ASTM D6041-97(2002)

(Specification)Standard Specification for Contact-Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) Corrosion Resistant Pipe and Fittings (Withdrawn 2011)

Standard Specification for Contact-Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) Corrosion Resistant Pipe and Fittings (Withdrawn 2011)

ABSTRACT

This specification covers contact-molded “fibreglass” (glass-fiber-reinforced thermosetting resin) corrosion resistant pipe and fittings. The laminate comprising the pipe wall shall consist of a corrosion barrier comprised of an inner surface and interior layer, a structural layer, and an outer surface. Test conditions, chemical resistance of resin, glass content, tensile strength, short-time hydraulic failure pressure, and physical properties tests shall be performed to conform to the specific requirements.

SCOPE

1.1 This specification covers pipe and fittings fabricated by contact molding, for pressures to 150 psi and made of a commercial-grade polyester resin. Included are requirements for materials, properties, design, construction, dimensions, tolerances, workmanship, and appearance.

1.2 This specification does not cover resins other than polyester, reinforcing materials other than glass fibers or fabrication methods other than contact molding.

Note 1—For the purposes of this specification, the term polyester resin will include both polyester and vinylester resins.

1.3 This specification does not cover the design of pipe and fittings intended for use with liquids heated above their flash points.

1.4 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are provided for information purposes only.

1.5 The following precautionary caveat pertains only to Section 10, the test methods portion, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 2—There is no similar or equivalent ISO standard.

WITHDRAWN RATIONALE

This specification covered pipe and fittings fabricated by contact molding, for pressures to 150 psi and made of a commercial-grade polyester resin. Included were requirements for materials, properties, design, construction, dimensions, tolerances, workmanship, and appearance.

Formerly under the jurisdiction of Committee D20 on Plastics, this specification was withdrawn in January 2011 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D6041 – 97 (Reapproved 2002)

Standard Specification for

Contact-Molded “Fiberglass” (Glass-Fiber-Reinforced

Thermosetting Resin) Corrosion Resistant Pipe and

Fittings

This standard is issued under the fixed designation D6041; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Structures Intended for Liquid Service

C582 Specification for Contact-Molded Reinforced Ther-

1.1 This specification covers pipe and fittings fabricated by

mosettingPlastic(RTP)LaminatesforCorrosion-Resistant

contact molding, for pressures to 150 psi and made of a

Equipment

commercial-grade polyester resin. Included are requirements

D618 Practice for Conditioning Plastics for Testing

for materials, properties, design, construction, dimensions,

D638 Test Method for Tensile Properties of Plastics

tolerances, workmanship, and appearance.

D883 Terminology Relating to Plastics

1.2 This specification does not cover resins other than

D1599 TestMethodforResistancetoShort-TimeHydraulic

polyester, reinforcing materials other than glass fibers or

Pressure of Plastic Pipe, Tubing, and Fittings

fabrication methods other than contact molding.

D1600 Terminology for Abbreviated Terms Relating to

NOTE 1—Forthepurposesofthisspecification,thetermpolyesterresin

Plastics

will include both polyester and vinylester resins.

D2583 Test Method for Indentation Hardness of Rigid

1.3 This specification does not cover the design of pipe and

Plastics by Means of a Barcol Impressor

fittings intended for use with liquids heated above their flash

D2584 Test Method for Ignition Loss of Cured Reinforced

points.

Resins

1.4 Thevaluesstatedininch-poundunitsaretoberegarded

D3567 Practice for Determining Dimensions of “Fiber-

as the standard.The SI units given in parentheses are provided

glass” (Glass-Fiber-ReinforcedThermosetting Resin) Pipe

for information purposes only.

and Fittings

1.5 The following precautionary caveat pertains only to

D3681 Test Method for Chemical Resistance of “Fiber-

Section 10, the test methods portion, of this specification: This

glass” (Glass−Fiber−Reinforced Thermosetting-Resin)

standard does not purport to address all of the safety concerns,

Pipe in a Deflected Condition

if any, associated with its use. It is the responsibility of the user

D5421 Specification for Contact Molded “Fiberglass”

of this standard to establish appropriate safety and health

(Glass-Fiber-Reinforced Thermosetting Resin) Flanges

practices and determine the applicability of regulatory limita-

F412 Terminology Relating to Plastic Piping Systems

tions prior to use.

2.2 ANSI Standards:

B16.1 Cast Iron Pipe Flanges and Flanged Fittings

NOTE 2—There is no similar or equivalent ISO Standard.

B16.5 Pipe Flanges and Flanged Fittings

2. Referenced Documents

B18.22 Type “B” Narrow Washers

2.3 National Sanitation Foundation Standard:

2.1 ASTM Standards:

NSF Standard 61 Drinking Water System Components—

C581 Practice for Determining Chemical Resistance of

Health Effects

Thermosetting Resins Used in Glass-Fiber-Reinforced

3. Terminology

This specification is under the jurisdiction of ASTM Committee D20 on

3.1 Definitions:

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced

3.1.1 General—Definitions are in accordance with Termi-

Plastic Piping Systems and Chemical Equipment.

nology D883 and Terminology F412 and abbreviations are in

Current edition approved Nov. 10, 2002. Published March 2003. Originally

approved in 1996. Last previous edition approved in 1997 as D6041–97. DOI:

10.1520/D6041-97R02.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

Standards volume information, refer to the standard’s Document Summary page on Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd.,Ann

the ASTM website. Arbor, MI 48113-0140, http://www.nsf.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6041 – 97 (2002)

improve the flame retardancy of non-halogenated resins.

accordance with Terminology D1600, unless otherwise indi-

cated.The abbreviation for reinforced thermosetting resin pipe

4.1.3 Ultraviolet Absorbers may be added for improved

is RTRP.

weather resistance when agreed upon between the manufac-

3.2 Definitions of Terms Specific to This Standard:

turer and the purchaser.

3.2.1 contact molding, n—a process for molding reinforced

4.1.4 Resin Pastes, used where necessary to fill crevices at

plasticsinwhichreinforcementandresinareplacedonanopen

joints prior to applying the joint laminate shall not be subject

mold or mandrel by either the “hand lay-up”(where resin and

to the limitations of 4.1.3. Pastes shall be made with resin and

glass mat are applied by hand), or the “spray-up” manufactur-

fillers.The resin used in the paste must be compatible with the

ingprocesses(whereresinandchoppedglassfibersaresprayed

resin used in the pipe and fittings.

under pressure), or a combination of the two. The resulting

4.2 Fiber Reinforcements:

laminate is then consolidated by rolling and cured without the

4.2.1 Surfacing Mat (Veil) is a thin mat of fine fibers used

application of pressure.

primarily to produce a smooth and corrosion–resistant resin-

3.2.2 fiberglass pipe, n—a tubular product containing glass

–rich surface on a reinforced plastic laminate.

fiber reinforcements embedded in or surrounded by cured

4.2.1.1 Veils are made from chemical resistant (type “C”)

thermosetting resin. The composite structure may contain

glass or organic fiber. The use of an organic-fiber surface mat

granular or platelet fillers, thixotropic agents, pigments, or

is recommended for environments that attack glass. The veil

dyes. Thermoplastic or thermosetting liners may be included.

used in a laminate shall be determined to be acceptable for the

3.2.3 polyester,n—resinsproducedbythepolycondensation

chemical service either by Practice C581 or by verified case

of dihydroxy glycols and dibasic organic acids or anhydrides,

history.

wherein at least one component contributes ethylenic unsat-

4.2.1.2 The veil shall be a minimum of 10 mils in dry

uration yielding resins that can be compounded with styrol

thicknessandproduceathicknessof0.010to0.020in.(0.25to

monomers and reacted to give highly crosslinked thermoset

0.50 mm) when saturated with resin.

copolymers.

NOTE 8—The primary chemical resistance of the RTR pipe is provided

3.2.4 vinyl ester, n—resins characterized by reactive unsat-

by the resin. In combination with the cured resin, the surfacing veil helps

uration located predominately in terminal positions that can be

determinethethicknessoftheresin-richlayer,andreducesmicrocracking.

compounded with styrol monomers and reacted to give highly

4.2.2 Chopped-strand Reinforcements shall be “E”-type or

crosslinked thermoset copolymers.

“ECR”-type glass fibers 1 to 2 in. (25 to 50 mm) long applied

4. Materials and Manufacture in a uniform layer with random orientation. The fibers shall

have a sizing compatible with the selected resin. Chopped

NOTE 3—Specification C582 provides additional information on the

strand reinforcements may be purchased and applied as a mat

materials and manufacturing of contact–molded laminates.

or as continuous strand roving which is chopped into short

NOTE 4—Fiberglass pipe intended for use in the transport of potable

lengths and sprayed onto the laminate in a process known as

watershouldbeevaluatedandcertifiedassafeforthispurposebyatesting

agency acceptable to the local health authority. The evaluation should be

“spray up.” Either form is most commonly applied in layers

2 2

in accordance with requirements for chemical extraction, taste, and odor

weighing 1 ⁄2 oz/ft (450g/m ) although other weights are

that are no less restrictive than those included in National Sanitation

available and may be used.

Foundation(NSF)Standard61.Thesealormarkofthelaboratorymaking

4.2.3 Woven Roving, shall be “E”-type or “ECR”-type glass

the evaluation should be included on the fiberglass pipe.

roving, woven into a fabric. The sizing on the roving shall be

4.1 Resin System:

compatible with the resin. The most common woven roving

4.1.1 Theresinusedshallbeacommercialgrade,corrosion- 2 2

hasa5by4 weave and a weight of 24 oz/yd (832 g/m ).

resistant polyester that has been determined to be acceptable

4.2.4 Non-woven Roving “E type or “ECR” glass reinforc-

for the service either by test, (see Practice C581), or by

ingfabricssuchasbiaxialsanduni-directionalsmaybeusedin

previous documented service. Where service conditions have

special applications such as reinforcing tees and other fittings

not been evaluated a suitable resin may also be selected by

or to improve the physical properties of the laminate in a

agreement between manufacturer and purchaser.

specific direction.

4.1.1.1 The use of one resin in the corrosion barrier and a

4.2.5 Multiple Layer Reinforcements are fabrics composed

different resin in the structural layer (see Section 6) is permit-

of two or more layers of reinforcement combined into one

ted with the acceptance of the purchaser. 2

fabric. The most common form is one layer of 1 ⁄2 oz/ft

4.1.2 Additives, such as additional styrene, fillers, dyes, 2

chopped strand mat combined with one layer of 24 oz/yd

pigments, or flame retardants may be used when agreed upon

wovenroving.Thepipemanufacturermustuseextracautionto

between the fabricator and purchaser. Thixotropic agents may

ensure proper laminate quality is maintained when using

be added to the resin for viscosity control.

multiple layer reinforcements.

NOTE 5—The addition of fillers, dyes, pigments, flame retardants, and

thixotropicagentsmayinterferewithvisualinspectionoflaminatequality. 5. Design

NOTE 6—Chemical resistance can be affected by the catalyst/promoter

5.1 Design Basis:

system, diluents, dyes, fillers, flame retardants, or thixotropic agents used

5.1.1 Class A—For pipe to be manufactured usingType I or

in the resin.

Type II laminates as described in Specification C582, the

NOTE 7—Antimony compounds or other fire-retardant agents may be

UltimateTensile Stresses shown in Specification C582 may be

added to halogenated resins for improved fire resistance, if agreed upon

between the manufacturer and the purchaser. These compounds do not used for the design basis.

D6041 – 97 (2002)

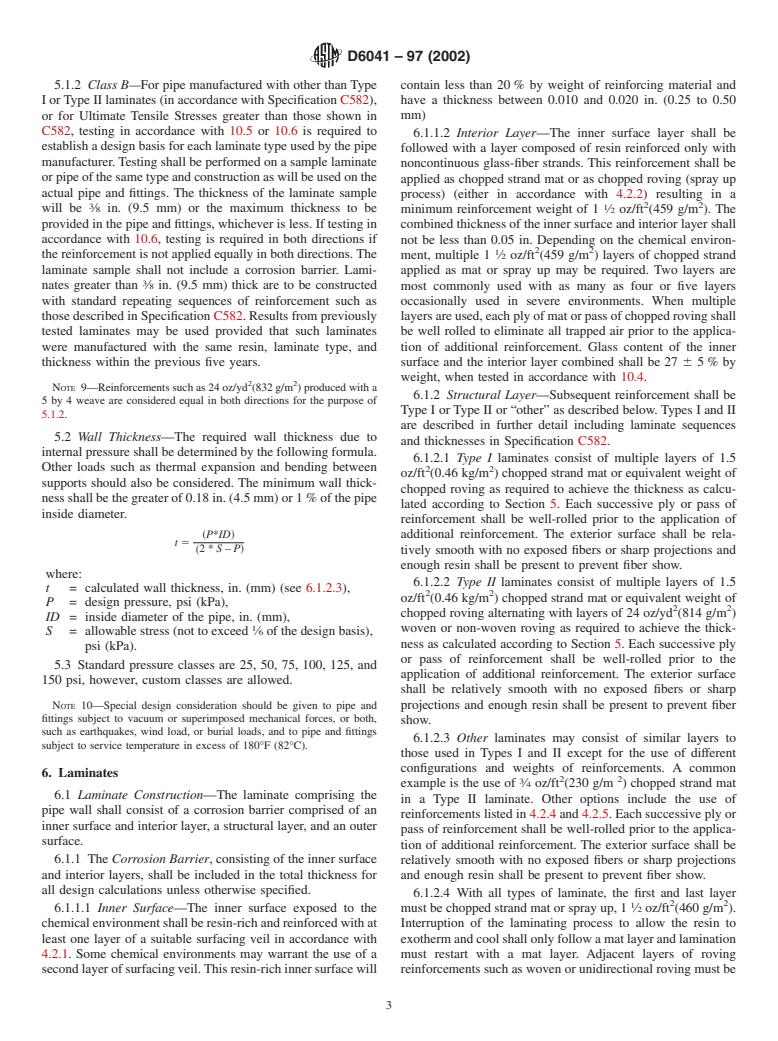

5.1.2 Class B—For pipe manufactured with other thanType contain less than 20% by weight of reinforcing material and

IorTypeIIlaminates(inaccordancewithSpecificationC582), have a thickness between 0.010 and 0.020 in. (0.25 to 0.50

or for Ultimate Tensile Stresses greater than those shown in mm)

C582, testing in accordance with 10.5 or 10.6 is required to

6.1.1.2 Interior Layer—The inner surface layer shall be

establishadesignbasisforeachlaminatetypeusedbythepipe

followed with a layer composed of resin reinforced only with

manufacturer.Testingshallbeperformedonasamplelaminate

noncontinuous glass-fiber strands. This reinforcement shall be

orpipeofthesametypeandconstructionaswillbeusedonthe

applied as chopped strand mat or as chopped roving (spray up

actual pipe and fittings. The thickness of the laminate sample

process) (either in accordance with 4.2.2) resulting in a

2 2

will be ⁄8 in. (9.5 mm) or the maximum thickness to be

minimum reinforcement weight of 1 ⁄2 oz/ft (459 g/m ). The

providedinthepipeandfittings,whicheverisless.Iftestingin combinedthicknessoftheinnersurfaceandinteriorlayershall

accordance with 10.6, testing is required in both directions if

not be less than 0.05 in. Depending on the chemical environ-

2 2

thereinforcementisnotappliedequallyinbothdirections.The ment, multiple 1 ⁄2 oz/ft (459 g/m ) layers of chopped strand

laminate sample shall not include a corrosion barrier. Lami-

applied as mat or spray up may be required. Two layers are

nates greater than ⁄8 in. (9.5 mm) thick are to be constructed most commonly used with as many as four or five layers

with standard repeating sequences of reinforcement such as

occasionally used in severe environments. When multiple

thosedescribedinSpecificationC582.Resultsfrompreviously layersareused,eachplyofmatorpassofchoppedrovingshall

tested laminates may be used provided that such laminates be well rolled to eliminate all trapped air prior to the applica-

were manufactured with the same resin, laminate type, and tion of additional reinforcement. Glass content of the inner

surface and the interior layer combined shall be 27 65%by

thickness within the previous five years.

weight, when tested in accordance with 10.4.

2 2

NOTE 9—Reinforcementssuchas24oz/yd (832g/m )producedwitha

6.1.2 Structural Layer—Subsequent reinforcement shall be

5 by 4 weave are considered equal in both directions for the purpose of

Type I orType II or “other” as described below.Types I and II

5.1.2.

are described in further detail including laminate sequences

5.2 Wall Thickness—The required wall thickness due to

and thicknesses in Specification C582.

internalpressureshallbedeterminedbythefollowingformula.

6.1.2.1 Type I laminates consist of multiple layers of 1.5

Other loads such as thermal expansion and bending between 2 2

oz/ft (0.46 kg/m ) chopped strand mat or equivalent weight of

supports should also be considered. The minimum wall thick-

chopped roving as required to achieve the thickness as calcu-

nessshallbethegreaterof0.18in.(4.5mm)or1%ofthepipe

lated according to Section 5. Each successive ply or pass of

inside diameter.

reinforcement shall be well-rolled prior to the application of

~P*ID!

additional reinforcement. The exterior surface shall be rela-

t 5

~2* S– P!

tively smooth with no exposed fibers or sharp projections and

enough resin shall be present to prevent fiber show.

where:

6.1.2.2 Type II laminates consist of multiple layers of 1.5

t = calculated wall thickness, in. (mm) (see 6.1.2.3),

2 2

oz/ft (0.46 kg/m ) chopped strand mat or equivalent weight of

P = design pressure, psi (kPa),

2 2

chopped roving alternating with layers of 24 oz/yd (814 g/m )

ID = inside diameter of the pipe, in. (mm),

1 woven or non-woven roving as required to achieve the thick-

S = allowablestress(nottoexceed ⁄6ofthedesignbasis),

ness as calculated according to Section 5. Each successive ply

psi (kPa).

or pass of reinforcement shall be well-rolled prior to the

5.3 Standard pressure classes

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.