ASTM D2417-88

(Specification)Specification for Perforated, Laminated Wall Bituminized Fiber Pipe for General Drainage (Withdrawn 1992)

Specification for Perforated, Laminated Wall Bituminized Fiber Pipe for General Drainage (Withdrawn 1992)

General Information

Standards Content (Sample)

c

- 1 NOTICE OF I

ADOPTION NOTICE 1

I AOOPTION I

17 November 1988

ASTM D 2417-88

February 1, 1988

SUPERSEDING

ASTM D 2417-77e

18 May 1981

"USED INSTEAD OF

SS-P-154Of3, TYPE I

ASTM O 2417-88 was adopted on 17 November 1988 and is approved for use by the

Department of Defense (Doo). ASTM has furnished clearances required by

existing regulations.

Copies of this document are stocked by Do0 Single

. ~ Stock Point, Naval Publications and Forms Center, 5801 Tabor Avenue,

Philadelphia, PA 19120, for issue to DoD activities only. All other

requestors must obtain documents from:

ASTM

1916 Race Street

Philadelphia, PA 19103

Title of Document: Standard Specification for Perforated, Laminated-Wall

Bituminized Fiber Pipe for General Drainage

Date of Specific Issue Adopted: February 1, 1988

Releasing Non-Government Standards Body: ASTM

II, use ASTM D 1862.

*NOTE: For Type

For Type II, class 2, style A, use ASTM 02417.

Custodians: -

Military Coordinating Activity:

Army - ME

Navy - YD

Navy - YO

Air Force - 99

(Project 5630-01 54)

User Activities:

Army - CE

Navy - HC

FSC 5630

DISTRIBUTION STATEMENT A. Approved for public release; distribution is

unlimited.

'THIS DOCUMENT CONTAINS [ PAGES. '

---------------------- Page: 1 ----------------------

ASTM D2437 88 E 0759530 0025445 9 W

Y

AMERICAN SOCIETY FOR TESTING AND MATERIALS

1918 Race St., Philadelphia, Pa. 19103

Reprinted from the Annual Bwk of ASTM Standards, Copyrlght ASTM

If not listed In the current combined index, wlli appear in the next edition.

Standard Specification for

Perforated, Laminated-Wall Bituminized Fiber Pipe for

General Drainage'

This standard is issued under the futed designation D 2417; the number immediately following the designation indicates the year of

original adoption or, in the cace of revision, fhe year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapprovai.

This specijication has been approved for irse by agencies of the Department of Defense to replace Federal Specijication SS-P-l540B,

Type II, Class 2, Style A and for listing in the DoD Index of Specijications and Standards.

1. Scope 4.2 Crushing Strengths-The pipe shall have a minimum

three-edge-bearing crushing strength of 13. I kN/m (900

1.1 This specification covers laminated-wall bituminized

lbf/ft) (wet and dry).

fiber perforated drainage pipe for use in agricultural, land,

4.3 Wafer Absorption-The maximum water absorption

and general drainage.

shall be 2 % of the original weight.

1.2 The values stated in SI units are to be regarded as the

4.4 Boiling Water Resistance-Specimens shall exhibit

standard,

not less than 90 % of the crushing strength.

4.5 Heat Resistance-The heat shall not cause a weight

2. Referenced Document

loss over 1 % in the specimen due to the exudation of the

impregnant.

2.1 ASTM Standard:

4.6 Chemical Resistance-Specimens shall show no vis-

D 23 15 Methods of Testing Laminated-Wail Bituminized

ible sign of chemical reaction or deterioration of the im-

Fiber Pipe2

pregnant.

4.7 Kerosine Resistance-Specimens shall meet the

3. Materials and Manufacture

crushing strength requirements,

3.1 Pipe and Couplings-Pipe and couplings shall be

composed of a multi-ply laminated convolute or spiral

5. Dimensions

fibrous structure, with the laminations being adhered with a

heat- and water-resistant adhesive and then thoroughíy

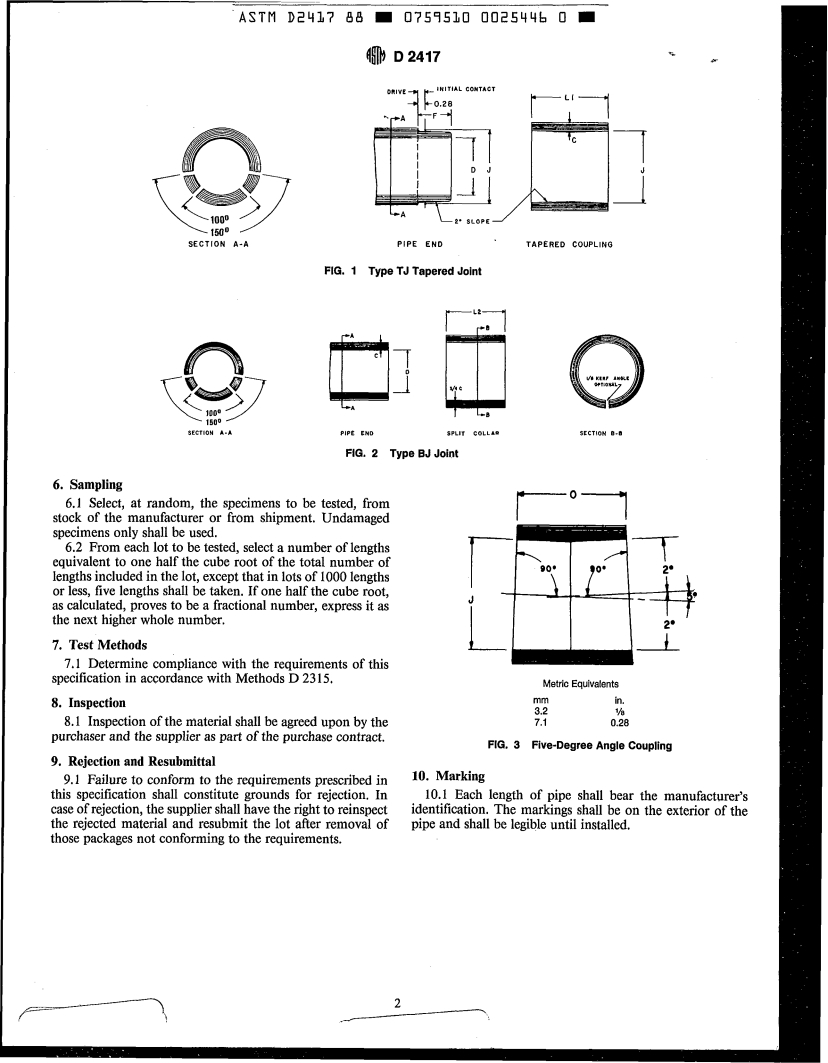

5.1 Pipe and Couplings-The dimensions of the pipe and

impregnated with a bituminous compound. The pipe shall

couplings shall be as specified in Figs. 2 and 3 and Table 1.

have a smooth interior surface free of obstructions and rough

5.2 Five-Degree Angle Couplings-The dimensions of 5"

or flaky areas. Bends, fittings and adapters shali be of the

angle couplings shall be as specified in Fig. 3 and Table 1.

same material as the pipe, or of a material having equal or

5.3 Bore-The bore shail be straight and circular in cross

better physical and chemical properties.

section as determined by passing a 1-m (40-in.) long man-

3.2 Joint Systems-Pipe and fittings shall use either of the

drel, 6.4 mm (V4 in.) smaller in diameter than the nominal

following joint systems:

diameter of the pipe, freely through the pipe.

3.2.1 Type TJ Joints-Pipe and fittings shall be provided

5.4 Length-Lengths other than standard shall be in

with accurately machined or molded tapered joints, and a

increments of 152 mm (6 in.) from standard, and unless

taper-sleeve coupling shall be provided for each length of

otherwise specified, up to 20 % of short lengths may be

pipe and for each fitting where applicable. The slope of the

supplied in a shipment. No lengths shorter than 1.2 m (4 ft)

taper in both pipe and coupling shall be 2" (4" including

shall be furnished, with no more than two different short

angle) (see Fig. 1).

lengths in any one shipment.

3.2.2 Type B

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.