ASTM C1683-10(2015)

(Practice)Standard Practice for Size Scaling of Tensile Strengths Using Weibull Statistics for Advanced Ceramics

Standard Practice for Size Scaling of Tensile Strengths Using Weibull Statistics for Advanced Ceramics

SIGNIFICANCE AND USE

5.1 Advanced ceramics usually display a linear stress-strain behavior to failure. Lack of ductility combined with flaws that have various sizes and orientations typically leads to large scatter in failure strength. Strength is not a deterministic property but instead reflects the intrinsic fracture toughness and a distribution (size and orientation) of flaws present in the material. This standard is applicable to brittle monolithic ceramics which fail as a result of catastrophic propagation of flaws. Possible rising R-curve effects are also not considered, but are inherently incorporated into the strength measurements.

5.2 Two- and three-parameter formulations exist for the Weibull distribution. This standard is restricted to the two-parameter formulation.

5.3 Tensile and flexural test specimens are the most commonly used test configurations for advanced ceramics. Ring-on-ring and pressure-on-ring test specimens which have multi-axial states of stress are also included. Closed-form solutions for the effective volume and effective surfaces and the Weibull material scale factor are included for these configurations. This practice also incorporates size scaling methods for C-ring test specimens for which numerical approaches are necessary. A generic approach for arbitrary shaped test specimens or components that utilizes finite element analyses is presented in Annex A3.

5.4 The fracture origins of failed test specimens can be determined using fractographic analysis. The spatial distribution of these strength controlling flaws can be over a volume or an area (as in the case of surface flaws). This standard allows for the conversion of strength parameters associated with either type of spatial distribution. Length scaling for strength controlling flaws located along edges of a test specimen is not covered in this practice.

5.5 The scaling of strength with size in accordance with the Weibull model is based on several key assumptions (5). It is assumed that the...

SCOPE

1.1 This standard practice provides methodology to convert fracture strength parameters (primarily the mean strength and the Weibull characteristic strength) estimated from data obtained with one test geometry to strength parameters representing other test geometries. This practice addresses uniaxial strength data as well as some biaxial strength data. It may also be used for more complex geometries proved that the effective areas and effective volumes can be estimated. It is for the evaluation of Weibull probability distribution parameters for advanced ceramics that fail in a brittle fashion. Fig. 1 shows the typical variation of strength with size. The larger the specimen or component, the weaker it is likely to be.Geometries and Stress Distributions

Annex A3

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5.1 The values stated in SI units are in accordance with IEEE/ASTM SI 10.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1683 − 10 (Reapproved 2015)

Standard Practice for

Size Scaling of Tensile Strengths Using Weibull Statistics

for Advanced Ceramics

This standard is issued under the fixed designation C1683; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope also assumes that the flaw population is stable with time and

that no slow crack growth occurs.

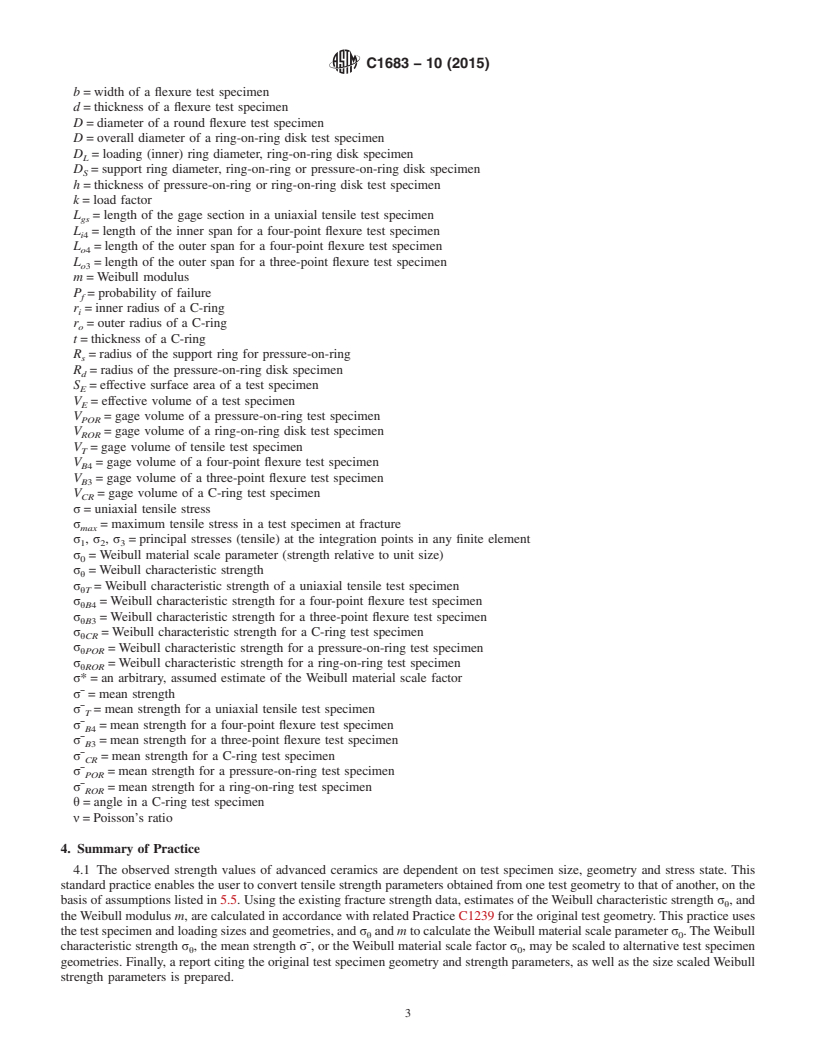

1.1 This standard practice provides methodology to convert

fracture strength parameters (primarily the mean strength and 1.4 This practice includes the following topics:

the Weibull characteristic strength) estimated from data ob-

Section

Scope 1

tained with one test geometry to strength parameters represent-

Referenced Documents 2

ing other test geometries. This practice addresses uniaxial

Terminology 3

strength data as well as some biaxial strength data. It may also

Summary of Practice 4

Significance and Use 5

be used for more complex geometries proved that the effective

Probability of Failure Relationships 6

areas and effective volumes can be estimated. It is for the

Test Specimens with Uniaxial Stress States—Effective 7

evaluation of Weibull probability distribution parameters for

Volume and Area Relationships

Uniaxial Tensile Test Specimens 7.1

advancedceramicsthatfailinabrittlefashion.Fig.1showsthe

Rectangular Flexure Test Specimens 7.2

typical variation of strength with size. The larger the specimen

Round Flexure Test Specimens 7.3

or component, the weaker it is likely to be.

C-Ring Test Specimens 7.4

Test Specimens with Multiaxial Stress States—Effective 8

1.2 As noted in Practice C1239, the failure strength of

Volume and Area Relationships

advanced ceramics is treated as a continuous random variable. Pressure-on-Ring Test Specimens 8.1

Ring-on-Ring Test Specimens 8.2

Anumberoffunctionsmaybeusedtocharacterizethestrength

Examples of Converting Characteristic Strengths 9

distribution of brittle ceramics, but the Weibull distribution is

Report 10

themostappropriateespeciallysinceitpermitsstrengthscaling Precision and Bias 11

Keywords 12

for the size of specimens or component.Typically, a number of

Combined Gamma Function for Round Rods Tested Annex A1

test specimens with well-defined geometry are broken under

in Flexure

well-defined loading conditions. The force at which each test Components or Test Specimens with Multiaxial Annex A2

Stress Distributions

specimen fails is recorded and fracture strength calculated.The

Components or Test Specimens with Complex Annex A3

strength values are used to obtain Weibull parameter estimates

Geometries and Stress Distributions

associated with the underlying population distribution.

1.5 The values stated in SI units are to be regarded as

1.3 This standard is restricted to the assumption that the

standard. No other units of measurement are included in this

distribution underlying the failure strengths is the two- standard.

parameter Weibull distribution with size scaling. The practice

1.5.1 The values stated in SI units are in accordance with

IEEE/ASTM SI 10.

1.6 This standard does not purport to address all of the

This practice is under the jurisdiction of ASTM Committee C28 on Advanced

Ceramics and is the direct responsibility of Subcommittee C28.01 on Mechanical

safety concerns, if any, associated with its use. It is the

Properties and Performance.

responsibility of the user of this standard to establish appro-

Current edition approved Jan. 1, 2015. Published April 2015. Originally

priate safety and health practices and determine the applica-

approved in 2008. Last previous edition approved in 2010 as C1683 –10. DOI:

10.1520/C1683-10R15. bility of regulatory limitations prior to use.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1683 − 10 (2015)

3.3 Nomenclature: A = gage area of a uniaxial tensile test

T

specimen

A = gage area of a four-point flexure test specimen

B4

A = gage area of a three-point flexure test specimen

B3

A = gage area of a pressure-on-ring test specimen

POR

A = gage area of a ring-on-ring test specimen

ROR

A = gage area of a C-ring test specimen

CR

b = thickness of a C-ring

b = width of a flexure test specimen

d = thickness of a flexure test specimen

D = diameter of a round flexure test specimen

D = overall diameter of a ring-on-ring disk test specimen

D = loading (inner) ring diameter, ring-on-ring disk speci-

L

men

D = support ring diameter, ring-on-ring or pressure-on-ring

S

disk specimen

h = thickness of pressure-on-ring or ring-on-ring disk test

specimen

FIG. 1 Strength Scales with Size

k = load factor

L = length of the gage section in a uniaxial tensile test

gs

2. Referenced Documents

specimen

L = length of the inner span for a four-point flexure test

i4

2.1 ASTM Standards:

specimen

C1145 Terminology of Advanced Ceramics

L = length of the outer span for a four-point flexure test

C1161 Test Method for Flexural Strength of Advanced o4

specimen

Ceramics at Ambient Temperature

L = length of the outer span for a three-point flexure test

C1211 Test Method for Flexural Strength of Advanced o3

specimen

Ceramics at Elevated Temperatures

m = Weibull modulus

C1239 Practice for Reporting Uniaxial Strength Data and

Estimating Weibull Distribution Parameters forAdvanced P = probability of failure

f

Ceramics r = inner radius of a C-ring

i

C1273 Test Method for Tensile Strength of Monolithic r = outer radius of a C-ring

o

Advanced Ceramics at Ambient Temperatures

t = thickness of a C-ring

C1322 Practice for Fractography and Characterization of

R = radius of the support ring for pressure-on-ring

s

Fracture Origins in Advanced Ceramics

R = radius of the pressure-on-ring disk specimen

d

C1323 Test Method for Ultimate Strength of Advanced

S = effective surface area of a test specimen

E

Ceramics with Diametrally Compressed C-Ring Speci-

V = effective volume of a test specimen

E

mens at Ambient Temperature

V = gage volume of a pressure-on-ring test specimen

POR

C1366 Test Method for Tensile Strength of Monolithic

V = gage volume of a ring-on-ring disk test specimen

ROR

Advanced Ceramics at Elevated Temperatures

V = gage volume of tensile test specimen

T

C1499 Test Method for Monotonic Equibiaxial Flexural

V = gage volume of a four-point flexure test specimen

B4

Strength of Advanced Ceramics at Ambient Temperature

V = gage volume of a three-point flexure test specimen

B3

E6 Terminology Relating to Methods of Mechanical Testing

V = gage volume of a C-ring test specimen

CR

E456 Terminology Relating to Quality and Statistics

σ = uniaxial tensile stress

σ = maximum tensile stress in a test specimen at fracture

3. Terminology max

σ , σ , σ = principal stresses (tensile) at the integration

1 2 3

3.1 Unless otherwise noted, the Weibull parameter estima-

points in any finite element

tiontermsandequationsfoundinPracticeC1239shallbeused.

σ = Weibull material scale parameter (strength relative to

3.2 For definitions of other statistical terms, terms related to

unit size)

mechanical testing, and terms related to advanced ceramics

σ = Weibull characteristic strength

θ

usedinthisguide,refertoTerminologiesE6,E456,andC1145,

σ = Weibull characteristic strength of a uniaxial tensile test

θT

or to appropriate textbooks on statistics (1-4).

specimen

σ = Weibullcharacteristicstrengthforafour-pointflexure

θB4

test specimen

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

σ = Weibull characteristic strength for a three-point flex-

θB3

Standards volume information, refer to the standard’s Document Summary page on

ure test specimen

the ASTM website.

σ = WeibullcharacteristicstrengthforaC-ringtestspeci-

The boldface numbers in parentheses refer to the list of references at the end of θCR

this standard. men

C1683 − 10 (2015)

σ = Weibull characteristic strength for a pressure-on- generic approach for arbitrary shaped test specimens or com-

θPOR

ring test specimen ponents that utilizes finite element analyses is presented in

Annex A3.

σ = Weibull characteristic strength for a ring-on-ring

θROR

test specimen

5.4 The fracture origins of failed test specimens can be

σ* = an arbitrary, assumed estimate of the Weibull material

determined using fractographic analysis. The spatial distribu-

scale factor

tion of these strength controlling flaws can be over a volume or

σ¯ = mean strength

an area (as in the case of surface flaws). This standard allows

σ¯ = mean strength for a uniaxial tensile test specimen

fortheconversionofstrengthparametersassociatedwitheither

T

σ¯ = mean strength for a four-point flexure test specimen type of spatial distribution. Length scaling for strength con-

B4

trolling flaws located along edges of a test specimen is not

σ¯ = mean strength for a three-point flexure test specimen

B3

covered in this practice.

σ¯ = mean strength for a C-ring test specimen

CR

σ¯ = mean strength for a pressure-on-ring test specimen

POR 5.5 The scaling of strength with size in accordance with the

σ¯ = mean strength for a ring-on-ring test specimen

ROR Weibull model is based on several key assumptions (5).Itis

θ = angle in a C-ring test specimen assumed that the same specific flaw type controls strength in

ν = Poisson’s ratio the various specimen configurations. It is assumed that the

material is uniform, homogeneous, and isotropic. If the mate-

rial is a composite, it is assumed that the composite phases are

4. Summary of Practice

sufficiently small that the structure behaves on an engineering

4.1 The observed strength values of advanced ceramics are

scale as a homogeneous and isotropic body. The composite

dependent on test specimen size, geometry and stress state.

must contain a sufficient quantity of uniformly-distributed,

This standard practice enables the user to convert tensile

randomly-oriented, reinforcing elements such that the material

strength parameters obtained from one test geometry to that of

is effectively homogeneous. Whisker-toughened ceramic com-

another, on the basis of assumptions listed in 5.5. Using the

posites may be representative of this type of material. This

existing fracture strength data, estimates of the Weibull char-

practice is also applicable to composite ceramics that do not

acteristic strength σ , and the Weibull modulus m, are calcu-

θ

exhibit any appreciable bilinear or nonlinear deformation

latedinaccordancewithrelatedPracticeC1239fortheoriginal

behavior. This standard and the conventional Weibull strength

test geometry. This practice uses the test specimen and loading

scaling with size may not be suitable for continuous fiber-

sizes and geometries, and σ and m to calculate the Weibull

θ

reinforced composite ceramics. The material is assumed to

materialscaleparameterσ .TheWeibullcharacteristicstrength

fracture in a brittle fashion, a consequence of stress causing

σ , the mean strengthσ¯, or theWeibull material scale factorσ ,

θ 0

catastrophic propagation of flaws. The material is assumed to

may be scaled to alternative test specimen geometries. Finally,

be consistent (batch to batch, day to day, etc.). It is assumed

a report citing the original test specimen geometry and strength

that the strength distribution follows a Weibull two parameter

parameters, as well as the size scaled Weibull strength param-

distribution. It is assumed that each test piece has a statistically

eters is prepared.

significant number of flaws and that they are randomly

distributed. It is assumed that the flaws are small relative to the

5. Significance and Use

specimen cross section size. If multiple flaw types are present

5.1 Advanced ceramics usually display a linear stress-strain and control strength, then strengths may scale differently for

each flaw type. Consult Practice C1239 and the example in 9.1

behavior to failure. Lack of ductility combined with flaws that

have various sizes and orientations typically leads to large forfurtherguidanceonhowtoapplycensoredstatisticsinsuch

cases. It is also assumed that the specimen stress state and the

scatter in failure strength. Strength is not a deterministic

propertybutinsteadreflectstheintrinsicfracturetoughnessand maximum stress are accurately determined. It is assumed that

the actual data from a set of fractured specimens are accurate

a distribution (size and orientation) of flaws present in the

material. This standard is applicable to brittle monolithic and precise. (SeeTerminology E456 for definitions of the latter

two terms.) For this reason, this standard frequently references

ceramics which fail as a result of catastrophic propagation of

flaws. Possible rising R-curve effects are also not considered, other ASTM standard test methods and practices which are

known to be reliable in this respect.

butareinherentlyincorporatedintothestrengthmeasurements.

5.2 Two- and three-parameter formulations exist for the 5.6 Even if test data has been accurately and precisely

measured, it should be recognized that the Weibull parameters

Weibull distribution. This standard is restricted to the two-

parameter formulation. determined from test data are in fact estimates. The estimates

can vary from the actual (population) material strength param-

5.3 Tensile and flexural test specimens are the most com-

eters. Consult Practice C1239 for further guidance on the

monly used test configurations for advanced ceramics. Ring-

confidence bounds of Weibull parameter estimates based on

on-ring and pressure-on-ring test specimens which have multi-

test data for a finite sample size of test fractures.

axial states of stress are also included. Closed-form solutions

for the effective volume and effective surfaces and the Weibull 5.7 When correlating strength parameters from test data

material scale factor are included for these configurations.This from one specimen geometry to a second, the accuracy of the

practice also incorporates size scaling methods for C-ring test correlation depends upon whether the assumptions listed in 5.5

specimens for which numerical approaches are necessary. A are met. In addition, statistical sampling effects as discussed in

C1683 − 10 (2015)

5.6 may also contribute to variations between computed and 6.1.2 As noted earlier, the Weibull characteristic strength is

observed strength-size scaling trends. dependent on the test specimen and will change with test

specimen geometry as well as the stress state. The Weibull

5.8 TherearepracticallimitstoWeibullstrengthscalingthat

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1683 − 10 C1683 − 10 (Reapproved 2015)

Standard Practice for

Size Scaling of Tensile Strengths Using Weibull Statistics

for Advanced Ceramics

This standard is issued under the fixed designation C1683; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This standard practice provides methodology to convert fracture strength parameters (primarily the mean strength and the

Weibull characteristic strength) estimated from data obtained with one test geometry to strength parameters representing other test

geometries. This practice addresses uniaxial strength data as well as some biaxial strength data. It may also be used for more

complex geometries proved that the effective areas and effective volumes can be estimated. It is for the evaluation of Weibull

probability distribution parameters for advanced ceramics that fail in a brittle fashion. Fig. 1 shows the typical variation of strength

with size. The larger the specimen or component, the weaker it is likely to be.

1.2 As noted in Practice C1239, the failure strength of advanced ceramics is treated as a continuous random variable. A number

of functions may be used to characterize the strength distribution of brittle ceramics, but the Weibull distribution is the most

appropriate especially since it permits strength scaling for the size of specimens or component. Typically, a number of test

specimens with well-defined geometry are broken under well-defined loading conditions. The force at which each test specimen

fails is recorded and fracture strength calculated. The strength values are used to obtain Weibull parameter estimates associated

with the underlying population distribution.

1.3 This standard is restricted to the assumption that the distribution underlying the failure strengths is the two-parameter

Weibull distribution with size scaling. The practice also assumes that the flaw population is stable with time and that no slow crack

growth occurs.

1.4 This practice includes the following topics:

Section

Scope 1

Referenced Documents 2

Terminology 3

Summary of Practice 4

Significance and Use 5

Probability of Failure Relationships 6

Test Specimens with Uniaxial Stress States—Effective 7

Volume and Area Relationships

Uniaxial Tensile Test Specimens 7.1

Rectangular Flexure Test Specimens 7.2

Round Flexure Test Specimens 7.3

C-Ring Test Specimens 7.4

Test Specimens with Multiaxial Stress States—Effective 8

Volume and Area Relationships

Pressure-on-Ring Test Specimens 8.1

Ring-on-Ring Test Specimens 8.2

Examples of Converting Characteristic Strengths 9

Report 10

Precision and Bias 11

Keywords 12

Combined Gamma Function for Round Rods Tested Annex A1

in Flexure

Components or Test Specimens with Multiaxial Annex A2

Stress Distributions

Components or Test Specimens with Complex Annex A3

Geometries and Stress Distributions

This practice is under the jurisdiction of ASTM Committee C28 on Advanced Ceramics and is the direct responsibility of Subcommittee C28.01 on Mechanical Properties

and Performance.

Current edition approved Dec. 1, 2010Jan. 1, 2015. Published January 2011April 2015. Originally approved in 2008. Last previous edition approved in 20082010 as

ε1

C1683 – 08C1683 . –10. DOI: 10.1520/C1683-10.10.1520/C1683-10R15.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1683 − 10 (2015)

FIG. 1 Strength Scales with Size

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5.1 The values stated in SI units are in accordance with IEEE/ASTM SI 10.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C1145 Terminology of Advanced Ceramics

C1161 Test Method for Flexural Strength of Advanced Ceramics at Ambient Temperature

C1211 Test Method for Flexural Strength of Advanced Ceramics at Elevated Temperatures

C1239 Practice for Reporting Uniaxial Strength Data and Estimating Weibull Distribution Parameters for Advanced Ceramics

C1273 Test Method for Tensile Strength of Monolithic Advanced Ceramics at Ambient Temperatures

C1322 Practice for Fractography and Characterization of Fracture Origins in Advanced Ceramics

C1323 Test Method for Ultimate Strength of Advanced Ceramics with Diametrally Compressed C-Ring Specimens at Ambient

Temperature

C1366 Test Method for Tensile Strength of Monolithic Advanced Ceramics at Elevated Temperatures

C1499 Test Method for Monotonic Equibiaxial Flexural Strength of Advanced Ceramics at Ambient Temperature

E6 Terminology Relating to Methods of Mechanical Testing

E456 Terminology Relating to Quality and Statistics

3. Terminology

3.1 Unless otherwise noted, the Weibull parameter estimation terms and equations found in Practice C1239 shall be used.

3.2 For definitions of other statistical terms, terms related to mechanical testing, and terms related to advanced ceramics used

in this guide, refer to Terminologies E6, E456, and C1145, or to appropriate textbooks on statistics (1-4).

3.3 Nomenclature:

A = gage area of a uniaxial tensile test specimen

T

A = gage area of a four-point flexure test specimen

B4

A = gage area of a three-point flexure test specimen

B3

A = gage area of a pressure-on-ring test specimen

POR

A = gage area of a ring-on-ring test specimen

ROR

A = gage area of a C-ring test specimen

CR

b = thickness of a C-ring

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The boldface numbers in parentheses refer to the list of references at the end of this standard.

C1683 − 10 (2015)

b = width of a flexure test specimen

d = thickness of a flexure test specimen

D = diameter of a round flexure test specimen

D = overall diameter of a ring-on-ring disk test specimen

D = loading (inner) ring diameter, ring-on-ring disk specimen

L

D = support ring diameter, ring-on-ring or pressure-on-ring disk specimen

S

h = thickness of pressure-on-ring or ring-on-ring disk test specimen

k = load factor

L = length of the gage section in a uniaxial tensile test specimen

gs

L = length of the inner span for a four-point flexure test specimen

i4

L = length of the outer span for a four-point flexure test specimen

o4

L = length of the outer span for a three-point flexure test specimen

o3

m = Weibull modulus

P = probability of failure

f

r = inner radius of a C-ring

i

r = outer radius of a C-ring

o

t = thickness of a C-ring

R = radius of the support ring for pressure-on-ring

s

R = radius of the pressure-on-ring disk specimen

d

S = effective surface area of a test specimen

E

V = effective volume of a test specimen

E

V = gage volume of a pressure-on-ring test specimen

POR

V = gage volume of a ring-on-ring disk test specimen

ROR

V = gage volume of tensile test specimen

T

V = gage volume of a four-point flexure test specimen

B4

V = gage volume of a three-point flexure test specimen

B3

V = gage volume of a C-ring test specimen

CR

σ = uniaxial tensile stress

σ = maximum tensile stress in a test specimen at fracture

max

σ , σ , σ = principal stresses (tensile) at the integration points in any finite element

1 2 3

σ = Weibull material scale parameter (strength relative to unit size)

σ = Weibull characteristic strength

θ

σ = Weibull characteristic strength of a uniaxial tensile test specimen

θT

σ = Weibull characteristic strength for a four-point flexure test specimen

θB4

σ = Weibull characteristic strength for a three-point flexure test specimen

θB3

σ = Weibull characteristic strength for a C-ring test specimen

θCR

σ = Weibull characteristic strength for a pressure-on-ring test specimen

θPOR

σ = Weibull characteristic strength for a ring-on-ring test specimen

θROR

σ* = an arbitrary, assumed estimate of the Weibull material scale factor

σ¯ = mean strength

σ¯ = mean strength for a uniaxial tensile test specimen

T

σ¯ = mean strength for a four-point flexure test specimen

B4

σ¯ = mean strength for a three-point flexure test specimen

B3

σ¯ = mean strength for a C-ring test specimen

CR

σ¯ = mean strength for a pressure-on-ring test specimen

POR

σ¯ = mean strength for a ring-on-ring test specimen

ROR

θ = angle in a C-ring test specimen

ν = Poisson’s ratio

4. Summary of Practice

4.1 The observed strength values of advanced ceramics are dependent on test specimen size, geometry and stress state. This

standard practice enables the user to convert tensile strength parameters obtained from one test geometry to that of another, on the

basis of assumptions listed in 5.5. Using the existing fracture strength data, estimates of the Weibull characteristic strength σ , and

θ

the Weibull modulus m, are calculated in accordance with related Practice C1239 for the original test geometry. This practice uses

the test specimen and loading sizes and geometries, and σ and m to calculate the Weibull material scale parameter σ . The Weibull

θ 0

characteristic strength σ , the mean strength σ¯, or the Weibull material scale factor σ , may be scaled to alternative test specimen

θ 0

geometries. Finally, a report citing the original test specimen geometry and strength parameters, as well as the size scaled Weibull

strength parameters is prepared.

C1683 − 10 (2015)

5. Significance and Use

5.1 Advanced ceramics usually display a linear stress-strain behavior to failure. Lack of ductility combined with flaws that have

various sizes and orientations typically leads to large scatter in failure strength. Strength is not a deterministic property but instead

reflects the intrinsic fracture toughness and a distribution (size and orientation) of flaws present in the material. This standard is

applicable to brittle monolithic ceramics which fail as a result of catastrophic propagation of flaws. Possible rising R-curve effects

are also not considered, but are inherently incorporated into the strength measurements.

5.2 Two- and three-parameter formulations exist for the Weibull distribution. This standard is restricted to the two-parameter

formulation.

5.3 Tensile and flexural test specimens are the most commonly used test configurations for advanced ceramics. Ring-on-ring and

pressure-on-ring test specimens which have multi-axial states of stress are also included. Closed-form solutions for the effective

volume and effective surfaces and the Weibull material scale factor are included for these configurations. This practice also

incorporates size scaling methods for C-ring test specimens for which numerical approaches are necessary. A generic approach for

arbitrary shaped test specimens or components that utilizes finite element analyses is presented in Annex A3.

5.4 The fracture origins of failed test specimens can be determined using fractographic analysis. The spatial distribution of these

strength controlling flaws can be over a volume or an area (as in the case of surface flaws). This standard allows for the conversion

of strength parameters associated with either type of spatial distribution. Length scaling for strength controlling flaws located along

edges of a test specimen is not covered in this practice.

5.5 The scaling of strength with size in accordance with the Weibull model is based on several key assumptions (5). It is

assumed that the same specific flaw type controls strength in the various specimen configurations. It is assumed that the material

is uniform, homogeneous, and isotropic. If the material is a composite, it is assumed that the composite phases are sufficiently small

that the structure behaves on an engineering scale as a homogeneous and isotropic body. The composite must contain a sufficient

quantity of uniformly-distributed, randomly-oriented, reinforcing elements such that the material is effectively homogeneous.

Whisker-toughened ceramic composites may be representative of this type of material. This practice is also applicable to composite

ceramics that do not exhibit any appreciable bilinear or nonlinear deformation behavior. This standard and the conventional

Weibull strength scaling with size may not be suitable for continuous fiber-reinforced composite ceramics. The material is assumed

to fracture in a brittle fashion, a consequence of stress causing catastrophic propagation of flaws. The material is assumed to be

consistent (batch to batch, day to day, etc.). It is assumed that the strength distribution follows a Weibull two parameter distribution.

It is assumed that each test piece has a statistically significant number of flaws and that they are randomly distributed. It is assumed

that the flaws are small relative to the specimen cross section size. If multiple flaw types are present and control strength, then

strengths may scale differently for each flaw type. Consult Practice C1239 and the example in 9.1 for further guidance on how to

apply censored statistics in such cases. It is also assumed that the specimen stress state and the maximum stress are accurately

determined. It is assumed that the actual data from a set of fractured specimens are accurate and precise. (See Terminology E456

for definitions of the latter two terms.) For this reason, this standard frequently references other ASTM standard test methods and

practices which are known to be reliable in this respect.

5.6 Even if test data has been accurately and precisely measured, it should be recognized that the Weibull parameters determined

from test data are in fact estimates. The estimates can vary from the actual (population) material strength parameters. Consult

Practice C1239 for further guidance on the confidence bounds of Weibull parameter estimates based on test data for a finite sample

size of test fractures.

5.7 When correlating strength parameters from test data from one specimen geometry to a second, the accuracy of the

correlation depends upon whether th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.