ASTM E378-97

(Test Method)Standard Test Method for Spectrographic Analysis of Silver by the Powder Technique (Withdrawn 2004)

Standard Test Method for Spectrographic Analysis of Silver by the Powder Technique (Withdrawn 2004)

SCOPE

1.1 This test method covers the spectrographic analysis of silver for the following elements in the ranges indicated: Element Concentration Range, % Copper 0.0001 to 0.1 Lead 0.0001 to 0.05 Zinc 0.001 to 0.01 Bismuth 0.0001 to 0.01 Palladium 0.001 to 0.005 Chromium 0.0001 to 0.005 Iron 0.0001 to 0.005 Nickel 0.0001 to 0.005 Manganese 0.0001 to 0.005 Tin 0.0001 to 0.005

1.2 This test method is designed for the analysis of commercial and high-purity silver samples in the form of needles, chips, cast bars, or sheet stock.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation:E378–97

Standard Test Method for

Spectrographic Analysis of Silver by the Powder Technique

This standard is issued under the fixed designation E 378; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the spectrographic analysis of 3.1 For definitions of terms used in this test method, refer to

silver for the following elements in the ranges indicated: Terminology E 135E 135.

Element Concentration Range, %

4. Summary of Test Method

Copper 0.0001 to 0.1

Lead 0.0001 to 0.05

4.1 Samples and standards are prepared in the form of dry

Zinc 0.001 to 0.01

silver nitrate powder and packed into the craters of specially

Bismuth 0.0001 to 0.01

Palladium 0.001 to 0.005

shaped graphite cup electrodes.The spectra are produced using

Chromium 0.0001 to 0.005

dc arc excitation and recorded photographically. Intensity

Iron 0.0001 to 0.005

ratios of selected pairs of analytical lines and internal standard

Nickel 0.0001 to 0.005

Manganese 0.0001 to 0.005

lines are determined photometrically. Concentrations are read

Tin 0.0001 to 0.005

from an analytical curve relating log intensity ratio to log

1.2 This test method is designed for the analysis of com- concentration.

mercial and high-purity silver samples in the form of needles,

5. Significance and Use

chips, cast bars, or sheet stock.

1.3 This standard does not purport to address all of the 5.1 Refined silver is marketed on purity. This test method is

safety concerns, if any, associated with its use. It is the suitable for analysis of refined silver for compliance with

responsibility of the user of this standard to establish appro- Specification B 413B 413.

priate safety and health practices and determine the applica-

6. Apparatus

bility of regulatory limitations prior to use.

6.1 Excitation Source providing a 12-A dc arc.

2. Referenced Documents

6.2 Spectrograph having sufficient resolving power and

2.1 ASTM Standards: linear dispersion to separate the analytical lines from other

B 413 Specification for Refined Silver lines in the spectrum of the sample in the spectral region from

E50 Practices for Apparatus, Reagents and Safety Precau- 2500 to 3500 Å. An instrument having a reciprocal linear

tions for Chemical Analysis of Metals dispersion of 5 to 10 Å/mm in the first order satisfies these

E115 Practice for Photographic Processing in Optical conditions.

Emission Spectrographic Analysis 6.3 Photographic Processing Equipment providing devel-

E116 Practice for Photographic Photometry in Spectro- opment, fixing, washing, and drying operations and conform-

chemical Analysis ing to the requirements of Practice E 115E115.

E 130 Practice for Designation of Shapes and Sizes of 6.4 Microphotometer conforming to criteria of Practice

Graphite Electrodes E 409E 409.

E 135 Terminology Relating to Analytical Chemistry for 6.5 Calculating Board to convert microphotometer read-

Metals, Ores, and Related Materials ings to log intensity ratios and concentrations.

E 409 Practice For Description and Performance of the

7. Reagents and Materials

Microphotometer

7.1 Purity and Concentration of Reagents—The purity and

concentration of the chemical reagents used in preparing the

This test method is under the jurisdiction of ASTM Committee E-1 on

standards and samples shall conform to the requirements

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct

prescribed in Practices E 50E50.

responsibility of Subcommittee E01.03 on Precious Metals.

Current edition approved April 10, 1997. Published June 1997. Originally

7.2 Electrodes—The sample electrode shall be high-purity

´1

published as E 378 – 68. Last previous edition E 378 – 83 (1992) .

Type S-4 and the counter electrode high-purity Type C-1 as

Annual Book of ASTM Standards, Vol 02.04.

3 described in Practice E 130E 130.

Annual Book of ASTM Standards, Vol 03.05.

Annual Book of ASTM Standards, Vol 03.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

E378–97

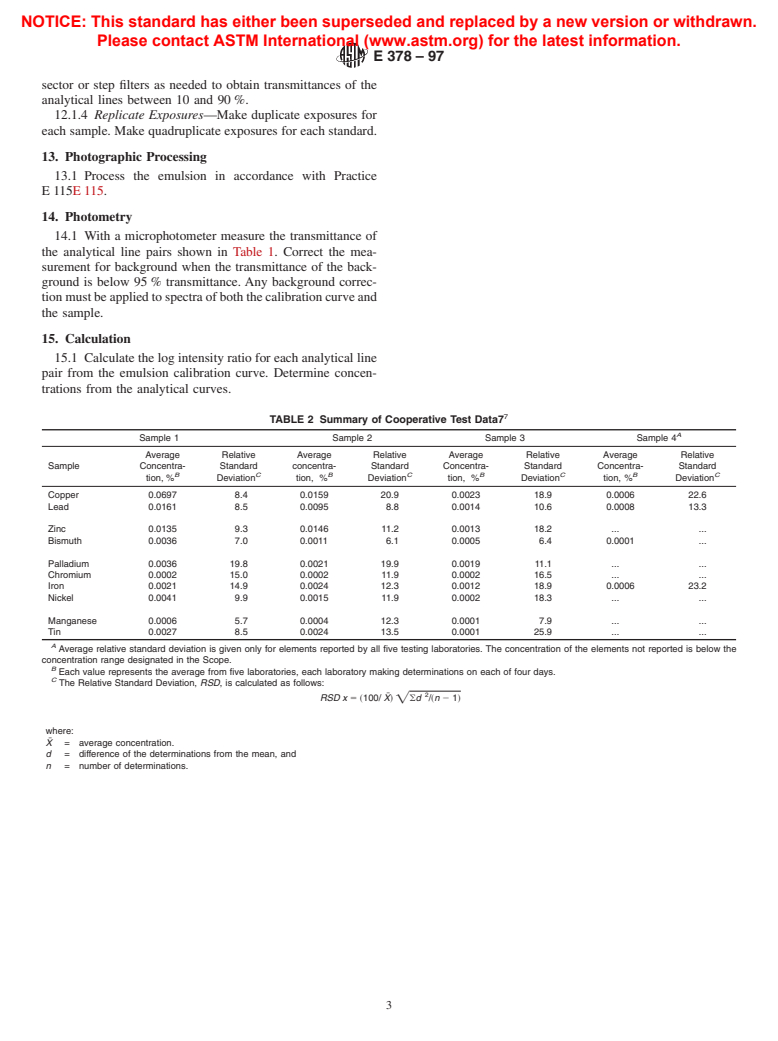

TABLE 1 Analytical and Internal Standard Lines

7.3 Silver Nitrate, High-Purity.

˚

Element Analytical Line, A Concentration Range,

NOTE 1—Detection limits will be affected by the amount of impurity

Copper 3247.54 0.0001 to 0.005

elements contained in the silver nitrate.

2961.16 0.005 to 0.1

7.4 Metals and Metal Salts —Bismuth, copper, iron, lead,

Lead 2833.06 0.0001 to 0.005

nickel, palladium, and zinc as metals; chromium as chromium

2873.32 0.001 to 0.05

nitrate; manganese as manganese sulfate monohydrate; and tin

Zinc 3345.02 0.001 to 0.01

as sodium stannate.

7.5 Photographic Emulsion.

Bismuth 3067.72 0.0001 to 0.005

7.6 Photographic Processing Solutions— The formulas for

2897.98 0.001 to 0.01

photographic processing solutions are given in Practice

Palladium 3242.70 0.001 to 0.005

E115E115.

Chromium 3021.56 0.0001 to 0.005

2835.63

8. Preparation of Standards

8.1 SilverNitrateStockSolution(1mL = 1gAg)—Dissolve Iron 3021.07 0.0001 to 0.005

2999.51 0.001 to 0.005

315.0 g of high-purity silver nitrate (AgNO ) in 150 mL of

water in a 200-mL volumetric flask and dilute to volume.

Nickel 3002.49 0.0001 to 0.005

8.2 Element Stock Solutions (1 mL = 0.5 mg of each 3050.82

element)—Dissolve 100 mg of each metal in 10 mL of nitric

Manganese 2801.06 0.0001 to 0.005

acid (HNO , 1 + 1); dissolve 770 mg of chromium nitrate

2798.27

[Cr(NO ) ·9 H O] and 308 mg of manganese sulfate monohy-

3 2 2

Tin 2839.99 0.0001 to 0.005

drate (MnSO ·H O) in 10 mL of water; combine element

4 2

2863.33

solutions in a 200-mLvolumetric flask and dilute with water to

Silver 3099.12 internal standard

volume.

8.2.1 Diluted Stock Solution—Make dilutions of the ele-

ment stock solutions with water to contain 0.05 mg and 0.005

10. Preparation of Apparatus

mg of each element.

8.2.2 Tin Stock Solution (1 mL = 0.5 mg Sn)—Dissolve 225

10.1 Electrode System—Firmly pack the dried silver nitrate

mg of sodium stannate (NaSnO ·3H O) in water in a 200-mL

powder level full into the crater of a preformed graphite

3 2

volumetric flask and dilute to volume.

electrode Type S-4 and insert in the lower electrode holder as

the anode. Insert a Type C-1 counter electrode in the upper

NO

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.