ASTM A563-15

(Specification)Standard Specification for Carbon and Alloy Steel Nuts

Standard Specification for Carbon and Alloy Steel Nuts

ABSTRACT

This specification covers chemical and mechanical requirements for eight property classes of hex and hex-flange carbon and alloy steel nuts for general structural and mechanical uses on bolts, studs, and other externally threaded parts. Materials shall be tested and the individual grades shall conform to specified values of material such as hardness and proof load, chemical, and mechanical requirements. Classes 8S3 and 10S3 nuts have atmospheric corrosion resistance and weathering characteristics comparable to those of the steels. The atmospheric corrosion resistance of these steels is substantially better than that of carbon steel with or without copper addition. When properly exposed to the atmosphere, these steels can be used bare (uncoated) for many applications.

SCOPE

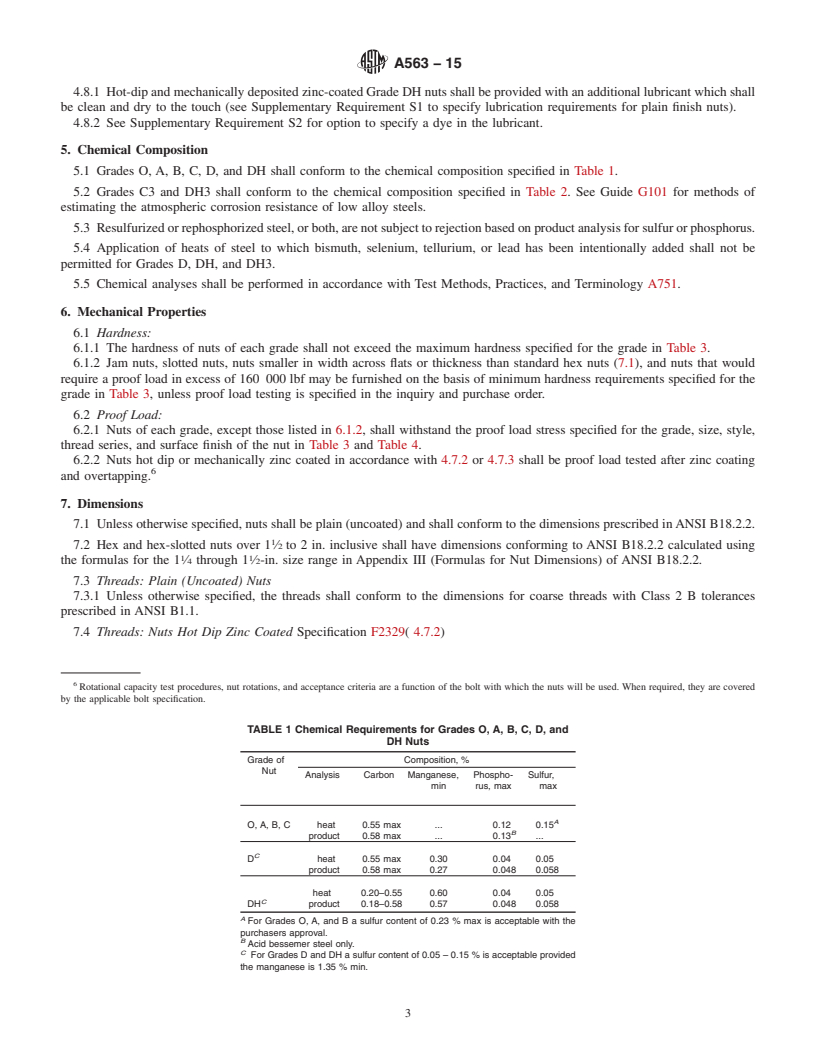

1.1 This specification2 covers chemical and mechanical requirements for eight grades of carbon and alloy steel nuts for general structural and mechanical uses on bolts, studs, and other externally threaded parts.

Note 1: See Appendix X1 for guidance on suitable application of nut grades.

1.2 The requirements for any grade of nut may, at the supplier's option, and with notice to the purchaser, be fulfilled by furnishing nuts of one of the stronger grades specified herein unless such substitution is barred in the inquiry and purchase order.

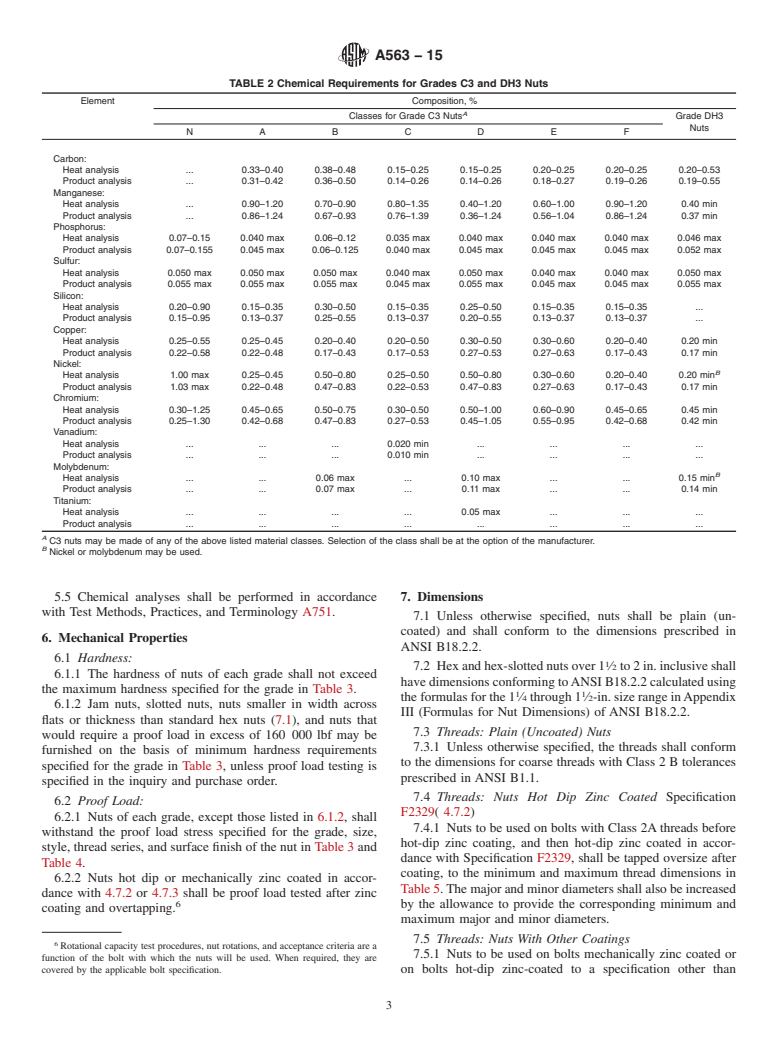

1.3 Grades C3 and DH3 nuts have atmospheric corrosion resistance and weathering characteristics comparable to that of the steels covered in Specifications A242/A242M, A588/A588M, and A709/A709M. The atmospheric corrosion resistance of these steels is substantially better than that of carbon steel with or without copper addition (see 5.2). When properly exposed to the atmosphere, these steels can be used bare (uncoated) for many applications.

Note 2: A complete metric companion to Specification A563 has been developed—A563M; therefore, no metric equivalents are presented in this specification.

1.4 Terms used in this specification are defined in Terminology F1789 unless otherwise defined herein.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A563 −15

Standard Specification for

1

Carbon and Alloy Steel Nuts

This standard is issued under the fixed designation A563; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* High Temperature Service, or Both

2 A242/A242M Specification for High-Strength Low-Alloy

1.1 This specification covers chemical and mechanical

Structural Steel

requirements for eight grades of carbon and alloy steel nuts for

A307 Specification for Carbon Steel Bolts, Studs, and

general structural and mechanical uses on bolts, studs, and

Threaded Rod 60 000 PSI Tensile Strength

other externally threaded parts.

A325 Specification for Structural Bolts, Steel, Heat Treated,

NOTE 1—See Appendix X1 for guidance on suitable application of nut

120/105 ksi Minimum Tensile Strength (Withdrawn

grades. 4

2016)

1.2 The requirements for any grade of nut may, at the

A354 Specification for Quenched and TemperedAlloy Steel

supplier’s option, and with notice to the purchaser, be fulfilled

Bolts, Studs, and Other Externally Threaded Fasteners

by furnishing nuts of one of the stronger grades specified

A394 Specification for Steel Transmission Tower Bolts,

herein unless such substitution is barred in the inquiry and

Zinc-Coated and Bare

purchase order.

A449 Specification for Hex Cap Screws, Bolts and Studs,

Steel, Heat Treated, 120/105/90 ksi Minimum Tensile

1.3 Grades C3 and DH3 nuts have atmospheric corrosion

Strength, General Use

resistance and weathering characteristics comparable to that of

A490 Specification for Structural Bolts, Alloy Steel, Heat

the steels covered in Specifications A242/A242M, A588/

Treated, 150 ksi Minimum Tensile Strength (Withdrawn

A588M, and A709/A709M. The atmospheric corrosion resis-

4

2016)

tance of these steels is substantially better than that of carbon

A563M Specification for Carbon andAlloy Steel Nuts (Met-

steel with or without copper addition (see 5.2). When properly

ric)

exposed to the atmosphere, these steels can be used bare

A588/A588M Specification for High-Strength Low-Alloy

(uncoated) for many applications.

Structural Steel, up to 50 ksi [345 MPa] Minimum Yield

NOTE 2—Acomplete metric companion to Specification A563 has been

Point, with Atmospheric Corrosion Resistance

developed—A563M; therefore, no metric equivalents are presented in this

A687 Specification for High-Strength Nonheaded Steel

specification.

4

Bolts and Studs (Withdrawn 1999)

1.4 Terms used in this specification are defined in Termi-

A709/A709M Specification for Structural Steel for Bridges

nology F1789 unless otherwise defined herein.

A751 Test Methods, Practices, and Terminology for Chemi-

cal Analysis of Steel Products

2. Referenced Documents

B695 Specification for Coatings of Zinc Mechanically De-

3

2.1 ASTM Standards:

posited on Iron and Steel

A194/A194M Specification for Carbon Steel, Alloy Steel,

D3951 Practice for Commercial Packaging

and Stainless Steel Nuts for Bolts for High Pressure or

F606 Test Methods for Determining the Mechanical Proper-

ties of Externally and Internally Threaded Fasteners,

Washers, and Rivets (Metric) F0606_F0606M

1

This specification is under the jurisdiction of ASTM Committee F16 on

F812/F812M Specification for Surface Discontinuities of

Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts,

Nuts, Rivets and Washers.

Nuts, Inch and Metric Series

CurrenteditionapprovedMay1,2015.PublishedJuly2015.Originallyapproved

F1789 Terminology for F16 Mechanical Fasteners

in 1966. Last previous edition approved in 2014 as A563 – 07a(2014). DOI:

F2329 Specification for Zinc Coating, Hot-Dip, Require-

10.1520/A0563-15.

2

ments for Application to Carbon and Alloy Steel Bolts,

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

cation SA – 563 in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A563−15

Screws, Washers, Nuts, and Special Threaded Fasteners 4.7.3 When mechanically deposited is specified, the fasten-

G101 Guide for Estimating the Atmospheric

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A563 − 07a (Reapproved 2014) A563 − 15

Standard Specification for

1

Carbon and Alloy Steel Nuts

This standard is issued under the fixed designation A563; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

2

1.1 This specification covers chemical and mechanical requirements for eight grades of carbon and alloy steel nuts for general

structural and mechanical uses on bolts, studs, and other externally threaded parts.

NOTE 1—See Appendix X1 for guidance on suitable application of nut grades.

1.2 The requirements for any grade of nut may, at the supplier’s option, and with notice to the purchaser, be fulfilled by

furnishing nuts of one of the stronger grades specified herein unless such substitution is barred in the inquiry and purchase order.

1.3 Grades C3 and DH3 nuts have atmospheric corrosion resistance and weathering characteristics comparable to that of the

steels covered in Specifications A242/A242M, A588/A588M, and A709/A709M. The atmospheric corrosion resistance of these

steels is substantially better than that of carbon steel with or without copper addition (see 5.2). When properly exposed to the

atmosphere, these steels can be used bare (uncoated) for many applications.

NOTE 2—A complete metric companion to Specification A563 has been developed—A563M; therefore, no metric equivalents are presented in this

specification.

1.4 Terms used in this specification are defined in Terminology F1789 unless otherwise defined herein.

2. Referenced Documents

3

2.1 ASTM Standards:

A194/A194M Specification for Carbon Steel, Alloy Steel, and Stainless Steel Nuts for Bolts for High Pressure or High

Temperature Service, or Both

A242/A242M Specification for High-Strength Low-Alloy Structural Steel

A307 Specification for Carbon Steel Bolts, Studs, and Threaded Rod 60 000 PSI Tensile Strength

A325 Specification for Structural Bolts, Steel, Heat Treated, 120/105 ksi Minimum Tensile Strength

A354 Specification for Quenched and Tempered Alloy Steel Bolts, Studs, and Other Externally Threaded Fasteners

A394 Specification for Steel Transmission Tower Bolts, Zinc-Coated and Bare

A449 Specification for Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120/105/90 ksi Minimum Tensile Strength,

General Use

A490 Specification for Structural Bolts, Alloy Steel, Heat Treated, 150 ksi Minimum Tensile Strength

A563M Specification for Carbon and Alloy Steel Nuts (Metric)

A588/A588M Specification for High-Strength Low-Alloy Structural Steel, up to 50 ksi [345 MPa] Minimum Yield Point, with

Atmospheric Corrosion Resistance

4

A687 Specification for High-Strength Nonheaded Steel Bolts and Studs (Withdrawn 1999)

A709/A709M Specification for Structural Steel for Bridges

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

B695 Specification for Coatings of Zinc Mechanically Deposited on Iron and Steel

D3951 Practice for Commercial Packaging

1

This specification is under the jurisdiction of ASTM Committee F16 on Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts, Nuts, Rivets

and Washers.

Current edition approved April 1, 2014May 1, 2015. Published May 2014July 2015. Originally approved in 1966. Last previous edition approved in 20072014 as

A563 – 07a.A563 – 07a(2014). DOI: 10.1520/A0563-07AR14.10.1520/A0563-15.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SA – 563 in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A563 − 15

F606 Test Methods for Determining the Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, and

Rivets (Metric) F0606_F0606M

F812/F812M Specification for Surface Discontinuities of Nuts, Inch

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.