ASTM D5341-99(2010)e1

(Test Method)Standard Test Method for Measuring Coke Reactivity Index (CRI) and Coke Strength After Reaction (CSR)

Standard Test Method for Measuring Coke Reactivity Index (CRI) and Coke Strength After Reaction (CSR)

SIGNIFICANCE AND USE

When coke lumps descend in the blast furnace, they are subjected to reaction with countercurrent CO2 and to abrasion as they rub together and against the walls of the furnace. These concurrent processes physically weaken and chemically react with the coke lumps, producing an excess of fines that can decrease burden permeability and result in increased coke rates and lost hot metal production. This test method is designed to measure indirectly this behavior of coke in the blast furnace.

SCOPE

1.1 This test method, patterned after the Nippon Steel test procedure, describes the equipment and techniques used for determining lump coke reactivity in carbon dioxide (CO2) gas at elevated temperatures and its strength after reaction in CO2 gas by tumbling in a cylindrical chamber referred to as an I-tester.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D5341 − 99(Reapproved 2010)

Standard Test Method for

Measuring Coke Reactivity Index (CRI) and Coke Strength

After Reaction (CSR)

This standard is issued under the fixed designation D5341; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Added research report information to Section 11 editorially in September 2010.

1. Scope 3. Summary of Test Method

1.1 This test method, patterned after the Nippon Steel test 3.1 A sample of dried coke of designated origin and size is

procedure, describes the equipment and techniques used for reacted with CO gas in a retort at a specified elevated

determining lump coke reactivity in carbon dioxide (CO ) gas temperature for a specified length of time. Two indices, coke

at elevated temperatures and its strength after reaction in CO reactivity index (CRI) and coke strength after reaction (CSR),

gas by tumbling in a cylindrical chamber referred to as an are determined using the reacted coke residue. The weight loss

I-tester. after reaction determines the CRI. The weight retained after

sieving the tumbled reacted coke in a designated number of

1.2 The values stated in SI units are to be regarded as the

revolutions over a designated turning rate determines the CSR.

standard. The values given in parentheses are for information

only.

4. Significance and Use

1.3 This standard does not purport to address all of the

4.1 When coke lumps descend in the blast furnace, they are

safety concerns, if any, associated with its use. It is the

subjected to reaction with countercurrent CO and to abrasion

responsibility of the user of this standard to establish appro-

as they rub together and against the walls of the furnace.These

priate safety and health practices and determine the applica-

concurrent processes physically weaken and chemically react

bility of regulatory limitations prior to use.

with the coke lumps, producing an excess of fines that can

decrease burden permeability and result in increased coke rates

2. Referenced Documents

and lost hot metal production. This test method is designed to

2.1 ASTM Standards:

measure indirectly this behavior of coke in the blast furnace.

D346 Practice for Collection and Preparation of Coke

Samples for Laboratory Analysis

5. Apparatus

E11 Specification for Woven Wire Test Sieve Cloth and Test

5.1 Electric Furnace (Fig. 1), capable of housing the reac-

Sieves

tion vessel assembly containing the coke sample and providing

E691 Practice for Conducting an Interlaboratory Study to

a uniform temperature of 1100 6 5°C in the assembly. Furnace

Determine the Precision of a Test Method

dimensions do not impact the test results and may vary from

2.2 British Carbonization Research Association Report:

240 to 1035 mm in length and 76.2 to 88.9 mm in outside

Carbonization Research Report 91, “The Evaluation of the

diameter. However, it is preferable that the furnace have

Nippon Steel Corporation Reactivity and Post-Reaction-

independently controlled heating in three zones to achieve

Strength Test for Coke.”

uniformity of heating in the retort and that this control be

achieved with a programmable controller.

5.2 Reaction Vessel (Fig. 1), constructed of a heat-resistant

This test method is under the jurisdiction of ASTM Committee D05 on Coal

steel or nickel alloy to the dimensions required to fit snugly

and Coke and is the direct responsibility of Subcommittee D05.15 on Metallurgical

Properties of Coal and Coke.

inside the electric furnace selected for use (Note 1). The coke

Current edition approved May 1, 2010. Published May 2010. Originally

to be tested sits on a porous plate in the reaction vessel. Below

approved in 1993. Last previous edition approved in 2004 as D5341 – 99 (2004).

this porous plate, a gas preheater, such as a bed of ceramic

DOI: 10.1520/D5341-99R10E01.

Al O balls sitting on a second perforated plate, diffuse the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

2 3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

nitrogen (N ) and carbon dioxide introduced into the vessel up

Standards volume information, refer to the standard’s Document Summary page on

through the coke bed during the course of the test. The gas

the ASTM website.

enters through inlets and exits through outlets varying from 6

Available from British Carbonization Research Association, Chesterfield,

Derbyshire, England. to 15 mm in inside diameter and positioned at the top and

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

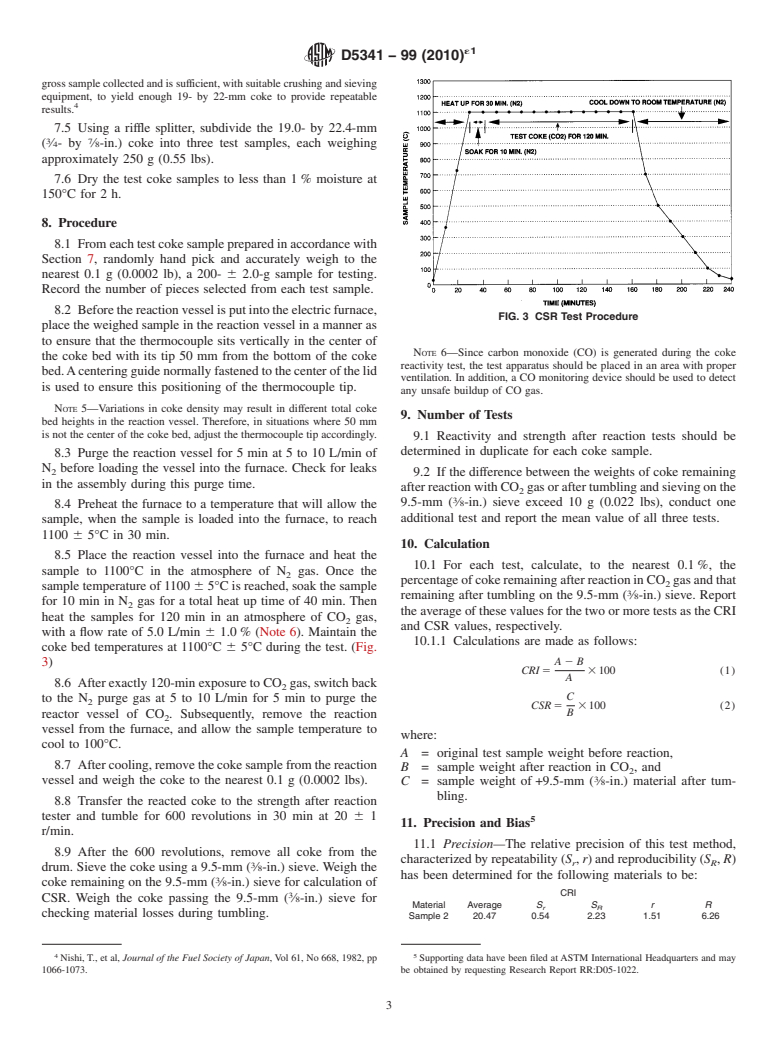

D5341 − 99 (2010)

FIG. 2 Example of I-Type Coke Tumbler (Dimensions in mm)

FIG. 1 Example of Reactivity Test Apparatus (Dimensions in mm)

with a direct drive fixed gearbox, a drive belt, or, preferably, a

hydraulic drive set for a revolving rate of 20 6 1 r/min (Note

3). A revolution counter is fitted so that the power is cut off

bottom of the reaction vessel. During the test, it is important

when the cylinder has revolved 600 times in 30 min.

that no backpressure be detected when gas enters or exits

throughtheseinletsoroutlets.Thereactionvesselispositioned

NOTE 2—Mild carbon steel should be selected to fabricate this tumbler

such that the coke sample contained in the vessel on top of the apparatus.

NOTE 3—Most Japanese publications refer to this as an I test.

600/10

ceramic Al O balls is in the center of the controlled tempera-

2 3

ture zone in the furnace.

6. Sampling

NOTE 1—Inconel 601 is recommended over stainless steel. Inconel 601

6.1 The gross sample of coke shall be collected in accor-

doesnotleavescale,that,ifnotproperlyremoved,canalteracokesample

dance with Test Method D346.

weight after the test.

6.2 Forthestandardprocedure,thequantitymustbenotless

5.3 Flowmeters—Rotometers or, preferably, mass flowme-

than 57 kg (125 lbs).

ters shall be used to monitor the amount of N and CO gases

2 2

used in the test. The accuracy of measuring gas flowrates

7. Preparation of Sample

should be 61 % of full scale since varying gas flow can cause

variability in the test results. Gas pressures through the 7.1 Sieve the gross sample at 25.0 mm (1 in.) and discard

the undersize.

flowmeters should be maintained at the manufacturer’s cali-

bration specification.

7.2 With suitable crushing equipment, preferably a jaw or

roll crusher, reduce the size of all of the remaining plus 25.0

5.4 Thermocouple (Fig. 1), of the K, S, or R type normal-

mm (1 in.) to pass a 22.4-mm ( ⁄8-in.) sieve opening.

ized at 20 to 21°C and enclosed in a heat-resistant steel or

nickel alloy or ceramic protection tube placed in the center of 7

7.3 Sieve the crushed sample using a 22.4-mm ( ⁄8-in.) sieve

the coke sample in the reaction vessel.Acentering pipe or tube

placed on top of a 19.0-mm ( ⁄4-in.) sieve. Discard the minus

also made of heat-resistant material is used to guide the

3 7

19.0-mm( ⁄4-in.)coke,andretainthe22.4-by19.0-mm( ⁄8-by

thermocouple into its proper location in the coke bed.

⁄4-in.) fraction for testing.

5.5 Sieves, used for sieving the coke during its preparation

7.4 The size reduction of the plus 25.0 mm (1 in.) should be

for reactivity testing and after tumbling for strength after

accomplished in stages by recrushing any plus 22.4-mm

reaction testing. Square mesh sieves having 22.4-, 19.0-, and

( ⁄8-in.) coke remaining after each subsequent double sieving

9.5-mm actual openings between the wires are to be used.

step until there is no oversize retained on the 22.4-mm ( ⁄8-in.)

Standard test sieves that conform to Specification E11 should

sieve. The opening to the crusher should be set such that the

always be used.

gross sample yields at least 10 % of 19.0- by 22.4-mm ( ⁄4-by

5.6 Balance, capable of weighing up to 25 kg and sensitive ⁄8-in.) test coke (Note 4).

to 0.1 g (0.000 22 lbs).

NOTE 4—The size of the sample required for most coke tests depends

on collecting sufficient received material to have sufficient natural sample

5.7 Coke Strength After Reaction Tumbler (Fig. 2), consist-

for testing, that is, stability 75.0 by 50.0 mm (

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.