ASTM D2595-96(2008)e1

(Test Method)Standard Test Method for Evaporation Loss of Lubricating Greases Over Wide-Temperature Range (Withdrawn 2017)

Standard Test Method for Evaporation Loss of Lubricating Greases Over Wide-Temperature Range (Withdrawn 2017)

SIGNIFICANCE AND USE

5.1 The loss of volatile materials from greases and oils can adversely affect the original performance characteristics of a lubricant and, therefore, could be a significant factor in evaluating a lubricant for a specific use. Such volatiles can also be considered contaminants in the environment in which the lubricant is to be used. Correlation between results from this test method and service performance has not been established.

5.2 The test method can be used at any specified temperature between 93 and 316°C (200 and 600°F) that may be agreed upon by the user of the method. (Warning—This test method should not be used at temperatures which exceed the flash point of the base oil of the grease.)Note 1—The specified flow of air, 2.58 ± 0.02 g/min, (2 L/min at standard temperature and pressure), assumes dry air. It is not known that the original work involved dry air but it has since been shown that this can be a factor in reproducibility and should be addressed. Air with a dew point of less than 10°C at standard temperature and pressure will be satisfactory.

SCOPE

1.1 This test method covers the determination of evaporation loss of lubricating greases at temperatures between 93 and 316°C (200 and 600°F). This test method is intended to augment Test Method D972, which is limited to 149°C (300°F).

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific safety information, see 5.2.

WITHDRAWN RATIONALE

This test method covers the determination of evaporation loss of lubricating greases at temperatures between 93 and 316°C (200 and 600°F). This test method is intended to augment Test Method D972, which is limited to 149°C (300°F).

Formerly under the jurisdiction of Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants, this test method was withdrawn in January 2017 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D2595 − 96 (Reapproved 2008)

Standard Test Method for

Evaporation Loss of Lubricating Greases Over Wide-

Temperature Range

This standard is issued under the fixed designation D2595; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Removed outdated source of supply footnote from Section 6 editorially in April 2013.

1. Scope 3.1.1 lubricating grease, n—a semi-fluid to solid product of

a thickener in a liquid lubricant.

1.1 This test method covers the determination of evapora-

3.1.1.1 Discussion—Thedispersionofthethickenerformsa

tionlossoflubricatinggreasesattemperaturesbetween93and

two-phase system and immobilizes the liquid lubricant by

316°C (200 and 600°F). This test method is intended to

surfacetensionandotherphysicalforces.Otheringredientsare

augment Test Method D972, which is limited to 149°C

commonly included to impart special properties. D217

(300°F).

3.1.2 thickener, n—a substance composed of finely-divided

1.2 The values stated in SI units are to be regarded as the

particles dispersed in a liquid to form the product’s structure.

standard. The values in parentheses are for information only.

3.1.2.1 Discussion—Thickeners can be fibers (such as vari-

1.3 This standard does not purport to address all of the

ous metallic soaps) or plates or spheres (such as certain

safety concerns, if any, associated with its use. It is the

non-soapthickeners),whichareinsolubleor,atmost,onlyvery

responsibility of the user of this standard to establish appro-

slightly soluble in the liquid lubricant. The general require-

priate safety and health practices and determine the applica-

ments are that the solid particles are extremely small, uni-

bility of regulatory limitations prior to use. For specific safety

formly dispersed, and capable of forming a relatively stable,

information, see 5.2.

gel-like structure with the liquid lubricant. D217

2. Referenced Documents

4. Summary of Test Method

2.1 ASTM Standards:

4.1 A weighed sample of grease in an evaporation cell is

A240/A240MSpecification for Chromium and Chromium-

placed in a heating device maintained at the desired test

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

temperature.Heatedairispassedoverthegreasesurfacefor22

Vessels and for General Applications

6 0.1 h. The loss in weight of the sample due to evaporation

D217Test Methods for Cone Penetration of Lubricating

is determined.

Grease

5. Significance and Use

D972Test Method for Evaporation Loss of Lubricating

Greases and Oils

5.1 The loss of volatile materials from greases and oils can

E1Specification for ASTM Liquid-in-Glass Thermometers

adversely affect the original performance characteristics of a

lubricant and, therefore, could be a significant factor in

3. Terminology

evaluatingalubricantforaspecificuse.Suchvolatilescanalso

be considered contaminants in the environment in which the

3.1 Definitions:

lubricant is to be used. Correlation between results from this

test method and service performance has not been established.

This test method is under the jurisdiction of ASTM Committee D02 on 5.2 The test method can be used at any specified tempera-

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

ture between 93 and 316°C (200 and 600°F) that may be

D02.G0.03 on Physical Tests.

agreed upon by the user of the method. (Warning—This test

Current edition approved May 1, 2008. Published September 2008. Originally

ε1

method should not be used at temperatures which exceed the

approved in 1967. Last previous edition approved in 2002 as D2595–96(2002) .

DOI: 10.1520/D2595-96R08.

flash point of the base oil of the grease.)

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

NOTE 1—The specified flow of air, 2.58 6 0.02 g/min, (2 L/min at

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on standard temperature and pressure), assumes dry air. It is not known that

the ASTM website. theoriginalworkinvolveddryairbutithassincebeenshownthatthiscan

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D2595 − 96 (2008)

SECTION OF GREASE SAMPLE CUP ALL DIMENSIONS 60.0156 in. (60.4

FIG. 1 Thermocouple Arrangement

mm) UNLESS OTHERWISE SPECIFIED

FIG. 2 Evaporation Test Cell

be a factor in reproducibility and should be addressed. Air with a dew

point of less than 10°C at standard temperature and pressure will be

satisfactory.

6. Apparatus

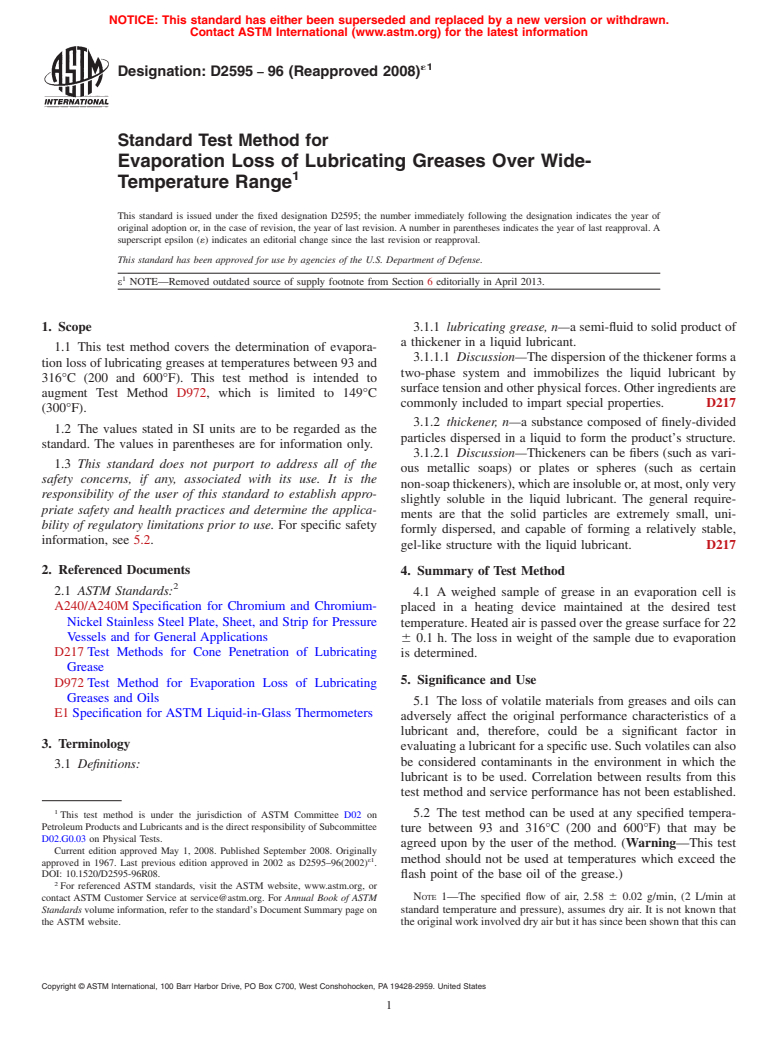

6.1 Evaporation Cell Assembly (Fig. 1) consisting of the

following items:

6.1.1 Sample Cup, A.

6.1.2 Hood, B.

6.1.3 Cover and Eduction Tube, C—These items (5.1.1 to

5.1.3) shall be constructed from a stainless steel conforming to

Type 304 of Specification A240/A240M. Design dimensions

anddimensionaltolerancesshallbeasshowninFig.2andFig.

3.

6.1.4 Gasket—Shall be of a heat-resistant (315°C (600°F))

material.Agasket cut from 3.2 mm ( ⁄8-in.) TFE-fluorocarbon

sheet has been found to work successfully.

6.1.5 Thermocouple Tube and Supports— The tube shall be

of stainless steel having an outside diameter of 3.18 6 0.025

mm(0.125 60.001in.)andfittedwithstainlesssteelcentering

devices as shown in Fig. 1.

6.2 Air Supply System—Shall consist of a calibrated FIG. 3 Assembled Test Cell in Aluminum Block Heater

flowmeter, filtering device, and accessory valves capable of

delivering and maintaining a flow of dust-free air at the rate of

2.58 6 0.02 g/min between 15.6 and 29.4°C (60 and 85°F) (2

for analysis should be large enough to make possible the

L/min at standard temperature and pressure).

selection of a representative portion for testing. Examine the

sample for any indication of non-homogeneity such as oil

6.3 Heating Device—An aluminum block heater similar to

separation, phase changes, or gross contamination. If any

that shown in Fig. 4 has been found to be satisfactory. It is

abnormal conditions are found, obtain a new sample.

more fully described in Appendix X1.

6.4 Thermometers—ASTM thermometers graduated in ei-

8. Preparation of Apparatus

ther Fahrenheit or Celsiu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.