ASTM F2168-13(2019)

(Specification)Standard Specification for Packing Material, Graphitic, Corrugated Ribbon or Textured Tape, and Die-Formed Ring

Standard Specification for Packing Material, Graphitic, Corrugated Ribbon or Textured Tape, and Die-Formed Ring

ABSTRACT

This specification covers various types, classes, and grades of flexible graphite material in which valve media temperatures are limited to a maximum temperature. The material shall be classified into two types, classes, and grades. Type I is a corrugated ribbon or textured tape, Type II is die-formed ring. Class 1 is for use where detrimental material content of the packing need not be controlled beyond normal manufacturing limit and Class 2 is for use where detrimental material content must be controlled to the limits specified herein. Grade A is treated with corrosion inhibitor and Grade B not treated with corrosion inhibitor. Different tests and measurements shall be conducted in order to determine the following properties: size, bulk density, ash content, and graphite purity.

SCOPE

1.1 Scope—This specification covers various types, classes, and grades of flexible graphite material in which valve media temperatures are limited to a maximum of 966°C. Where this specification is invoked as ASTM F2168, Sections 1 – 18 apply. Where this specification is invoked as ASTM/DoD F2168, Sections 1 – 18 and the Supplementary Requirements apply.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F2168 −13 (Reapproved 2019) An American National Standard

Standard Specification for

Packing Material, Graphitic, Corrugated Ribbon or Textured

Tape, and Die-Formed Ring

This standard is issued under the fixed designation F2168; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1246 Test Method for Bromide Ion in Water

D3178 Test Methods for Carbon and Hydrogen in the

1.1 Scope—This specification covers various types, classes,

Analysis Sample of Coal and Coke (Withdrawn 2007)

and grades of flexible graphite material in which valve media

D3684 Test Method for Total Mercury in Coal by the

temperatures are limited to a maximum of 966°C. Where this

Oxygen Bomb Combustion/Atomic Absorption Method

specification is invoked as ASTM F2168, Sections 1–18

(Withdrawn 2014)

apply. Where this specification is invoked as ASTM/DoD

D3761 Test Method for Total Fluorine in Coal by the

F2168, Sections1–18 and the Supplementary Requirements

Oxygen Bomb Combustion/Ion Selective Electrode

apply.

Method (Withdrawn 2019)

1.2 The values stated in SI units are to be regarded as

D3951 Practice for Commercial Packaging

standard. No other units of measurement are included in this

D4239 Test Method for Sulfur in the Analysis Sample of

standard.

Coal and Coke Using High-Temperature Tube Furnace

1.3 This international standard was developed in accor-

Combustion

dance with internationally recognized principles on standard-

3. Terminology

ization established in the Decision on Principles for the

3.1 Definitions:

Development of International Standards, Guides and Recom-

3.1.1 accordion crease, n—because of the method of con-

mendations issued by the World Trade Organization Technical

struction of die-formed rings, an accordion-like linear indica-

Barriers to Trade (TBT) Committee.

tion (crease) appear singularly or in multiple locations around

2. Referenced Documents

the inside and outside diameter surface.

2.1 ASTM Standards: 3.1.2 corrosion inhibitors, n—additives to the products to

function in a passive or sacrificial manner to reduce galvanic

C559 Test Method for Bulk Density by Physical Measure-

ments of Manufactured Carbon and Graphite Articles corrosion. These additives are typically embedded zinc

powder, phosphorus, or barium molybdate.

C561 Test Method for Ash in a Graphite Sample

C816 Test Method for Sulfur Content in Graphite by

3.1.3 corrugated ribbon, n—graphite ribbon or tape that is

Combustion-Iodometric Titration Method

subjected to mechanical pressure in a consistent manner to

C889 Test Methods for Chemical and Mass Spectrometric

apply surface indentations to the tape or ribbon.

Analysis of Nuclear-Grade Gadolinium Oxide (Gd O )

2 3

3.1.4 density, n—the mass per unit volume at a specified

Powder

temperature.

D129 Test Method for Sulfur in Petroleum Products (Gen-

3.1.5 detrimental materials, n—abrasive or chemically ac-

eral High Pressure Decomposition Device Method)

tiveconstituentssuchasashparticles(inhighashcontentfoils)

D512 Test Methods for Chloride Ion In Water

or elemental materials that cause galvanic action or corrosion

D1179 Test Methods for Fluoride Ion in Water

in long-term storage or service environments.

3.1.6 die-formed ring, n—a packing ring made by mechani-

This specification is under the jurisdiction of ASTM Committee F25 on Ships

cally compacting winds of graphite ribbon or braided packing

and Marine Technology and is the direct responsibility of Subcommittee F25.02 on

in a die or fixture.

Insulation/Processes.

3.1.7 lot, n—allfinishedpackingofonesize,type,class,and

Current edition approved Dec. 1, 2019. Published January 2020. Originally

approved in 2002. Last previous edition approved in 2013 as F2168 – 13. DOI:

grade produced in a continuous run or at the same time under

10.1520/F2168-13R19.

essentially the same conditions.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2168−13 (2019)

TABLE 1 Chemical and Physical Properties TABLE 2 Detrimental Materials (Class 2 Only (See 13.6))

Property Value Unit Test Maximum Total Allowable

Element Impurity Levels in Parts

Density, bulk as specified kg/m 13.5

per Million (ppm)

Ash 1 % by mass, max 13.3

Graphite purity 99 %, min 13.4 Mercury (Hg) 10

Sulfur (S) 750

Total halogens (chlorine, bromine, and fluorine) 500

Chlorine (Cl) 250

3.1.8 set, n—the packing components required to pack one

Bromine (Br) 250

Fluorine (F) 250

valve.

3.1.9 size, n—the physical dimensions of the packing mate-

rial.

4. Classification

6.1.3 Coating and Corrosion-Inhibiting Treatments:

4.1 Classification—The material shall be of the following

6.1.3.1 Grade A—GradeApacking shall be provided with a

types, classes, and grades as specified (see Section 5).

powdered zinc active corrosion-inhibiting treatment or a pas-

4.1.1 Type I—Corrugated ribbon or textured tape.

sive inhibiting treatment such as phosphorous or barium

4.1.2 Type II—Die-formed ring.

molybdate, as specified (see Section 5). When the use of

4.1.3 Class 1—For use where detrimental material content

inhibitors is required, both passive and active inhibitors shall

of the packing need not be controlled beyond normal manu-

be permitted to be used.

facturing limit (commercial grade).

6.1.3.2 Grade B—Grade B packing shall not contain

4.1.4 Class 2—For use where detrimental material content

corrosion-inhibiting additives.

shall be controlled to the limits specified herein.

6.1.4 Mercury Exclusion—During manufacturing,

4.1.5 Grade A—Treated with corrosion inhibitor.

fabrication, handling, packaging, and packing, the packing

4.1.6 Grade B—No corrosion inhibitor.

material shall not come in contact with mercury or mercury

5. Ordering Information containing compounds.

5.1 Contracts or orders for the units under this specification

7. Properties

shall include the following information:

5.1.1 Title, number, and date of this specification. 7.1 Chemical and Physical Properties—Unless otherwise

5.1.2 Type, class, and grade.

specified, the properties of the finished packing shall conform

5.1.3 Type of corrosion inhibitor (see 6.1.3 and Supplemen- to the requirements of Table 1. Class 2 also requires compli-

tary Requirements). ance with Table 2.

5.1.4 Specify density of die-formed rings.

7.2 Prohibited Additions—There shall be no intentional

5.1.5 Inspection, testing, and certification of the material

additions of any of the detrimental materials of Table 2 or

shall be agreed upon between the purchaser and the supplier as

antimony (Sb), arsenic (As), bismuth (Bi), cadmium (Cd),

part of the purchase contract (see Sections 14 and 16).

gallium(Ga),indium(In),lead(Pb),mercury(Hg),silver(Ag),

5.1.6 When die-formed (Type II) packing rings are desired,

or tin (Sn) during the manufacturing, fabrication, handling,

the ring height, inside diameter, outside diameter, number of

packaging, and packing of the product.

cuts, and number of packing rings required per set (see 9.2 and

9.3).

8. Other Requirements

5.1.7 Marking requirements (see Section 17 and Supple-

8.1 No other requirements noted.

mentary Requirements).

5.1.8 Packaging requirements (see Section 18 and Supple-

9. Dimensions, Mass, and Permissible Variations

mentary Requirements).

5.1.9 Application data (to include operating pressure, oper-

9.1 Type I Ribbon Packing—Unless otherwise specified (see

ating temperature, and media).

Section 5), the packing shall be uniformly coiled, spooled, or

5.1.10 Specify thickness of Type I.

reeled in accordance with Table 3.

6. Materials and Manufacture 9.2 Type II Die-Formed Packing—Unless otherwise speci-

fied (see Section 5), the tolerances for Type II packing shall be

6.1 Material—Requirements specified herein apply to Class

in accordance with Table 4. The tolerance applies to finished

1 and Class 2 and GradeAand Grade B packing, except where

rings before any cutting operations.

noted.

6.1.1 Type I—The packing shall be made entirely of flexible 9.3 Split Rings—The number of cuts (zero, one, or two)

graphitic material having no binders and meeting the require-

shall be as specified (see Section 5). Cuts shall be made at

ments of Tables 1 and 2. approximately a 45° angle such that an overlapping joint is

6.1.2 Type II—Die-formed packing rings shall be manufac-

formed in the compressed state. When two cuts are required

tured from flexible graphitic material conforming to the re- (separating the ring into two parts), the resulting parts shall be

quirements of Tables 1 and 2.

approximately the same dimension. When the number of cuts

is not specified, single-cut rings shall be provided.

F2168−13 (2019)

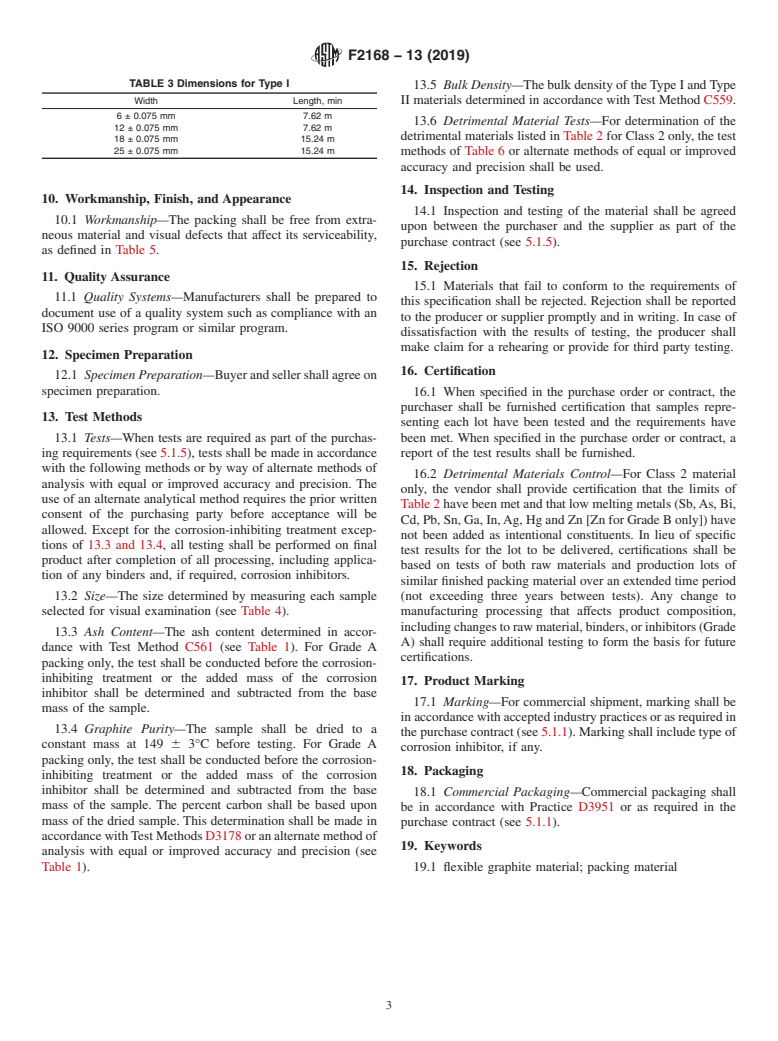

TABLE 3 Dimensions for Type I

13.5 Bulk Density—The bulk density of theType I andType

Width Length, min II materials determined in accordance with Test Method C559.

6 ± 0.075 mm 7.62 m

13.6 Detrimental Material Tests—For determination of the

12 ± 0.075 mm 7.62 m

detrimental materials listed in Table 2 for Class 2 only, the test

18 ± 0.075 mm 15.24 m

25 ± 0.075 mm 15.24 m

methods of Table 6 or alternate methods of equal or improved

accuracy and precision shall be used.

14. Inspection and Testing

10. Workmanship, Finish, and Appearance

14.1 Inspection and testing of the material shall be agreed

10.1 Workmanship—The packing shall be free from extra-

upon between the purchaser and the supplier as part of the

neous material and visual defects that affect its serviceability,

purchase contract (see 5.1.5).

as defined in Table 5.

15. Rejection

11. Quality Assurance

15.1 Materials that fail to conform to the requirements of

11.1 Quality Systems—Manufacturers shall be prepared to

this specification shall be rejected. Rejection shall be reported

document use of a quality system such as compliance with an

to the producer or supplier promptly and in writing. In case of

ISO 9000 series program or similar program.

dissatisfaction with the results of testing, the producer shall

make claim for a rehearing or provide for third party testing.

12. Specimen Preparation

16. Certification

12.1 Specimen Preparation—Buyerandsellershallagreeon

specimen preparation.

16.1 When specified in the purchase order or contract, the

purchaser shall be furnished certification that samples repre-

13. Test Methods

senting each lot have been tested and the requirements have

13.1 Tests—When tests are required as part of the purchas- been met. When specified in the purchase order or contract, a

ing requirements (see 5.1.5), tests shall be made in accordance report of the test results shall be furnished.

with the following methods or by way of alternate methods of

16.2 Detrimental Materials Control—For Class 2 material

analysis with equal or improved accuracy and precision. The

only, the vendor shall provide certification that the limits of

use of an alternate analytical method requires the prior written

Table 2 have been met and that low melting metals (Sb,As, Bi,

consent of the purchasing party before acceptance will be

Cd, Pb, Sn, Ga, In,Ag, Hg and Zn [Zn for Grade B only]) have

allowed. Except for the corrosion-inhibiting treatment excep-

not been added as intentional constituents. In lieu of specific

tions of 13.3 and 13.4, all testing shall be performed on final

test results for the lot to be delivered, certifications shall be

product after completion of all processing, including applica-

based on tests of both raw materials and production lots of

tion of any binders and, if required, corrosion inhibitors.

similar finished packing material over an extended time period

13.2 Size—The size determined by measuring each sample (not exceeding three years between tests). Any change to

manufacturing processing that affects product composition,

selected for visual examination (see Table 4).

includingchangestorawmaterial,binders,orinhibitors(Grade

13.3 Ash Content—The ash content determined in accor-

A) shall require additional testing to form the basis for future

dance with Test Method C561 (see Table 1). For Grade A

certifications.

packing only, the test shall be conducted before the corrosion-

inhibiting treatment or the added mass of the corrosion

17. Product Marking

inhibitor shall be determined and subtracted from the base

17.1 Marking—For commercial shipment, marking shall be

mass of the sample.

inaccordancewithacceptedindustrypracticesorasrequiredin

13.4 Graphite Purity—The sample shall be dried to a

the purchase contract (see 5.1.1). Marking shall include type of

constant mass at 149 6 3°C before testing. For Grade A

corrosion inhibitor, if any.

packing only, the test shall be conducted before the corrosion-

18. Packaging

inhibiting treatment or the added mass of the corrosion

inhibitor shall be determined and subtracted from the base

18.1 Commercial Packaging—Commercial packaging shall

mass of the sample. The percent carbon shall be based upon

be in accordance with Practice D3951 or as required in the

mass of the dried sample. This determination shall be made in

purchase contract (see 5.1.1).

accordancewithTestMethodsD3178oranalternatemethodof

19. Keywords

analysis with equal or improved accuracy and precision (see

Table 1). 19.1 flexible graphite material; packing material

F2168−13 (2019)

TABLE 4 Tolerances for Type II Packing

Inside Diameter (i.d.) Outside Diameter (o.d.) Thickness

+0.25 mm +0.000 mm ±0.50 mm

to 25 mm o.d.

-0.000 mm -0.25 mm

+0.38 mm +0.000 mm ±0.75 mm

25 mm and above o.d.

-0.000 mm -0.38 mm

TABLE 5 Classification of Visual Defects

Item Category—Major

Type I corrugated ribbon or textured tape Void.

Rip or tear in ribbon.

Particulate or extraneous matter on surface that is not easily removed without damaging the packing.

Noncontinuous length (no joints).

Lack of corrugation or textured surface area.

Creasing or crimping.

Type II die-formed rings Holes or voids.

Particulate or extraneous matter on surface that is not easily removed without damaging the packing.

Delaminations (laminated rings).

Gouges (minor indentations less than 0.12 mm in depth resulting from normal prod

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.