ASTM D4854-95(2001)

(Guide)Standard Guide for Estimating the Magnitude of Variability from Expected Sources in Sampling Plans (Withdrawn 2009)

Standard Guide for Estimating the Magnitude of Variability from Expected Sources in Sampling Plans (Withdrawn 2009)

SIGNIFICANCE AND USE

This guide is useful in estimating the variation due to lot sampling units, laboratory sampling units, and specimen selection and testing during the sampling and testing of a lot of material.

Estimates of variation from the several sources will make it possible to write sampling plans which balance the cost of sampling and testing with the desired precision of the plan.

This guide is useful in: (1) designing process controls and (2) developing sampling plans as parts of product specifications.

This guide can be used for designing new sampling plans or for improving old plans.

This guide is concerned with the process of sampling. This is unlike Practice D 2904 or Practice D 4467 which are concerned with the process of testing.

Studies based on this guide are applicable only to the material(s) on which the studies are made. If the conclusions are to be used for a specification, then separate studies should be made on three or more kinds of materials of the type on which the test method may be used and which produce test results covering the range of interest.

SCOPE

1.1 This guide serves as an aid to subcommittees in writing specifications and sampling procedures.

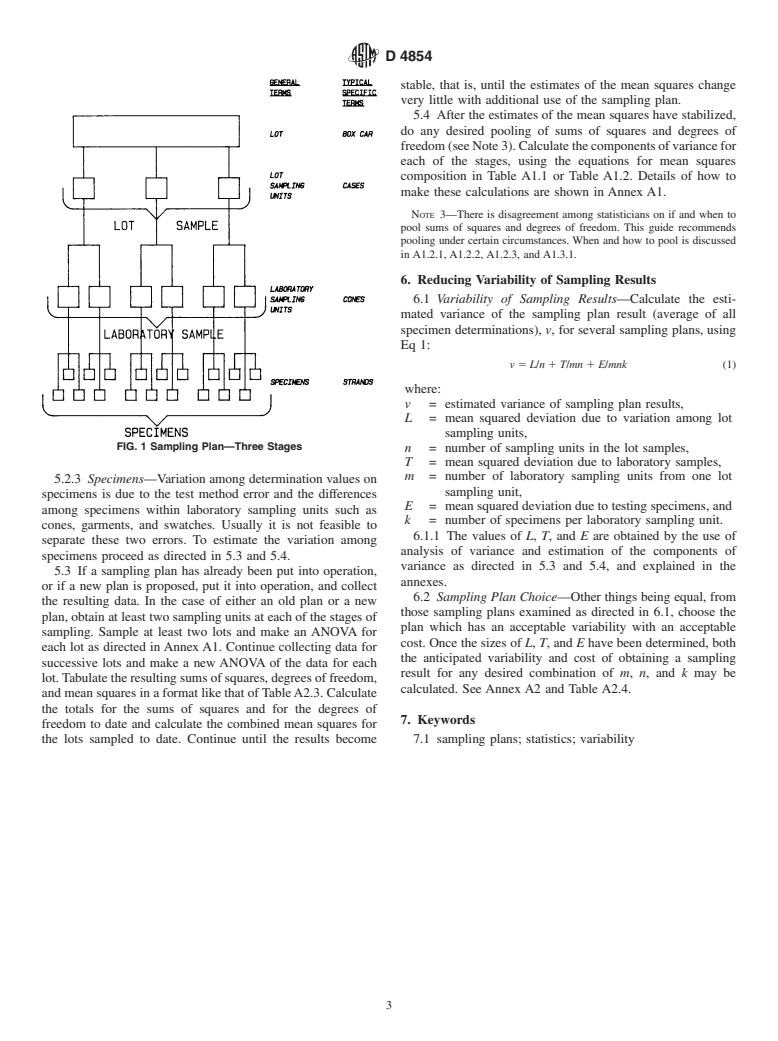

1.2 The guide explains how to estimate the contributions of the variability of lot sampling units, laboratory sampling units, and specimens to the variation of the test result of a sampling plan.

1.3 The guide explains how to combine the estimates of the variability from the three sources to obtain an estimate of the variability of the sampling plan results.

1.4 The guide is applicable to all sampling plans that produce variables data (Note 1). It is not applicable to plans that produce attribute data, since such plans do not take specimens in stages, but require that specimens be taken at random from all of the individual items in the lot. Note 0This guide is applicable to all sampling plans that produce variables data regardless of the kind of frequency distribution of these data, because no estimates are made of any probabilities.

1.5 This guide includes the following topics:Topic TitleSectionNumberScope1Referenced Documents2Terminology3Significance and Use4Sampling Plans Producing Variables Data5Reducing Variability of Sampling Results6Keywords 7Analysis of Data Using ANOVAAnnex A1A Numerical ExampleAnnex A2

WITHDRAWN RATIONALE

This guide serves as an aid to subcommittees in writing specifications and sampling procedures.

Formerly under the jurisdiction of Committee D13 on Textiles, this guide was withdrawn in March 2009 because D13 no longer has the expertise to maintain and statistical standards are being maintained by committee E11.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4854 – 95 (Reapproved 2001)

Standard Guide for

Estimating the Magnitude of Variability from Expected

1

Sources in Sampling Plans

This standard is issued under the fixed designation D4854; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D4271 PracticeforWritingStatementsonSamplinginTest

3

Methods for Textiles

1.1 This guide serves as an aid to subcommittees in writing

D4467 Practice for InterlaboratoryTesting of aTextileTest

specifications and sampling procedures.

3

Method that Produces Non-Normally Distributed Data

1.2 The guide explains how to estimate the contributions of

4

E456 Terminology Relating to Quality and Statistics

the variability of lot sampling units, laboratory sampling units,

2.2 ASTM Adjuncts:

and specimens to the variation of the test result of a sampling

5

TEX-PAC

plan.

1.3 The guide explains how to combine the estimates of the

NOTE 2—Tex-Pac is a group of PC programs on floppy disks, available

variability from the three sources to obtain an estimate of the throughASTM Headquarters, 100 Barr Harbor Drive, Conshohocken, PA

19428, USA. The calculations described in the annexes of this guide,

variability of the sampling plan results.

including the cost comparisons of various sampling plans, can be

1.4 The guide is applicable to all sampling plans that

conducted using one of these programs.

produce variables data (Note 1). It is not applicable to plans

that produce attribute data, since such plans do not take

3. Terminology

specimens in stages, but require that specimens be taken at

3.1 Definitions:

random from all of the individual items in the lot.

3.1.1 analysis of variance (ANOVA), n—a procedure for

NOTE 1—This guide is applicable to all sampling plans that produce

dividing the total variation of a set of data into two or more

variables data regardless of the kind of frequency distribution of these

parts, one of which estimates the error due to selecting and

data, because no estimates are made of any probabilities.

testing specimens and the other part(s) possible sources of

1.5 This guide includes the following topics:

additional variation.

Section 3.1.2 attribute data, n—observed values or determinations

Topic Title

Number

which indicate the presence or absence of specific character-

Scope 1

istics.

Referenced Documents 2

Terminology 3 3.1.3 component of variance, n—a part of a total variance

Significance and Use 4

identified with a specific source of variability.

Sampling Plans Producing Variables Data 5

3.1.4 degrees of freedom, n—for a set,thenumberofvalues

Reducing Variability of Sampling Results 6

Keywords 7 that can be assigned arbitrarily and still get the same value for

Analysis of Data Using ANOVA Annex A1

each of one or more statistics calculated from the set of data.

A Numerical Example Annex A2

3.1.4.1 Discussion— For example, if only an average is

2. Referenced Documents specifiedforasetoffiveobservations,therearefourdegreesof

freedom since the same average can be obtained with any

2.1 ASTM Standards:

2

values substituted for four of the observations as long as the

D123 Terminology Relating to Textiles

fifth value is set to give the correct total. If both the average

D2904 Practice for InterlaboratoryTesting of aTextileTest

2

andstandarddeviationhavebeenspecified,thereareonlythree

Method that Produces Normally Distributed Data

degrees of freedom left.

1

This guide is under the jurisdiction of ASTM Committee D13 on Textiles and

3

is the direct responsibility of Subcommittee D13.93 on Statistics. Annual Book of ASTM Standards, Vol 07.02.

4

Current edition approved May 15, 1995. Published July 1995. Originally Annual Book of ASTM Standards, Vol 14.02.

5

1

published as D4854–88. Last previous edition D4854–91. PC programs on floppy disks are available throughASTM. For a 3 ⁄2 inch disk

2

1

Annual Book of ASTM Standards, Vol 07.01. request PCN:12-429040-18, for a 5 ⁄4 inch disk request PCN:12-429041-18.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 4854

2

3.1.5 determination value, n—the numerical quantity calcu- 3.1.20 variance, s , n—of a population, a measure of the

lated by means of the test method equation from the measure- dispersion of members of the population expressed as a

ment values obtained as directed in a test method. (Syn. function of the sum of the squared deviations from the

determination) (See also observation.) population mean.

2

3.1.21 variance, s , n—of a sample, a measure of the

3.1.6 laboratory sample, n—a po

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.