ASTM C1403-06

(Test Method)Standard Test Method for Rate of Water Absorption of Masonry Mortars

Standard Test Method for Rate of Water Absorption of Masonry Mortars

SIGNIFICANCE AND USE

This test method provides a laboratory procedure for determining the relative water absorption properties over time of mortars used for masonry construction. Because the specimens are made under laboratory conditions and do not take into account the effect of the masonry substrate or field mixing procedures, this method is not intended for field use. Data generated from this test method may be useful for determining the relative effectiveness of water repellent admixtures or the effect of other admixtures or mortar components on the water repellency of a mortar. However, use caution in interpreting the results. While the resistance of masonry to water penetration may be related to the water absorption of the mortar, it also depends on other factors, such as the workmanship, extent of bond, and the properties of the masonry units and mortar.

SCOPE

1.1 This test method covers a standardized laboratory procedure for determining the relative water absorption by capillary uptake (wicking) characteristics of masonry mortars. This test method is not applicable for determining the effectiveness of water repellent coatings.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1403 − 06

StandardTest Method for

1

Rate of Water Absorption of Masonry Mortars

This standard is issued under the fixed designation C1403; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 4. Significance and Use

1.1 This test method covers a standardized laboratory pro-

4.1 This test method provides a laboratory procedure for

cedure for determining the relative water absorption by capil-

determining the relative water absorption properties over time

lary uptake (wicking) characteristics of masonry mortars. This

of mortars used for masonry construction. Because the speci-

test method is not applicable for determining the effectiveness

mensaremadeunderlaboratoryconditionsanddonottakeinto

of water repellent coatings.

account the effect of the masonry substrate or field mixing

procedures, this method is not intended for field use. Data

1.2 The values stated in SI units are to be regarded as the

generated from this test method may be useful for determining

standard. The inch-pound units given in parentheses are for

the relative effectiveness of water repellent admixtures or the

information only.

effect of other admixtures or mortar components on the water

1.3 This standard does not purport to address all of the

repellencyofamortar.However,usecautionininterpretingthe

safety concerns, if any, associated with its use. It is the

results. While the resistance of masonry to water penetration

responsibility of the user of this standard to establish appro-

may be related to the water absorption of the mortar, it also

priate safety and health practices and determine the applica-

depends on other factors, such as the workmanship, extent of

bility of regulatory limitations prior to use.

bond, and the properties of the masonry units and mortar.

2. Referenced Documents

5. Apparatus

2

2.1 ASTM Standards:

5.1 Balance—A balance sensitive to 0.1 g.

C109/C109M Test Method for Compressive Strength of

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

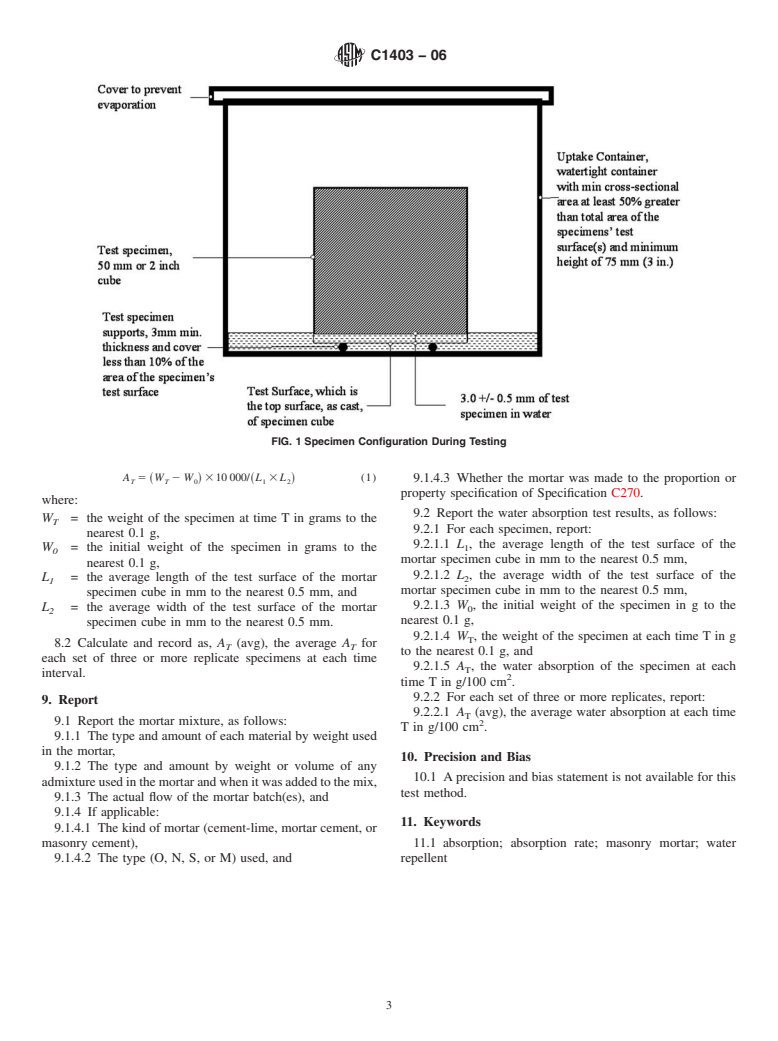

5.2 Uptake Container—A watertight container with a mini-

Specimens)

mum cross sectional area that is at least 50 % greater than the

C270 Specification for Mortar for Unit Masonry

total area of the specimens’ test surface(s) and a minimum

C305 Practice for Mechanical Mixing of Hydraulic Cement

depth of 75 mm (3 in.). Provide a cover for the container to

Pastes and Mortars of Plastic Consistency

minimize evaporation.

C511 Specification for Mixing Rooms, Moist Cabinets,

5.2.1 Usespecimensupportsthatallowaminimumof3mm

Moist Rooms, and Water Storage Tanks Used in the

(0.12 in.) clearance from the bottom of the container and that

Testing of Hydraulic Cements and Concretes

cover a maximum of 10 % of the area of the specimen’s test

C778 Specification for Sand

surface. Use supports made of a material that does not float in

C1180 Terminology of Mortar and Grout for Unit Masonry

water and that does not rust, expand, or contract as a result of

C1437 Test Method for Flow of Hydraulic Cement Mortar

water exposure.

5.2.2 The container shall be flat so that when a specimen is

3. Terminology

set on the supports the water level as specified in 7.4 shall not

3.1 Definitions—For definitions of terms used in this test

vary by more than 1 mm (0.04 in.) from one end of the

method, refer to Terminology C1180.

specimen to the opposite end.

5.3 Specimen Molds—Metal 50-mm or 2-in. cube specimen

1

This test method is under the jurisdiction ofASTM Committee C12 on Mortars

moldswithremovableplasticwatertightdisposableliners.The

and Grouts for Unit Masonryand is the direct responsibility of Subcommittee

plastic liners shall be rigid enough to retain their shape when

C12.02 on Research and Methods of Test.

free standing and filled with mortar.

Current edition approved Dec. 15, 2006. Published January 2007. Originally

approved in 1999. Last previous edition approved in 2005 as C1403 – 05. DOI:

5.4 Spoon—Ametal spoon approximately 230 mm (9 in.) in

10.1520/C1403-06.

2 lengthandwithabowlapproximately100mm(4in.)inlength.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.5 Straightedge—Asteelstraightedgenotlessthan150mm

Standards volume information, refer to the standard’s Document Summary page on

1 1

the ASTM website. (6 in.) long and approximately 1.5-3.0 mm ( ⁄16 to ⁄8 in.) thick.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ---

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.