ASTM D6859-03

(Test Method)Standard Test Method for Pile Thickness of Finished Level Pile Yarn Floor Coverings

Standard Test Method for Pile Thickness of Finished Level Pile Yarn Floor Coverings

SCOPE

1.1 This test method covers the determination of pile thickness of finished level pile yarn floor covering using a thickness measuring instrument having a stationary surface (platen), a circular pressure foot under specified force, and capable of being moved vertically above the platen.

1.2 This test method is applicable only to finished level loop and cut pile constructions with tuft heights less than 6 mm (0.25 in.).

Note 1—Determination of pile thickness of finished level pile yarn floor coverings was previously contained within Test Methods D 418. For user convenience, Subcommittee D13.21 subdivided Test Methods D 418 into separate standards of which this test method is one.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6859–03

Standard Test Method for

Pile Thickness of Finished Level Pile Yarn Floor Coverings

This standard is issued under the fixed designation D 6859; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 For definitions of textile terms relating to pile yarn

floor coverings, refer to Terminology D 5684.

1.1 This test method covers the determination of pile

3.1.1.1 For discussion of terminology specific to this stan-

thickness of finished level pile yarn floor covering using a

dard, see Annex A1.

thickness measuring instrument having a stationary surface

3.1.2 For definitions of other textile terms used in this test

(platen), a circular pressure foot under specified force, and

method, refer to Terminology D 123.

capable of being moved vertically above the platen.

1.2 Thistestmethodisapplicableonlytofinishedlevelloop

4. Summary of Test Method

and cut pile constructions with tuft heights less than 6 mm

4.1 The total thickness of an unsheared strip specimen is

(0.25 in.).

measured as the distance between two parallel plates exerting

NOTE 1—Determination of pile thickness of finished level pile yarn

a specified pressure on the test specimen. The pile yarn of the

floor coverings was previously contained within Test Methods D 418. For

strip specimen is sheared down to a stubble. The backing

user convenience, Subcommittee D13.21 subdivided Test Methods D 418

thickness of the sheared strip specimen is measured as the

into separate standards of which this test method is one.

distance between two parallel plates exerting a different speci-

1.3 This standard does not purport to address all of the

fied pressure on the sheared strip specimen. The difference

safety concerns, if any, associated with its use. It is the

between the two measurements is the pile thickness.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 5. Significance and Use

bility of regulatory limitations prior to use.

5.1 The determination of pile thickness of level pile yarn

floor covering is useful in quality and cost control during the

2. Referenced Documents

manufacture of pile yarn floor covering. The appearance and

2.1 ASTM Standards:

performance may be affected by changes in pile thickness of

D 123 Terminology Relating to Textiles

pile yarn floor coverings. This test method is considered

D 418 Test Methods of Testing Pile Yarn Floor Covering

satisfactory for acceptance testing of commercial shipments

Construction

because current estimates of between laboratory precision are

D 1776 Practice for Conditioning and Testing Textiles

acceptable, and this test method is commonly used in the trade

D 5684 Terminology Relating to Pile Floor Coverings

for acceptance testing.

D 5823 Test Method for Tuft Height of Pile Floor Cover-

5.2 If there are differences of practical significance between

ings

reported test results for two laboratories (or more), compara-

E 122 Practice for Choice of Sample Size to Estimate the

tive tests should be performed to determine if there is a

Average Quality of a Lot Process

statistical bias between them, using competent statistical assis-

tance. As a minimum, use the samples for such comparative

3. Terminology

tests that are as homogenous as possible, drawn from the same

3.1 Definitions:

lot of material as the samples that resulted in disparate results

during initial testing and randomly assigned in equal numbers

1 to each laboratory. The test results from the laboratories

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

involved should be compared using a statistical test for

and is the direct responsibility of Subcommittee D13.21 on Pile Yarn Floor

Coverings.

unpaired data, a probability level chosen prior to the testing

Current edition approved Feb 10, 2003. Published May 2003.

series. If a bias is found either its cause must be found and

Annual Book of ASTM Standards, Vol 07.01.

corrected, or future test results for that material must be

Discontinued, see 1997 Annual Book of ASTM StandardsVol 07.01.

Annual Book of ASTM Standards, Vol 07.02. adjusted in consideration of the known bias.

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6859–03

6. Sampling Units and Test Specimens (0.001 in.) and capable of developing and indicating a force up

to 2.77 n (0.6 lbf) between the presser foot and the plate.

6.1 Sampling Units:

6.1.1 Coated Floor Covering—The basic sampling unit of

8. Conditioning

coated floor covering is a shipping roll. The number of

8.1 Condition the test sample or test specimens in the

shipping rolls obtained from each production roll ranges from

standardatmospherefortestingtextiles,thatis21 61°C(70 6

one to over ten.

2°F) at 65 6 2 % relative humidity, 12 h or until the mass

6.2 Lot Sample—Take a lot sample as directed in Practice

changes no more than 0.1 % in2has directed in Practice

E 122whenstatisticalknowledgeoftheproductvariabilityand

D 1776.

test method precision is available, and a decision has been

made on the maximum deviation that can be tolerated between

9. Procedure

the estimate to be made from the sample and the result that

9.1 Total Thickness:

wouldbeobtainedbymeasuringeverysamplingunitofthelot.

9.1.1 Select the number and location of the test specimens

Otherwisethenumberofsamplingunitsinalotsampleandthe

as directed in Section 6. Prepare the test specimens according

use of the test results obtained from the individual test samples

to the procedures listed in Section 8. The test specimens shall

shall be in accordance with the manufacturer’s quality control

be250 63mm(10.0 60.1in.)inthelengthwisedirectionand

program or with the specification agreed upon between the

320 6 3 mm (12.5 6 0.1 in.) in the widthwise direction. The

purchaser and supplier.

test specimens may be prepared according to the examples in

6.3 Laboratory Sampling Unit—Alaboratory sampling unit

Appendix X1.

shall consist of a full width section of floor covering cut from

9.1.2 Select a strip specimen from each of the test speci-

one end of each roll in the lot sample and shall be at least 100

mens. The strip specimens shall be 250 6 3 mm (10.0 6 0.1

mm (4 in.) longer than the specimens required for the tests

in.) in the lengthwise direction and 64 6 3 mm (2.5 6 0.1 in.)

being conducted. Do not cut a laboratory sampling unit of

in the widthwise direction and shall be conditioned as directed

coated floor covering from a seam end of a production roll.

in Section 8.

6.4 Test Specimens:

9.1.3 Attach the 57.15 mm (2.250 in.) diameter presser foot

6.4.1 A test specimen is a designated area cut from a

loosely to the moveable stem or head of the instrument and

laboratory sampling unit. For laboratory sampling units 3000

bring the diameter presser foot into firm contact with the plate.

mm (120 in.) wide or wider, three test specimens are required

Tighten the presser foot on the stem.

for a test method, one at each edge no nearer to the edge than

9.1.4 Checktheinstrumentzerobyloweringthepresserfoot

5 % of the total floor covering width and one in the middle

intocontactwiththeplateuntiltheindicatedpressureincreases

portion of laboratory sampling unit. For laboratory sampling

to the pressure to be used in measuring the indicated distance

units at least 1500 mm (60 in.) wide but less than 3000 mm

between the foot and the plate, which must read 0 6 0.03 mm

(120 in.), take two test specimens, one at each edge no nearer

(6 0.001 in.). If the reading is not within this range, make an

to the edge than 5 % of the total floor covering width. For

adjustment appropriate to the type of instrument being used.

laboratory sampling units less than 1500 mm (120 in.) wide,

Verify the instrument with calibrated thickness blocks.

take one test specimen from the middle.

9.1.5 For each strip specimen, raise the presser foot and

6.4.2 Where it is known that systematic variations in a floor

center the specimen, pile face up, on the plate under the foot.

covering characteristic may occur in bands 460 mm (18 in.) or

Lowerthepresserfootslowly(takeabout5stoapplyfullload)

more in width, as with a modular pattern device having

onto the pile surface until a pressure of 689 6 21 Pa (0.100 6

separate controls or adjustments for each module, take test

0.003 psi) is exerted on the specimen. Read the distance

specimens from the middle of each band.

between the presser foot and the plate to the nearest 0.03 mm

6.4.3 When a full-width laboratory sampling unit is not

(0.001in.),determinethetotalthicknessinthreedifferentareas

available,taketestspecimensasdirectedin6.4,andstateinthe

for each strip specimen and record the average as the total

report the width available and the number of test specimens

thickness, T.

taken.

9.1.6 Shear the pile on the strip specimen down to a stubble

measuring approximately 1.3 mm (0.05 in.).

7. Apparatus

NOTE 2—Both adhesive projections and a fiber layer needle punched to

7.1 Shear or Clipper, capable of shearing close enough to

the surface of the backing can interfere with shearing the pile down to a

the backing to leave a stubble of no more than 1.3 mm (0.05

stubble of 1.3 mm (0.05 in.).Therefore, a seven and one half fold increase

in pressure in measuring the thickness of the stubble specimen is used to

in.).

level out minor variations in stubble height.

7.2 Thickness Measuring Instrument:

7.2.1 Having a stationary surface (plate) on which to place

9.2 Backing Thickness:

the specimen, and a presser foot capable of being moved 9.2.1 Attach the 25.40 mm (1.000 in.) diameter presser foot

vertically above the plate, at least 25 mm (1 in.) from the plate.

loosely to the stem and bring the presser foot into firm contact

7.2.2 Having two interchangeable presser feet; one 25.40 6 with the plate. Tighten the presser foot on the stem. Check the

0.03mm(1.000 60.001in.)diameter,theother57.15 60.003

instrument zero as directed in 9.1.4.

mm (2.250 6 0.001 in.) in diameter. 9.2.2 For each stubble specimen, raise the presser foot and

7.2.3 Having means for indicating the vertical distance center the specimen, stubble side up, on the plate. Lower the

between the presser foot and the plate to the nearest 0.03 mm presser foot onto the stubble surface until a pressure of 5170 6

D6859–03

69 Pa (0.75 6 0.01 psi) is exerted on the stubble specimen. in Tables 1 and 2 for the respective number of tests in 95 out

Read the distance between the presser foot and the plate to the of 100 cases when all the observations are taken by the same

nearest 0.03 mm (0.01 in.), determine the backing thickness in well-trained operator using the same piece of equipment and

three different areas for of each strip specimen and record the specimens randomly drawn from the sample of material.

average as the backing thickness, B. Larger differences are likely to occur under all other circum-

stances.

10. Calculation

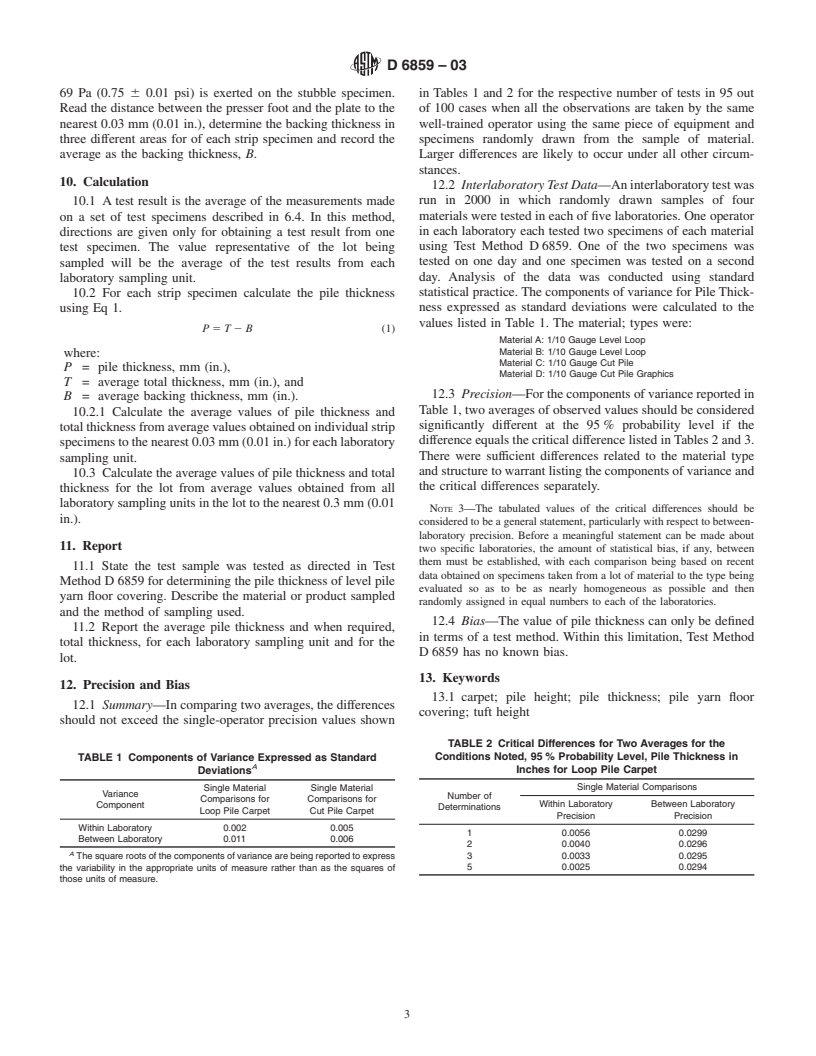

12.2 Interlaboratory Test Data—Aninterlaboratorytestwas

run in 2000 in which randomly drawn samples of four

10.1 A test result is the average of the measurements made

materials were tested in each of five laboratories. One operator

on a set of test specimens described in 6.4. In this method,

in each laboratory each tested two specimens of each material

directions are given only for obtaining a test result from one

using Test Method D 6859. One of the two specimens was

test specimen. The value representative of the lot being

sampled will be the average of the test results from each tested on one day and one specimen was tested on a second

day. Analysis of the data was conducted using standard

laboratory sampling unit.

10.2 For each strip specimen calculate the pile thickness statistical practice. The components of variance for Pile Thick-

ness expressed as standard deviations were calculated to the

using Eq 1.

values listed in Table 1. The material; types were:

P 5 T 2 B (1)

Material A: 1/10 Gauge Level Loop

Material B: 1/10 Gauge Level Loop

where:

Material C: 1/10 Gauge Cut Pile

P = pile thickness, mm (in.),

Material D: 1/10 Gauge Cut Pile Graphics

T = average total thickness, mm (in.), and

12.3 Precision—For the components of variance reported in

B = average backing thickness, mm (in.).

Table 1, two averages of observed values should be considered

10.2.1 Calculate the average values of pile thickness and

significantly different at the 95 % probability level if the

totalthicknessfromaveragevaluesobtainedonindividualstrip

difference equals the critical difference listed inTables 2 and 3.

specimenstothenearest0.03mm(0.01in.)foreachlaboratory

There were sufficient differences related to the material type

sampling unit.

and structure to warrant listing the components of variance and

10.3 Calculate the average values of pile thickness and total

the critical differences separately.

thickness for the lot from average values obtained from all

laboratory sampling units in the lot to the nearest 0.3 mm (0.01

NOTE 3—The tabulated values of the critical differences should be

in.).

considered to be a general statement, particularly with respect to between-

laboratory precision. Before a meaningful statement can be made about

11. Report

two specific laboratories, the amount of statistical bias, if any, between

them must be established, with each comparison being based on recent

11.1 State the test sample was tested as directed in Test

data obtained on specimens taken from a lot of material to the type being

Method D 6859 for determining the pile thickness of level pile

evaluated so as to be as nearly homogeneous as possible and then

yarn floor covering. Describe the material or product sampled

randomly assigned in equal numbers to each of the laboratories.

and the method of sampling used.

12.4 Bias—The value of pile thickness can only be defined

11.2 Report the average pile thickness and when required,

in terms of a test method. Within this limitation, Test Method

total thickness, for each laboratory sampling unit and for the

D 6859 has no known bias.

lot.

13. Keywords

12. Precision and Bias

13.1 carpet; pile height; pile thickness; pile yarn floor

12.1 Summary—In comparing two averages, the differences

covering; tuft height

should not exceed the single-operator precision values shown

TABLE 2 Critical Differences for Two Averages for the

Conditions Noted, 95% Probability Level, Pile Thickness in

TABLE 1 Components of Variance Expressed as Standard

A

Inches fo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.