ASTM D3117-96e1

(Test Method)Standard Test Method for Wax Appearance Point of Distillate Fuels

Standard Test Method for Wax Appearance Point of Distillate Fuels

SCOPE

1.1 This test method covers the detection of wax in burner fuels, diesel fuels, and turbine engine fuels in the range from -26 to +2°C. It is applicable to a dark-colored oil if the stirrer can be seen under illumination.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Notes 2 through 5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

e1

Designation: D 3117 – 96

Standard Test Method for

Wax Appearance Point of Distillate Fuels

This standard is issued under the fixed designation D 3117; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE— Figure was corrected editorially in October 1997.

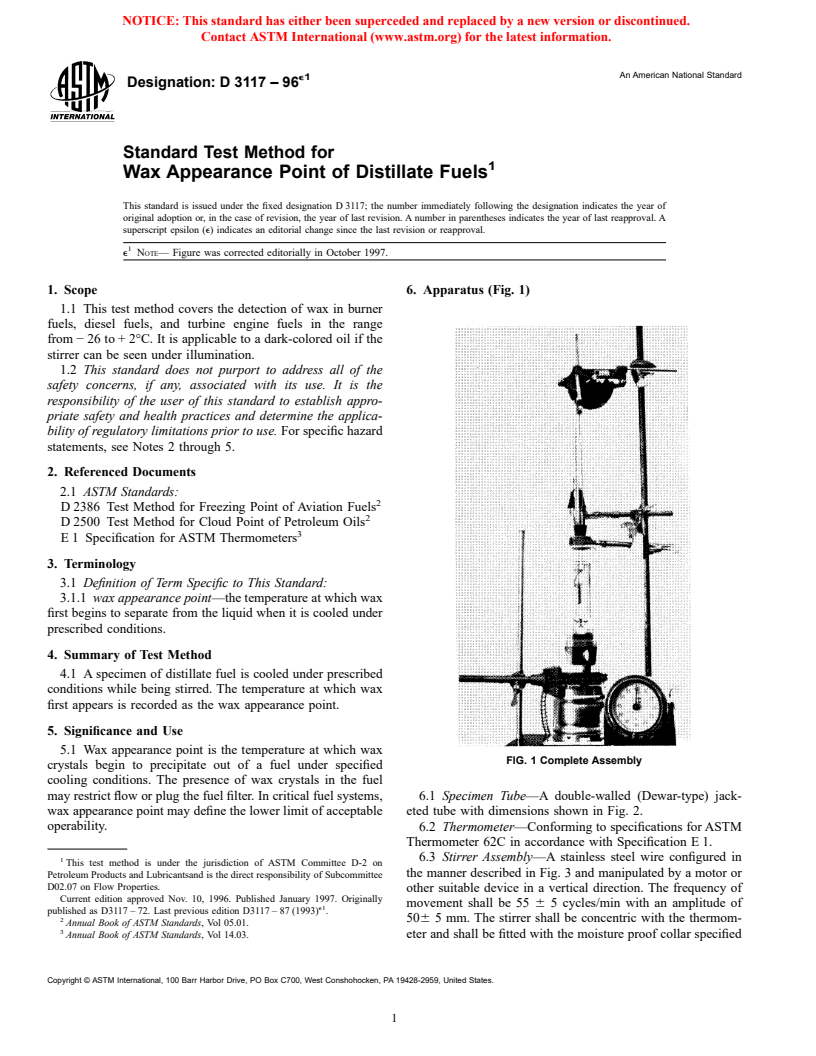

1. Scope 6. Apparatus (Fig. 1)

1.1 This test method covers the detection of wax in burner

fuels, diesel fuels, and turbine engine fuels in the range

from − 26 to + 2°C. It is applicable to a dark-colored oil if the

stirrer can be seen under illumination.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific hazard

statements, see Notes 2 through 5.

2. Referenced Documents

2.1 ASTM Standards:

D 2386 Test Method for Freezing Point of Aviation Fuels

D 2500 Test Method for Cloud Point of Petroleum Oils

E 1 Specification for ASTM Thermometers

3. Terminology

3.1 Definition of Term Specific to This Standard:

3.1.1 wax appearance point—the temperature at which wax

first begins to separate from the liquid when it is cooled under

prescribed conditions.

4. Summary of Test Method

4.1 A specimen of distillate fuel is cooled under prescribed

conditions while being stirred. The temperature at which wax

first appears is recorded as the wax appearance point.

5. Significance and Use

5.1 Wax appearance point is the temperature at which wax

FIG. 1 Complete Assembly

crystals begin to precipitate out of a fuel under specified

cooling conditions. The presence of wax crystals in the fuel

may restrict flow or plug the fuel filter. In critical fuel systems,

6.1 Specimen Tube—A double-walled (Dewar-type) jack-

wax appearance point may define the lower limit of acceptable eted tube with dimensions shown in Fig. 2.

operability. 6.2 Thermometer—Conforming to specifications for ASTM

Thermometer 62C in accordance with Specification E 1.

6.3 Stirrer Assembly—A stainless steel wire configured in

This test method is under the jurisdiction of ASTM Committee D-2 on

the manner described in Fig. 3 and manipulated by a motor or

Petroleum Products and Lubricantsand is the direct responsibility of Subcommittee

D02.07 on Flow Properties.

other suitable device in a vertical direction. The frequency of

Current edition approved Nov. 10, 1996. Published January 1997. Originally

movement shall be 55 6 5 cycles/min with an amplitude of

e1

published as D3117 – 72. Last previous edition D3117 – 87 (1993) .

2 506 5 mm. The stirrer shall be concentric with the thermom-

Annual Book of ASTM Standards, Vol 05.01.

Annual Book of ASTM Standards, Vol 14.03. eter and shall be fitted with the moisture proof collar specified

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D3117

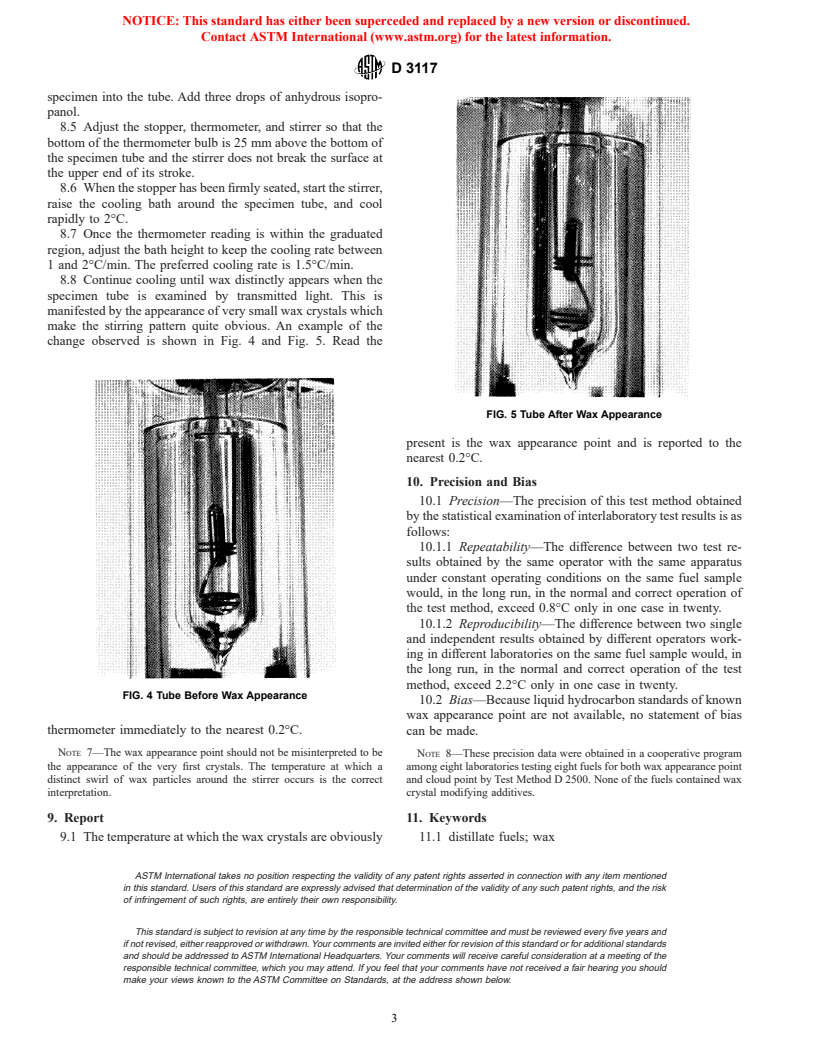

rescent tube shall be mounted behind the specimen to illumi-

nate it with transmitted light. Observations shall be made with

the sample tube between the observer’s eye and the lamp.

6.6 Clock—Use a clock or other timing device readable to

10 s to monitor the cooling rate.

7. Materials

7.1 Carbon Dioxide (Solid) or Dry Ice —(Warning—see

Note 2). A commercial grade of dry ice is suitable for use in the

cooling bath (Note 6).

NOTE 2—Warning: Extremely cold, − 78°C.

7.2 Isopropanol or Isopropyl Alcohol—(Warning—see

Note 3). A commercial or technical grade of isopropanol is

suitable for the cooling bath.

NOTE 3—Warning: Extremely flammable.

7.3 Liquid Nitrogen (Warning—see Note 4). A commercial

or technical grade of liquid nitrogen is suitable for the cooling

bath. See Note 6.

NOTE 4—Warning: Extremely cold, − 196°C.

NOTE 5—Warning: Carbon dioxide (solid) and liquid nitrogen liberate

gases that can cause suffocation. Contact with skin causes burns, freezing,

or both.

8. Procedure

8.1 Check the thermometer each day the test is run by

FIG. 2 Specimen Tube

NOTE 1—Tolerance on all dimensions are + or − 2 mm, except on wire thickness.

FIG. 3 Stirrer

in Test Method D 2386. A No. 3, two-hole neoprene rubber immersing it in an ice-water slurry. An acceptable thermometer

stopper shall be used to seal the top of the specimen tube. will show 06 0.1°C.

6.4 Cooling Bath—Use an unsilvered vacuum flask having

NOTE 6—Because ambient temperatures are well above the range of

minimum dimensions of 200-mm depth and 65-mm internal

Thermometer 62C, the mercury thread will extend upward into the

diameter. The bath temperature, below − 45°C, may be main-

expansion chamber. During cooling, the thermometer must be examined to

tained by refrigeration or suitable freezing mixtures (Note 2). make certain that no mercury separation occurs. If a lo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.