ASTM D2844-01e1

(Test Method)Standard Test Method for Resistance R-Value and Expansion Pressure of Compacted Soils

Standard Test Method for Resistance <i>R</i>-Value and Expansion Pressure of Compacted Soils

SCOPE

1.1 This test method covers the procedure for testing both treated and untreated laboratory compacted soils or aggregates with the stabilometer and expansion pressure devices to obtain results indicative of performance when placed in the base, subbase, or subgrade of a road subjected to traffic.

1.2 The values stated in inch-pound units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

ϵ1

Designation:D 2844–01

Standard Test Method for

Resistance R-Value and Expansion Pressure of Compacted

1

Soils

This standard is issued under the fixed designation D 2844; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

1

ϵ NOTE—Sections 4.8 and 4.9 were corrected editorially in June 2004.

1. Scope*

1.1 This test method covers the procedure for testing both

treated and untreated laboratory compacted soils or aggregates

with the stabilometer and expansion pressure devices to obtain

results indicative of performance when placed in the base,

subbase, or subgrade of a road subjected to traffic.

1.2 The values stated in inch-pound units are to be regarded

as the standard.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C670 Practice for Preparing Precision and Bias Statements

2

for Test Methods for Construction Materials

3

E4 Practices for Force Verification of Testing Machines

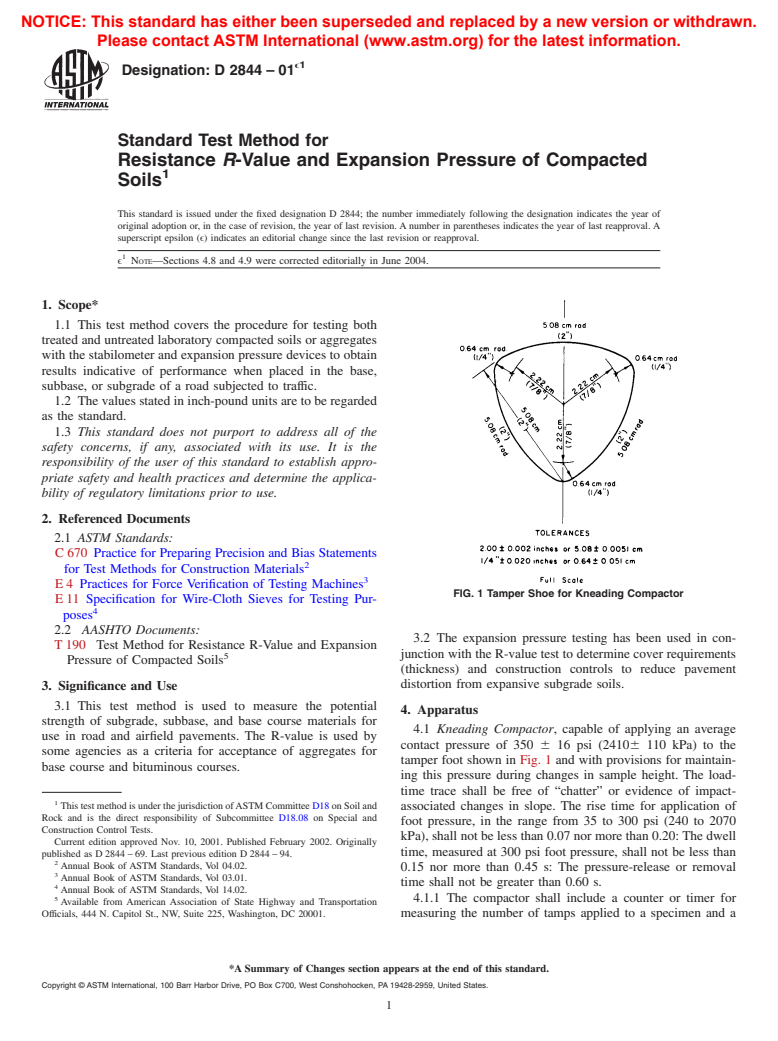

FIG. 1 Tamper Shoe for Kneading Compactor

E11 Specification for Wire-Cloth Sieves for Testing Pur-

4

poses

2.2 AASHTO Documents:

3.2 The expansion pressure testing has been used in con-

T190 Test Method for Resistance R-Value and Expansion

junction with the R-value test to determine cover requirements

5

Pressure of Compacted Soils

(thickness) and construction controls to reduce pavement

distortion from expansive subgrade soils.

3. Significance and Use

3.1 This test method is used to measure the potential

4. Apparatus

strength of subgrade, subbase, and base course materials for

4.1 Kneading Compactor, capable of applying an average

use in road and airfield pavements. The R-value is used by

contact pressure of 350 6 16 psi (24106 110 kPa) to the

some agencies as a criteria for acceptance of aggregates for

tamper foot shown in Fig. 1 and with provisions for maintain-

base course and bituminous courses.

ing this pressure during changes in sample height. The load-

time trace shall be free of “chatter” or evidence of impact-

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland

associated changes in slope. The rise time for application of

Rock and is the direct responsibility of Subcommittee D18.08 on Special and

foot pressure, in the range from 35 to 300 psi (240 to 2070

Construction Control Tests.

kPa), shall not be less than 0.07 nor more than 0.20:The dwell

Current edition approved Nov. 10, 2001. Published February 2002. Originally

time, measured at 300 psi foot pressure, shall not be less than

published as D2844–69. Last previous edition D2844–94.

2

Annual Book of ASTM Standards, Vol 04.02.

0.15 nor more than 0.45 s: The pressure-release or removal

3

Annual Book of ASTM Standards, Vol 03.01.

time shall not be greater than 0.60 s.

4

Annual Book of ASTM Standards, Vol 14.02.

5 4.1.1 The compactor shall include a counter or timer for

Available from American Association of State Highway and Transportation

Officials, 444 N. Capitol St., NW, Suite 225, Washington, DC 20001. measuring the number of tamps applied to a specimen and a

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

ϵ1

D 2844–01

6

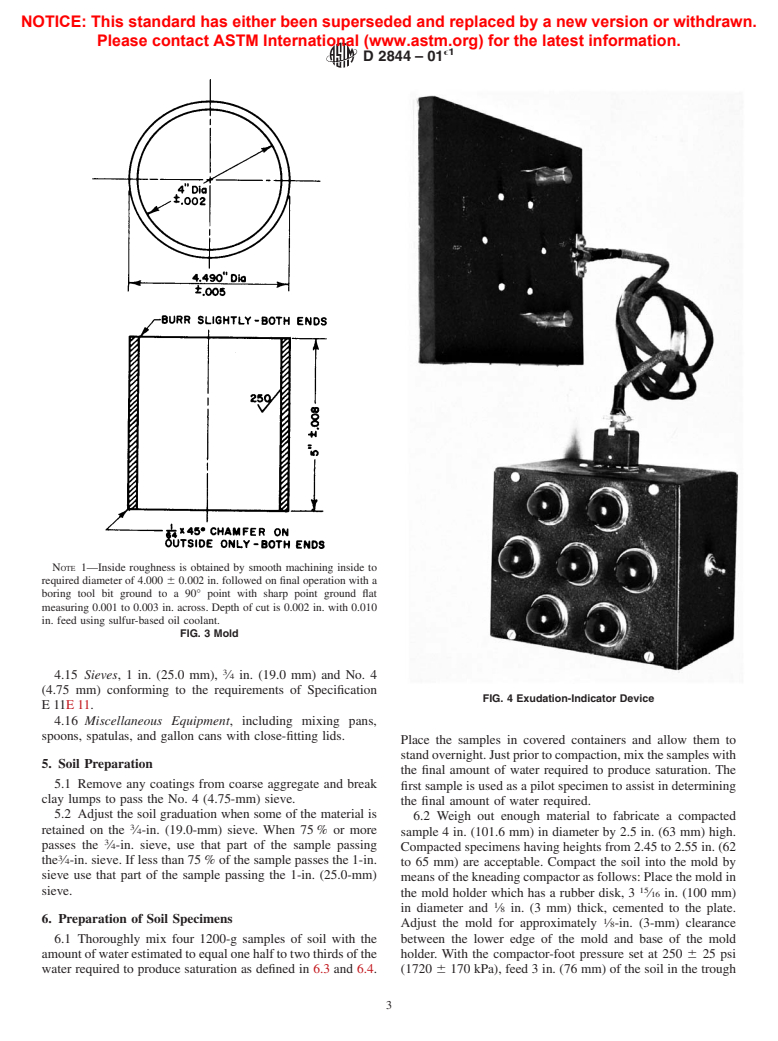

mold holder, for use in compacting specimens, that rotates 4.6 Exudation Device, as shown in Fig. 4.

equally between tamps to give 5 to 7 tamps per revolution of 4.7 Phosphor Bronze Disk, as shown in Fig. 5.

the mold. The holder shall firmly restrain the mold during 4.8 Filter Paper, 100 mm in diameter and 0.006 in. (.15

compaction. The base of the mold holder shall have a metal mm) thick, smooth surface, medium filtering speed, medium

31

plate 3 ⁄32 in. (100.8 mm) in diameter and 0.5 in. (12.7 mm) retention.

high to which is cemented a rubber disk having a diameter of 4.9 Filter Paper, 110 mm in diameter and 0.006 in. (.15

15 1

3 ⁄16in.(100.0mm)andaheightof ⁄8in.(3.2mm).Theplate mm) thick, creped surface, medium-fast filtering speed, me-

shall be an integral part of the base of the mold holder. The dium retention.

compactor shall also include a trough for feeding the sample 4.10 Expansion-Press

...

This May Also Interest You

SIGNIFICANCE AND USE

4.1 These test methods are used to determine the resistance of compacted soil-cement specimens to repeated wetting and drying. These test methods were developed to be used in conjunction with Test Methods D560/D560M and criteria given in the Soil-Cement Laboratory Handbook4 to determine the minimum amount of cement required in soil-cement to achieve a degree of hardness adequate to resist field weathering.

Note 1: The quality of the result produced by this standard is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this standard are cautioned that compliance with Practice D3740 does not in itself ensure reliable results. Reliable results depend on many factors; Practice D3740 provides a means of evaluating some of those factors.

SCOPE

1.1 These test methods cover procedures for determining the soil-cement losses, water content changes, and volume changes (swell and shrinkage) produced by repeated wetting and drying of hardened soil-cement specimens. The specimens are compacted in a mold, before cement hydration, to maximum density at optimum water content using the compaction procedure described in Test Methods D558/D558M.

1.2 Two test methods, depending on soil gradation, are covered for preparation of material for molding specimens and for molding specimens as follows:

Sections

Test Method A, using soil material passing a 4.75-mm [No. 4] sieve.

This method shall be used when 100 % of the soil sample passes the 4.75-mm [No. 4] sieve.

7

Test Method B, using soil material passing a 19.0 mm [0.75-in.] sieve.

This method shall be used when part of the soil sample is retained on the 4.75-mm [No. 4] sieve.

This test method may be used only on materials with 30 % or less retained on the 19.0-mm [0.75-in.] sieve.

8

1.3 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice D6026, unless superseded by this test method.

1.3.1 The procedures used to specify how data are collected/recorded and calculated in the standard are regarded as the industry standard. In addition, they are representative of the significant digits that generally should be retained. The procedures used do not consider material variation, purpose for obtaining the data, special purpose studies, or any considerations for the user’s objectives; and it is common practice to increase or reduce significant digits of reported data to be commensurate with these considerations. It is beyond the scope of these test methods to consider significant digits used in analysis methods for engineering data.

1.4 Units—The values stated in either SI units or inch-pound units [presented in brackets] are to be regarded separately as standard. The values stated in each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. Sieve size is identified by its standard designation in Specification E11. The alternative designation given in parentheses is for information only and does not represent a different standard sieve size.

1.4.1 The gravitational system of inch-pound units is used when dealing with inch-pound units. In this system, the pound (lbf) represents a unit of force (weight), while the unit for mass is slugs. The rationalized slug unit is not given, unless dynamic (F = ma) calculations are involved.

1.4.2 It is common practice in the engineering/construction profession to use pounds to represent both a unit of mass (lbm) and of force (lbf). This implicitly combines two separate systems of units; that is, the absolute system and the gravitational system. It is scientifically undesirable to combine the use of tw...

- Standard6 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 Compaction tests on soils performed in accordance with Test Methods D698, D1557, D4253, and D7382 place limitations on the maximum size of particles that may be used in the test. If a soil contains cobbles or gravel, or both, test options may be selected which result in particles retained on a specific sieve being discarded (for example the 4.75-mm [No. 4], the 19-mm [3/4-in.] or other appropriate size) and the test performed on the finer fraction. The unit weight-water content relations determined by the tests reflect the characteristics of the actual material tested, and not the characteristics of the total soil material from which the test specimen was obtained.

4.2 It is common engineering practice to use laboratory compaction tests for the design, specification, and construction control of soils used in earth construction. If a soil used in construction contains large particles, and only the finer fraction is used for laboratory tests, some method of correcting the laboratory test results to reflect the characteristics of the total soil is needed. This practice provides a mathematical equation for correcting the unit weight and water content of the finer fraction of a soil, tested to determine the unit weight and water content of the total soil.

4.3 Similarly, as utilized in Test Methods D1556/D1556M, D2167, D6938, D7698, and D7830/D7830M, this practice provides a means for correcting the unit weight and water content of field compacted samples of the total soil, so that values can be compared with those for a laboratory compacted finer fraction.

Note 2: The quality of the result produced by this standard is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this standard are cautioned that compliance with Practice D3740 does not in i...

SCOPE

1.1 This practice presents a procedure for calculating the unit weights and water contents of soils containing oversize particles when the data are known for the soil fraction with the oversize particles removed.

1.2 This practice also can be used to calculate the unit weights and water contents of soil fractions when the data are known for the total soil sample containing oversize particles.

1.3 This practice is based on tests performed on soils and soil-rock mixtures in which the portion considered oversize is that fraction of the material retained on the 4.75-mm [No. 4] sieve. Based on these tests, this practice is applicable to soils and soil-rock mixtures in which up to 40 % of the material is retained on the 4.75-mm [No. 4] sieve. The practice also is considered valid when the oversize fraction is that portion retained on some other sieve, but the limiting percentage of oversize particles for which the correction is valid may be lower. However, the practice is considered valid for materials having up to 30 % oversize particles when the oversize fraction is that portion retained on the 19-mm [3/4-in.] sieve.

1.4 The factor controlling the maximum permissible percentage of oversize particles is whether interference between the oversize particles affects the unit weight of the finer fraction. For some gradations, this interference may begin to occur at lower percentages of oversize particles, so the limiting percentage must be lower for these materials to avoid inaccuracies in the computed correction. The person or agency using this practice shall determine whether a lower percentage is to be used.

1.5 This practice may be applied to soils with any percentage of oversize particles subject to the limitations given in 1.3 and 1.4. However, the correction may not be of practical significance for soils with only small percentages of oversize particles. The person or agency specifying this practice shall specif...

- Standard4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 By definition, the tensile strength is obtained by the direct tensile test. However, the direct tensile test is difficult and expensive for routine application. The splitting tensile test appears to offer a desirable alternative because it is much simpler and inexpensive. Furthermore, engineers involved in rock mechanics design usually deal with complex stress fields, including various combinations of compressive and tensile stress fields. Under such conditions, the tensile strength should be obtained with the presence of compressive stresses to be representative of the field conditions.

5.2 The splitting tensile strength test is one of the simplest tests in which such stress fields occur. Also, by testing across different diametral directions, any variations in tensile strength for anisotropic rocks can be determined. Since it is widely used in practice, a uniform test method is needed for data to be comparable. A uniform test is also needed to make sure that the disk specimens break diametrically due to tensile stresses perpendicular to the loading axis.

Note 2: The quality of the results produced by this standard is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this standard are cautioned that compliance with Practice D3740 does not in itself assure reliable results. Reliable results depend on many factors; Practice D3740 provides a means of evaluating some of those factors.

SCOPE

1.1 This test method covers testing apparatus, specimen preparation, and testing procedures for determining the splitting tensile strength of rock by diametral line compression of disk shaped specimens.

Note 1: The tensile strength of rock determined by tests other than the straight pull test is designated as the “indirect” tensile strength and, specifically, the value obtained in Section 9 of this test is termed the “splitting” tensile strength. This test method is also sometimes referred to as the Brazilian test method.

1.2 Units—The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units, which are provided for information only and are not considered standard. Reporting of test results in units other than SI shall not be regarded as nonconformance with this test method.

1.3 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice D6026.

1.3.1 The procedures used to specify how data are collected/recorded or calculated, in this standard are regarded as the industry standard. In addition, they are representative of the significant digits that generally should be retained. The procedures used do not consider material variation, the purpose for obtaining the data, special purpose studies, or any considerations for the user's objectives; and it is common practice to increase or reduce significant digits of reported data to be commensurate with these considerations. It is beyond the scope of this standard to consider significant digits used in analysis methods for engineering design.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard6 pagesEnglish languagesale 15% off

- Standard6 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Where sulfates are suspected, subgrade soils should be tested as an integral part of a geotechnical evaluation because the possibility that sulfate induced heave may occur if calcium containing stabilizers are used to improve the soils and sulfate reactions may also cause deterioration in concrete structures. When planning to treat a soil used in construction with lime, testing the soil for water soluble sulfates prior to treatment becomes very important (Note 2).

5.2 When sulfate containing cohesive soils are treated with calcium-based stabilizers for foundation improvements, sulfates and free alumina in natural soils react with calcium and free hydroxide to form crystalline minerals, such as ettringite and thaumasite.4 Thaumasite forms when ettringite undergoes changes in the presence of carbonates at low temperatures.5 The sulfate minerals expand considerably when they are hydrated.

Note 2: For more information on the effect of treating soils containing water soluble sulfates, refer to the following publication: Little, D.N., Stabilization of Pavement Subgrades and Base Course with Lime, Kendal/Hunt Publishing Co., Dubuque, IA, 1995.

Note 3: The quality of the result produced by this standard is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this standard are cautioned that compliance with Practice D3740 does not in itself assure reliable results. Reliable results depend on many factors; Practice D3740 provides a means of evaluating some of those factors.

SCOPE

1.1 These methods determine the water soluble sulfate content of cohesive soils used in construction by using the colorimetric technique. Two methods are presented in this standard. Method A is for use in the field and Method B is for use in the laboratory. The colorimetric technique involves measuring the scattering of a light beam through a solution that contains suspended particulate matter. Measurements of sulfate concentrations in construction soils can be used to guide professionals in the selection of appropriate stabilization methods and to assist in assessment of potential deterioration in concrete structures.

Note 1: These test methods are partially based on the research conducted by Texas A & M University.

1.2 The field method, Method A, is used as a screening test for the presence of sulfates and their concentration. The laboratory method, Method B, provides better resolution than the field method.

1.3 Ion chromatography is also an acceptable alternative method that can be used to evaluate results, however, it is outside the scope of this standard.

1.4 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice D6026, unless superseded by this test method.

1.5.1 The procedures used to specify how data are collected/recorded and calculated in the standard are regarded as the industry standard. In addition, they are representative of the significant digits that generally should be retained. The procedures used do not consider material variation, purpose for obtaining the data, special purpose studies, or any considerations for the user’s objectives; and it is common practice to increase or reduce significant digits of reported data to be commensurate with these considerations. It is beyond the scope of these test methods to consider significant digits used in analysis methods for engineering data.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropri...

- Standard9 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 In this test method, the compressive strength of a soil is determined in terms of the total stress, therefore, the resulting strength depends on the pressure developed in the pore fluid during loading. In this test method, fluid flow is not permitted from or into the soil specimen as the load is applied, therefore the resulting pore pressure, and hence strength, differs from that developed in the case where drainage can occur.

5.2 If the test specimens is 100 % saturated, consolidation cannot occur when the confining pressure is applied nor during the shear portion of the test since drainage is not permitted. Therefore, if several specimens of the same material are tested, and if they are all at approximately the same water content and void ratio when they are tested, they will have approximately the same unconsolidated-undrained shear strength.

5.3 If the test specimens are partially saturated, or compacted/reconstituted specimens, where the degree of saturation is less than 100 %, consolidation may occur when the confining pressure is applied and during application of axial load, even though drainage is not permitted. Therefore, if several partially saturated specimens of the same material are tested at different confining stresses, they will not have the same unconsolidated-undrained shear strength.

5.4 Mohr failure envelopes may be plotted from a series of unconsolidated undrained triaxial tests. The Mohr’s circles at failure based on total stresses are constructed by plotting a half circle with a radius of half the principal stress difference (deviator stress) beginning at the axial stress (major principal stress) and ending at the confining stress (minor principal stress) on a graph with principal stresses as the abscissa and shear stress as the ordinate and equal scale in both directions. The failure envelopes will usually be a horizontal line for saturated specimens and a curved line for partially saturated specimens.

5.5 The unconsolidated-u...

SCOPE

1.1 This test method covers determination of the strength and stress-strain relationships of a cylindrical specimen of either intact, compacted, or remolded cohesive soil. Specimens are subjected to a confining fluid pressure in a triaxial chamber. No drainage of the specimen is permitted during the application of the confining fluid pressure or during the compression phase of the test. The specimen is axially loaded at a constant rate of axial deformation (strain controlled).

1.2 This test method provides data for determining undrained strength properties and stress-strain relations for soils. This test method provides for the measurement of the total stresses applied to the specimen, that is, the stresses are not corrected for pore-water pressure.

Note 1: The determination of the unconfined compressive strength of cohesive soils is covered by Test Method D2166/D2166M.

Note 2: The determination of the consolidated, undrained strength of cohesive soils with pore pressure measurement is covered by Test Method D4767.

1.3 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice D6026.

1.3.1 The procedures used to specify how data are collected/recorded or calculated in this standard are regarded as the industry standard. In addition, they are representative of the significant digits that generally should be retained. The procedures used do not consider material variation, purpose for obtaining the data, special purpose studies, or any considerations for the user’s objectives; and it is common practice to increase or reduce significant digits of reported data to be commensurate with these considerations. It is beyond the scope of this standard to consider significant digits used in analysis methods for engineering design.

1.4 Units—The values stated in SI units are to be regarded as the standard. The values given in parentheses are mathemat...

- Standard7 pagesEnglish languagesale 15% off

- Standard7 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This test method is used to determine the percentage of sand by volume in construction slurry. The significance of this test method mainly relates to construction slurries used for concrete wall and drilled piers construction. The range of measurement is too limited for use in applications where the sand content is intended to be greater than 20 %, such as in the cases of cement bentonite or soil bentonite walls.

5.2 A high sand content in the construction slurry is abrasive for construction plant such as pumps, and is furthermore adverse to the formation of a filter cake in applications where bentonite fluid is used to stabilize an excavation.

Note 1: The quality of the result produced by this standard depends on the competence of the personnel performing it and the suitability of the equipment and facilities being used. Agencies that meet the criteria of Practice D3740 are generally considered capable of competent and objective testing, sampling, inspection, etc. Users of this standard are cautioned that compliance with Practice D3740 does not in itself ensure reliable results. Reliable results depend on many factors; Practice D3740 provides a means of evaluating some of those factors.

SCOPE

1.1 This test method covers the determination of the sand content of bentonitic slurries used in slurry construction techniques. This test method has been modified from API Recommended Practice 13B.

1.2 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice D6026.

1.3 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. Except, the sieve designation is identified using the “alternative” system in accordance with Practice E11 instead of the “standard system,” such that the sieve used is referred to as a No. 200 sieve, instead of a 75 µm sieve.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The purpose of this test method is to obtain values for comparison with other test values to verify uniformity of materials or the effects of controllable variables, in grout-soil compositions.

5.2 This test method is similar, in principle, to Test Method D2166/D2166M, but is not intended for determination of strength parameters to be used in design. Such values are more properly obtained from long-term triaxial tests.

Note 1: The quality of the result produced by this standard is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this standard are cautioned that compliance with Practice D3740 does not in itself assure reliable results. Reliable results depend on many factors; Practice D3740 provides a means of evaluating some of those factors.

SCOPE

1.1 This test method covers the determination of the short-term unconfined compressive strength index of chemically grouted soils, using displacement-controlled application of test load.

1.2 Units—The values stated in SI units are to be regarded as standard. The values given in parentheses are provided for information only and are not considered standard. Reporting of test results in units other than SI shall not be regarded as nonconformance with this standard.

1.2.1 It is common practice in the engineering/construction profession to concurrently use pounds to represent both a unit of mass (lbm) and of force (lbf). This practice implicitly combines two separate systems of units; the absolute and the gravitational systems. It is scientifically undesirable to combine the use of two separate sets of inch-pound units within a single standard. As stated, this standard includes the gravitational system of inch-pound units and does not use/present the slug unit of mass. However, the use of balances and scales recording pounds of mass (lbm) or recording density in lbm/ft3 shall not be regarded as nonconformance with this standard.

1.3 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice D6026, unless superseded by this test method.

1.3.1 For purposes of comparing a measured or calculated value(s) with specified limits, the measured or calculated value(s) shall be rounded to the nearest decimal of significant digits in the specified limit.

1.3.2 The procedures used to specify how data are collected/recorded or calculated in the standard are regarded as the industry standard. In addition, they are representative of the significant digits that generally should be retained. The procedures used do not consider material variation, purpose for obtaining the data, special purpose studies, or any considerations for the user’s objectives; and it is common practice to increase or reduce significant digits of reported data to be commensurate with these considerations. It is beyond the scope of this standard to consider significant digits used in analysis methods for engineering design.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Compression testing of soil-lime specimens is performed to determine unconfined compressive strength of the cured soil-lime-water mixture to determine the suitability of the mixture for uses such as in pavement bases and subbases, stabilized subgrades, and structural fills.

5.2 Compressive strength data are used in soil-lime mix design procedures: (a) to determine if a soil will achieve a significant strength increase with the addition of lime; (b) to group soil-lime mixtures into strength classes; (c) to study the effects of variables such as lime percentage, unit weight, water content, curing time, curing temperature, etc.; and (d) to estimate other engineering properties of soil-lime mixtures.

5.3 Lime is generally classified as calcitic or dolomitic. Usually in soil stabilization, high-calcium lime [CaO] or dolomitic lime [CaO + MgO] are used. The lime is transformed from oxide to hydroxide form [[Ca(OH)2 or [Ca(OH)2 + Mg(OH)2]] by the addition of water in the soil, a slurry tank, or at a manufacturing facility. Lime may increase the strength of cohesive soil. The type of lime in combination with soil type influences the resulting compressive strength.

Note 2: The agency performing this test method can be evaluated in accordance with Practice D3740. Notwithstanding statements on precision and bias contained in this method: The precision of this test method is dependent on the competence of the personnel performing it and the suitability of the equipment and facility used. Agencies that meet the criteria of Practice D3740 are generally considered capable of competent and objective testing. Users of this test method are cautioned that compliance with Practice D3740 does not, in itself, ensure reliable testing. Reliable testing depends on many factors; Practice D3740 provides a means of evaluating some of these factors.

SCOPE

1.1 This test method covers procedures for preparing, curing, and testing laboratory-compacted specimens of soil-lime and other lime-treated materials (Note 1) for determining unconfined compressive strength. Depending on the diameter to height ratio, two procedures for determining the unconfined compressive strength of compacted soil-lime mixtures have been developed for specimens prepared at the maximum unit weight and optimum water content, or for specimens prepared at other target unit weight and water content levels. Other applications are given in Section 5 on Significance and Use.

Note 1: Lime-based products other than commercial quicklime and hydrated lime are also used in the lime treatment of fine-grained cohesive soils. Lime kiln dust (LKD) is collected from the kiln exhaust gases by cyclone, electrostatic, or baghouse-type collection systems. Some lime producers hydrate various blends of LKD plus quicklime to produce a lime-based product.

1.2 Cored specimens of soil-lime should be tested in accordance with Test Methods D2166/D2166M.

1.3 Two alternative procedures are provided:

1.3.1 Procedure A describes procedures for preparing and testing compacted soil-lime specimens having height-to-diameter ratios between 2.00 and 2.50. This test method provides the standard measure of compressive strength.

1.3.2 Procedure B describes procedures for preparing and testing compacted soil-lime specimens using Test Methods D698 compaction equipment and molds commonly available in most soil testing laboratories. Procedure B is considered to provide relative measures of individual specimens in a suite of test specimens rather than standard compressive strength values. Because of the lesser height-to-diameter ratio (1.15) of the cylinders, compressive strength determined by Procedure B will normally be greater than that by Procedure A.

1.3.3 Results of unconfined compressive strength tests using Procedure B should not be directly compared to those obtained using Procedure A.

1.4 All observed and calculated values shall conform to the guideline...

- Standard7 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Many geotechnical tests require the utilization of intact, representative samples of soil. The quality of these samples depends on many factors. Many of the samples obtained by intact sampling methods have inherent anomalies. Sampling procedures cause disturbances of varying types and intensities. These anomalies and disturbances, however, are not always readily detectable by visual inspection of the intact samples before or after testing. Often test results would be enhanced if the presence and the extent of these anomalies and disturbances are known before testing or before destruction of the sample by testing. Such determinations assist the user in detecting flaws in sampling methods, the presence of natural or induced shear planes, and the presence of natural intrusions, such as gravels or shells at critical regions in the samples, the presence of sand and silt seams, and the intensity of disturbances caused by sampling.

5.2 X-ray radiography provides the user with a picture of the internal massive structure of the soil sample, regardless of whether the soil is X-rayed within or without the sampling tube. X-ray radiography assists the user in identifying the following:

5.2.1 Appropriateness of sampling methods used.

5.2.2 Effects of sampling in terms of the disturbances caused by the turning of the edges of various thin layers in varved soils, large disturbances caused in soft soils, shear planes induced by sampling, or extrusion, or both, effects of overdriving of samplers, the presence of cuttings in sampling tubes, or the effects of using bent, corroded, or nonstandard tubes for sampling.

5.2.3 Naturally occurring fissures, shear planes, etc.

5.2.4 The presence of intrusions within the sample, such as calcareous nodules, gravel, or shells.

5.2.5 Sand and silt seams, organic matter, large voids, and channels developed by natural or artificial leaching of soil components.

Note 1: The quality of the results produced by this standard is de...

SCOPE

1.1 This practice covers the determination of the quality of soil samples in thin wall tubes or of extruded soil cores by X-ray radiography.

1.2 This practice enables the user to determine the effects of sampling and natural variations within samples as identified by the extent of the relative penetration of X-rays through soil samples.

1.3 This practice can be used to X-ray soil cores (or observe their features on a fluoroscope) in thin wall tubes or liners ranging from approximately 50 to 150 mm [2 to 6 in.] in diameter. X-rays of samples in the larger diameter tubes provide a radiograph of major features of soils and disturbances, such as large scale bending of edges of varved clays, shear planes, the presence of large concretions, silt and sand seams thicker than 6 mm [1/4 in.], large lumps of organic matter, and voids or other types of intrusions. X-rays of the smaller diameter cores provide higher resolution of soil features and disturbances, such as small concretions (3 mm [1/8 in.] diameter or larger), solution channels, slight bending of edges of varved clays, thin silt or sand seams, narrow solution channels, plant root structures, and organic matter. The X-raying of samples in thin wall tubes or liners requires minimal preparation.

1.4 Greater detail and resolution of various features of the soil can be obtained by X-raying extruded soil cores, as compared to samples in metal tubes. The method used for X-raying soil cores is the same as that for tubes and liners, except that extruded cores have to be handled with extreme care and have to be placed in sample troughs (similar to Fig. 2) before X-raying. This practice should be used only when natural water content or other intact soil characteristics are irrelevant to the end use of the sample.

1.4.1 Often it is necessary to obtain greater resolution of features to determine the propriety of sampling methods, the representative nature of soil samples,...

- Standard17 pagesEnglish languagesale 15% off

- Standard17 pagesEnglish languagesale 15% off

ABSTRACT

This test method covers the determination of the coefficient of permeability by a constant-head method for the laminar flow of water through granular soils. The procedure is to establish representative values of the coefficient of permeability of granular soils that may occur in natural deposits as placed in embankments, or when used as base courses under pavements. The different apparatus used in determining the granular soil permeability are presented. The methods in preparing the test specimen are presented in details. The testing and calculation procedure for granular soil permeability determination are presented.

SIGNIFICANCE AND USE

5.1 These test methods are used to measure one-dimensional vertical flow of water through initially saturated coarse-grained, pervious (that is, free-draining) soils under an applied hydraulic gradient. Hydraulic conductivity of coarse-grained soils is used in various civil engineering applications. These test methods are suitable for determination of hydraulic conductivity for soils with k > 10–7 m/s.

Note 2: Clean coarse-grained soils that are classified using Practice D2487-17 as GP, GW, SP, and SW can be tested using these test methods. Depending on fraction and characteristics of fine-grained particles present in soils, these test methods may be suitable for testing other soil types with fines content greater than 5 % (for example, GP-GC, SP-SM).

5.2 Coarse-grained soils are to be tested at a void ratio representative of field conditions. For engineered fills, compaction specification can be used to provide target test conditions, whereas for natural soils, field testing of in-situ density can be used to provide target test conditions.

5.3 Use of a dual-ring permeameter is included in these test methods in addition to a single-ring permeameter for the rigid wall test apparatus. The dual-ring permeameter allows for reducing potential adverse effects of sidewall leakage on measured hydraulic conductivity of the test specimens. The use of a plate at the outflow end of the specimen that contains a ring with a diameter smaller than the diameter of the permeameter and the presence of two outflow ports (one from the inner ring, one from the annular space between the inner ring and the permeameter wall) allows for separating the flow from the central region of the test specimen from the flow near the sidewall of the permeameter.

Note 3: Sidewall leakage has been reported to have significant influence on flow conditions for coarse-grained soils due to presence of larger voids at the boundary and higher void ratio in this region of the specimen. Three modificat...

SCOPE

1.1 These test methods cover laboratory measurement of the hydraulic conductivity (also referred to as coefficient of permeability) of water-saturated coarse-grained soils (for example, sands and gravels) with k > 10–7 m/s. The test methods utilize low hydraulic gradient conditions.

1.2 This standard describes two methods (A and B) for determining hydraulic conductivity of coarse-grained soils. Method A incorporates use of a rigid wall permeameter and Method B incorporates the use of a flexible wall permeameter. A single- or dual-ring rigid wall permeameter may be used in Method A. A dual-ring permeameter may be preferred over a single-ring permeameter when adverse effects from short-circuiting of permeant water along the sidewalls of the permeameter (that is, prevent sidewall leakage) are suspected by the user of this standard.

1.3 The test methods are used under constant head conditions.

1.4 The test methods are used under saturated soil conditions.

1.5 Water is used to permeate the test specimen with these test methods.

1.6 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

Note 1: Hydraulic conductivity has traditionally been reported in cm/s in the US, even though the official SI unit for hydraul...

- Standard16 pagesEnglish languagesale 15% off

- Standard16 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.