ASTM E2481-06

(Test Method)Standard Test Method for Hot Spot Protection Testing of Photovoltaic Modules

Standard Test Method for Hot Spot Protection Testing of Photovoltaic Modules

SCOPE

1.1 This test method provides a procedure to determine the ability of a photovoltaic (PV) module to endure the long-term effects of periodic "hot spot" heating associated with common fault conditions such as severely cracked or mismatched cells, single-point open circuit failures (for example, interconnect failures), partial (or non-uniform) shadowing or soiling. Such effects typically include solder melting or deterioration of the encapsulation, but in severe cases could progress to combustion of the PV module and surrounding materials.

1.2 There are two ways that cells can cause a hot spot problem; either by having a high resistance so that there is a large resistance in the circuit, or by having a low resistance area (shunt) such that there is a high-current flow in a localized region. This test method selects cells of both types to be stressed.

1.3 This test method does not establish pass or fail levels. The determination of acceptable or unacceptable results is beyond the scope of this test method.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2481–06

Standard Test Method for

Hot Spot Protection Testing of Photovoltaic Modules

This standard is issued under the fixed designation E 2481; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 1799 Practice for Visual Inspections of Photovoltaic

Modules

1.1 This test method provides a procedure to determine the

E 1802 Test Methods forWet Insulation IntegrityTesting of

ability of a photovoltaic (PV) module to endure the long-term

Photovoltaic Modules

effects of periodic “hot spot” heating associated with common

fault conditions such as severely cracked or mismatched cells,

3. Terminology

single-point open circuit failures (for example, interconnect

3.1 Definitions—definitions of terms used in this test

failures), partial (or non-uniform) shadowing or soiling. Such

method may be found in Terminology E 772 and Terminology

effects typically include solder melting or deterioration of the

E 1328.

encapsulation, but in severe cases could progress to combus-

3.2 Definitions of Terms Specific to This Standard:

tion of the PV module and surrounding materials.

3.2.1 hot spot—aconditionthatoccurs,usuallyasaresultof

1.2 There are two ways that cells can cause a hot spot

shadowing, when a solar cell or group of cells is forced into

problem; either by having a high resistance so that there is a

reverse bias and must dissipate power, which can result in

large resistance in the circuit, or by having a low resistance

abnormally high cell temperatures.

area (shunt) such that there is a high-current flow in a localized

region. This test method selects cells of both types to be

4. Significance and Use

stressed.

4.1 The design of a photovoltaic module or system intended

1.3 This test method does not establish pass or fail levels.

to provide safe conversion of the sun’s radiant energy into

The determination of acceptable or unacceptable results is

useful electricity must take into consideration the possibility of

beyond the scope of this test method.

partial shadowing of the module(s) during operation. This test

1.4 This standard does not purport to address all of the

method describes a procedure for verifying that the design and

safety concerns, if any, associated with its use. It is the

construction of the module provides adequate protection

responsibility of the user of this standard to establish appro-

against the potential harmful effects of hot spots during normal

priate safety and health practices and determine the applica-

installation and use.

bility of regulatory limitations prior to use.

4.2 This test method describes a procedure for determining

2. Referenced Documents the ability of the module to provide protection from internal

2 defects which could cause loss of electrical insulation or

2.1 ASTM Standards:

combustion hazards.

E 772 Terminology Relating to Solar Energy Conversion

4.3 Hot-spot heating occurs in a module when its operating

E 927 Specification for Solar Simulation for Photovoltaic

current exceeds the reduced short-circuit current (Isc) of a

Testing

shadowed or faulty cell or group of cells. When such a

E 1036 Test Methods for Electrical Performance of Non-

condition occurs, the affected cell or group of cells is forced

concentrator Terrestrial Photovoltaic Modules and Arrays

into reverse bias and must dissipate power, which can cause

Using Reference Cells

overheating.

E 1328 Terminology Relating to Photovoltaic Solar Energy

Conversion

NOTE 1—The correct use of bypass diodes can prevent hot spot damage

from occurring.

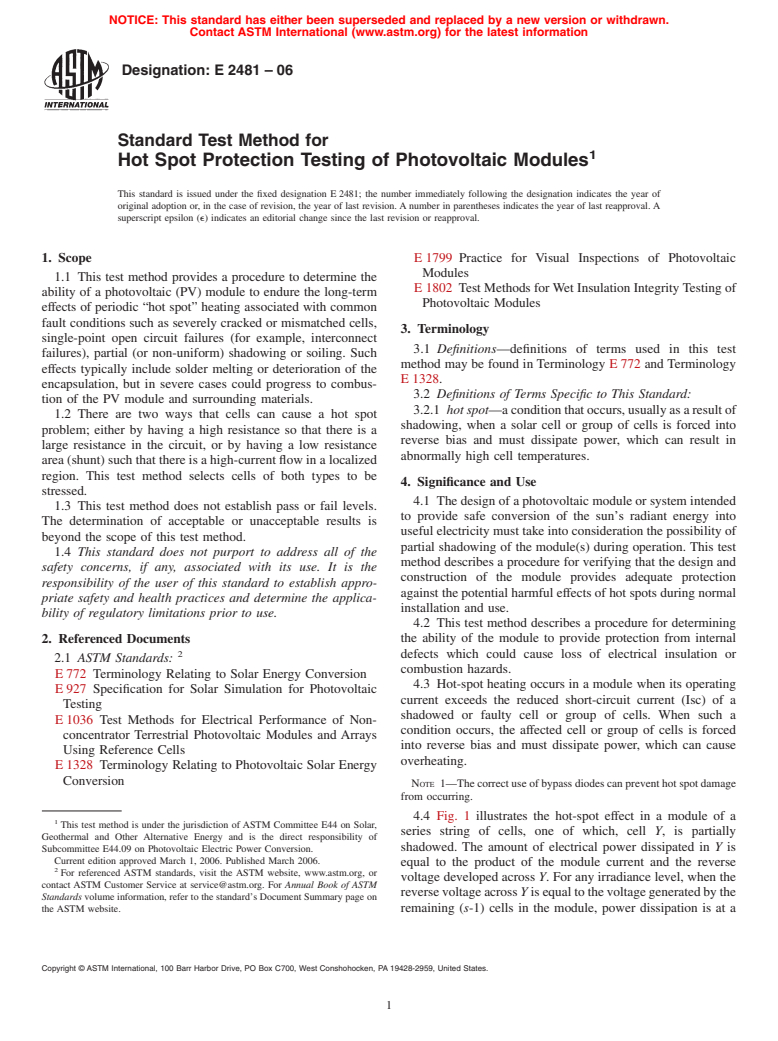

4.4 Fig. 1 illustrates the hot-spot effect in a module of a

This test method is under the jurisdiction of ASTM Committee E44 on Solar,

series string of cells, one of which, cell Y, is partially

Geothermal and Other Alternative Energy and is the direct responsibility of

shadowed. The amount of electrical power dissipated in Y is

Subcommittee E44.09 on Photovoltaic Electric Power Conversion.

Current edition approved March 1, 2006. Published March 2006.

equal to the product of the module current and the reverse

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

voltage developed across Y. For any irradiance level, when the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

reversevoltageacross Yisequaltothevoltagegeneratedbythe

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. remaining (s-1) cells in the module, power dissipation is at a

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2481–06

FIG. 1 Hot Spot Effect

maximum when the module is short-circuited.This is shown in 4.6.1.2 Oftenlowshuntresistancecellsarethiswaybecause

Fig. 1 by the shaded rectangle constructed at the intersection of oflocalizedshunts.Inthiscasehotspotheatingoccursbecause

the reverse I-V characteristic of Y with the image of the a large amount of current flows in a small area. Because this is

forward I-V characteristic of the (s-1) cells. a localized phenomenon, there is a great deal of scatter in

4.5 By-pass diodes, if present, as shown in Fig. 2, begin performance of this type of cell. Cells with the lowest shunt

conducting when a series-connected string in a module is in resistance have a high likelihood of operating at excessively

reverse bias, thereby limiting the power dissipation in the high temperatures when reverse biased.

reduced-output cell.

4.6.1.3 Because the heating is localized, hot spot failures of

low shunt resistance cells occur quickly.

NOTE 2—If the module does not contain bypass diodes, check the

manufacturer’sinstructionstoseeifamaximumnumberofseriesmodules 4.6.2 High Shunt Resistance Cells:

is recommended before installing bypass diodes. If the maximum number

4.6.2.1 The worst case shadowing conditions occur when a

of modules recommended is greater than one, the hot spot test should be

small fraction of the cell is shadowed.

preformed with that number of modules in series. For convenience, a

4.6.2.2 High shunt resistance cells limit the reverse current

constant current power supply may be substituted for the additional

modules to maintain the specified current. flow of the circuit and therefore heat up. The cell with the

highest shunt resistance will have the highest power dissipa-

4.6 The reverse characteristics of solar cells can vary

tion.

considerably. Cells can have either high shunt resistance where

4.6.2.3 Because the heating is uniform over the whole area

the reverse performance is voltage-limited or have low shunt

of the cell, it can take a long time for the cell to heat to the

resistance where the reverse performance is current-limited.

point of causing damage.

Each of these types of cells can suffer hot spot problems, but in

different ways. 4.6.2.4 High shunt resistance cells define the need for

4.6.1 Low-Shunt Resistance Cells: bypass diodes in the module’s circuit, and their performance

4.6.1.1 The worst case shadowing conditions occur when characteristics determine the number of cells that can be

the whole cell (or a large fraction) is shadowed. protected by each diode.

FIG. 2 Bypass Diode Effect

E2481–06

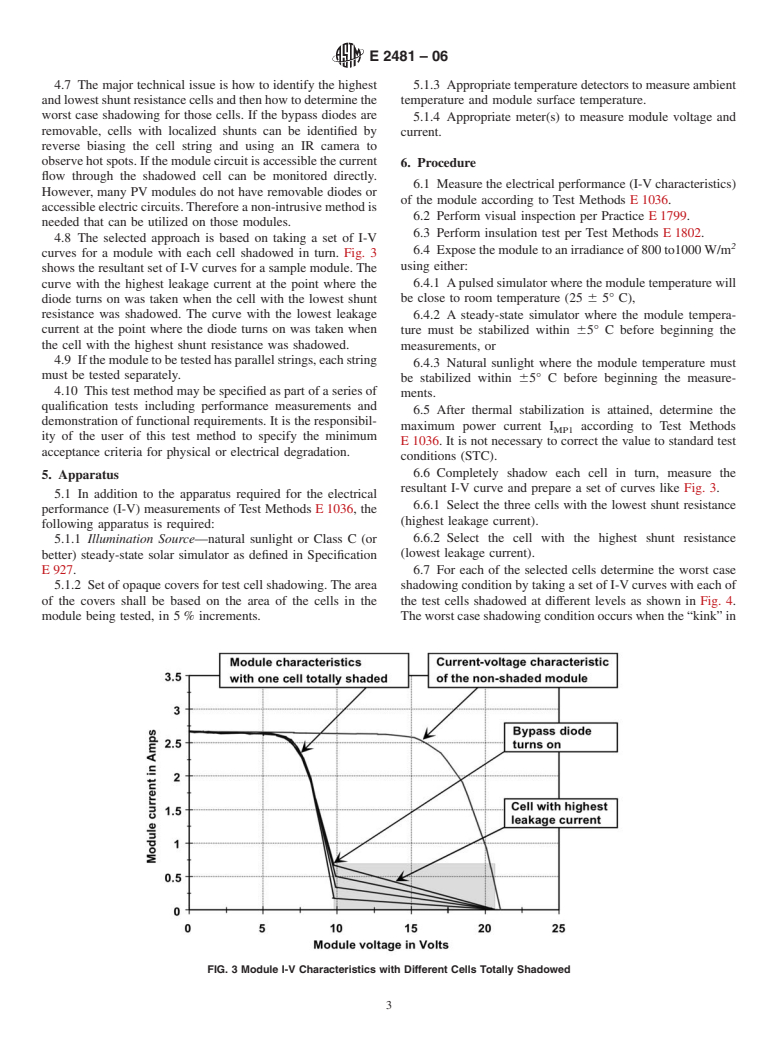

4.7 The major technical i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.