ASTM C889-99

(Test Method)Standard Test Methods for Chemical and Mass Spectrographic Analysis of Nuclear-Grade Gadolinium Oxide (Gd2O3) Powder

Standard Test Methods for Chemical and Mass Spectrographic Analysis of Nuclear-Grade Gadolinium Oxide (Gd<sub>2</sub>O<sub>3</sub>) Powder

SCOPE

1.1 These test methods cover procedures for the chemical and mass spectrographic analysis of nuclear-grade gadolinium oxide powders to determine compliance with specifications.

1.2 The analytical procedures appear in the following order: Sections Carbon by Direct Combustion---Thermal Conductivity 7 to 16 Total Chlorine and Fluorine by Pyrohydrolysis Ion- 17 to 23 Selective Electrode Loss of Weight on Ignition 24 to 30 Sulfur by Combustion---Iodometric Titration 31 to 38 Impurity Elements by a Spark-Source Mass Spectrographic 39 to 45 Gadolinium Content in Gadolinium Oxide by Impurity 46 to 49 Correction

1.2 This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C889–99

Standard Test Methods for

Chemical and Mass Spectrographic Analysis of Nuclear-

Grade Gadolinium Oxide (Gd O ) Powder

2 3

This standard is issued under the fixed designation C 889; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C 1287 Test Method for Determination of Impurities In

Uranium Dioxide By Inductively Coupled Plasma Mass

1.1 These test methods cover procedures for the chemical

Spectrometry

and mass spectrographic analysis of nuclear-grade gadolinium

D 1193 Specification for Reagent Water

oxide powders to determine compliance with specifications.

E 115 Practice for Photographic Processing in Optical

1.2 The analytical procedures appear in the following order:

Emission Spectrographic Analysis

Sections

E 116 Practice for Photographic Photometry in Spectro-

Carbon by Direct Combustion—Thermal Conductivity

C 1408 Test Method for Carbon (Total) in Uranium Oxide

chemical Analysis

Powders and Pel lets By Direct Combustion-Infrared Detec-

E 130 Practice for Designation of Shapes and Sizes of

tion Method

Graphite Electrodes

Total Chlorine and Fluorine by Pyrohydrolysis Ion— 7-13

Selective Electrode

C 1408 Test Method for Carbon (Total) in Uranium Oxide

Loss of Weight on Ignition 14-20

Powders and Pel lets By Direct Combustion-Infrared

Sulfur by Combustion—Iodometric Titration

Impurity Elements by a Spark-Source Mass Spectrographic Detection Method

C 761 Test Methods for Chemical, Mass Spectrometric,

Spectrochemical,Nuclear, and Radiochemical Analysis of

3. Significance and Use

Uranium Hexafluoride

C 1287 Test Method for Determination of Impurities In Ura- 3.1 Gadolinium oxide powder is used, with subsequent

nium Dioxide By Inductively Coupled Plasma Mass Spec-

processing, in nuclear fuel applications, such as an addition to

trometry

uranium dioxide.These test methods are designed to determine

Gadolinium Content in Gadolinium Oxide by Impurity 21-24

Correction whether the material meets the requirements described in

Specification C 888.

1.3 This standard does not purport to address all of the

3.1.1 The material is analyzed to determine whether it

safety concerns, if any, associated with its use. It is the

contains the minimum gadolinium oxide content specified.

responsibility of the user of this standard to establish appro-

3.1.2 The loss on ignition and impurity content are deter-

priate safety and health practices and determine the applica-

mined to ensure that the weight loss and the maximum

bility of regulatory limitations prior to use. For specific hazard

concentration limit of specified impurity elements are not

statements, see Section 5.

exceeded.

2. Referenced Documents

4. Reagents

2.1 ASTM Standards:

4.1 Purity of Reagents—Reagent grade chemicals shall be

C 696 Test Methods for Chemical, Mass Spectrometric, and

used in all tests. Unless otherwise indicated, it is intended that

Spectrochemical Analysis of Nuclear-Grade Uranium Di-

all reagents shall conform to the specifications of the Commit-

oxide Powders and Pellets

tee onAnalytical Reagents of theAmerican Chemical Society,

C 761 Test Methods for Chemical, Mass Spectrometric,

where such specifications are available. Other grades may be

Spectrochemical,Nuclear, and Radiochemical Analysis of

3 used, provided it is first ascertained that the reagent is of

Uranium Hexafluoride

sufficiently high purity to permit its use without lessening the

C 888 Specification for Nuclear-Grade Gadolinium Oxide

3 accuracy of the determination.

(Gd O ) Powder

2 3

1 4

These test methods are under the jurisdiction of ASTM Committee C-26 on Annual Book of ASTM Standards, Vol 11.01.

Nuclear Fuel Cycle and is the direct responsibility of Subcommittee C26.05 on Annual Book of ASTM Standards, Vol 03.05.

Methods of Test. “Reagent Chemicals,American Chemical Society Specifications,”Am. Chemi-

Current edition approved Jan. 10, 1999. Published March 1999. Originally cal Soc., Washington, DC. For suggestions on the testing of reagents not listed by

published as C 889 – 78. Last previous edition C 889 – 90. theAmerican Chemical Society, see “Reagent Chemicals and Standards,” by Joseph

Discontined January 1999. See C 889–90. Rosin, D. Van Nostrand Co., Inc., New York, NY, and the “United States

Annual Book of ASTM Standards, Vol 12.01. Pharmacopeia.”

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C889

4.2 Purity of Water—Unless otherwise indicated, references 9. Apparatus

to water shall be understood to mean reagent water as defined

9.1 Pyrohydrolysis Equipment—A suitable assembly of ap-

in Specification D 1193.

paratus as shown in Fig. 1.

9.1.1 Gas Flow Regulator and Flowmeter.

5. Hazards

9.1.2 Hot Plate, used to warm the water saturating the

5.1 Proper precautions should be taken to prevent inhalation sparge gas to 50 to 80°C.

or ingestion of gadolinium oxide powders or dust during 9.1.3 Combustion Tube Furnace, having a bore of about 32

grinding or handling operations. mm (1 ⁄4in.), a length of about 305 mm (12 in.), and the

5.2 Workers should observe precautions as specified in capability of maintaining a temperature of 1000°C.

vendor supplied Material Safety Data Sheets (MSDS).

9.1.4 Quartz Reaction Tube (Fig. 2)—The exit end should

not extend over 51 mm (2 in.) beyond the furnace with a

6. Sampling

ground joint connecting to the delivery tube. The delivery tube

extendsintoapolyethyleneabsorptionvesselwithatipcapable

6.1 Criteria for sampling this material are given in Specifi-

of giving a stream of fine bubbles.

cation C 888.

9.1.5 Combustion Boat—A ceramic, platinum, or quartz

boat with a 10-mL capacity, 89 to 102 mm (3 ⁄2 to 4 in.) long,

CARBON BY DIRECT COMBUSTION—

1 3

12.7 mm ( ⁄2 in.) wide, and 9.53 mm ( ⁄8 in.) high.

THERMAL CONDUCTIVITY

9.1.6 Absorption Vessel—A 50-mL polyethylene graduate

This Test Method was discontinued in January 1999 and

or tube is satisfactory.

replaced by C1408

9.2 Ion-Selective Electrodes—A chloride-ion-selective ac-

8 9

tivity electrode; fluoride-ion-selective activity electrode.

TOTAL CHLORINE AND FLUORINE BY

9.3 pH Meter and Double-Junction Reference Electrode,

PYROHYDROLYSIS ION—SELECTIVE ELECTRODE

such as a mercuric sulfate, sleeve junction type. The meter

should have an expandable scale with a sensitivity of 1 mV.

7. Scope

9.4 Magnetic Stirrer.

7.1 This test method covers the determination of chlorine

9.5 Beakers, 50-mL, polyethylene.

and fluorine in nuclear-grade gadolinium oxide (Gd O ) pow-

2 3

der.Witha1to 10-g sample of Gd O , concentrations of 5 to

10. Reagents

2 3

200 µg of chlorine and 1 to 200 µg of fluorine per gram of

10.1 Accelerator, U O (Halogen-free), can be used, but a

3 8

Gd O are determined without interference.

2 3

flux of sodium tungstate (Na WO ) with tungsten trioxide

2 4

(WO ) may be used to advantage (1). (See Method C 696.)

8. Summary of Test Method

Special preparation of the mixture is necessary, that is, dehy-

8.1 The halogens are separated from powdered gadolinium

drate 165 g of Na WO in a large platinum dish. Transfer the

2 4

oxide by pyrohydrolysis in a quartz tube with a stream of wet

dried material to a mortar, add 116 g of WO , and grind the

oxygen at a temperature of 900 to 1000°C (1, 2, 3, 4).

mixture to ensure good mixing. Transfer the mixture into a

Chlorine and fluorine are volatilized simultaneously as acids,

platinum dish and heat with a burner for 2 h. Cool the melt,

absorbed in a buffer solution as chloride and fluoride, and

transferthefluxtoamortar,andgrindtoacoarsepowder.Store

measured with ion-selective electrodes (4, 5, 6).

the flux in an airtight bottle. Mix about 8 g of flux with each

portion of sample to be pyrohydrolyzed.

The Orion Model No. 96–17 has been found satisfactory.

The Orion Model No. 9409 has been found satisfactory.

The boldface numbers in parentheses refer to the list of references appended to

this standard.

FIG. 1 Pyrohydrolysis of Gadolinium Oxide

C889

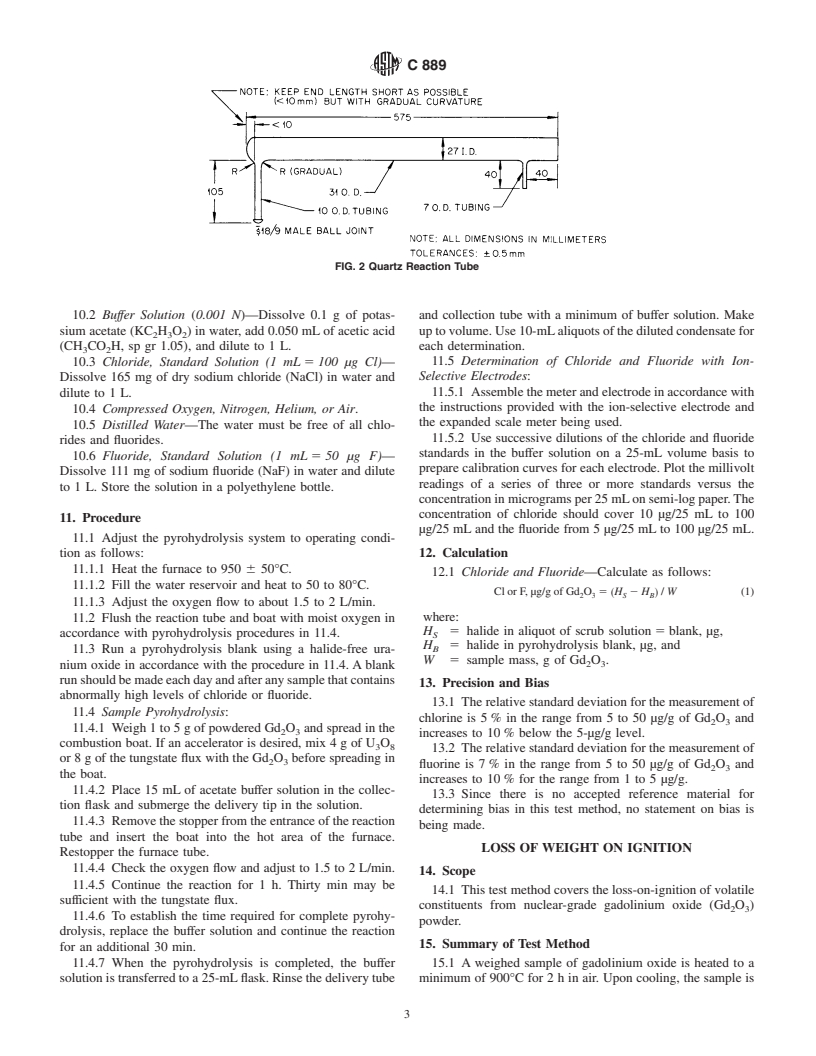

FIG. 2 Quartz Reaction Tube

10.2 Buffer Solution (0.001 N)—Dissolve 0.1 g of potas- and collection tube with a minimum of buffer solution. Make

sium acetate (KC H O ) in water, add 0.050 mL of acetic acid uptovolume.Use10-mLaliquotsofthedilutedcondensatefor

2 3 2

(CH CO H, sp gr 1.05), and dilute to 1 L. each determination.

3 2

11.5 Determination of Chloride and Fluoride with Ion-

10.3 Chloride, Standard Solution (1 mL 5 100 µg Cl)—

Dissolve 165 mg of dry sodium chloride (NaCl) in water and Selective Electrodes:

11.5.1 Assemble the meter and electrode in accordance with

dilute to 1 L.

the instructions provided with the ion-selective electrode and

10.4 Compressed Oxygen, Nitrogen, Helium, or Air.

the expanded scale meter being used.

10.5 Distilled Water—The water must be free of all chlo-

11.5.2 Use successive dilutions of the chloride and fluoride

rides and fluorides.

standards in the buffer solution on a 25-mL volume basis to

10.6 Fluoride, Standard Solution (1 mL 5 50 µg F)—

prepare calibration curves for each electrode. Plot the millivolt

Dissolve 111 mg of sodium fluoride (NaF) in water and dilu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.