ASTM C762-86(1994)e1

(Practice)Practice for Application of Spray-Applied Fibrous Thermal Insulation for Elevated Temperatures (Withdrawn 1999)

Practice for Application of Spray-Applied Fibrous Thermal Insulation for Elevated Temperatures (Withdrawn 1999)

SCOPE

1.1 This practice covers the application recommendations for spray-applied fibrous insulations consisting of uniform mixtures of thermally resistant binders and inorganic fibrous materials for use on substrates operating at elevated temperatures above 100°F (38°C).

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

W 0759510 0549786 O33

AMERICAN SOCIETY FOR TESTING AND MATERIALS

[# Designation: C 762 - 86 (Reapproved 1994)‘’

1916 Race St Philadelphia, ?a 19103

Reprinted from the Annual Book of ASTM Standards Copyright ASTM

If not listed in the current combined indew, will appear in the next edition

Standard Practice for

Application of Spray-Applied Fibrous Thermal Insulation for

Elevated Temperatures’

This standard is issued under the fixed designation C 762; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This practice covers the application recommendations 4.1 The purpose of this practice is to provide standard

for spray-applied fibrous insulations consisting of uniform application procedures, specifically regarding surface prepa-

mixtures of thermally resistant binders and inorganic fibrous rations, general sprayed fiber techniques, reinforcement and

materials for use on substrates operating at elevated temper- mechanical supports, and finish applications and limitations,

atures above 100°F (38°C). and to provide common precautions necessary to avoid

1.2 The values stated in inch-pound units are to be application and performance difficulties.

regarded as the standard. The values given in parentheses are 4.2 When thermal insulations are not applied in accor-

for information only. dance with prescribed and proven procedures, poor adhesion

1.3 This standard does not purport to address all of the and appearance often occur. The various sections of this

safety concerns, if any, associated with its use. It is the recommended practice explain certain methods suitable for

responsibility of the user of this standard to establish appro- obtaining optimum results with spray-applied fibrous ther-

priate safety and health practices and determine the applica- mal insulation.

bility of regulatory limitations prior to use. 4.3 This practice is only a guide. The requirements herein

discussed are general in nature and considered practical.

2. Referenced Documents

They are not intended as specific recommendations.

2.1 ASTM Standards:

5. Apparatus, Utilities, and Operational Requirements

C 168 Terminology Relating to Thermal Insulating Mate-

rials2

5.1 Application Machine and Related Spray Equipment-

C 720 Specification for Spray-Applied Fibrous Thermal

The insulation shall be applied with manufacturer-approved

Insulation for Elevated Temperature’

spray application machines, spray nozzles, and other neces-

2.2 Other Documents:

sary equipment, in strict accordance with manufacturer’s

Occupational Safety and Health Act (OSHA), current instructions and recommendations.

issue3 5.2 Utilities and Operational Requirements-Unless oth-

erwise specified, the following services are normally provided:

3. Terminology

5.2.1 Electricity-220 V, 60 A.

3.1 Definitions-See Terminology C 168. 5.2.2 Water-4 gal (15 L)/min at 60 psi (4.1 atm) (414

3,l.l high-temperature substrates-those substrates which kPa) at the application level.

are at temperatures above 2 12’ F (100’ C) during application 5.2.3 Air-10 ft3 (0.28 m3)/min at 100 psi (6.8 atm) (689

of spray-applied fibrous thermal insulations.

kPa).

3.1.2 overspray-that portion of material from a spray- 5.2.4 Illumination-Sufficient illumination shall be pro-

pattern not adhering to intended substrates. vided for proper application.

3.1.3 spray-applied fibrous thermal insulation-material

5.2.5 Ventilation-Sufficient air circulation must be pro-

applied by pneumatic conveyance in a dry state and then vided to reduce any accumulated dust during application

wetted with an atomizing liquid at the spray nozzle. and to allow adequate drying of applied insulation after

3.1.4 spray liquid-usually potable water or mixes of application.

water-soluble adhesives and water. 5.2.6 Prolective Equipment-Current OSHA regulations

3.1.5 spray nozzle-a tube with a liquid atomizing unit shall apply. As a guide, personnel working within 15 ft (4.6

attached to intermix fibers and liquid. These nozzles can be m) of the spraying or feeding operation shall wear approved

produced to operate with or without compressed air. masks, and goggles or face shields, if desired.

3.1.6 tamping insulation-procedure by which sprayed 5.2.7 Adhesives-Adhesives, when used, shall be in accor-

insulations are flattened with a tool to achieve a desired dance with manufacturer’s recommendations.

uniform thickness or pleasing appearance. 5.2.8 Reinforcement-Pins, studs, and other attachments,

when used, shall be secured to substrates prior to application

of insulation.

I This practice is under the jurisdiction of ASTM Committee C-16 on Thermal

5.2.9 Windbreaks-As necessary, in order to minimize

Insulation and is the direct responsibility of Subcommittee C16.23 on Blanket and

overspray, provide windbreaks within the application area.

Loose Fill insulation.

Current edition approved March 27, 1986. Published May 1986. Originally

published as C 762 - 73. Last previous edition C 762 - 73 (1980).

6. Materials

Annual Book of ASTM Siandards, Vol 04.06.

Available from OSHA, 200 Constitution Ave., NW, Washington, DC 20210. 6.1 The fibrous thermal insulations shali consist of min-

= 0759530 05qï787 T7T H

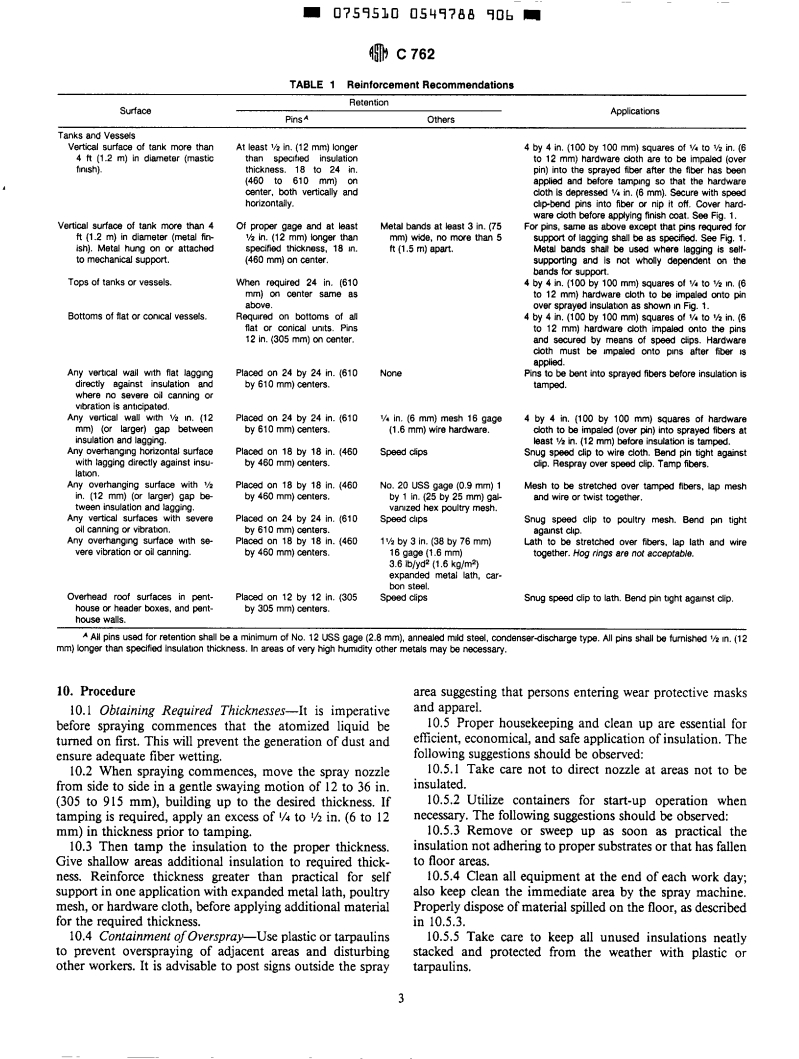

I-lelded pin of specified

gage shown in place

Sprayed fibrous insulation

untamped

Base

UNTAMPED SPRAYED INSULATION

1/4 in. n to be

(6 mm) pi

clip

snipped at top of

in. by 4 in

Speed cl ip with 4

(inn by 100 mm) h ardware

cloth.

Sprayed fibrous i nsulation

tamped

TAP4 P E D S PRAY E D I N S U LAT I O N

tla s t i c finish

Hard f inish

Speed clip

Hardwa re cloth

FINISHED APPLICATION

FIG. 1 Application Technique for Mechanical Support Using Pins and Hardware Cloth

eral or refractory fibers or both, combined with thermally be applied in accordance with manufacturer's instructions.

resistant binders in accordance with Specification C 720.

7. Application

9. Application Conditions and Limitations

7.1 The application of spray-applied thermal insulating

9.1 Application Conditions:

materials shall consist ofi 9.1.1 Surface Preparation-The surface to be treated shall

7.1.1 Fluffing the otherwise compacted fiber and metering

be clean and free of loose paint, rust, oil, grease, or any other

it through an application machine,

condition that would prevent good adhesion of the sprayed

7.1.2 Pneumatically conveying this processed fiber

fibrous thermal insulation to the substrate. Certain sub-

through a flexible hose to the fiber spray nozzle, strates, such as painted surfaces, may need adhesive in order

7.1.3 Introducing an atomized liquid as the fiber emerges to obtain an adequately adhering bond.

from the nozzle, and

9.1.2 Application Temperature-Application tempera-

7.1.4 Directing the wetted material to a substrate in an

tures must be observed. Application should not be made

even, unintempted pattern.

under ambient conditions where freezing can occur. Ice

formation within the insulation or at the substrate interface

8. Preconditions

can cause delamination.

8.1 Prior to commencing the application of spray-applied

9.1.3 Material may be applied under two temperature

fibrous thermal insulations, certain preconditions shall be of the substrate:

conditions

observed: 9.1.3.1 Temperature of substrate below 2 12" F (100' C).

8.1.1 Type of Spray Nozzle-The type of atomizing spray 9.1.3.2 High temperature substrate that is above 212" F

nozzle shall be as specified by the manufacturer. (100' C).

Atomization may be accomplished by direct water pressure, 9.1.4 When treating high temperature substrates apply a

compressed air, or by blower pressure. minimal thickness of insulation and aiiow to dry before

8.1.2 Liquid/Fiber Ratio-Normally 0.75 to 1.25 lb of application of additional insulation. This will reduce blow-

liquid per pound (0.75 to 1.25 kg per kilogram) of insulation offs and poor adhesion of the applied insulation from the

is used. Specific recommendations of the thermal insulation steam created.

manufacturer must be followed. Liquid flow tests should be 9.2 Limitations on Maximum Thickness-A maximum

made periodically to assure a proper ratio.

thickness of 2 in. (5 1 mm) shall be applied without reinforce-

8.1.3 Prewetting Surfaces-Surfaces shall be pre-wetted

ment. Applications in excess o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.