ASTM D228/D228M-09(2014)

(Test Method)Standard Test Methods for Sampling, Testing, and Analysis of Asphalt Roll Roofing, Cap Sheets, and Shingles Used in Roofing and Waterproofing

Standard Test Methods for Sampling, Testing, and Analysis of Asphalt Roll Roofing, Cap Sheets, and Shingles Used in Roofing and Waterproofing

SIGNIFICANCE AND USE

4.1 These test methods include procedures for sampling, examination, physical testing, and analyses of asphalt roll roofing, cap sheets, and shingles used in roofing and waterproofing. Other components of these materials are allowed to include, but are not limited to, felts, mats, films, foils, mineral stabilizers, papers, and mineral surfacing.

4.2 These test methods include tests that are not required by every product standard that references Test Methods D228/D228M. The individual product standards are the authority for which tests are required for compliance. It is not prohibited to run tests in addition to those required in the product standards, but these test methods make no claim to their suitability or significance.

4.3 Five random samples are required from lots equal to or less than 1000 packages. The number of samples required for lots greater than 1000 packages is dependent on the variation in the unit mass within the lot and is determined by the two-step sampling plan in 7.4.

4.4 The results of a visual examination, physical testing, and compositional analysis are required for each sample. The analytical data are further used to compute the probable minimum and the probable range for the average mass of each of the components.

SCOPE

1.1 These test methods cover procedures for sampling, examination, physical testing, and analyses of asphalt-containing materials used in roofing and waterproofing. These materials include but are not limited to roll roofing, cap sheets, and shingles. Any of these materials are allowed to be partially or fully coated, surfaced, or laminated, or a combination thereof.

1.2 The test methods and procedures in this standard appear in the following order:

Section

Content

6

Types of Roofing

7

Sampling

8

Mass and Area Determination

9

Selection of Representative Specimens

10

Moisture

11

Pliability

12

Mass Loss and Behavior on Heating

13

Tear Strength

14

Fastener Pull-Through Resistance

15

Preparation and Selection of Small Test Specimens

for Analyses

16

Analysis of Glass Felt Products

17

Analysis of Roofing Products with Organic Felts

18

Ash of Desaturated Felt

19

Calculation

20

Adjusting Back Coating Fine Mineral Matter and

Back Surfacing

21

Report

22

Precision and Bias

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D228/D228M −09(Reapproved 2014)

Standard Test Methods for

Sampling, Testing, and Analysis of Asphalt Roll Roofing,

Cap Sheets, and Shingles Used in Roofing and

Waterproofing

This standard is issued under the fixed designation D228/D228M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 These test methods cover procedures for sampling,

bility of regulatory limitations prior to use.

examination, physical testing, and analyses of asphalt-

containing materials used in roofing and waterproofing. These

2. Referenced Documents

materials include but are not limited to roll roofing, cap sheets,

and shingles.Any of these materials are allowed to be partially 2.1 ASTM Standards:

or fully coated, surfaced, or laminated, or a combination D95Test Method for Water in Petroleum Products and

thereof. Bituminous Materials by Distillation

D146Test Methods for Sampling and Testing Bitumen-

1.2 The test methods and procedures in this standard appear

Saturated Felts and Woven Fabrics for Roofing and

in the following order:

Waterproofing

Section Content

D225Specification forAsphalt Shingles (Organic Felt) Sur-

6 Types of Roofing faced With Mineral Granules (Withdrawn 2012)

7 Sampling

D1079Terminology Relating to Roofing and Waterproofing

8 Mass and Area Determination

D1922Test Method for Propagation Tear Resistance of

9 Selection of Representative Specimens

10 Moisture Plastic Film and Thin Sheeting by Pendulum Method

11 Pliability

D2178Specification forAsphalt Glass Felt Used in Roofing

12 Mass Loss and Behavior on Heating

and Waterproofing

13 Tear Strength

14 Fastener Pull-Through Resistance D2626Specification for Asphalt-Saturated and Coated Or-

15 Preparation and Selection of Small Test Specimens

ganic Felt Base Sheet Used in Roofing

for Analyses

D3462Specification for Asphalt Shingles Made from Glass

16 Analysis of Glass Felt Products

17 Analysis of Roofing Products with Organic Felts

Felt and Surfaced with Mineral Granules

18 Ash of Desaturated Felt

D3909Specification for Asphalt Roll Roofing (Glass Felt)

19 Calculation

Surfaced With Mineral Granules

20 Adjusting Back Coating Fine Mineral Matter and

Back Surfacing D4601Specification for Asphalt-Coated Glass Fiber Base

21 Report

Sheet Used in Roofing

22 Precision and Bias

D4897SpecificationforAsphalt-CoatedGlass-FiberVenting

1.3 The values stated in either SI units or inch-pound units

Base Sheet Used in Roofing

are to be regarded separately as standard. The values stated in

D4932Test Method for Fastener Rupture and Tear Resis-

each system may not be exact equivalents; therefore, each

tance of Roofing andWaterproofing Sheets, Roll Roofing,

system shall be used independently of the other. Combining

and Shingles

values from the two systems may result in non-conformance

D6380SpecificationforAsphaltRollRoofing(OrganicFelt)

with the standard.

F1667SpecificationforDrivenFasteners:Nails,Spikes,and

1.4 This standard does not purport to address all of the

Staples

safety concerns, if any, associated with its use. It is the

1 2

These test methods are under the jurisdiction of ASTM Committee D08 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Roofing and Waterproofing and are the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

D08.02 on Steep Roofing Products and Assemblies. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved May 1, 2014. Published May 2014. Originally the ASTM website.

ε2 3

approved in 1925. Last previous edition approved in 2009 as D228/D228M–09 . The last approved version of this historical standard is referenced on

DOI: 10.1520/D0228_D0228M-09R14. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D228/D228M − 09 (2014)

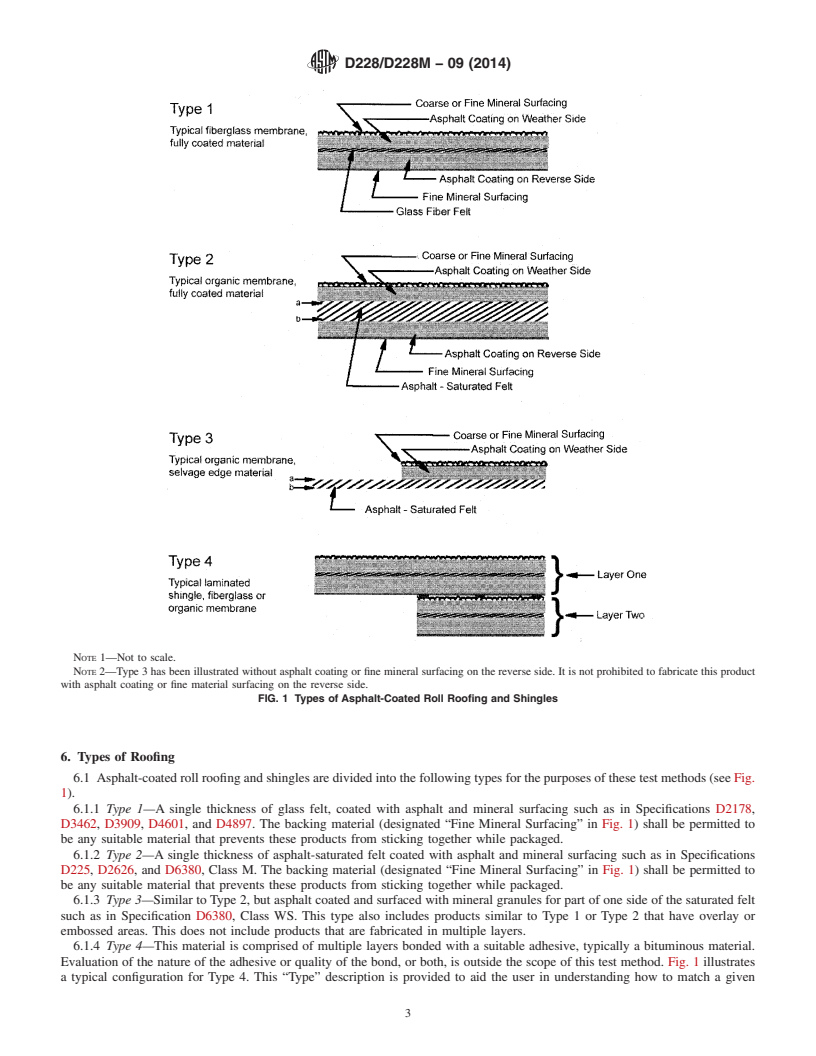

3. Terminology embossed shingles (where not all of the product has the same

thickness). See Fig. 1, Type 3.

3.1 Definitions:

3.1.4 As referenced in 15.4, “Materials of Multiple Layer

3.1.1 Fordefinitionsoftermsusedinthesetestmethods,see

Composition” designates products that are fabricated in mul-

Terminology D1079.

tiple layers. See Fig. 1, Type 4.

3.1.2 As referenced in 15.1, “Materials of Uniform Compo-

3.1.5 As referenced in these test methods, “Machine Direc-

sition” designates products that are manufactured to be the

tion” (indicated as MD) is the direction running the long

same thickness, ply count, and mass per unit area in all areas

dimension of a roll product (before samples or specimens are

ofthematerial.Thiswouldincludetraditionalmineralsurfaced

cut) or the long dimension of a shingle, unless otherwise

rolls, “3 Tab” shingles, and other shingles that have areas of

known and agreed to between supplier and purchaser. “Cross

material removed for appearance purposes (cut-outs) but the

Direction” (indicated as CD) designates the direction perpen-

rest of the shingle is of uniform composition. See Fig. 1, Type

dicular to the MD.

1 or Type 2.

3.1.3 As referenced in 15.2, “Materials of Nonuniform 3.1.6 A production lot is defined as all material produced

Composition” designates products that are intentionally manu- within one production shift of the same type, composition, and

facturedtohavedifferentthicknessormassperunitareawithin color (where applicable). A delivery lot is defined as a

different areas of the product. Examples of materials of

shipmentorfractionthereofrepresentingaproductofthesame

nonuniform composition are selvage edge rolls and overlaid or type, composition, and color (where applicable).

NOTE 1—Not to scale.

NOTE 2—Type 3 has been illustrated without asphalt coating or fine mineral surfacing on the reverse side. It is not prohibited to fabricate this product

with asphalt coating or fine material surfacing on the reverse side.

FIG. 1 Types of Asphalt-Coated Roll Roofing and Shingles

D228/D228M − 09 (2014)

4. Significance and Use 6.1.4 Type 4—This material is comprised of multiple layers

bonded with a suitable adhesive, typically a bituminous mate-

4.1 These test methods include procedures for sampling,

rial. Evaluation of the nature of the adhesive or quality of the

examination, physical testing, and analyses of asphalt roll

bond, or both, is outside the scope of this test method. Fig. 1

roofing, cap sheets, and shingles used in roofing and water-

illustrates a typical configuration for Type 4. This “Type”

proofing. Other components of these materials are allowed to

description is provided to aid the user in understanding how to

include, but are not limited to, felts, mats, films, foils, mineral

match a given product composition and assembly to its

stabilizers, papers, and mineral surfacing.

corresponding Type. It is not intended to limit or exclude

4.2 Thesetestmethodsincludeteststhatarenotrequiredby

products with similar, but not identical constructions. Ex-

every product standard that references Test Methods D228/

amples of known variations, which shall not be prohibited

D228M. The individual product standards are the authority for

include (but are not limited to):

which tests are required for compliance. It is not prohibited to

6.1.4.1 Materials using other adhesives,

run tests in addition to those required in the product standards,

6.1.4.2 Materials fabricated with more than two layers,

but these test methods make no claim to their suitability or

6.1.4.3 Materials that use different relative proportions for

significance.

the layers, and

4.3 Five random samples are required from lots equal to or

6.1.4.4 Materials with other core compositions

less than 1000 packages. The number of samples required for

lotsgreaterthan1000packagesisdependentonthevariationin

7. Sampling

the unit mass within the lot and is determined by the two-step

7.1 The rolls or packages selected in accordance with this

sampling plan in 7.4.

section constitute the representative sample used in Sections 8

4.4 Theresultsofavisualexamination,physicaltesting,and

and 9.

compositional analysis are required for each sample. The

7.2 Select five rolls or packages from the lot at random. Do

analytical data are further used to compute the probable

notselectanymaterialthatshowsvisualindicationsofdamage

minimum and the probable range for the average mass of each

from shipping or handling. Determine the average net mass in

of the components.

2 2

g/m [lb⁄100ft ]andthestandarddeviationinaccordancewith

8.1 – 8.8.

5. Materials

7.3 If the lot is 1000 or fewer rolls or packages, proceed to

5.1 Filter Paper—The extractions for analysis of glass felt

Section 8. If the lot is 1001 or greater in number, follow the

products (Section 16) and analysis of roofing products with

second part of the sampling plan in 7.4.

organic felt (Section 17) require the use of filter paper with a

particle retention of 2.7 µm (see Note 1), This filter paper is

7.4 Calculate the required number of samples based on the

dried for 60 min 6 10% in an 80°C [176°F] oven and stored

standard deviation (s) of the preliminary sampling by:

until needed in a desiccator.

2 2

t s

n 5 (1)

NOTE 1—Whitman No. 50 filter paper [185 mm] has been found

d

satisfactory for this use.

where:

6. Types of Roofing

n = total number of samples required (n−5 more rolls or

packages must be selected at random as samples),

6.1 Asphalt-coatedrollroofingandshinglesaredividedinto

t = test statistic for number of samples in the preliminary

the following types for the purposes of these test methods (see

test series for 4° and a 95% confidence that the

Fig. 1).

calculated average mass will not exceed d (t=2.776),

6.1.1 Type 1—A single thickness of glass felt, coated with

and

asphalt and mineral surfacing such as in Specifications D2178,

2 2

d = 100 g/m [2 lb/100 ft ] (the mean mass obtained from

D3462, D3909, D4601, and D4897. The backing material

the analysis should be within 6100 g/m of the true

(designated “Fine Mineral Surfacing” in Fig. 1) shall be

value, with 95% confidence).

permitted to be any suitable material that prevents these

products from sticking together while packaged.

7.5 See Fig. 2.

6.1.2 Type 2—A single thickness of asphalt-saturated felt

coated with asphalt and mineral surfacing such as in Specifi-

8. As Received Mass and Area Determinations, All Types

cations D225, D2626, and D6380, Class M. The backing

of Roofing

material (designated “Fine Mineral Surfacing” in Fig. 1) shall

8.1 Gross Mass—Determine and record the mass of each

be permitted to be any suitable material that prevents these

representative sample to the nearest 0.1 kg [0.2 lb].

products from sticking together while packaged.

6.1.3 Type 3—Similar to Type 2, but asphalt coated and 8.2 Net Mass—Disassemble each package or unroll each

surfaced with mineral granules for part of one side of the roll of the representative sample; shake off any loose surfacing

saturated felt such as in Specification D6380, Class WS. This anddetermineandrecordthenetmassofalltheshinglesorthe

type also includes products similar to Type 1 or Type 2 that entire roll to the nearest 0.1 kg [0.2 lb]. Where a product

have overlay or embossed areas. This does not include prod- standard requires it, the loose surfacing is to be collected and

ucts that are fabricated in multiple layers. the mass determined.

D228/D228M − 09 (2014)

In Section 7, initial “Representative Samples” are selected (typically five per lot). These are full bundles or rolls. These are the samples used in Section 8.

In Section 9, one large “Specimen” is taken from each representative sample (full shingles from 8.5 or a portion of each roll selected in Section 7). These are confirmed

to be within 1.5 % of the mass per area (from 8.6) for the corresponding representative sample.

In Section 10 (where product standards require measurement of water content perTest Method D95), 50-g small test specimens are taken from each “Large Specimen”

for determination of water.

In Section 11, five MD and five CD small test specimens are cut from one of the “Large Specimens” for evaluation of pliability.

12, two small test specimens are cut from one of the “Large Specimens” for evaluation of behavior on heating.

In Section

In Section 15, small test specimens (three for glass felt, four for organic felt) are cut from each of the “Large Specimens” for analysis by Section 16 (for glass felt) or

by Section 17 (for organic felt).

FIG. 2 Sample Selection Summary and Flow Diagram

(See Individual Sections for Sample Selection Details)

8.3 Packaging and Fixture Mass—Determineandrecordthe

(∑X) = the square of the sum of the individual mass

mass to the nearest 0.1 kg [0.2 lb] of the packaging and all

determinations, and

associated fixtures shipped with each roll or package of the

n = the number of rolls or packages in the representa-

representative sample, such as nails and adhesive.

tive sample.

8.4 Dimensions of Roll Products—Measure and record the

8.9 Calculate the 95% confidence interval for the average

length and width of each roll of roofing and the selvage width

mass by:

to the nearest 3 mm [ ⁄8 in.].

X ts

(

8.5 Shingle Count and Dimensions—From each of the

6 (3)

n

=

n

representative sample packages generated in Section 7, count

and record the number of shingles in each package. Select one

where:

shingle randomly from each package. Measure the width,

∑X = sum of the individual mass determinations, and

length, and cutout dimensions for each of these selected

t = appropriate tstatisticfor95%confidenceand n−1dF

shingles to the nearest 1 mm [ ⁄32 in.]. Calculate and record the

(t=2.776 for n=5; consult standard reference table

average for each of these measurements.

for other values of n).

8.6 Calculate the area of the roofing and the net mass per

unit area of the roofing. Report the net mass per unit area in

9. Selection of Representative Specimens, All Roofing

2 2

g/m [lb⁄100 ft ] for each representative sample (without

Types

packaging, cut outs or loose surfacing).

9.1 Several product standards reference sampling as desig-

8.7 Calculate and record the average net mass per unit area

nated in Test Methods D228/D228M for tests that are not

for the combined representative samples (without packaging,

2 2 specifically covered by Test Methods D228/D228M. Unless

cut outs, or loose surfacing) in g/m [lb/100 ft ].

otherwise specified in these test methods, the large spe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´2

Designation: D228/D228M − 09 D228/D228M − 09 (Reapproved 2014)

Standard Test Methods for

Sampling, Testing, and Analysis of Asphalt Roll Roofing,

Cap Sheets, and Shingles Used in Roofing and

Waterproofing

This standard is issued under the fixed designation D228/D228M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Former Figs. 5–8 were editorially corrected to become Tables 1–4 in September 2011.

ε NOTE—Editorial changes were made to Sections 7 and 8 in September 2012.

1. Scope

1.1 These test methods cover procedures for sampling, examination, physical testing, and analyses of asphalt-containing

materials used in roofing and waterproofing. These materials include but are not limited to roll roofing, cap sheets, and shingles.

Any of these materials are allowed to be partially or fully coated, surfaced, or laminated, or a combination thereof.

1.2 The test methods and procedures in this standard appear in the following order:

Section Content

6 Types of Roofing

7 Sampling

8 Mass and Area Determination

9 Selection of Representative Specimens

10 Moisture

11 Pliability

12 Mass Loss and Behavior on Heating

13 Tear Strength

14 Fastener Pull-Through Resistance

15 Preparation and Selection of Small Test Specimens

for Analyses

16 Analysis of Glass Felt Products

17 Analysis of Roofing Products with Organic Felts

18 Ash of Desaturated Felt

19 Calculation

20 Adjusting Back Coating Fine Mineral Matter and

Back Surfacing

21 Report

22 Precision and Bias

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D95 Test Method for Water in Petroleum Products and Bituminous Materials by Distillation

D146 Test Methods for Sampling and Testing Bitumen-Saturated Felts and Woven Fabrics for Roofing and Waterproofing

These test methods are under the jurisdiction of ASTM Committee D08 on Roofing and Waterproofing and are the direct responsibility of Subcommittee D08.02 on Steep

Roofing Products and Assemblies.

Current edition approved Dec. 1, 2009May 1, 2014. Published January 2010May 2014. Originally approved in 1925. Last previous edition approved in 20082009 as

ε2

D228 – 08.D228/D228M – 09 . DOI: 10.1520/D0228_D0228M-09E01.10.1520/D0228_D0228M-09R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D228/D228M − 09 (2014)

D225 Specification for Asphalt Shingles (Organic Felt) Surfaced With Mineral Granules (Withdrawn 2012)

D1079 Terminology Relating to Roofing and Waterproofing

D1922 Test Method for Propagation Tear Resistance of Plastic Film and Thin Sheeting by Pendulum Method

D2178 Specification for Asphalt Glass Felt Used in Roofing and Waterproofing

D2626 Specification for Asphalt-Saturated and Coated Organic Felt Base Sheet Used in Roofing

D3462 Specification for Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules

D3909 Specification for Asphalt Roll Roofing (Glass Felt) Surfaced With Mineral Granules

D4601 Specification for Asphalt-Coated Glass Fiber Base Sheet Used in Roofing

D4897 Specification for Asphalt-Coated Glass-Fiber Venting Base Sheet Used in Roofing

D4932 Test Method for Fastener Rupture and Tear Resistance of Roofing and Waterproofing Sheets, Roll Roofing, and Shingles

D6380 Specification for Asphalt Roll Roofing (Organic Felt)

F1667 Specification for Driven Fasteners: Nails, Spikes, and Staples

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in these test methods, see Terminology D1079.

3.1.2 As referenced in 15.1, “Materials of Uniform Composition” designates products that are manufactured to be the same

thickness, ply count, and mass per unit area in all areas of the material. This would include traditional mineral surfaced rolls, “3

Tab” shingles, and other shingles that have areas of material removed for appearance purposes (cut-outs) but the rest of the shingle

is of uniform composition. See Fig. 1, Type 1 or Type 2.

3.1.3 As referenced in 15.2, “Materials of Nonuniform Composition” designates products that are intentionally manufactured

to have different thickness or mass per unit area within different areas of the product. Examples of materials of nonuniform

composition are selvage edge rolls and overlaid or embossed shingles (where not all of the product has the same thickness). See

Fig. 1, Type 3.

3.1.4 As referenced in 15.4, “Materials of Multiple Layer Composition” designates products that are fabricated in multiple

layers. See Fig. 1, Type 4.

3.1.5 As referenced in these test methods, “Machine Direction” (indicated as MD) is the direction running the long dimension

of a roll product (before samples or specimens are cut) or the long dimension of a shingle, unless otherwise known and agreed

to between supplier and purchaser. “Cross Direction” (indicated as CD) designates the direction perpendicular to the MD.

3.1.6 A production lot is defined as all material produced within one production shift of the same type, composition, and color

(where applicable). A delivery lot is defined as a shipment or fraction thereof representing a product of the same type, composition,

and color (where applicable).

4. Significance and Use

4.1 These test methods include procedures for sampling, examination, physical testing, and analyses of asphalt roll roofing, cap

sheets, and shingles used in roofing and waterproofing. Other components of these materials are allowed to include, but are not

limited to, felts, mats, films, foils, mineral stabilizers, papers, and mineral surfacing.

4.2 These test methods include tests that are not required by every product standard that references Test Methods

D228D228/D228M. The individual product standards are the authority for which tests are required for compliance. It is not

prohibited to run tests in addition to those required in the product standards, but these test methods make no claim to their

suitability or significance.

4.3 Five random samples are required from lots equal to or less than 1000 packages. The number of samples required for lots

greater than 1000 packages is dependent on the variation in the unit mass within the lot and is determined by the two-step sampling

plan in 7.4.

4.4 The results of a visual examination, physical testing, and compositional analysis are required for each sample. The analytical

data are further used to compute the probable minimum and the probable range for the average mass of each of the components.

5. Materials

5.1 Filter Paper—The extractions for analysis of glass felt products (Section 16) and analysis of roofing products with organic

felt (Section 17) require the use of filter paper with a particle retention of 2.7 μm (see Note 1), This filter paper is dried for 60 min

6 10 % in an 80°C [176°F] oven and stored until needed in a desiccator.

NOTE 1—Whitman No. 50 filter paper [185 mm] has been found satisfactory for this use.

The last approved version of this historical standard is referenced on www.astm.org.

D228/D228M − 09 (2014)

NOTE 1—Not to scale.

NOTE 2—Type 3 has been illustrated without asphalt coating or fine mineral surfacing on the reverse side. It is not prohibited to fabricate this product

with asphalt coating or fine material surfacing on the reverse side.

FIG. 1 Types of Asphalt-Coated Roll Roofing and Shingles

6. Types of Roofing

6.1 Asphalt-coated roll roofing and shingles are divided into the following types for the purposes of these test methods (see Fig.

1).

6.1.1 Type 1—A single thickness of glass felt, coated with asphalt and mineral surfacing such as in Specifications D2178,

D3462, D3909, D4601, and D4897. The backing material (designated “Fine Mineral Surfacing” in Fig. 1) shall be permitted to

be any suitable material that prevents these products from sticking together while packaged.

6.1.2 Type 2—A single thickness of asphalt-saturated felt coated with asphalt and mineral surfacing such as in Specifications

D225, D2626, and D6380, Class M. The backing material (designated “Fine Mineral Surfacing” in Fig. 1) shall be permitted to

be any suitable material that prevents these products from sticking together while packaged.

6.1.3 Type 3—Similar to Type 2, but asphalt coated and surfaced with mineral granules for part of one side of the saturated felt

such as in Specification D6380, Class WS. This type also includes products similar to Type 1 or Type 2 that have overlay or

embossed areas. This does not include products that are fabricated in multiple layers.

6.1.4 Type 4—This material is comprised of multiple layers bonded with a suitable adhesive, typically a bituminous material.

Evaluation of the nature of the adhesive or quality of the bond, or both, is outside the scope of this test method. Fig. 1 illustrates

a typical configuration for Type 4. This “Type” description is provided to aid the user in understanding how to match a given

D228/D228M − 09 (2014)

product composition and assembly to its corresponding Type. It is not intended to limit or exclude products with similar, but not

identical constructions. Examples of known variations, which shall not be prohibited include (but are not limited to):

6.1.4.1 Materials using other adhesives,

6.1.4.2 Materials fabricated with more than two layers,

6.1.4.3 Materials that use different relative proportions for the layers, and

6.1.4.4 Materials with other core compositions

7. Sampling

7.1 The rolls or packages selected in accordance with this section constitute the representative sample used in Sections 8 and

9.

7.2 Select five rolls or packages from the lot at random. Do not select any material that shows visual indications of damage from

2 2

shipping or handling. Determine the average net mass in g/m [lb/100 ft ] and the standard deviation in accordance with 8.1 – 8.8.

7.3 If the lot is 1000 or fewer rolls or packages, proceed to Section 8. If the lot is 1001 or greater in number, follow the second

part of the sampling plan in 7.4.

7.4 Calculate the required number of samples based on the standard deviation (s) of the preliminary sampling by:

2 2

t s

n 5 (1)

d

where:

n = total number of samples required (n − 5 more rolls or packages must be selected at random as samples),

t = test statistic for number of samples in the preliminary test series for 4° and a 95 % confidence that the calculated average

mass will not exceed d (t = 2.776), and

2 2 2

d = 100 g/m [2 lb/100 ft ] (the mean mass obtained from the analysis should be within 6100 g/m of the true value, with 95 %

confidence).

7.5 See Fig. 2.

8. As Received Mass and Area Determinations, All Types of Roofing

8.1 Gross Mass—Determine and record the mass of each representative sample to the nearest 0.1 kg [0.2 lb].

In Section 7, initial “Representative Samples” are selected (typically five per lot). These are full bundles or rolls. These are the samples used in Section 8.

In Section 9, one large “Specimen” is taken from each representative sample (full shingles from 8.5 or a portion of each roll selected in Section 7). These are confirmed

to be within 1.5 % of the mass per area (from 8.6) for the corresponding representative sample.

In Section 10 (where product standards require measurement of water content per Test Method D95), 50-g small test specimens are taken from each “Large Specimen”

for determination of water.

In Section 11, five MD and five CD small test specimens are cut from one of the “Large Specimens” for evaluation of pliability.

In Section 12, two small test specimens are cut from one of the “Large Specimens” for evaluation of behavior on heating.

In Section 15, small test specimens (three for glass felt, four for organic felt) are cut from each of the “Large Specimens” for analysis by Section 16 (for glass felt) or

by Section 17 (for organic felt).

FIG. 2 Sample Selection Summary and Flow Diagram

(See Individual Sections for Sample Selection Details)

D228/D228M − 09 (2014)

8.2 Net Mass—Disassemble each package or unroll each roll of the representative sample; shake off any loose surfacing and

determine and record the net mass of all the shingles or the entire roll to the nearest 0.1 kg [0.2 lb]. Where a product standard

requires it, the loose surfacing is to be collected and the mass determined.

8.3 Packaging and Fixture Mass—Determine and record the mass to the nearest 0.1 kg [0.2 lb] of the packaging and all

associated fixtures shipped with each roll or package of the representative sample, such as nails and adhesive.

8.4 Dimensions of Roll Products—Measure and record the length and width of each roll of roofing and the selvage width to the

nearest 3 mm [ ⁄8 in.].

8.5 Shingle Count and Dimensions —Dimensions—From each of the representative sample packages generated in Section 7,

count and record the number of shingles in each package. Select one shingle randomly from each package. Measure the width,

length, and cutout dimensions for each of these selected shingles to the nearest 1 mm [ ⁄32 in.]. Calculate and record the average

for each of these measurements.

8.6 Calculate the area of the roofing and the net mass per unit area of the roofing. Report the net mass per unit area in

2 2

g/m [lb/100 ft ] for each representative sample (without packaging, cut outs or loose surfacing).

8.7 Calculate and record the average net mass per unit area for the combined representative samples (without packaging, cut

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.