ASTM G217-16(2022)

(Guide)Standard Guide for Corrosion Monitoring in Laboratories and Plants with Coupled Multielectrode Array Sensor Method

Standard Guide for Corrosion Monitoring in Laboratories and Plants with Coupled Multielectrode Array Sensor Method

SIGNIFICANCE AND USE

4.1 Guide G96 describes a linear-polarization method and an electrical resistance method for online monitoring of corrosion in plant equipment without the need to enter the system physically to withdraw coupons. These two online monitoring techniques are useful in systems in which process upsets or other problems can create corrosive conditions. An early warning of corrosive attack can permit remedial action before significant damage occurs to process equipment. The two methods described in Guide G96 are suitable for uniform corrosion, but may not be sensitive enough for non-uniform corrosion, especially localized corrosion. This guide describes a new method for monitoring non-uniform corrosion, especially localized corrosion.

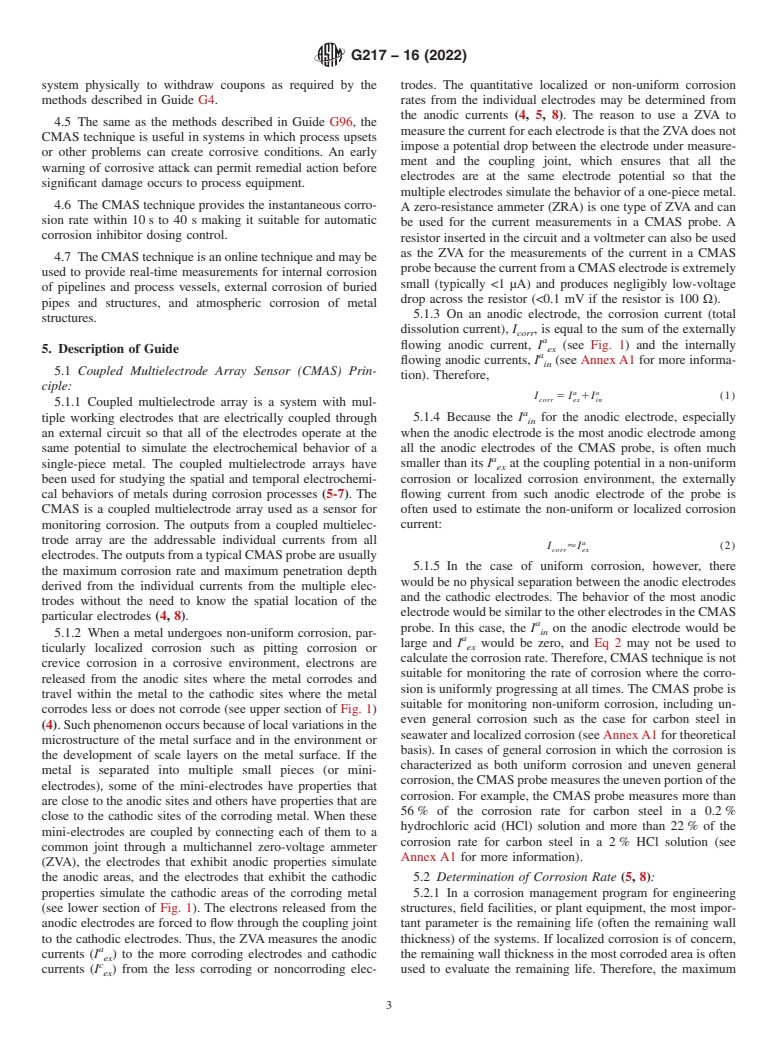

4.2 The CMAS technique measures the net anodic current or net cathodic current from each of the individual electrodes (Iaex or Icex in Fig. 1), which is the characteristic of non-uniform corrosion such as localized corrosion and uneven general corrosion. Therefore, the CMAS technique can be used to estimate the rate of uneven general corrosion and localized corrosion (see Section 5).

FIG. 1 Principle of CMAS Probe

Note 1: The upper section shows the electron flows from the corroding area to the less corroding areas inside a metal when localized corrosion takes place; the lower section shows the electron flows after the anodic and cathodic areas are separated into individual small electrodes and coupled through an external circuit that measures the anodic current (Iaex) and cathodic current (Icex) through each of the individual electrodes (4).

4.3 Unlike uniform corrosion, the rate of non-uniform corrosion, especially localized corrosion, can vary significantly from one area to another area of the same metal exposed to the same environment. Allowance shall be made for such variations when the measured non-uniform corrosion rate is used to estimate the penetration of the actual metal structure or the actual wall of process equipment. T...

SCOPE

1.1 This guide outlines the procedure for conducting corrosion monitoring in laboratories and plants by use of the coupled multielectrode array sensor (CMAS) technique.

1.2 For plant applications, this technique can be used to assess the instantaneous non-uniform corrosion rate, including localized corrosion rate, on a continuous basis, without removal of the monitoring probes, from the plant.

1.3 For laboratory applications, this technique can be used to study the effects of various testing conditions and inhibitors on non-uniform corrosion, including pitting corrosion and crevice corrosion.

1.4 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G217 − 16 (Reapproved 2022)

Standard Guide for

Corrosion Monitoring in Laboratories and Plants with

1

Coupled Multielectrode Array Sensor Method

This standard is issued under the fixed designation G217; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G4 Guide for Conducting Corrosion Tests in Field Applica-

tions

1.1 This guide outlines the procedure for conducting corro-

G16 Guide for Applying Statistics to Analysis of Corrosion

sionmonitoringinlaboratoriesandplantsbyuseofthecoupled

Data

multielectrode array sensor (CMAS) technique.

G46 Guide for Examination and Evaluation of Pitting Cor-

1.2 For plant applications, this technique can be used to

rosion

assess the instantaneous non-uniform corrosion rate, including

G48 Test Methods for Pitting and Crevice Corrosion Resis-

localized corrosion rate, on a continuous basis, without re-

tance of Stainless Steels and Related Alloys by Use of

moval of the monitoring probes, from the plant.

Ferric Chloride Solution

G96 Guide for Online Monitoring of Corrosion in Plant

1.3 For laboratory applications, this technique can be used

to study the effects of various testing conditions and inhibitors Equipment (Electrical and Electrochemical Methods)

G102 Practice for Calculation of Corrosion Rates and Re-

on non-uniform corrosion, including pitting corrosion and

crevice corrosion. lated Information from Electrochemical Measurements

G193 Terminology and Acronyms Relating to Corrosion

1.4 Units—The values stated in SI units are to be regarded

G199 Guide for Electrochemical Noise Measurement

as the standard. No other units of measurement are included in

this standard.

3. Terminology

1.5 This standard does not purport to address all of the

3.1 Definitions—The terminology used herein, if not spe-

safety concerns, if any, associated with its use. It is the

cifically defined otherwise, shall be in accordance with Termi-

responsibility of the user of this standard to establish appro-

nology G193. Definitions provided herein and not given in

priate safety, health, and environmental practices and deter-

Terminology G193 are limited only to this guide.

mine the applicability of regulatory limitations prior to use.

3.2 Definitions of Terms Specific to This Standard:

1.6 This international standard was developed in accor-

3.2.1 coupled multielectrode array sensor, CMAS,

dance with internationally recognized principles on standard-

n—device with multiple working electrodes that are coupled

ization established in the Decision on Principles for the

through an external circuit such that all the electrodes operate

Development of International Standards, Guides and Recom-

at the same electrode potential to simulate the electrochemical

mendations issued by the World Trade Organization Technical

behavior of a single-piece metal.

Barriers to Trade (TBT) Committee.

3.2.2 non-uniform corrosion, n—corrosion that occurs at

2. Referenced Documents various rates across the metal surface, with some locations

2

exhibiting higher anodic rates while others have higher ca-

2.1 ASTM Standards:

thodic rates, thereby requiring that the electron transfer occurs

G1 Practice for Preparing, Cleaning, and Evaluating Corro-

between these sites within the metal.

sion Test Specimens

3.2.2.1 Discussion—Non-uniform corrosion includes both

3

localized corrosion and uneven general corrosion (1). Non-

uniform corrosion also includes the type of general corrosion

1

This guide is under the jurisdiction ofASTM Committee G01 on Corrosion of

Metals and is the direct responsibility of Subcommittee G01.11 on Electrochemical that produces even surfaces at the end of a large time interval,

Measurements in Corrosion Testing.

but uneven surfaces during small time intervals.

Current edition approved May 1, 2022. Published May 2022. Originally

3.2.3 uneven general corrosion, n—corrosion that occurs

approved in 2016. Last previous edition approved in 2016 as G217–16. DOI:

10.1520/G0217-16R22.

overthewholeexposedsurfaceoralargeareaatdifferentrates.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to a list of references at the end of

the ASTM website. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.