ASTM D6518-02a

(Practice)Standard Practice for Bias Testing a Mechanical Coal Sampling System

Standard Practice for Bias Testing a Mechanical Coal Sampling System

SCOPE

1.1 This practice presents sample collection and statistical evaluation procedures for testing mechanical sampling systems, subsystems, and individual system components for bias. It is the responsibility of the user of this practice to select the appropriate procedure for a specific sampling situation.

1.2 This practice does not purport to define an absolute bias. Bias defined by this practice is the difference between the population mean of the mechanical sampler test results and the accepted reference value.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6518 – 02a

Standard Practice for

1

Bias Testing a Mechanical Coal Sampling System

This standard is issued under the fixed designation D 6518; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 bias, n—the difference between the population mean

of the mechanical sampler test results and the accepted

1.1 This practice presents sample collection and statistical

reference value.

evaluation procedures for testing mechanical sampling sys-

3.2.2 confidence interval, n—a numeric interval with a

tems, subsystems, and individual system components for bias.

lower limit and a higher limit within which the true parameter

It is the responsibility of the user of this practice to select the

value is estimated to fall. The confidence interval percentage

appropriate procedure for a specific sampling situation.

indicates the percentage of time the true value will fall within

1.2 This practice does not purport to define an absolute bias.

the interval if the procedure is continuously repeated.

Bias defined by this practice is the difference between the

3.2.3 correlation, n—a measure of the linear dependence

population mean of the mechanical sampler test results and the

between paired system and reference measurements. Correla-

accepted reference value.

tion frequently is expressed by the correlation coefficient,

1.3 This standard does not purport to address all of the

which can take a value from minus one (perfect negative linear

safety concerns, if any, associated with its use. It is the

relationship) to plus one (perfect positive linear relationship).

responsibility of the user of this standard to establish appro-

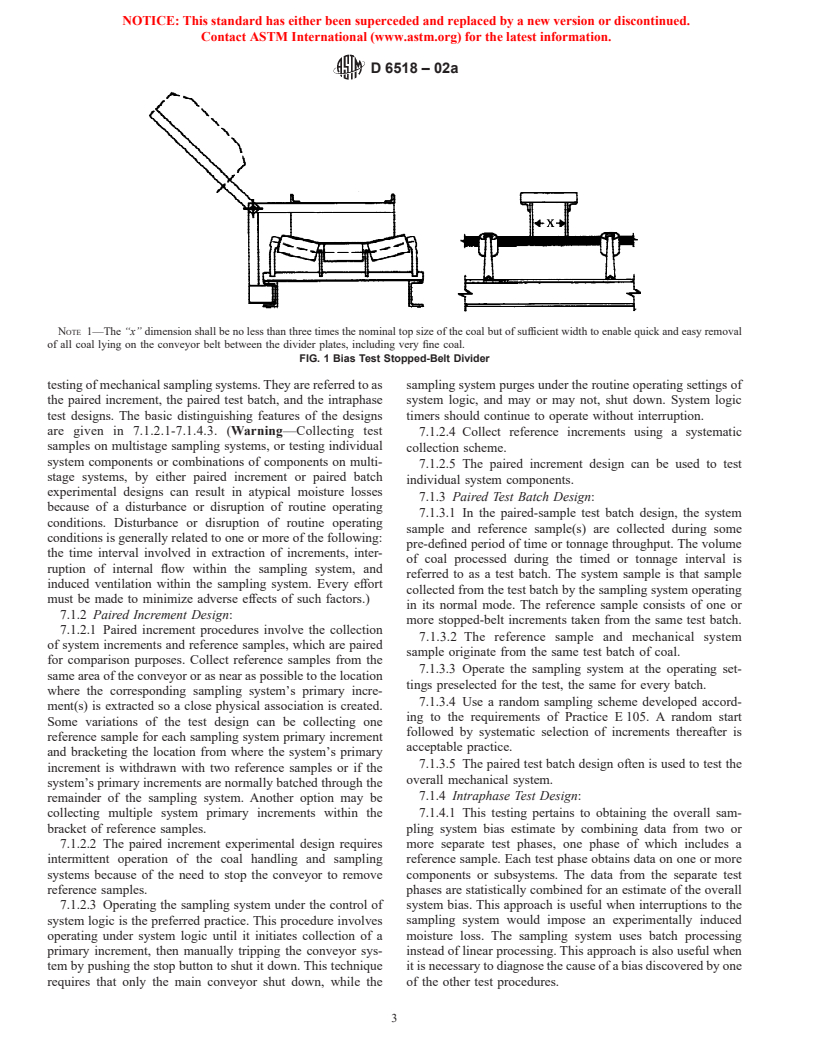

3.2.4 delimitation error, n—a material error that occurs

priate safety and health practices and determine the applica-

when all the elements in a cross section of a coal stream do not

bility of regulatory limitations prior to use.

have an equal probability of being intercepted (captured) by the

2. Referenced Documents sampler cutter during increment collection.

3.2.5 ellipsoidal region, n—an area that is formed by plane

2.1 ASTM Standards:

2

sections of ellipses that are defined by the values selected for

D 121 Terminology of Coal and Coke

2

the largest tolerable bias of each coal characteristic used in the

D 2013 Practice for Preparing Coal Samples for Analysis

2

bias test. The region will be used to determine if the system is

D 2234 Practice for Collection of a Gross Sample of Coal

biased.

D 4621 Guide for Quality Management in an Organization

2

2

3.2.6 Hotelling’s T test, n—a statistical test that is used to

that Samples or Tests Coal and Coke

evaluate multivariate data. It is the multivariate equivalent of

D 4702 Guide for Inspecting Crosscut, Sweep-Arm, and

the Student’s t-test.

Auger Mechanical Coal Sampling Systems for Conform-

2

3.2.7 largest tolerable bias (LTB), n—an interval whose

ance with Current ASTM Standards

3

upper and lower bounds represent the limits of an acceptable

E 105 Practice for Probability Sampling of Materials

bias.

E 122 Practice for Calculating Sample Size to Estimate,

3.2.8 mechanical sampling system, n—a single machine or

with a Specified Tolerable Error, the Average for a Char-

3

series of interconnected machines whose purpose is to extract

acteristic of a Lot or Process

3

mechanically, or process (divide and reduce), or a combination

E 456 Terminology Relating to Quality and Statistics

thereof, a sample of coal.

E 691 Practice for Conducting an Interlaboratory Study to

3

3.2.9 paired data set, n—system and reference values ob-

Determine the Precision of a Test Method

served on samples collected and compared from the same batch

3. Terminology

of material.

3.2.10 reference sample, n—a sample used in testing of a

3.1 Definitions—For additional definitions of terms used in

mechanical sampling system which is comprised of one or

this practice refer to Terminologies D 121 and E 456.

more increments collected from the test batch or lot of coal by

3.2 Definitions of Terms Specific to This Standard:

the stopped belt method as described in Practice D 2234.

3.2.11 reject stream, n—the coal flow within a mechanical

1

This practice is under the jurisdiction of ASTM Committee D05 on Coal and

sampling system, which occurs at each stage of division, before

Coke and is the direct responsibility of Subcommittee D05.23 on Sampling.

and after reduction, and is not included in the system sample.

Current edition approved Oct. 10, 2002. Published November 2002.

Originally published as D 6518–00. Last previous edition D 6518–02.

3.2.12 save stream, n—the coal flow within a mech

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.