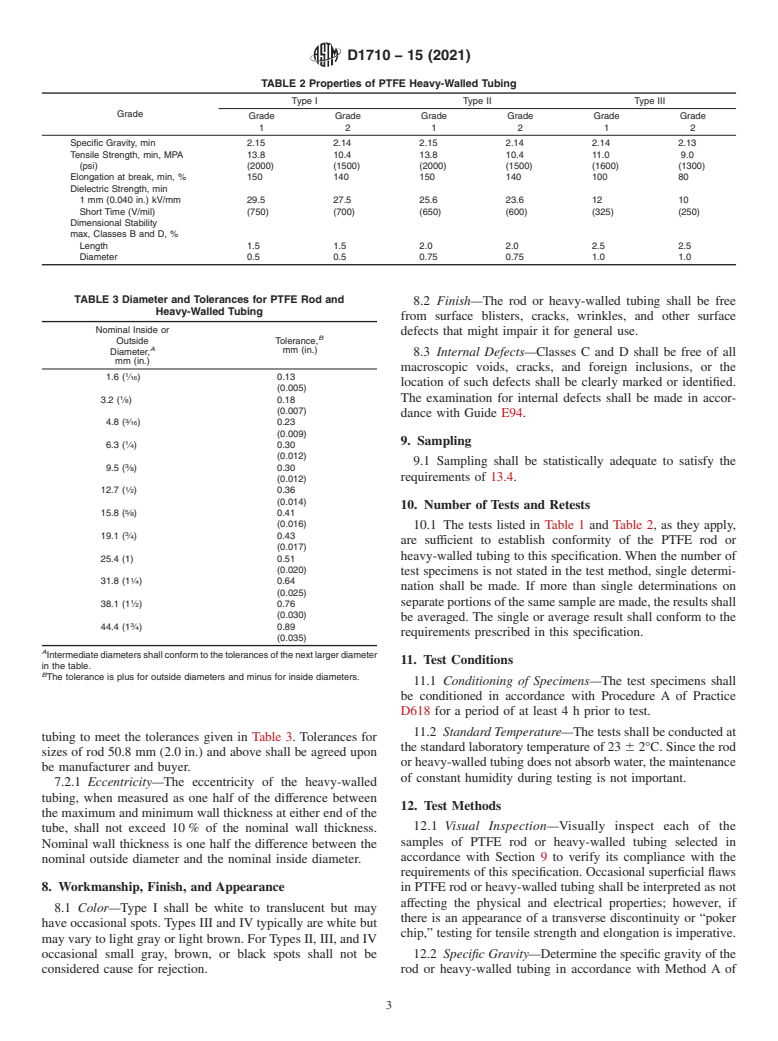

TABLE 2 Properties of PTFE Heavy-Walled Tubing

Type I Type II Type III

Grade

Grade Grade Grade Grade Grade Grade

1 2 1 2 1 2

Specific Gravity, min 2.15 2.14 2.15 2.14 2.14 2.13

Tensile Strength, min, MPA 13.8 10.4 13.8 10.4 11.0 9.0

(psi) (2000) (1500) (2000) (1500) (1600) (1300)

Elongation at break, min, % 150 140 150 140 100 80

Dielectric Strength, min

1 mm (0.040 in.) kV/mm 29.5 27.5 25.6 23.6 12 10

Short Time (V/mil) (750) (700) (650) (600) (325) (250)

Dimensional Stability

max, Classes B and D, %

Length 1.5 1.5 2.0 2.0 2.5 2.5

Diameter 0.5 0.5 0.75 0.75 1.0 1.0

TABLE 3 Diameter and Tolerances for PTFE Rod and

8.2 Finish—The rod or heavy-walled tubing shall be free

Heavy-Walled Tubing

from surface blisters, cracks, wrinkles, and other surface

Nominal Inside or

defects that might impair it for general use.

B

Outside Tolerance,

A

mm (in.)

Diameter,

8.3 Internal Defects—Classes C and D shall be free of all

mm (in.)

macroscopic voids, cracks, and foreign inclusions, or the

1.6 ( ⁄16) 0.13

location of such defects shall be clearly marked or identified.

(0.005)

The examination for internal defects shall be made in accor-

3.2 ( ⁄8) 0.18

(0.007)

dance with Guide E94.

4.8 ( ⁄16) 0.23

(0.009)

1 9. Sampling

6.3 ( ⁄4) 0.30

(0.012)

9.1 Sampling shall be statistically adequate to satisfy the

9.5 ( ⁄8) 0.30

requirements of 13.4.

(0.012)

12.7 ( ⁄2) 0.36

(0.014)

10. Number of Tests and Retests

15.8 ( ⁄8) 0.41

(0.016)

10.1 The tests listed in Table 1 and Table 2, as they apply,

19.1 ( ⁄4) 0.43

are sufficient to establish conformity of the PTFE rod or

(0.017)

heavy-walled tubing to this specification. When the number of

25.4 (1) 0.51

(0.020)

test specimens is not stated in the test method, single determi-

31.8 (1 ⁄4) 0.64

nation shall be made. If more than single determinations on

(0.025)

separateportionsofthesamesamplearemade,theresultsshall

38.1 (1 ⁄2) 0.76

(0.030)

be averaged. The single or average result shall conform to the

44.4 (1 ⁄4) 0.89

requirements prescribed in this specification.

(0.035)

A

Intermediatediametersshallconformtothetolerancesofthenextlargerdiameter

11. Test Conditions

in the table.

B

The tolerance is plus for outside diameters and minus for inside diameters.

11.1 Conditioning of Specimens—The test specimens shall

be conditioned in accordance with Procedure A of Practice

D618 for a period of at least 4 h prior to test.

11.2 Standard Temperature—Thetestsshallbeconductedat

tubing to meet the tolerances given in Table 3. Tolerances for

thestandardlaboratorytemperatureof23 62°C.Sincetherod

sizes of rod 50.8 mm (2.0 in.) and above shall be agreed upon

orheavy-walledtubingdoesnotabsorbwater,themaintenance

be manufacturer and buyer.

of constant humidity during testing is not important.

7.2.1 Eccentricity—The eccentricity of the heavy-walled

tubing, when measured as one half of the difference between

12. Test Methods

the maximum and minimum wall thickness at either end of the

12.1 Visual Inspection—Visually inspect each of the

tube, shall not exceed 10% of the nominal wall thickness.

samples of PTFE rod or heavy-walled tubing selected in

Nominal wall thickness is one half the difference between the

accordance with Section 9 to verify its compliance with the

nominal outside diameter and the nominal inside diameter.

requirements of this specification. Occasional superficial flaws

8. Workmanship, Finish, and Appearance in PTFE rod or heavy-walled tubing shall be interpreted as not

affecting the physical and electrical properties; however, if

8.1 Color—Type I shall be white to translucent but may

there is an appearance of a transverse discontinuity or “poker

have occasional spots.Types III and IVtypically are white but

chip,” testing for tensile strength and elongation is imperative.

may vary to light gray or light brown. ForTypes II, III, and IV

occasional small gray, brown, or black spots shall not be 12.2 Specific Gravity—Determine the specific gravity of the

considered cause for rejection. rod or heavy-walled tubing in accordance with Method A of

D1710 − 15 (2021)

TABLE 4 Precision Summary, Tensile Strength and Elongation at

Break

NOTE 1—I =2.8× CV ; I =2.8× CV

r r R R

Tensile Strength

Material

Mean, psi CV,% CV ,% I,% I ,%

r R r R

Granular PTFE 4801 2.79 8.85 7.81 24.78

12.3.1.3 For the tensile strength and elongation of heavy-

walled tubing, machine a sleeve 1.27-2.54 mm (0.05-0.10 in.)

wall thickness approximately 25.4 mm (1 in.) long from the

innerareaofthetubing.Slitthissleeveusingautilityknife(cut

parallel to direction of extrusion) to open up and lay flat this

tubing. Using steel rule diameter as described in Specification

D4894 stamp samples around perimeter of the tubing.

12.3.2 Test at a speed of 50.8 mm (2 in.)/min, five speci-

mens to be tested and averaged for all specimen types.

12.3.3 Precision and Bias—The precision and bias data

available is shown in Table 4.

12.4 Dielectric Strength:

12.4.1 Determine the dielectric strength in accordance with

the short-timed test of Test Method D149. Electrode shall be

1/16” diameter pin electrode having beveled edges where they

impinge on the specimen. Sample

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.