ASTM D6381/D6381M-15(2020)

(Test Method)Standard Test Method for Measurement of Asphalt Shingle Mechanical Uplift Resistance

Standard Test Method for Measurement of Asphalt Shingle Mechanical Uplift Resistance

SIGNIFICANCE AND USE

5.1 Uplift resistance is one of the properties of an applied shingle that relates to its ability to withstand wind forces. The mechanical tests described are laboratory methods to measure that resistance at a designated temperature after the shingles have been sealed under designated conditions.

5.1.1 This test method determines the mechanical uplift resistance of sealed shingles by direct measurement in a prescribed manner. See Test Method D7158/D7158M for the relationship between this mechanical uplift resistance and the uplift forces derived from the action of wind.

5.2 Many factors influence the sealing characteristics of shingles in the field; for example, temperature, time, contamination by dirt and debris, roof slope, and interference by misplaced fasteners. It is not the objective of this test method to address all of these influences. This test method is designed to determine the mechanical uplift resistance when representative specimens of shingles are sealed under selected conditions prior to testing.

5.3 Procedure A produces lower results than Procedure B. Procedure A provides an edge-lift load value and Procedure B provides a perpendicular load value. The procedure applicable to a specific product depends on the specific product design, geometry, and rigidity. It is the responsibility of the user of this test method to determine the appropriate procedure with reference to the specific product and application. It is possible that engineering calculations would require both procedures to be employed, and for both results to be used in the calculation of the resistance of that specific product to the effects of wind.

5.4 When using this method in conjunction with Test Method D7158/D7158M to determine the uplift resistance of shingles as part of the determination of wind resistance of the shingles, determine the appropriate procedure (Procedure A, Procedure B, or both) in accordance with the discussion, and examples, of shingle geometry and seal...

SCOPE

1.1 This test method covers measuring the uplift resistance of asphalt roofing shingles by mechanical means. It is applicable to shingles that use a factory-applied or field-applied sealant.

1.2 There are several types of shingles designed for service without a factory-applied or field-applied sealant. These shingles, when applied in accordance with the manufacturers' application instructions, employ other means to provide resistance against the forces generated by the action of wind such as geometry and shingle construction. Field experience has shown that these types of shingles function satisfactorily in service. Because there are a variety of these shingle designs, it is not practical to describe in this test method how to test these shingles for uplift resistance. The testing of these types of shingles, therefore, goes beyond the scope of this test method.

1.3 This test method describes two procedures for measuring shingle uplift resistance. Procedure A employs a specially designed apparatus with a clamping device which facilitates lifting of the edge of the shingle and measuring the force required to break the seal. Procedure B employs a metal “T” section adhered to the weather surface of the shingle to facilitate application and measurement of a perpendicular force to break the seal.

1.4 It is not prohibited to use this test method over a range of sealing time and temperature combinations and testing temperatures to simulate a variety of actual field use conditions. The times and temperatures used shall be stated in the report.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.6 This standard does not purport to address all of the saf...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6381/D6381M − 15 (Reapproved 2020)

Standard Test Method for

Measurement of Asphalt Shingle Mechanical Uplift

Resistance

This standard is issued under the fixed designation D6381/D6381M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers measuring the uplift resistance

responsibility of the user of this standard to establish appro-

of asphalt roofing shingles by mechanical means. It is appli-

priate safety, health, and environmental practices and deter-

cable to shingles that use a factory-applied or field-applied

mine the applicability of regulatory limitations prior to use.

sealant.

1.7 This international standard was developed in accor-

1.2 There are several types of shingles designed for service

dance with internationally recognized principles on standard-

without a factory-applied or field-applied sealant. These

ization established in the Decision on Principles for the

shingles, when applied in accordance with the manufacturers’

Development of International Standards, Guides and Recom-

application instructions, employ other means to provide resis-

mendations issued by the World Trade Organization Technical

tanceagainsttheforcesgeneratedbytheactionofwindsuchas

Barriers to Trade (TBT) Committee.

geometryandshingleconstruction.Fieldexperiencehasshown

that these types of shingles function satisfactorily in service.

2. Referenced Documents

Because there are a variety of these shingle designs, it is not 2

2.1 ASTM Standards:

practical to describe in this test method how to test these

D228/D228M Test Methods for Sampling, Testing, and

shingles for uplift resistance. The testing of these types of

Analysis of Asphalt Roll Roofing, Cap Sheets, and

shingles, therefore, goes beyond the scope of this test method.

Shingles Used in Roofing and Waterproofing

1.3 This test method describes two procedures for measur- D1079 Terminology Relating to Roofing and Waterproofing

ing shingle uplift resistance. Procedure A employs a specially

D3462/D3462M Specification for Asphalt Shingles Made

designed apparatus with a clamping device which facilitates from Glass Felt and Surfaced with Mineral Granules

lifting of the edge of the shingle and measuring the force

D7158/D7158M Test Method for Wind Resistance of As-

required to break the seal. Procedure B employs a metal “T”

phalt Shingles (Uplift Force/Uplift Resistance Method)

section adhered to the weather surface of the shingle to

3. Terminology

facilitate application and measurement of a perpendicular force

to break the seal.

3.1 Definitions—For definitions of terms used in this test

method, refer to Terminology D1079.

1.4 It is not prohibited to use this test method over a range

of sealing time and temperature combinations and testing

3.2 Definitions of Terms Specific to This Standard:

temperatures to simulate a variety of actual field use condi-

3.2.1 seal—as it relates to steep roofing shingles,isthe

tions. The times and temperatures used shall be stated in the

bonding that results from the activation of the sealant under the

report.

action of time and temperature.

1.5 The values stated in either SI units or inch-pound units 3.2.2 sealant—as it relates to steep roofing shingles,is

are to be regarded separately as standard. The values stated in

defined as factory-applied or field-applied material designed to

each system may not be exact equivalents; therefore, each seal the shingles to each other under the action of time and

system shall be used independently of the other. Combining

temperature after the shingles are applied to a roof.

values from the two systems may result in nonconformance

3.2.3 sealed—as it relates to steep roofing shingles,isthe

with the standard.

condition of the shingles after the sealant has been activated by

the action of time and temperature.

This test method is under the jurisdiction ofASTM Committee D08 on Roofing

andWaterproofingandisthedirectresponsibilityofSubcommitteeD08.02onSteep

Roofing Products and Assemblies. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2020. Published October 2020. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1999. Last previous edition approved in 2015 as D6381/D6381M – 15. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D6381_D6381M-15R20. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6381/D6381M − 15 (2020)

4. Summary of Test Method be employed, and for both results to be used in the calculation

of the resistance of that specific product to the effects of wind.

4.1 The test specimens are constructed from pieces of

shingles, overlaid and sealed prior to testing.All specimens are 5.4 When using this method in conjunction with Test

then conditioned and tested at selected temperatures. Speci- Method D7158/D7158M to determine the uplift resistance of

mens are tested in ProcedureAby lifting the exposed edge and shingles as part of the determination of wind resistance of the

recording the uplift force required to break the seal, and in shingles, determine the appropriate procedure (Procedure A,

Procedure B by recording the perpendicular force required to Procedure B, or both) in accordance with the discussion, and

break the seal. examples, of shingle geometry and sealant configuration in

Section 12.2 of Test Method D7158/D7158M.

5. Significance and Use

6. Apparatus

5.1 Uplift resistance is one of the properties of an applied

shingle that relates to its ability to withstand wind forces. The 6.1 Tensile Testing Machine, shall be a constant-rate-of-

extension (CRE) type.

mechanical tests described are laboratory methods to measure

that resistance at a designated temperature after the shingles

6.2 Heavy-Duty Paper Cutter, steel rule, die, or template 95

have been sealed under designated conditions. 3 1 3

by 114 mm [3 ⁄4 by 4 ⁄2 in.] and 95 by 178 mm [3 ⁄4 by 7 in.]

5.1.1 This test method determines the mechanical uplift

for Procedure A, and 102 by 152 mm [4 by 6 in.] and 95 by

resistance of sealed shingles by direct measurement in a 3 1

38 mm [3 ⁄4 by 1 ⁄2 in.] for Procedure B.

prescribed manner. See Test Method D7158/D7158M for the

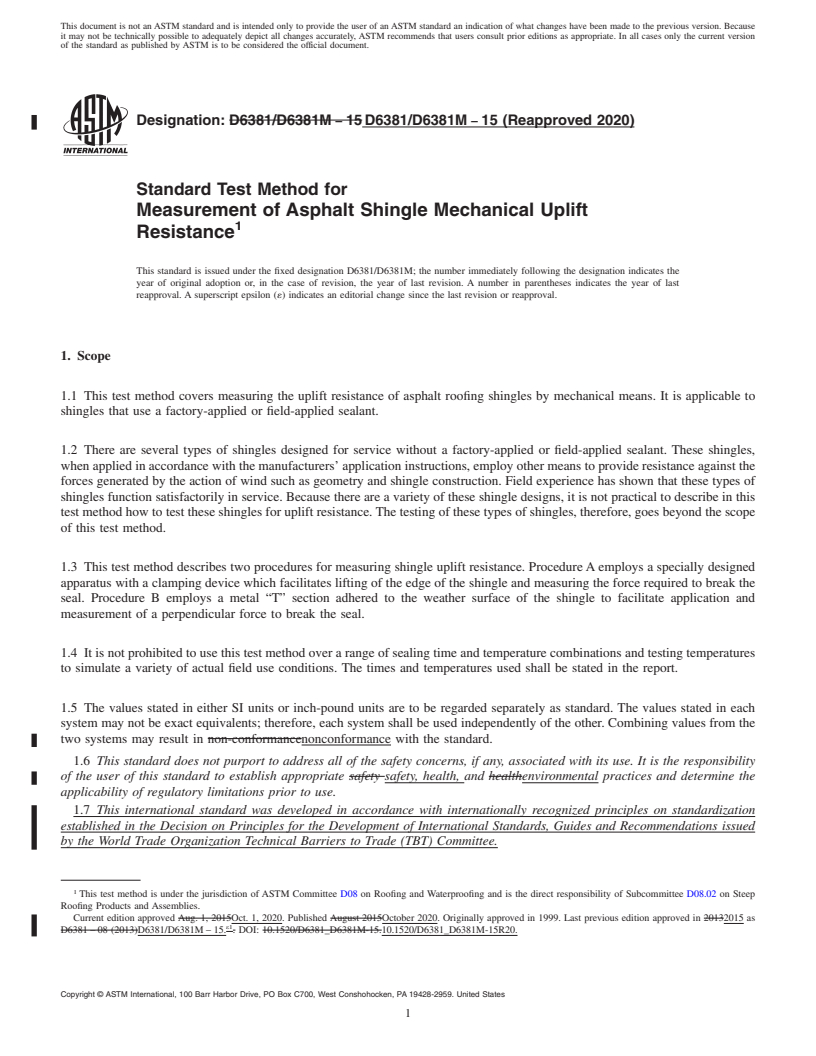

6.3 The test fixture for Procedure A is a specially designed

relationship between this mechanical uplift resistance and the

apparatus and drawings are on file at ASTM International

uplift forces derived from the action of wind.

Headquarters. Fig. 1 is a photo of the apparatus in a typical

5.2 Many factors influence the sealing characteristics of

tensile testing machine with a specimen in place.

shingles in the field; for example, temperature, time, contami-

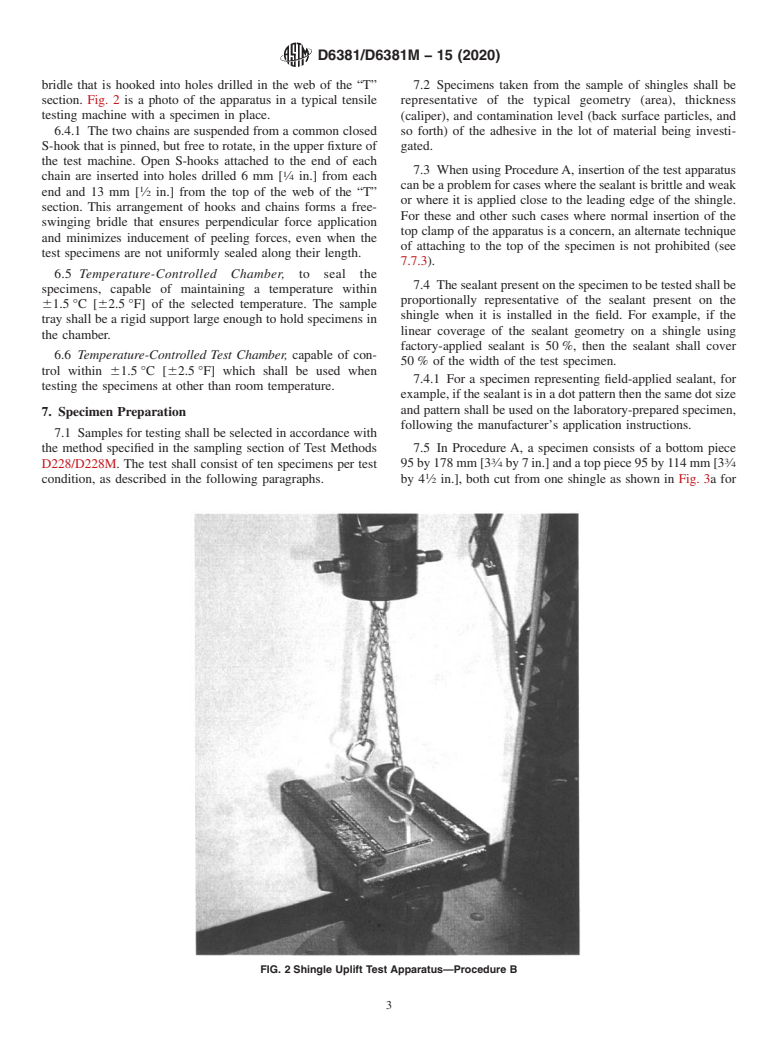

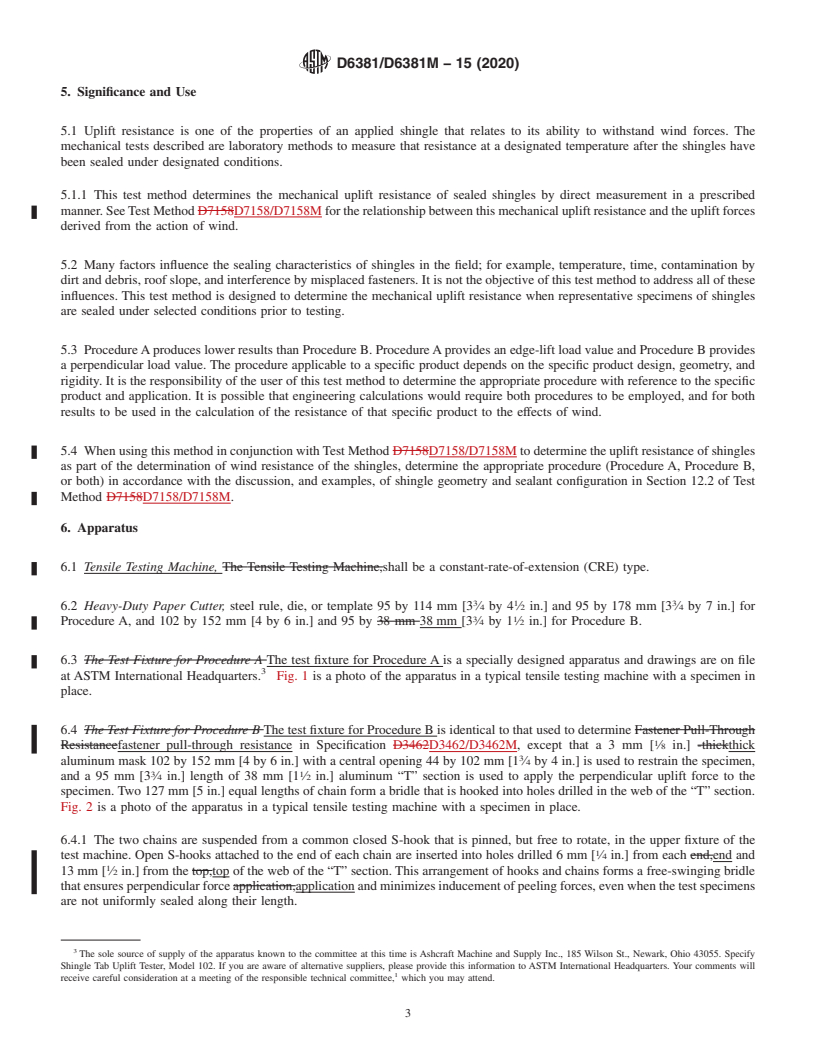

6.4 The test fixture for Procedure B is identical to that used

nation by dirt and debris, roof slope, and interference by

to determine fastener pull-through resistance in Specification

misplaced fasteners. It is not the objective of this test method

D3462/D3462M, except thata3mm[ ⁄8 in.] thick aluminum

to address all of these influences. This test method is designed

mask 102 by 152 mm [4 by 6 in.] with a central opening 44 by

to determine the mechanical uplift resistance when represen-

102 mm [1 ⁄4 by 4 in.] is used to restrain the specimen, and a

tative specimens of shingles are sealed under selected condi-

3 1

95 mm [3 ⁄4 in.] length of 38 mm [1 ⁄2 in.] aluminum “T”

tions prior to testing.

section is used to apply the perpendicular uplift force to the

5.3 Procedure A produces lower results than Procedure B.

specimen. Two 127 mm [5 in.] equal lengths of chain form a

Procedure A provides an edge-lift load value and Procedure B

provides a perpendicular load value. The procedure applicable

to a specific product depends on the specific product design,

The sole source of supply of the apparatus known to the committee at this time

isAshcraft Machine and Supply Inc., 185 Wilson St., Newark, Ohio 43055. Specify

geometry, and rigidity. It is the responsibility of the user of this

Shingle Tab Uplift Tester, Model 102. If you are aware of alternative suppliers,

test method to determine the appropriate procedure with

please provide this information to ASTM International Headquarters. Your com-

reference to the specific product and application. It is possible

ments will receive careful consideration at a meeting of the responsible technical

that engineering calculations would require both procedures to committee, which you may attend.

FIG. 1 Shingle Uplift Test Apparatus—Procedure A

D6381/D6381M − 15 (2020)

bridle that is hooked into holes drilled in the web of the “T” 7.2 Specimens taken from the sample of shingles shall be

section. Fig. 2 is a photo of the apparatus in a typical tensile representative of the typical geometry (area), thickness

testing machine with a specimen in place. (caliper), and contamination level (back surface particles, and

6.4.1 The two chains are suspended from a common closed so forth) of the adhesive in the lot of material being investi-

S-hook that is pinned, but free to rotate, in the upper fixture of

gated.

the test machine. Open S-hooks attached to the end of each

7.3 When using ProcedureA, insertion of the test apparatus

chain are inserted into holes drilled 6 mm [ ⁄4 in.] from each

canbeaproblemforcaseswherethesealantisbrittleandweak

end and 13 mm [ ⁄2 in.] from the top of the web of the “T”

or where it is applied close to the leading edge of the shingle.

section. This arrangement of hooks and chains forms a free-

For these and other such cases where normal insertion of the

swinging bridle that ensures perpendicular force application

top clamp of the apparatus is a concern, an alternate technique

and minimizes inducement of peeling forces, even when the

of attaching to the top of the specimen is not prohibited (see

test specimens are not uniformly sealed along their length.

7.7.3).

6.5 Temperature-Controlled Chamber, to seal the

7.4 The sealant present on the specimen to be tested shall be

specimens, capable of maintaining a temperature within

proportionally representative of the sealant present on the

61.5 °C [62.5 °F] of the selected temperature. The sample

shingle when it is installed in the field. For example, if the

tray shall be a rigid support large enough to hold specimens in

linear coverage of the sealant geometry on a shingle using

the chamber.

factory-applied sealant is 50 %, then the sealant shall cover

6.6 Temperature-Controlled Test Chamber, capable of con-

50 % of the width of the test specimen.

trol within 61.5 °C [62.5 °F] which shall be used when

7.4.1 For a specimen representing field-applied sealant, for

testing the specimens at other than room temperature.

example, if the sealant is in a dot pattern then the same dot size

and pattern shall be used on the laboratory-prepared specimen,

7. Specimen Preparation

following the manufacturer’s application instructions.

7.1 Samples for testing shall be selected in accordance with

the method specified in the sampling section of Test Methods 7.5 In Procedure A, a specimen consists of a bottom piece

3 3

D228/D228M. The test shall consist of ten specimens per test 95by178mm[3 ⁄4by7in.]andatoppiece95by114mm[3 ⁄4

condition, as described in the following paragraphs. by 4 ⁄2 in.], both cut from one shingle as shown in Fig. 3a for

FIG. 2 Shingle Uplift Test Apparatus—Procedure B

D6381/D6381M − 15 (2020)

FIG. 3a Plan View of Shingle-Layer Shingle Showing Typical Specimen Locations

FIG. 3b Plan View of Multi-Layer Shingle Showing Typical Specimen Locations

FIG. 3 Plan View Showing Typical Specimen Locations

single-layer shingles or Fig. 3b for multi-layer shingles. For 7.6 In Procedure B, a specimen consists of a bottom piece

multi-layer shingles that do not have a single-layer area from 102 by 152 mm [4 by 6 in.] and a top piece 38 by 95 mm [1 ⁄2

which to cut the top piece, cut the top piece at the point of the by 3 ⁄4 in.], both cut from one shingle as shown in Fig. 3a for

fewest layers. Longer or shorter specimens are not prohibited single-layer shingles or Fig. 3b for multi-layer shingles. For

provided both clamps secure the specimen when it is aligned in multi-layer shingles that do not have a single-layer top piece,

the test fixture. The length of the specimens shall be deter- cut the top piece at the point of the fewest layers. Dimensional

mined for proper alignment in the fixture. Dimensional toler- tolerances are 63mm[6 ⁄8 in.] on the width and length of the

ances are 63mm[6 ⁄8 in.] on the width of the specimen. specimen.

D6381/D6381M − 15 (2020)

7.7 In ProcedureA, lay the top piece over the bottom piece, instructions. The critical dimension in Procedure A is the

as shown in Figs. 4a and 4b, and in a manner representative of distance the top piece overlaps the sealant on the bottom piece

the actual alignment as specified in the shingle manufacturer’s (denoted A in Figs. 4a and 4b). This dimension shall be equal

application instructions. to the overlap in the specified application.

7.7.1 Not all multi-layer shingles have the sealant in the 7.7.2 Position the specimens on the tray without overlap-

same location on the shingle. Whether the sealant is on the top ping or stacking of the individual specimens.

of the bottom piece, or on the bottom of the top piece, the “A” 7.7.3 For cases when an alternate top attachment method is

dimension in Procedure A is determined by measuring the desired (see 7.3) a special metal connector shall be epoxy-

distance from the leading edge of the sealant to the leading bonded to the top piece of the specimen following sealant

edge of the top piece when the sample pieces are correctly

positioned (in accordance with 7.7). In the case where the

sealant is on the back of the top piece, the bottom piece shall

The sole source of supply of the apparatus known to the committee at this time

isAshcraftMachineandSupply,185WilsonSt.,Newark,Ohio43055,andspecified

be cut so that when the top piece is correctly positioned on the

on the drawings for the apparatus. If

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6381/D6381M − 15 (Reapproved 2020)

Standard Test Method for

Measurement of Asphalt Shingle Mechanical Uplift

Resistance

This standard is issued under the fixed designation D6381/D6381M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers measuring the uplift resistance

responsibility of the user of this standard to establish appro-

of asphalt roofing shingles by mechanical means. It is appli-

priate safety, health, and environmental practices and deter-

cable to shingles that use a factory-applied or field-applied

mine the applicability of regulatory limitations prior to use.

sealant.

1.7 This international standard was developed in accor-

1.2 There are several types of shingles designed for service

dance with internationally recognized principles on standard-

without a factory-applied or field-applied sealant. These

ization established in the Decision on Principles for the

shingles, when applied in accordance with the manufacturers’

Development of International Standards, Guides and Recom-

application instructions, employ other means to provide resis-

mendations issued by the World Trade Organization Technical

tance against the forces generated by the action of wind such as

Barriers to Trade (TBT) Committee.

geometry and shingle construction. Field experience has shown

that these types of shingles function satisfactorily in service. 2. Referenced Documents

Because there are a variety of these shingle designs, it is not

2.1 ASTM Standards:

practical to describe in this test method how to test these

D228/D228M Test Methods for Sampling, Testing, and

shingles for uplift resistance. The testing of these types of

Analysis of Asphalt Roll Roofing, Cap Sheets, and

shingles, therefore, goes beyond the scope of this test method.

Shingles Used in Roofing and Waterproofing

1.3 This test method describes two procedures for measur-

D1079 Terminology Relating to Roofing and Waterproofing

ing shingle uplift resistance. Procedure A employs a specially D3462/D3462M Specification for Asphalt Shingles Made

designed apparatus with a clamping device which facilitates

from Glass Felt and Surfaced with Mineral Granules

lifting of the edge of the shingle and measuring the force

D7158/D7158M Test Method for Wind Resistance of As-

required to break the seal. Procedure B employs a metal “T”

phalt Shingles (Uplift Force/Uplift Resistance Method)

section adhered to the weather surface of the shingle to

3. Terminology

facilitate application and measurement of a perpendicular force

to break the seal.

3.1 Definitions—For definitions of terms used in this test

method, refer to Terminology D1079.

1.4 It is not prohibited to use this test method over a range

of sealing time and temperature combinations and testing

3.2 Definitions of Terms Specific to This Standard:

temperatures to simulate a variety of actual field use condi-

3.2.1 seal—as it relates to steep roofing shingles, is the

tions. The times and temperatures used shall be stated in the

bonding that results from the activation of the sealant under the

report.

action of time and temperature.

1.5 The values stated in either SI units or inch-pound units

3.2.2 sealant—as it relates to steep roofing shingles, is

are to be regarded separately as standard. The values stated in defined as factory-applied or field-applied material designed to

each system may not be exact equivalents; therefore, each

seal the shingles to each other under the action of time and

system shall be used independently of the other. Combining temperature after the shingles are applied to a roof.

values from the two systems may result in nonconformance

3.2.3 sealed—as it relates to steep roofing shingles, is the

with the standard.

condition of the shingles after the sealant has been activated by

the action of time and temperature.

This test method is under the jurisdiction of ASTM Committee D08 on Roofing

and Waterproofing and is the direct responsibility of Subcommittee D08.02 on Steep

Roofing Products and Assemblies. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2020. Published October 2020. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1999. Last previous edition approved in 2015 as D6381/D6381M – 15. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D6381_D6381M-15R20. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6381/D6381M − 15 (2020)

4. Summary of Test Method be employed, and for both results to be used in the calculation

of the resistance of that specific product to the effects of wind.

4.1 The test specimens are constructed from pieces of

shingles, overlaid and sealed prior to testing. All specimens are 5.4 When using this method in conjunction with Test

then conditioned and tested at selected temperatures. Speci- Method D7158/D7158M to determine the uplift resistance of

mens are tested in Procedure A by lifting the exposed edge and shingles as part of the determination of wind resistance of the

recording the uplift force required to break the seal, and in shingles, determine the appropriate procedure (Procedure A,

Procedure B by recording the perpendicular force required to Procedure B, or both) in accordance with the discussion, and

break the seal. examples, of shingle geometry and sealant configuration in

Section 12.2 of Test Method D7158/D7158M.

5. Significance and Use

6. Apparatus

5.1 Uplift resistance is one of the properties of an applied

6.1 Tensile Testing Machine, shall be a constant-rate-of-

shingle that relates to its ability to withstand wind forces. The

mechanical tests described are laboratory methods to measure extension (CRE) type.

that resistance at a designated temperature after the shingles

6.2 Heavy-Duty Paper Cutter, steel rule, die, or template 95

have been sealed under designated conditions.

3 1 3

by 114 mm [3 ⁄4 by 4 ⁄2 in.] and 95 by 178 mm [3 ⁄4 by 7 in.]

5.1.1 This test method determines the mechanical uplift

for Procedure A, and 102 by 152 mm [4 by 6 in.] and 95 by

resistance of sealed shingles by direct measurement in a

3 1

38 mm [3 ⁄4 by 1 ⁄2 in.] for Procedure B.

prescribed manner. See Test Method D7158/D7158M for the

6.3 The test fixture for Procedure A is a specially designed

relationship between this mechanical uplift resistance and the

apparatus and drawings are on file at ASTM International

uplift forces derived from the action of wind.

Headquarters. Fig. 1 is a photo of the apparatus in a typical

5.2 Many factors influence the sealing characteristics of

tensile testing machine with a specimen in place.

shingles in the field; for example, temperature, time, contami-

6.4 The test fixture for Procedure B is identical to that used

nation by dirt and debris, roof slope, and interference by

to determine fastener pull-through resistance in Specification

misplaced fasteners. It is not the objective of this test method

D3462/D3462M, except that a 3 mm [ ⁄8 in.] thick aluminum

to address all of these influences. This test method is designed

mask 102 by 152 mm [4 by 6 in.] with a central opening 44 by

to determine the mechanical uplift resistance when represen-

102 mm [1 ⁄4 by 4 in.] is used to restrain the specimen, and a

tative specimens of shingles are sealed under selected condi-

3 1

95 mm [3 ⁄4 in.] length of 38 mm [1 ⁄2 in.] aluminum “T”

tions prior to testing.

section is used to apply the perpendicular uplift force to the

5.3 Procedure A produces lower results than Procedure B.

specimen. Two 127 mm [5 in.] equal lengths of chain form a

Procedure A provides an edge-lift load value and Procedure B

provides a perpendicular load value. The procedure applicable

to a specific product depends on the specific product design,

The sole source of supply of the apparatus known to the committee at this time

is Ashcraft Machine and Supply Inc., 185 Wilson St., Newark, Ohio 43055. Specify

geometry, and rigidity. It is the responsibility of the user of this

Shingle Tab Uplift Tester, Model 102. If you are aware of alternative suppliers,

test method to determine the appropriate procedure with

please provide this information to ASTM International Headquarters. Your com-

reference to the specific product and application. It is possible

ments will receive careful consideration at a meeting of the responsible technical

that engineering calculations would require both procedures to committee, which you may attend.

FIG. 1 Shingle Uplift Test Apparatus—Procedure A

D6381/D6381M − 15 (2020)

bridle that is hooked into holes drilled in the web of the “T” 7.2 Specimens taken from the sample of shingles shall be

section. Fig. 2 is a photo of the apparatus in a typical tensile representative of the typical geometry (area), thickness

testing machine with a specimen in place. (caliper), and contamination level (back surface particles, and

6.4.1 The two chains are suspended from a common closed

so forth) of the adhesive in the lot of material being investi-

S-hook that is pinned, but free to rotate, in the upper fixture of gated.

the test machine. Open S-hooks attached to the end of each

7.3 When using Procedure A, insertion of the test apparatus

chain are inserted into holes drilled 6 mm [ ⁄4 in.] from each

can be a problem for cases where the sealant is brittle and weak

end and 13 mm [ ⁄2 in.] from the top of the web of the “T”

or where it is applied close to the leading edge of the shingle.

section. This arrangement of hooks and chains forms a free-

For these and other such cases where normal insertion of the

swinging bridle that ensures perpendicular force application

top clamp of the apparatus is a concern, an alternate technique

and minimizes inducement of peeling forces, even when the

of attaching to the top of the specimen is not prohibited (see

test specimens are not uniformly sealed along their length.

7.7.3).

6.5 Temperature-Controlled Chamber, to seal the

7.4 The sealant present on the specimen to be tested shall be

specimens, capable of maintaining a temperature within

proportionally representative of the sealant present on the

61.5 °C [62.5 °F] of the selected temperature. The sample

shingle when it is installed in the field. For example, if the

tray shall be a rigid support large enough to hold specimens in

linear coverage of the sealant geometry on a shingle using

the chamber.

factory-applied sealant is 50 %, then the sealant shall cover

6.6 Temperature-Controlled Test Chamber, capable of con-

50 % of the width of the test specimen.

trol within 61.5 °C [62.5 °F] which shall be used when

7.4.1 For a specimen representing field-applied sealant, for

testing the specimens at other than room temperature.

example, if the sealant is in a dot pattern then the same dot size

and pattern shall be used on the laboratory-prepared specimen,

7. Specimen Preparation

following the manufacturer’s application instructions.

7.1 Samples for testing shall be selected in accordance with

the method specified in the sampling section of Test Methods 7.5 In Procedure A, a specimen consists of a bottom piece

3 3

D228/D228M. The test shall consist of ten specimens per test 95 by 178 mm [3 ⁄4 by 7 in.] and a top piece 95 by 114 mm [3 ⁄4

condition, as described in the following paragraphs. by 4 ⁄2 in.], both cut from one shingle as shown in Fig. 3a for

FIG. 2 Shingle Uplift Test Apparatus—Procedure B

D6381/D6381M − 15 (2020)

FIG. 3a Plan View of Shingle-Layer Shingle Showing Typical Specimen Locations

FIG. 3b Plan View of Multi-Layer Shingle Showing Typical Specimen Locations

FIG. 3 Plan View Showing Typical Specimen Locations

single-layer shingles or Fig. 3b for multi-layer shingles. For 7.6 In Procedure B, a specimen consists of a bottom piece

multi-layer shingles that do not have a single-layer area from 102 by 152 mm [4 by 6 in.] and a top piece 38 by 95 mm [1 ⁄2

which to cut the top piece, cut the top piece at the point of the by 3 ⁄4 in.], both cut from one shingle as shown in Fig. 3a for

fewest layers. Longer or shorter specimens are not prohibited single-layer shingles or Fig. 3b for multi-layer shingles. For

provided both clamps secure the specimen when it is aligned in multi-layer shingles that do not have a single-layer top piece,

the test fixture. The length of the specimens shall be deter- cut the top piece at the point of the fewest layers. Dimensional

mined for proper alignment in the fixture. Dimensional toler- tolerances are 63 mm [6 ⁄8 in.] on the width and length of the

ances are 63 mm [6 ⁄8 in.] on the width of the specimen. specimen.

D6381/D6381M − 15 (2020)

7.7 In Procedure A, lay the top piece over the bottom piece, instructions. The critical dimension in Procedure A is the

as shown in Figs. 4a and 4b, and in a manner representative of distance the top piece overlaps the sealant on the bottom piece

the actual alignment as specified in the shingle manufacturer’s (denoted A in Figs. 4a and 4b). This dimension shall be equal

application instructions. to the overlap in the specified application.

7.7.1 Not all multi-layer shingles have the sealant in the 7.7.2 Position the specimens on the tray without overlap-

same location on the shingle. Whether the sealant is on the top ping or stacking of the individual specimens.

of the bottom piece, or on the bottom of the top piece, the “A” 7.7.3 For cases when an alternate top attachment method is

dimension in Procedure A is determined by measuring the desired (see 7.3) a special metal connector shall be epoxy-

distance from the leading edge of the sealant to the leading bonded to the top piece of the specimen following sealant

edge of the top piece when the sample pieces are correctly

positioned (in accordance with 7.7). In the case where the

sealant is on the back of the top piece, the bottom piece shall

The sole source of supply of the apparatus known to the committee at this time

is Ashcraft Machine and Supply, 185 Wilson St., Newark, Ohio 43055, and specified

be cut so that when the top piece is correctly positioned on the

on the drawings for the apparatus. If you are aware of alter

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6381/D6381M − 15 D6381/D6381M − 15 (Reapproved 2020)

Standard Test Method for

Measurement of Asphalt Shingle Mechanical Uplift

Resistance

This standard is issued under the fixed designation D6381/D6381M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers measuring the uplift resistance of asphalt roofing shingles by mechanical means. It is applicable to

shingles that use a factory-applied or field-applied sealant.

1.2 There are several types of shingles designed for service without a factory-applied or field-applied sealant. These shingles,

when applied in accordance with the manufacturers’ application instructions, employ other means to provide resistance against the

forces generated by the action of wind such as geometry and shingle construction. Field experience has shown that these types of

shingles function satisfactorily in service. Because there are a variety of these shingle designs, it is not practical to describe in this

test method how to test these shingles for uplift resistance. The testing of these types of shingles, therefore, goes beyond the scope

of this test method.

1.3 This test method describes two procedures for measuring shingle uplift resistance. Procedure A employs a specially designed

apparatus with a clamping device which facilitates lifting of the edge of the shingle and measuring the force required to break the

seal. Procedure B employs a metal “T” section adhered to the weather surface of the shingle to facilitate application and

measurement of a perpendicular force to break the seal.

1.4 It is not prohibited to use this test method over a range of sealing time and temperature combinations and testing temperatures

to simulate a variety of actual field use conditions. The times and temperatures used shall be stated in the report.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformancenonconformance with the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

This test method is under the jurisdiction of ASTM Committee D08 on Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.02 on Steep

Roofing Products and Assemblies.

Current edition approved Aug. 1, 2015Oct. 1, 2020. Published August 2015October 2020. Originally approved in 1999. Last previous edition approved in 20132015 as

ε1

D6381 – 08 (2013)D6381/D6381M – 15. . DOI: 10.1520/D6381_D6381M-15.10.1520/D6381_D6381M-15R20.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6381/D6381M − 15 (2020)

2. Referenced Documents

2.1 ASTM Standards:

D228D228/D228M Test Methods for Sampling, Testing, and Analysis of Asphalt Roll Roofing, Cap Sheets, and Shingles Used

in Roofing and Waterproofing

D1079 Terminology Relating to Roofing and Waterproofing

D3462D3462/D3462M Specification for Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules

D7158D7158/D7158M Test Method for Wind Resistance of Asphalt Shingles (Uplift Force/Uplift Resistance Method)

3. Terminology

3.1 Definitions—For definitiondefinitions of terms used in this test method, refer to Terminology D1079.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 seal—as it relates to steep roofing shingles, is the bonding that results from the activation of the sealant under the action of

time and temperature.

3.2.2 sealant—as it relates to steep roofing shingles, is defined as factory-applied or field-applied material designed to seal the

shingles to each other under the action of time and temperature after the shingles are applied to a roof.

3.2.3 sealed—as it relates to steep roofing shingles, is the condition of the shingles after the sealant has been activated by the

action of time and temperature.

4. Summary of Test Method

4.1 The test specimens are constructed from pieces of shingles, overlaid and sealed prior to testing. All specimens are then

conditioned and tested at selected temperatures. Specimens are tested in Procedure A by lifting the exposed edge and recording

the uplift force required to break the seal, and in Procedure B,B by recording the perpendicular force required to break the seal.

FIG. 1 Shingle Uplift Test Apparatus—Procedure A

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

D6381/D6381M − 15 (2020)

5. Significance and Use

5.1 Uplift resistance is one of the properties of an applied shingle that relates to its ability to withstand wind forces. The

mechanical tests described are laboratory methods to measure that resistance at a designated temperature after the shingles have

been sealed under designated conditions.

5.1.1 This test method determines the mechanical uplift resistance of sealed shingles by direct measurement in a prescribed

manner. See Test Method D7158D7158/D7158M for the relationship between this mechanical uplift resistance and the uplift forces

derived from the action of wind.

5.2 Many factors influence the sealing characteristics of shingles in the field; for example, temperature, time, contamination by

dirt and debris, roof slope, and interference by misplaced fasteners. It is not the objective of this test method to address all of these

influences. This test method is designed to determine the mechanical uplift resistance when representative specimens of shingles

are sealed under selected conditions prior to testing.

5.3 Procedure A produces lower results than Procedure B. Procedure A provides an edge-lift load value and Procedure B provides

a perpendicular load value. The procedure applicable to a specific product depends on the specific product design, geometry, and

rigidity. It is the responsibility of the user of this test method to determine the appropriate procedure with reference to the specific

product and application. It is possible that engineering calculations would require both procedures to be employed, and for both

results to be used in the calculation of the resistance of that specific product to the effects of wind.

5.4 When using this method in conjunction with Test Method D7158D7158/D7158M to determine the uplift resistance of shingles

as part of the determination of wind resistance of the shingles, determine the appropriate procedure (Procedure A, Procedure B,

or both) in accordance with the discussion, and examples, of shingle geometry and sealant configuration in Section 12.2 of Test

Method D7158D7158/D7158M.

6. Apparatus

6.1 Tensile Testing Machine, The Tensile Testing Machine,shall be a constant-rate-of-extension (CRE) type.

3 1 3

6.2 Heavy-Duty Paper Cutter, steel rule, die, or template 95 by 114 mm [3 ⁄4 by 4 ⁄2 in.] and 95 by 178 mm [3 ⁄4 by 7 in.] for

3 1

Procedure A, and 102 by 152 mm [4 by 6 in.] and 95 by 38 mm 38 mm [3 ⁄4 by 1 ⁄2 in.] for Procedure B.

6.3 The Test Fixture for Procedure A The test fixture for Procedure A is a specially designed apparatus and drawings are on file

at ASTM International Headquarters. Fig. 1 is a photo of the apparatus in a typical tensile testing machine with a specimen in

place.

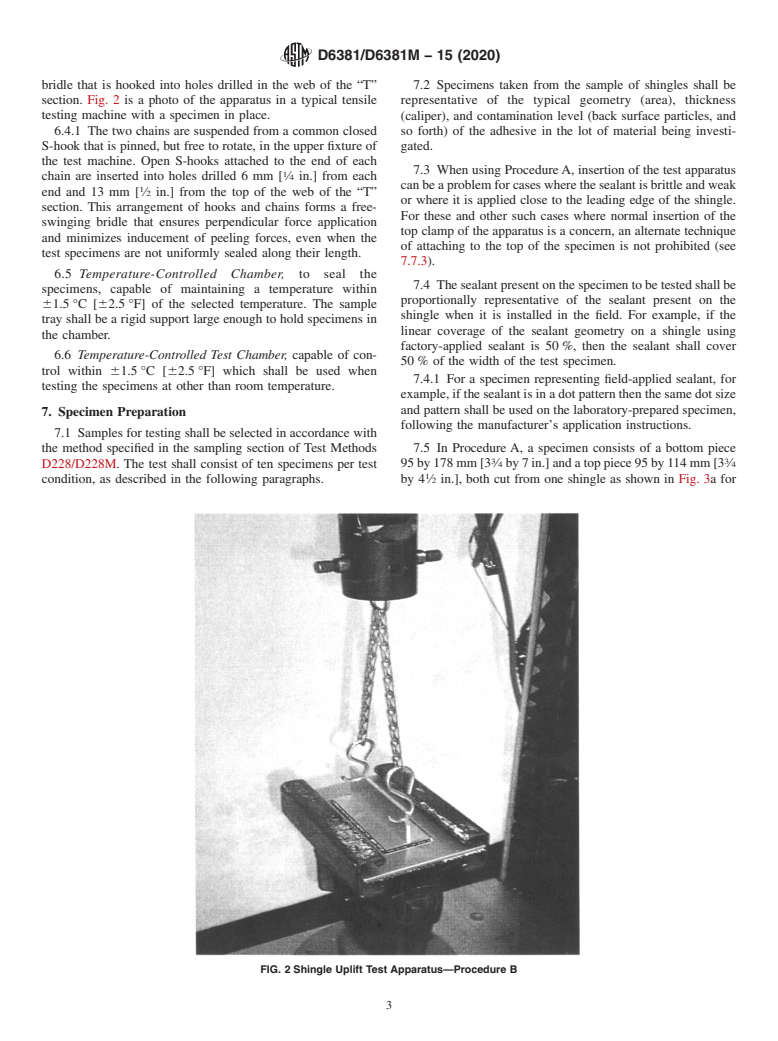

6.4 The Test Fixture for Procedure B The test fixture for Procedure B is identical to that used to determine Fastener Pull-Through

Resistancefastener pull-through resistance in Specification D3462D3462/D3462M, except that a 3 mm [ ⁄8 in.] -thickthick

aluminum mask 102 by 152 mm [4 by 6 in.] with a central opening 44 by 102 mm [1 ⁄4 by 4 in.] is used to restrain the specimen,

3 1

and a 95 mm [3 ⁄4 in.] length of 38 mm [1 ⁄2 in.] aluminum “T” section is used to apply the perpendicular uplift force to the

specimen. Two 127 mm [5 in.] equal lengths of chain form a bridle that is hooked into holes drilled in the web of the “T” section.

Fig. 2 is a photo of the apparatus in a typical tensile testing machine with a specimen in place.

6.4.1 The two chains are suspended from a common closed S-hook that is pinned, but free to rotate, in the upper fixture of the

test machine. Open S-hooks attached to the end of each chain are inserted into holes drilled 6 mm [ ⁄4 in.] from each end,end and

13 mm [ ⁄2 in.] from the top,top of the web of the “T” section. This arrangement of hooks and chains forms a free-swinging bridle

that ensures perpendicular force application,application and minimizes inducement of peeling forces, even when the test specimens

are not uniformly sealed along their length.

The sole source of supply of the apparatus known to the committee at this time is Ashcraft Machine and Supply Inc., 185 Wilson St., Newark, Ohio 43055. Specify

Shingle Tab Uplift Tester, Model 102. If you are aware of alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will

receive careful consideration at a meeting of the responsible technical committee, which you may attend.

D6381/D6381M − 15 (2020)

FIG. 2 Shingle Uplift Test Apparatus—Procedure B

6.5 Temperature-Controlled Chamber, to seal the specimens, capable of maintaining a temperature within 61.5°C

[62.5°F]61.5 °C [62.5 °F] of the selected temperature. The sample tray shall be a rigid support large enough to hold specimens

in the chamber.

6.6 Temperature-Controlled Test Chamber, capable of control within 61.5°C [62.5°F]61.5 °C [62.5 °F] which shall be used

when testing the specimens at other than room temperature.

7. Specimen Preparation

7.1 Samples for testing shall be selected in accordance with the method specified in the sampling section of Test Methods

D228D228/D228M. The test shall consist of ten specimens per test condition, as described in the following paragraphs.

7.2 Specimens taken from the sample of shingles shall be representative of the typical geometry (area), thickness (caliper), and

contamination level (back surface particles, and so forth) of the adhesive in the lot of material being investigated.

7.3 When using Procedure A, insertion of the test apparatus can be a problem for cases where the sealant is brittle and weak or

where it is applied close to the leading edge of the shingle. For these,these and other such cases where normal insertion of the top

clamp of the apparatus is a concern, an alternate technique of attaching to the top of the specimen is not prohibited (see 7.7.3).

7.4 The sealant present on the specimen to be tested shall be proportionally representative of the sealant present on the shingle

when it is installed in the field. For example, if the linear coverage of the sealant geometry on a shingle using factory-applied

sealant is 50 %, then the sealant shall cover 50 % of the width of the test specimen.

D6381/D6381M − 15 (2020)

7.4.1 For a specimen representing field-applied sealant, for example, if the sealant is in a dot pattern then the same dot size and

pattern shall be used on the laboratory-prepared specimen, following the manufacturer’s application instructions.

3 3

7.5 In Procedure A, a specimen consists of a bottom piece 95 by 178 mm [3 ⁄4 by 7 in.];in.] and a top piece 95 by 114 mm [3 ⁄4

by 4 ⁄2 in.];in.], both cut from one shingle as shown in Fig. 3a for single-layer shingles or Fig. 3b for multi-layer shingles. For

multi-layer shingles that do not have a single-layer area from which to cut the top piece, cut the top piece at the point of the fewest

FIG. 3a Plan View of Shingle-Layer Shingle Showing Typical Specimen Locations

FIG. 3b Plan View of Multi-Layer Shingle Showing Typical Specimen Locations

FIG. 3 Plan View Showing Typical Specimen Locations

D6381/D6381M − 15 (2020)

layers. Longer or shorter specimens are not prohibited provided both clamps secure the specimen when it is aligned in the test

fixture. The length of the specimens shall be determined for proper alignment in the fixture. Dimensional tolerances are 63 mm

[6 ⁄8 in.] on the width of the specimen.

1 3

7.6 In Procedure B, a specimen consists of a bottom piece 102 by 152 mm [4 by 6 in.] and a top piece 38 by 95 mm [1 ⁄2 by 3 ⁄4

in.]in.], both cut from one shingle as shown in Fig. 3a for single-layer shingles,shingles or Fig. 3b for multi-layer shingles. For

multi-layer shingles that do not have a single-layer top piece, cut the top piece at the point of the fewest layers. Dimensional

tolerances are 63 mm [6 ⁄8 in.] on the width and length of the specimen.

7.7 In Procedure A, lay the top piece over the bottom piece, as shown in Figs. 4a and 4b, and in a manner representative of the

actual alignment as specified in the shingle manufacturer’s application instructions.

7.7.1 Not all multi-layer shingles have the sealant in the same location on the shingle. Whether the sealant is on the top of the

bottom piece, or on the bottom of the top piece, the “A” dimension in Procedure A is determined by measuring the distance from

the leading edge of the sealant to the leading edge of the top piece when the sample pieces are correctly positioned (in accordance

FIG. 4a Top and Side View of Test Specimen—Procedure A

FIG. 4b Side View of Multi-Layer Test Specimen—Procedure A

FIG. 4 Top and Side Views of Test Specimen—Procedure A

D638

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.