ASTM C1256-93(2013)

(Practice)Standard Practice for Interpreting Glass Fracture Surface Features

Standard Practice for Interpreting Glass Fracture Surface Features

SIGNIFICANCE AND USE

5.1 Fractography is often used to help identify the events that have resulted in the fracture of a glass object. This practice defines the appearance of various fracture surface features, as well as their method of formation. Thus, there can be a common understanding of their relationship to the fracture process as well as a common terminology.

SCOPE

1.1 Fracture features on the surface of a crack reflect the nature and course of the fracture event associated with the breakage of a glass object. This practice is a guide to the identification and interpretation of these fracture surface features.

1.2 The practice describes the various fracture surface features as to their appearance, the process of formation and their significance.

1.3 The practice does not provide the procedural information necessary for a complete fractographic analysis. Such information is available in the general literature. (See Glossary for suggested literature).

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1256 − 93 (Reapproved 2013)

Standard Practice for

Interpreting Glass Fracture Surface Features

This standard is issued under the fixed designation C1256; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.5 fracture mirror radius—a dimension of the fracture

mirror as measured along the original specimen surface. It is

1.1 Fracture features on the surface of a crack reflect the

defined as the distance from the origin to the first detectable

nature and course of the fracture event associated with the

mist.

breakage of a glass object. This practice is a guide to the

identification and interpretation of these fracture surface fea- 3.1.6 fracture surface markings—features of the fracture

tures. surface produced during the fracture event which are useful in

determining the origin and the nature of the local stresses that

1.2 The practice describes the various fracture surface

produced the fracture.

features as to their appearance, the process of formation and

their significance. 3.1.7 fracture system—the fracture surfaces that have a

common cause or origin.

1.3 The practice does not provide the procedural informa-

tion necessary for a complete fractographic analysis. Such 3.1.8 terminal velocity—the uppermost limiting velocity at

information is available in the general literature. (See Glossary which a crack can propagate in a material, the approach to

for suggested literature). which is marked on the fracture generated surface by the

presence of mist. The terminal velocity is approximately one

2. Referenced Documents half the velocity of sound in the material.

2.1 ASTM Standards: 3.1.9 uniform stress—a state of stress that does not change

within the region of concern.

C162Terminology of Glass and Glass Products

3. Terminology 4. Summary

3.1 Definitions: 4.1 This practice is intended to aid in the identification of

3.1.1 bending stress—a continuously and linearly changing

fracturesurfacemarkingsaswellastoassistintheunderstand-

stress across the thickness of a glass body, varying from ing of their formation and significance.

compression on one surface to tension on the opposite surface.

5. Significance and Use

3.1.2 forking—amechanismwherebyapropagatingfracture

branches into two fractures, separated from each other by an

5.1 Fractography is often used to help identify the events

acute angle.

thathaveresultedinthefractureofaglassobject.Thispractice

3.1.3 forking angle—the angle subtended by two immedi- defines the appearance of various fracture surface features, as

well as their method of formation. Thus, there can be a

ately adjacent fractures which have just branched or forked.

common understanding of their relationship to the fracture

3.1.4 fracture mirror constant—a constant, characteristic of

process as well as a common terminology.

a given glass composition, which, when divided by the square

root of the fracture mirror radius, will yield the fracture stress.

6. Fracture Surface Markings

6.1 Origin:

6.1.1 Identification—The origin is almost always found at

ThispracticeisunderthejurisdictionofASTMCommitteeC14GlassandGlass

Products and is the direct responsibility of Subcommittee C14.04 on Physical and

the junction where the fracture-generated surface meets a free

Mechanical Properties

surface or a dissimilar material. Commonly, the origin is

Current edition approved Oct. 1, 2013. Published October 2013. Originally

symmetrically located near the apex of the mirror and it is

approved in 1993. Last previous edition approved in 2008 as C1256–93 (2008)

DOI: 10.1520/C1256-93R13. usually small compared to the mirror. Fig. 1 shows typical

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

origins and mirrors bounded by mist.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1.2 Formation—The origin represents the single, unique

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. location at which every fracture system begins to form.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1256 − 93 (2013)

6.3.1 Identification—The mirror is a smooth portion of the

fracture surface surrounding the origin (see Fig. 2). It is

commonly bounded by mist, but mist may not form when the

local stress at the fracture front diminishes as the crack

extends.

6.3.2 Formation—It represents the initial portion of the

propagating crack where the velocity is accelerating from the

origin to a value sufficient to induce turbulence at the crack

front, that is, approaching terminal velocity, where mist and

forking may appear.

6.3.3 Significance—It is often helpful in locating the origin.

The shape defined by the mist boundary is indicative of the

uniformityofthestressfieldatthetimeoffailure,forexample;

anopenmirror,definedbymistonlyalongtheoriginalsurface,

implies bending; a semicircular mirror implies uniform ten-

sion: (See Fig. 1) The mirror dimensions may be used to

calculate the stress at breakage, because the mirror radius is

FIG. 1 Origin Areas Produced Under Various Stress Functions

inverselyproportionaltothesquareofthestressatthetimethe

and Their Typical Fracture Features

mirror was formed. If the mirror is symmetrical, then use the

radius to the mist boundary.To calculate the stress at breakage

when the mirror is not symmetrical, the mirror radius is best

6.1.3 Significance—The origin defines the location where

determined by dividing the mirror diameter by two. A more

the fracture began. It may contain the stress concentrator or it

detailed description of the relationship between the mirror and

may be the stress concentrator.

the breaking strength for various glasses is found on p. 364 of

6.2 Mist Region:

(1) and in (2) and (3). Further discussion on quantitative

6.2.1 Identification—Under low power (5 − 50 × )

fracture analysis techniques is well summarized in (4).

magnification, it has a misty appearance. Proceeding away

6.4 Wallner Lines:

from the origin, it becomes more fibrous in appearance and

6.4.1 Identification—Wallnerlines,alsocalledripplemarks,

elongated in the direction of crack spread. (See Fig. 2.)

are rib-shaped marks, frequently appearing as a series of

6.2.2 Formation—It is produced as the crack front breaks

curved lines resembling ripples created when an object is

into numerous segments, which then round into one another.

dropped into still water. (See Figs. 3-8.)

Theirpropagationabortsasthecrackfrontapproachesterminal

6.4.2 Formation—They are produced when the plane of the

velocity.

propagating crack front is temporarily altered by an elastic

6.2.3 Significance—It defines the limit of the mirror region

pulse.

and indicates that the crack has nearly reached terminal

6.4.3 Significance—The direction of local propagation is

velocity, or both.

perpendicular to the Wallner lines; it proceeds from the

6.3 Mirror:

concave to the convex side of the line. The shape of the line

indicatesthedirectionofstressesatvariouspointsonthecrack

front. The more advanced portions of the line generally

correspond to regions of higher tension.

6.5 Wallner Lines, Primary:

FIG. 3 Primary Wallner Lines Generated From a Surface Noncon-

FIG. 2 An Origin Area, with Mirror and Mist formity and an Inclusion

C1256 − 93 (2013)

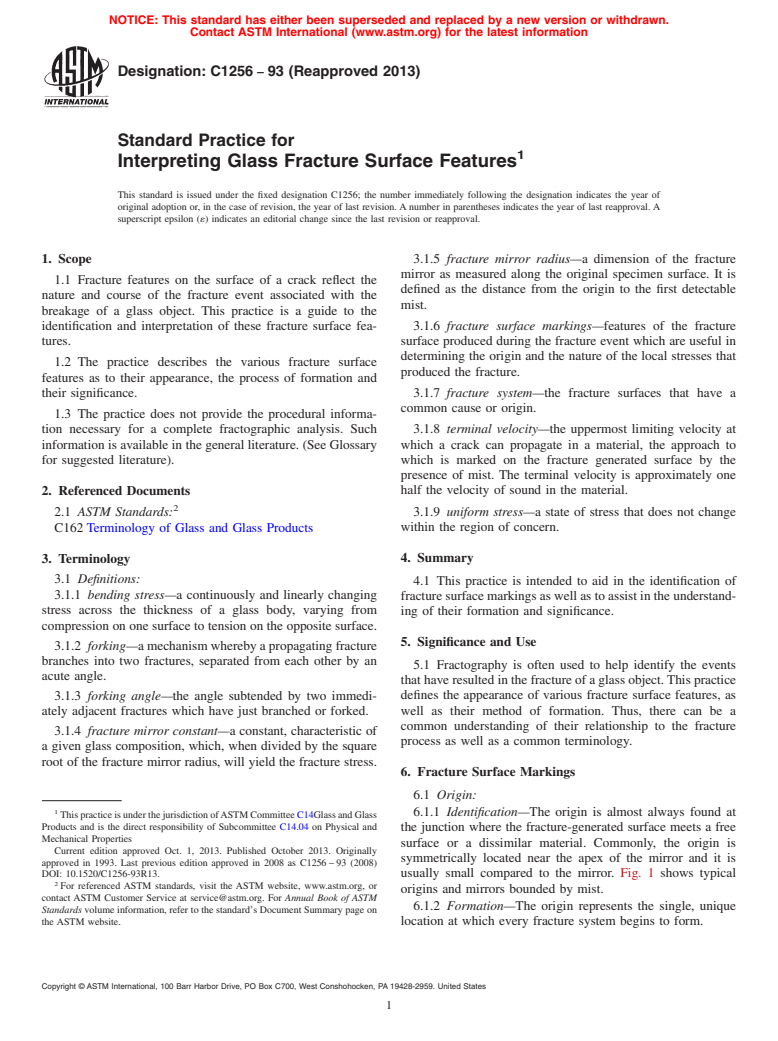

FIG. 4 Primary Wallner Lines Generated; (a) From Surface

Scratches, (b) A Bubble Generating Gull Wings

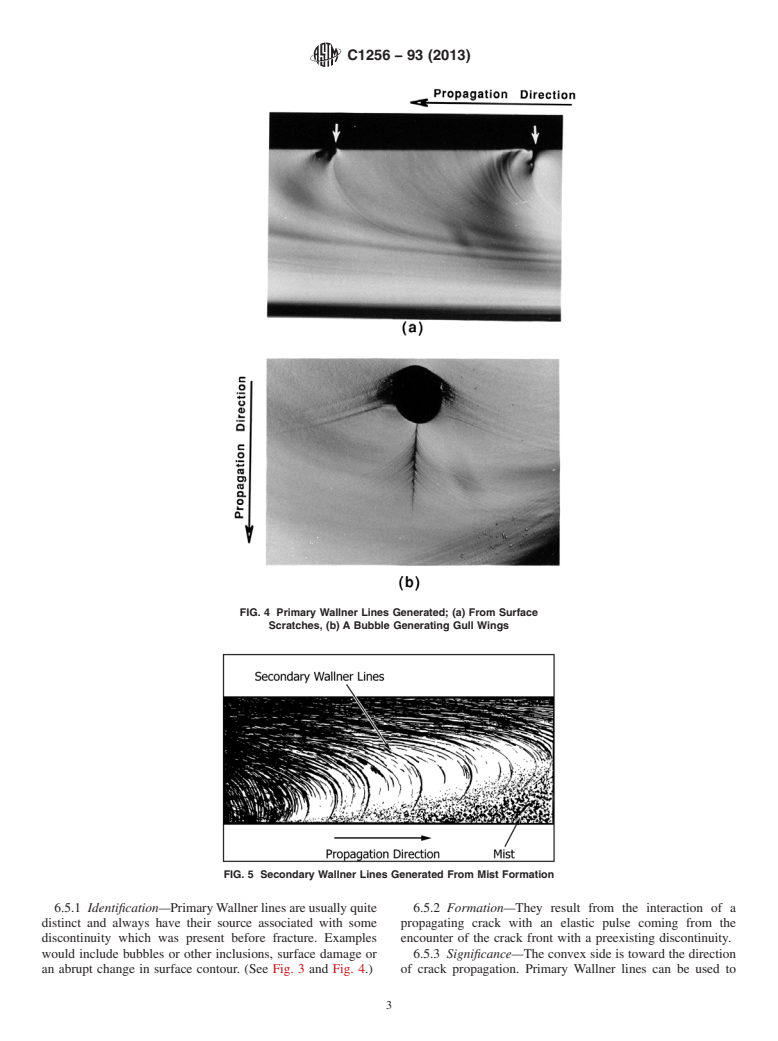

FIG. 5 Secondary Wallner Lines Generated From Mist Formation

6.5.1 Identification—PrimaryWallnerlinesareusuallyquite 6.5.2 Formation—They result from the interaction of a

distinct and always have their source associated with some propagating crack with an elastic pulse coming from the

discontinuity which was present before fracture. Examples encounter of the crack front with a preexisting discontinuity.

would include bubbles or other inclusions, surface damage or 6.5.3 Significance—The convex side is toward the direction

an abrupt change in surface contour. (See Fig. 3 and Fig. 4.) of crack propagation. Primary Wallner lines can be used to

C1256 − 93 (2013)

FIG. 6 Secondary Wallner Lines Generated From Mist Formation

FIG. 8 Tertiary Wallner Lines

within the pattern.They are neither hook-shaped nor trace to a

discontinuity as the source of an elastic pulse. (See Fig. 7 and

Fig. 8.)

6.7.2 Formation—They result from an interaction at the

crack front with sonic waves from an external shock or from

stress release at the onset of cracking.

6.7.3 Significance—They indicate that the failure resulted

fromamechanicalshock,whereanelasticpulsewasgenerated

outside the plane of crack propagation.

6.8 Dwell Mark:

6.8.1 Identification—Dwell marks, also called arrest lines,

have a similar rib-shaped contour to that of Wallner lines but

are distinctly sharper, often exhibiting a noticeable change in

FIG. 7 Tertiary Wallner Lines Created by Sonic Pulses Produced

fracture plane after the mark and may have twist hackle

from Mechanical Shock Which Broke the Material

associated. (See Fig. 9 and Fig. 10.)

6.8.2 Formation—They are formed when there is an abrupt

change in the direction of the stress field such as when the

crack stops and then is re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.