ASTM D5927-99a

(Specification)Standard Specification for Thermoplastic Polyester (TPES) Injection and Extrusion Materials Based on ISO Test Methods

Standard Specification for Thermoplastic Polyester (TPES) Injection and Extrusion Materials Based on ISO Test Methods

SCOPE

1.1 This specification covers thermoplastic polyester materials suitable for molding or extrusion.

1.2 This specification allows for the use of recycled thermoplastic polyester materials provided that the requirements as stated in this specification are met. The proportions of recycled material used, as well as the nature and amount of any contaminant, however, cannot be covered practically in this specification.

1.3 The properties included in this specification are those required to identify the compositions covered. There may be other requirements necessary to identify particular characteristics important to specialized applications. These may be specified by using the suffixes as given in Section 5.

1.4 This classification system and subsequent line callout (specification) are intended to provide a means of calling out plastic materials used in the fabrication of end items or parts. It is not intended for the selection of materials. Material selection should be made by those having expertise in the plastic field after careful consideration of the design and performance required of the part, the environment to which it will be exposed, the fabrication process to be used, the costs involved, and the inherent properties of the material other than those covered by this specification.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 The following hazards caveat pertains only to the test methods portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1--This specification is similar to ISO 7792-1:1995 and ISO 7792-2:1988, although the technical content is significantly different.

General Information

Relations

Standards Content (Sample)

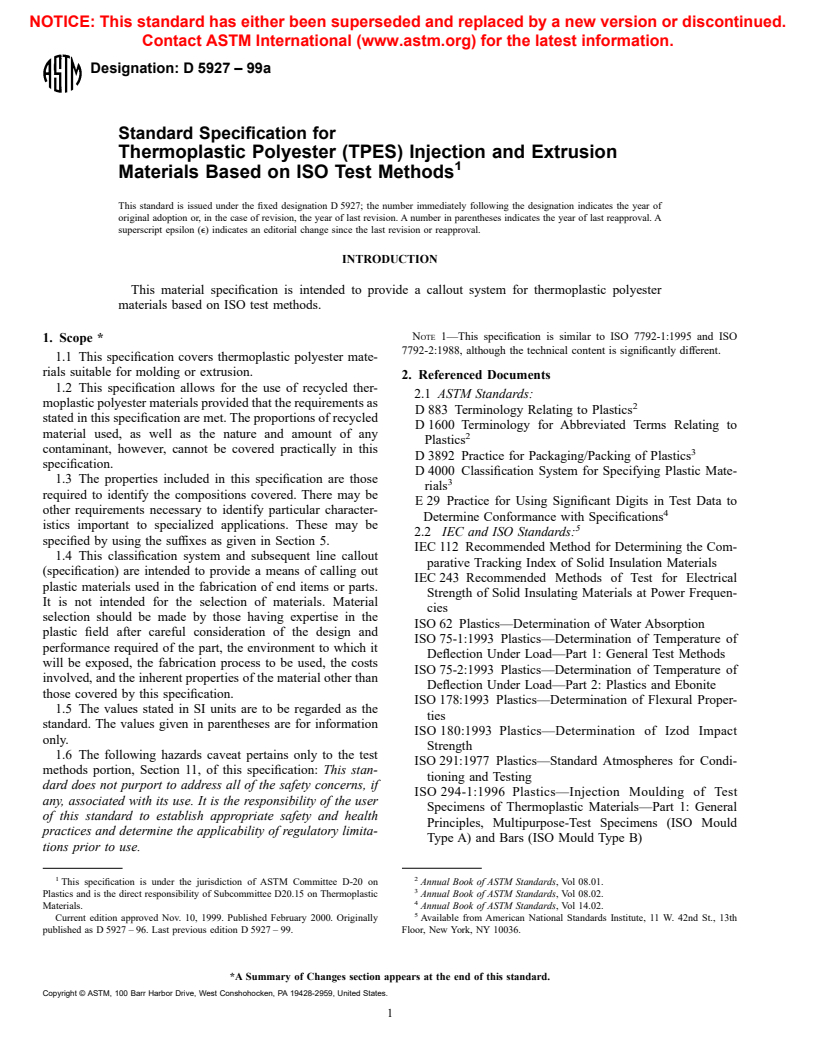

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5927 – 99a

Standard Specification for

Thermoplastic Polyester (TPES) Injection and Extrusion

Materials Based on ISO Test Methods

This standard is issued under the fixed designation D 5927; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This material specification is intended to provide a callout system for thermoplastic polyester

materials based on ISO test methods.

NOTE 1—This specification is similar to ISO 7792-1:1995 and ISO

1. Scope *

7792-2:1988, although the technical content is significantly different.

1.1 This specification covers thermoplastic polyester mate-

rials suitable for molding or extrusion.

2. Referenced Documents

1.2 This specification allows for the use of recycled ther-

2.1 ASTM Standards:

moplastic polyester materials provided that the requirements as

D 883 Terminology Relating to Plastics

stated in this specification are met. The proportions of recycled

D 1600 Terminology for Abbreviated Terms Relating to

material used, as well as the nature and amount of any

Plastics

contaminant, however, cannot be covered practically in this

D 3892 Practice for Packaging/Packing of Plastics

specification.

D 4000 Classification System for Specifying Plastic Mate-

1.3 The properties included in this specification are those

rials

required to identify the compositions covered. There may be

E 29 Practice for Using Significant Digits in Test Data to

other requirements necessary to identify particular character-

Determine Conformance with Specifications

istics important to specialized applications. These may be

2.2 IEC and ISO Standards:

specified by using the suffixes as given in Section 5.

IEC 112 Recommended Method for Determining the Com-

1.4 This classification system and subsequent line callout

parative Tracking Index of Solid Insulation Materials

(specification) are intended to provide a means of calling out

IEC 243 Recommended Methods of Test for Electrical

plastic materials used in the fabrication of end items or parts.

Strength of Solid Insulating Materials at Power Frequen-

It is not intended for the selection of materials. Material

cies

selection should be made by those having expertise in the

ISO 62 Plastics—Determination of Water Absorption

plastic field after careful consideration of the design and

ISO 75-1:1993 Plastics—Determination of Temperature of

performance required of the part, the environment to which it

Deflection Under Load—Part 1: General Test Methods

will be exposed, the fabrication process to be used, the costs

ISO 75-2:1993 Plastics—Determination of Temperature of

involved, and the inherent properties of the material other than

Deflection Under Load—Part 2: Plastics and Ebonite

those covered by this specification.

ISO 178:1993 Plastics—Determination of Flexural Proper-

1.5 The values stated in SI units are to be regarded as the

ties

standard. The values given in parentheses are for information

ISO 180:1993 Plastics—Determination of Izod Impact

only.

Strength

1.6 The following hazards caveat pertains only to the test

ISO 291:1977 Plastics—Standard Atmospheres for Condi-

methods portion, Section 11, of this specification: This stan-

tioning and Testing

dard does not purport to address all of the safety concerns, if

ISO 294-1:1996 Plastics—Injection Moulding of Test

any, associated with its use. It is the responsibility of the user

Specimens of Thermoplastic Materials—Part 1: General

of this standard to establish appropriate safety and health

Principles, Multipurpose-Test Specimens (ISO Mould

practices and determine the applicability of regulatory limita-

Type A) and Bars (ISO Mould Type B)

tions prior to use.

1 2

This specification is under the jurisdiction of ASTM Committee D-20 on Annual Book of ASTM Standards, Vol 08.01.

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Annual Book of ASTM Standards, Vol 08.02.

Materials. Annual Book of ASTM Standards, Vol 14.02.

Current edition approved Nov. 10, 1999. Published February 2000. Originally Available from American National Standards Institute, 11 W. 42nd St., 13th

published as D 5927 – 96. Last previous edition D 5927 – 99. Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 5927

ISO 527-1:1993 Plastics—Determination of Tensile

Symbol Material Tolerance

Properties—Part 1: General Principles

C carbon- and graphite-fiber- 62%

ISO 527-2:1993 Plastics—Determination of Tensile

reinforced

G glass-reinforced 62%

Properties—Part 2: Testing Conditions

L lubricants (such as PTFE, depends on material and pro-

ISO 604 Plastics—Determination of Compressive Proper-

graphite, silicone, and mo- cess—to be specified

lybdenum disulfide)

ties

M mineral-reinforced 62%

ISO/DIS 1133:1995 Plastics—Determination of the Melt R combinations of reinforce- 63%

ments or fillers, or both

Mass-Flow Rate (MFR) and the Melt Volume-Flow Rate

NOTE 3—An example of this classification system for reinforced

(MVR) of Thermoplastics

thermoplastic polyester is given as follows. The designation TPES

ISO 1183:1987 Plastics—Methods for Determining the

021G30 indicates the following:

Density and Relative Density of Non-Cellular Plastics

TPES 5 thermoplastic polyester as found in Terminology

ISO 3451-2:1984 Plastics—Determination of Ash—Part 2: D 1600,

02 (group) 5 PET,

Polyalkylene Terephthalates

1 (class) 5 unmodified, and

ISO 7792-1:1995 Plastics—Saturated Polyester (SP) Moul- G30 (grade) 5 nominal 30 % glass with the requirements given in

Table TPES.

ding and Extrusion Materials—Part 1: Designation Sys-

NOTE 4—This part of the classification system uses the percent of

tem and Basis for Specification

reinforcements or fillers, or both, in the callout of the modified base

ISO 7792-2:1988 Plastics—Polyalkylene Terephthalates—

material. The types and percentages of reinforcements and fillers should

Part 2: Preparation of Test Specimens and Determination

be shown on the supplier’s technical data sheet unless they are proprietary

of Properties

in nature. If necessary, additional callout of these reinforcements and

additives can be accomplished by use of the suffix part of the system (see

2.3 Underwriters Laboratories (UL):

Section 5).

UL 94 Test for Flammability of Plastic Materials for Parts

NOTE 5—Materials containing reinforcements or fillers, or both, at

in Devices and Appliances

nominal levels not in multiples of five are included in the nearest TPES

designation. For example, a material with a nominal glass content of 28 %

2.4 National Technical Information Service (NTIS):

is included with Grade G30.

AD297457 Procedure and Analytical Method for Determin-

NOTE 6—The ash content of filled or reinforced materials may be

ing Toxic Gases Produced by Synthetic Compounds

determined using ISO 3451-2:1984.

4.2 Variations of thermoplastic polyester materials that are

3. Terminology

not included in Table TPES are classified in accordance with

3.1 Definitions—The terminology used in this specification

Table TPES and Table A or B. Table TPES is used to specify

is in accordance with Terminologies D 883 and D 1600.

the group of thermoplastic polyester, and Table A or B is used

to specify property requirements.

4. Classification

4.2.1 Specific requirements for variations of thermoplastic

polyester materials shall be indicated by a six-character desig-

4.1 Thermoplastic polyester materials are classified into

nator. The designation will consist of the letter “A” or “B” and

groups according to their composition. These groups are

the five digits comprising the cell numbers for the property

subdivided into classes and grades, as indicated in the basic

requirements in the order as they appear in Table A or B.

property table (Table TPES).

4.2.1.1 Although the values listed are necessary to include

the range of properties available in existing material, users

NOTE 2—An example of this classification system is as follows. The

designation TPES 0113 would indicate: should not infer that every possible combination of the

properties exists or can be obtained.

TPES 5 thermoplastic polyester as found in Terminology D 1600,

01 (group) 5 PBT,

4.2.2 When the grade of the basic material is not known or

1 (class) 5 general purpose, and

is not important, the use of “0” grade classification shall be

3 (grade) 5 requirements given in Table TPES.

used for materials in this system (see Note 7).

4.1.1 Grades of reinforced or filled versions, or both, of the

NOTE 7—An example of a reinforced thermoplastic polyester of this

basic materials are identified by a single letter that indicates the

classification system is as follows. The designation TPES

reinforcement or filler used and two digits, in multiples of five,

0310G30A22450 would indicate the following material requirements

that indicate the nominal quantity in percent by weight. Thus,

from Table A:

a letter designation G for glass reinforced and 35 for percent or

TPES0310 5 PET copolymer, from Table TPES,

reinforcement, G35, specifies a material with a nominal glass G30 5 glass-reinforced at 30 % nominal glass content,

A 5 Table A for property requirements,

level of 35 %. The reinforcement letter designations and

2 5 tensile strength, 50 MPa, min,

associated tolerance levels are shown as tabulated as follows:

2 5 flexural modulus, 2700 MPa, min,

4 5 Izod impact, 6.0 kJ/m , min,

5 5 deflection temperature, 185°C, at 1.8 MPa, min,

and

0 5 unspecified.

Available from Underwriters Laboratories, 333 Pfingsten Rd., Northbrook, IL

If no properties are specified, the designation would be TPES

60062–2096.

Available from NTIS, 5285 Port Royal Rd., Springfield, VA 22161. 0310G30A00000.

D 5927

A

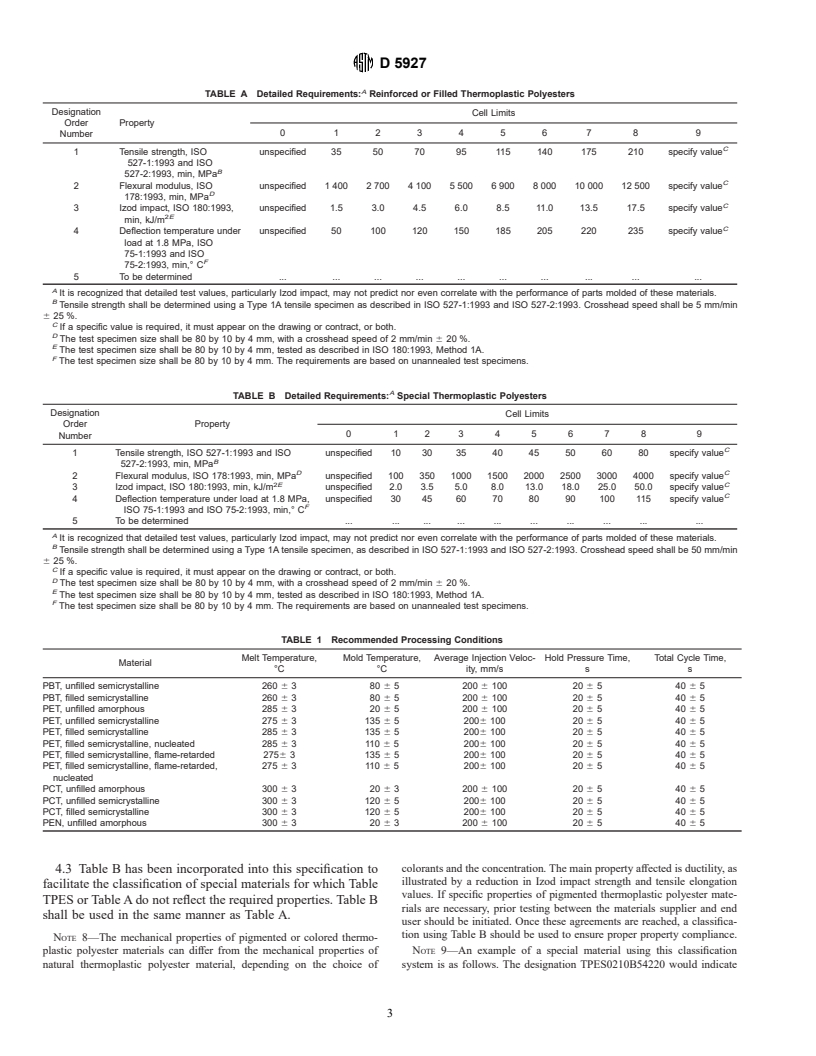

TABLE A Detailed Requirements: Reinforced or Filled Thermoplastic Polyesters

Designation

Cell Limits

Order Property

Number 0 123456 7 8 9

C

1 Tensile strength, ISO unspecified 35 50 70 95 115 140 175 210 specify value

527-1:1993 and ISO

B

527-2:1993, min, MPa

C

2 Flexural modulus, ISO unspecified 1 400 2 700 4 100 5 500 6 900 8 000 10 000 12 500 specify value

D

178:1993, min, MPa

C

3 Izod impact, ISO 180:1993, unspecified 1.5 3.0 4.5 6.0 8.5 11.0 13.5 17.5 specify value

2E

min, kJ/m

C

4 Deflection temperature under unspecified 50 100 120 150 185 205 220 235 specify value

load at 1.8 MPa, ISO

75-1:1993 and ISO

F

75-2:1993, min,° C

5 To be determined . . . . . . . . . .

A

It is recognized that detailed test values, particularly Izod impact, may not predict nor even correlate with the performance of parts molded of these materials.

B

Tensile strength shall be determined using a Type 1A tensile specimen as described in ISO 527-1:1993 and ISO 527-2:1993. Crosshead speed shall be 5 mm/min

6 25 %.

C

If a specific value is required, it must appear on the drawing or contract, or both.

D

The test specimen size shall be 80 by 10 by 4 mm, with a crosshead speed of 2 mm/min 6 20 %.

E

The test specimen size shall be 80 by 10 by 4 mm, tested as described in ISO 180:1993, Method 1A.

F

The test specimen size shall be 80 by 10 by 4 mm. The requirements are based on unannealed test specimens.

A

TABLE B Detailed Requirements: Special Thermoplastic Polyesters

Designation Cell Limits

Order Property

0 1 2 345678 9

Number

C

1 Tensile strength, ISO 527-1:1993 and ISO unspecified 10 30 35 40 45 50 60 80 specify value

B

527-2:1993, min, MPa

D C

2 Flexural modulus, ISO 178:1993, min, MPa unspecified 100 350 1000 1500 2000 2500 3000 4000 specify value

2E C

3 Izod impact, ISO 180:1993, min, kJ/m unspecified 2.0 3.5 5.0 8.0 13.0 18.0 25.0 50.0 specify value

C

4 Deflection temperature under load at 1.8 MPa, unspecified 30 45 60 70 80 90 100 115 specify value

F

ISO 75-1:1993 and ISO 75-2:1993, min,° C

5 To be determined . . . . . . . . . .

A

It is recognized that detailed test values, particularly Izod impact, may not predict nor even correlate with the performance of parts molded of these materials.

B

Tensile strength shall be determined using a Type 1A tensile specimen, as described in ISO 527-1:1993 and ISO 527-2:1993. Crosshead speed shall be 50 mm/min

6 25 %.

C

If a specific value is required, it must appear on the drawing or contract, or both.

D

The test specimen size shall be 80 by 10 by 4 mm, with a crosshead speed of 2 mm/min 6 20 %.

E

The test specimen size shall be 80 by 10 by 4 mm, tested as described in ISO 180:1993, Method 1A.

F

The test specimen size shall be 80 by 10 by 4 mm. The requirements are based on unannealed test specimens.

TABLE 1 Recommended Processing Conditions

Melt Temperature, Mold Temperature, Average Injection Veloc- Hold Pressure Time, Total Cycle Time,

Material

°C °C ity, mm/s s s

PBT, unfilled semicrystalline 260 6380 6 5 200 6 100 20 6540 6 5

PBT, filled semicrystalline 260 6380 6 5 200 6 100 20 6540 6 5

PET, unfilled amorphous 285 6320 6 5 200 6 100 20 6540 6 5

PET, unfilled semicrystalline 275 6 3 135 6 5 2006 100 20 6540 6 5

PET, filled semicrystalline 285 6 3 135 6 5 2006 100 20 6540 6 5

PET, filled semicrystalline, nucleated 285 63110 6 5 2006 100 20 6540 6 5

PET, filled semicrystalline, flame-retarded 2756 3 135 6 5 2006 100 20 6540 6 5

PET, filled semicrystalline, flame-retarded, 275 63110 6 5 2006 100 20 6540 6 5

nucleated

PCT, unfilled amorphous 300 6320 6 3 200 6 100 20 6540 6 5

PCT, unfilled semicrystalline 300 6 3 120 6 5 2006 100 20 6540 6 5

PCT, filled semicrystalline 300 6 3 120 6 5 2006 100 20 6540 6 5

PEN, unfilled amorphous 300 6320 6 3 200 6 100 20 6540 6 5

colorants and the concentration. The main property affected is ductility, as

4.3 Table B has been incorporated into this specification to

illustrated by a reduction in Izod impact strength and tensile elongation

facilitate the classification of special materials for which Table

values. If specific properties of pigmented thermoplastic polyester mate-

TPES or Table A do not reflect the required properties. Table B

rials are necessary, prior testing between the materials supplier and end

shall be used in the same manner as Table A.

user should be initiated. Once these agreements are reached, a classifica-

tion using Table B should be used to ensure proper property compliance.

NOTE 8—The mechanical properties of pigmented or colored thermo-

plastic polyester materials can differ from the mechanical properties of NOTE 9—An example of a special material using this classification

natural thermoplastic polyester material, depending on the choice of system is as follows. The designation TPES0210B54220 would ind

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.