ASTM D5417-11

(Practice)Standard Practice for Operation of the Vettermann Drum Tester

Standard Practice for Operation of the Vettermann Drum Tester

SIGNIFICANCE AND USE

This equipment may be used to bring about the changes in texture on the surface of pile floor covering caused by mechanical action.

The acceptance criteria of this practice shall be set by mutual agreement between the purchaser and the supplier.

SCOPE

1.1 This practice describes the equipment and operation of the Vettermann drum tester for testing pile yarn floor covering to produce changes in appearance and color due to changes in surface structure by mechanical action.

1.2 This practice is only applicable for use in testing unused pile floor covering of all types. It is not applicable for use in testing used pile yarn floor coverings.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5417 − 11

StandardPractice for

1

Operation of the Vettermann Drum Tester

This standard is issued under the fixed designation D5417; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Practice

1.1 This practice describes the equipment and operation of 4.1 The test specimen is mounted in the rotatable drum with

the Vettermann drum tester for testing pile yarn floor covering the pile surface towards the center of the drum and the edges

to produce changes in appearance and color due to changes in under the retaining segments.Asteel ball, with 14 rubber studs

surface structure by mechanical action. rolls randomly inside the drum on the pile surface for a

specified number of revolutions.

1.2 This practice is only applicable for use in testing unused

pile floor covering of all types. It is not applicable for use in

5. Significance and Use

testing used pile yarn floor coverings.

5.1 This equipment may be used to bring about the changes

1.3 The values stated in inch-pound units are to be regarded

in texture on the surface of pile floor covering caused by

as standard. The values given in parentheses are mathematical

mechanical action.

conversions to SI units that are provided for information only

and are not considered standard. 5.2 The acceptance criteria of this practice shall be set by

mutual agreement between the purchaser and the supplier.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

6. Apparatus and Material

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

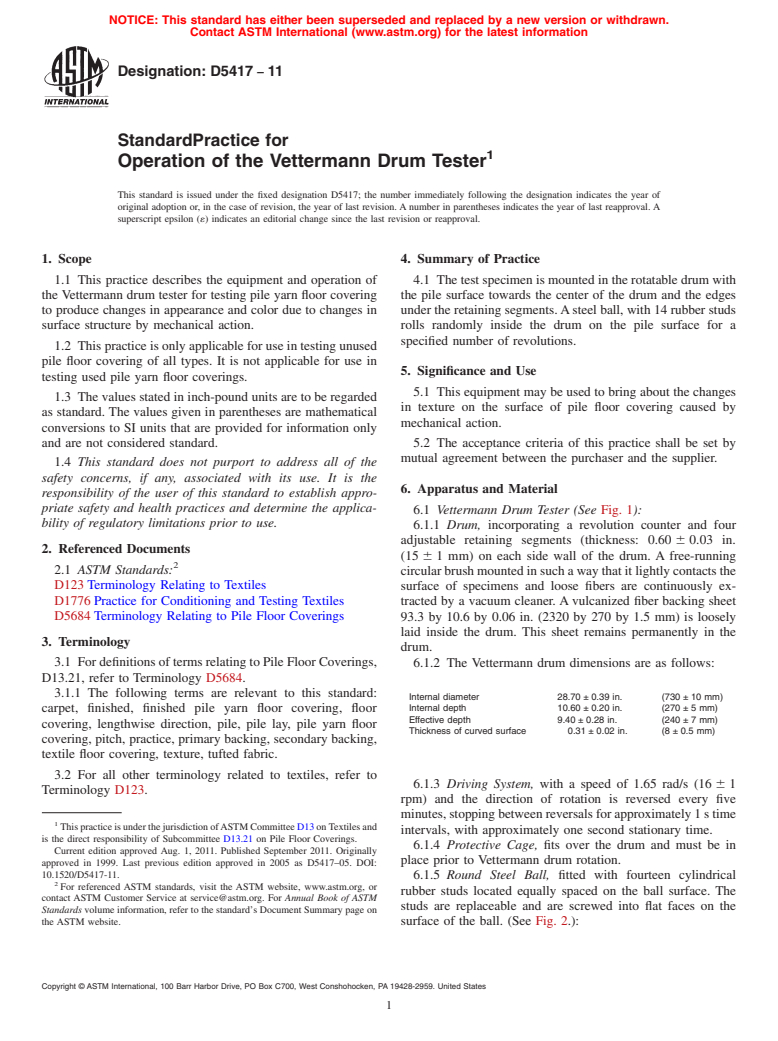

6.1 Vettermann Drum Tester (See Fig. 1):

bility of regulatory limitations prior to use.

6.1.1 Drum, incorporating a revolution counter and four

adjustable retaining segments (thickness: 0.60 6 0.03 in.

2. Referenced Documents

(15 6 1 mm) on each side wall of the drum. A free-running

2

2.1 ASTM Standards: circularbrushmountedinsuchawaythatitlightlycontactsthe

D123 Terminology Relating to Textiles

surface of specimens and loose fibers are continuously ex-

D1776 Practice for Conditioning and Testing Textiles

tracted by a vacuum cleaner. A vulcanized fiber backing sheet

D5684 Terminology Relating to Pile Floor Coverings

93.3 by 10.6 by 0.06 in. (2320 by 270 by 1.5 mm) is loosely

laid inside the drum. This sheet remains permanently in the

3. Terminology

drum.

3.1 For definitions of terms relating to Pile Floor Coverings, 6.1.2 The Vettermann drum dimensions are as follows:

D13.21, refer to Terminology D5684.

3.1.1 The following terms are relevant to this standard:

Internal diameter 28.70 ± 0.39 in. (730 ± 10 mm)

carpet, finished, finished pile yarn floor covering, floor Internal depth 10.60 ± 0.20 in. (270 ± 5 mm)

Effective depth 9.40 ± 0.28 in. (240 ± 7 mm)

covering, lengthwise direction, pile, pile lay, pile yarn floor

Thickness of curved surface 0.31 ± 0.02 in. (8 ± 0.5 mm)

covering, pitch, practice, primary backing, secondary backing,

textile floor covering, texture, tufted fabric.

3.2 For all other terminology related to textiles, refer to

6.1.3 Driving System, with a speed of 1.65 rad/s (16 6 1

Terminology D123.

rpm) and the direction of rotation is reversed every five

minutes,stoppingbetweenreversalsforapproximately1stime

1

ThispracticeisunderthejurisdictionofASTMCommitteeD13onTextilesand

intervals, with approximately one second stationary time.

is the direct responsibility of Subcommittee D13.21 on Pile Floor Coverings.

6.1.4 Protective Cage, fits over the drum and must be in

Current edition approved Aug. 1, 2011. Published September 2011. Originally

place prior to Vettermann drum rotation.

approved in 1999. Last previous edition approved in 2005 as D5417–05. DOI:

10.1520/D5417-11.

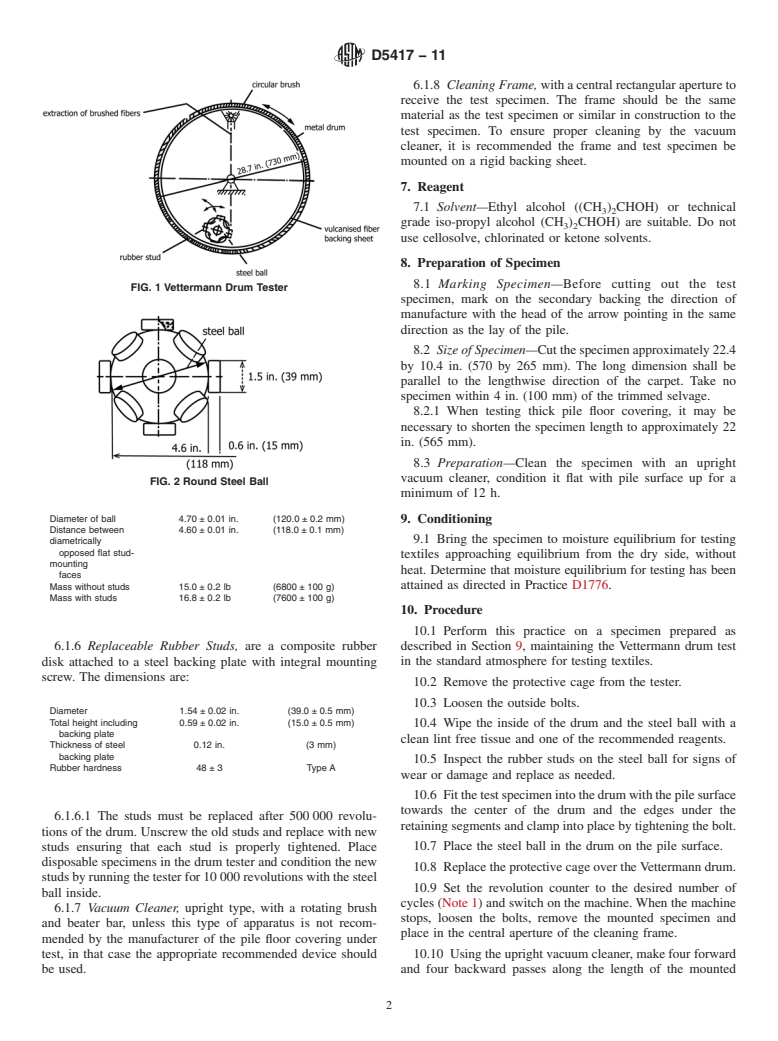

6.1.5 Round Steel Ball, fitted with fourteen cylindrical

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

rubber studs located equally spaced on the ball surface. The

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

studs are replaceable and are screwed into flat faces on the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. surface of the ball. (See Fig. 2.):

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5417 − 11

1

---------------------- Page: 2 ----------------------

D5417 − 11

6.1.8 CleaningFrame, with a central rectangular aperture to

receive the test specimen. The frame shou

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5417–05 Designation:D5417–11

Standard Practice for

1

Operation of the Vettermann Drum Tester

This standard is issued under the fixed designation D5417; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes the equipment and operation of the Vettermann drum tester for testing pile yarn floor covering to

produce changes in appearance and color due to changes in surface structure by mechanical action.

1.2 This practice is only applicable for use in testing unused pile floor covering of all types. It is not applicable for use in testing

used pile yarn floor coverings.

1.3The values stated in inch-pound units are to be regarded as the standard for all measurements except mass. The SI (metric)

units for all measurements except mass are provided for information only.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D1776 Practice for Conditioning and Testing Textiles

D5684 Terminology Relating to Pile Floor Coverings

3. Terminology

3.1 For definitions of terms relating to Pile Floor Coverings, D13.21, refer to Terminology D5684.

3.1.1 The following terms are relevant to this standard: carpet, finished, finished pile yarn floor covering, floor covering,

lengthwise direction, pile, pile lay, pile yarn floor covering, pitch, practice, primary backing, secondary backing, textile floor

covering, texture, tufted fabric.

3.2 For all other terminology related to textiles, refer to Terminology D123.

4. Summary of Practice

4.1 The test specimen is mounted in the rotatable drum with the pile surface towards the center of the drum and the edges under

the retaining segments.Asteel ball, with 14 rubber studs rolls randomly inside the drum on the pile surface for a specified number

of revolutions.

5. Significance and Use

5.1 Thisequipmentmaybeusedtobringaboutthechangesintextureonthesurfaceofpilefloorcoveringcausedbymechanical

action.

5.2 The acceptance criteria of this practice shall be set by mutual agreement between the purchaser and the supplier.

6. Apparatus and Material

6.1 Vettermann Drum Tester (See Fig. 1):

6.1.1 Drum, incorporating a revolution counter and four adjustable retaining segments (thickness: 1561 mm (0.660.03

1

This practice is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.21 on Pile Floor Coverings.

Current edition approved March 1, 2005. Published April 2005. Originally approved in 1999. Last previous edition approved in 2003 as D5417–99 (2003) DOI:

10.1520/D5417-05.

Current edition approved Aug. 1, 2011. Published September 2011. Originally approved in 1999. Last previous edition approved in 2005 as D5417–05. DOI:

10.1520/D5417-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5417–11

FIG. 1 Vettermann Drum Tester

in.)0.60 6 0.03 in. (15 6 1 mm) on each side wall of the drum.Afree-running circular brush mounted in such a way that it lightly

contactsthesurfaceofspecimensandloosefibersarecontinuouslyextractedbyavacuumcleaner.Avulcanizedfiberbackingsheet

232093.3 by 27010.6 by 1.5 mm (93.30.06 in. (2320 by 10.6270 by 0.06 in.)1.5 mm) is loosely laid inside the drum. This sheet

remains permanently in the drum.

6.1.2 The Vettermann drum dimensions are as follows:

Internal diameter 730 6 10 mm (28.7 6 0.39 in.)

Internal diameter 28.70 6 0.39 in. (730 6 10 mm)

Internal depth 270 65mm (10.6 6 0.20 in.)

Internal depth 10.60 6 0.20 in. (270 6 5 m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.