ASTM C373-14a

(Test Method)Standard Test Method for Water Absorption, Bulk Density, Apparent Porosity, and Apparent Specific Gravity of Fired Whiteware Products, Ceramic Tiles, and Glass Tiles

Standard Test Method for Water Absorption, Bulk Density, Apparent Porosity, and Apparent Specific Gravity of Fired Whiteware Products, Ceramic Tiles, and Glass Tiles

SIGNIFICANCE AND USE

2.1 Measurement of density, porosity, and specific gravity is a tool for determining the degree of maturation of a ceramic body, or for determining structural properties that may be required for a given application.

SCOPE

1.1 This test method covers procedures for determining water absorption, bulk density, apparent porosity, and apparent specific gravity of fired unglazed whiteware products, glazed or unglazed ceramic tiles, and glass tiles.

1.2 The values stated in metric units are normative. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not normative.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C373 −14a

StandardTest Method for

Water Absorption, Bulk Density, Apparent Porosity, and

Apparent Specific Gravity of Fired Whiteware Products,

Ceramic Tiles, and Glass Tiles

This standard is issued under the fixed designation C373; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* immersed in water with the sample and the wire loop com-

pletely free of contact with any part of the container.

1.1 This test method covers procedures for determining

water absorption, bulk density, apparent porosity, and apparent

3.5 Stainless Steel Boiling Container, suitable for boiling

specific gravity of fired unglazed whiteware products, glazed

water and with sufficient capacity to hold the test specimens

or unglazed ceramic tiles, and glass tiles.

and quantity of water specified in 5.2. The container shall be

equipped with a loose removable cover which does not allow

1.2 The values stated in metric units are normative. The

pressure to build.

values given in parentheses are mathematical conversions to

inch-poundunitsthatareprovidedforinformationonlyandare

3.6 Deionized (DI) or Distilled Water.

not normative.

3.7 Leather Chamois.

1.3 This standard does not purport to address all of the

3.8 HeatSource,suchasahotplate,burner,orequivalentto

safety concerns, if any, associated with its use. It is the

heat the water to boiling.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3.9 Desiccator—a sealed chamber containing desiccants

bility of regulatory limitations prior to use.

which is of sufficient size and capacity to allow specimens to

cool while preventing the specimens from absorbing moisture

2. Significance and Use

from ambient air.

2.1 Measurementofdensity,porosity,andspecificgravityis

a tool for determining the degree of maturation of a ceramic

4. Test Specimens:

body, or for determining structural properties that may be

4.1 Ceramic Whitewares:

required for a given application.

4.1.1 At least five representative test specimens shall be

3. Apparatus and Materials

selected that have not been previously tested. The specimens

shallbeunglazedandshallhaveasmuchofthesurfacefreshly

3.1 Balance, of adequate capacity, suitable to weigh accu-

fractured as is practical. Sharp edges or corners shall be

rately to 0.01 g (0.00002 lb).

removed. The specimens shall contain no cracks. The indi-

3.2 Oven, capable of maintaining a temperature of 150 6

vidual test specimens shall weigh at least 50 g.

5°C (302 6 9°F).

4.2 Ceramic Tiles and Glass Tiles:

3.3 Wire Loop, Halter, or Basket, capable of supporting

4.2.1 The specimens shall contain no visible damage or

specimens under water for making suspended mass measure-

cracks prior to testing. At least five representative test speci-

ments.

mens shall be selected that have not been previously tested.

3.4 Suspended Mass Container (if Determination of Sus-

Cutting of specimens, as described in the following sections,

pended Mass is Desired)—A glass beaker or similar container

shall consist of scoring and snapping, or sawing when impos-

of such size and shape that the sample, when suspended from

sible to score and snap with conventional tile scoring equip-

the balance by the wire loop, specified in 3.3, is completely

ment (as can be the case with some glass tiles and highly

textured and structured porcelain tiles).

4.2.2 For tiles less than or equal to 205 × 205 mm (8 ×

ThistestmethodisunderthejurisdictionofASTMCommitteeC21onCeramic

Whitewares and Related Products and is the direct responsibility of Subcommittee

8in.), specimens shall be cut in half, within 10 mm (0.4 in).

C21.03 on Methods for Whitewares and Environmental Concerns.

Specimens shall be cut perpendicular to the longest side if the

Current edition approved Dec. 1, 2014. Published December 2014. Originally

specimen has unequal sides. Select one half at random from

approved in 1955. Last previous edition approved in 2014 as C373–2014. DOI:

10.1520/C0373-14A. each specimen for testing (see Fig. 1a and Fig. 1b).

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C373−14a

(a.) Equal Sides: x# 205 mm, , a = ⁄2x (within 10 mm)

FIG. 3

x>410mm,y>410mm,a=205mm(within10mm)

(b.) Unequal Sides: x# 205 mm, y# 205 mm, x > y, a = ⁄2x (within 10mm)

FIG. 1

FIG. 4

x > 205 mm, y#205mm,a=205mm(within10mm)

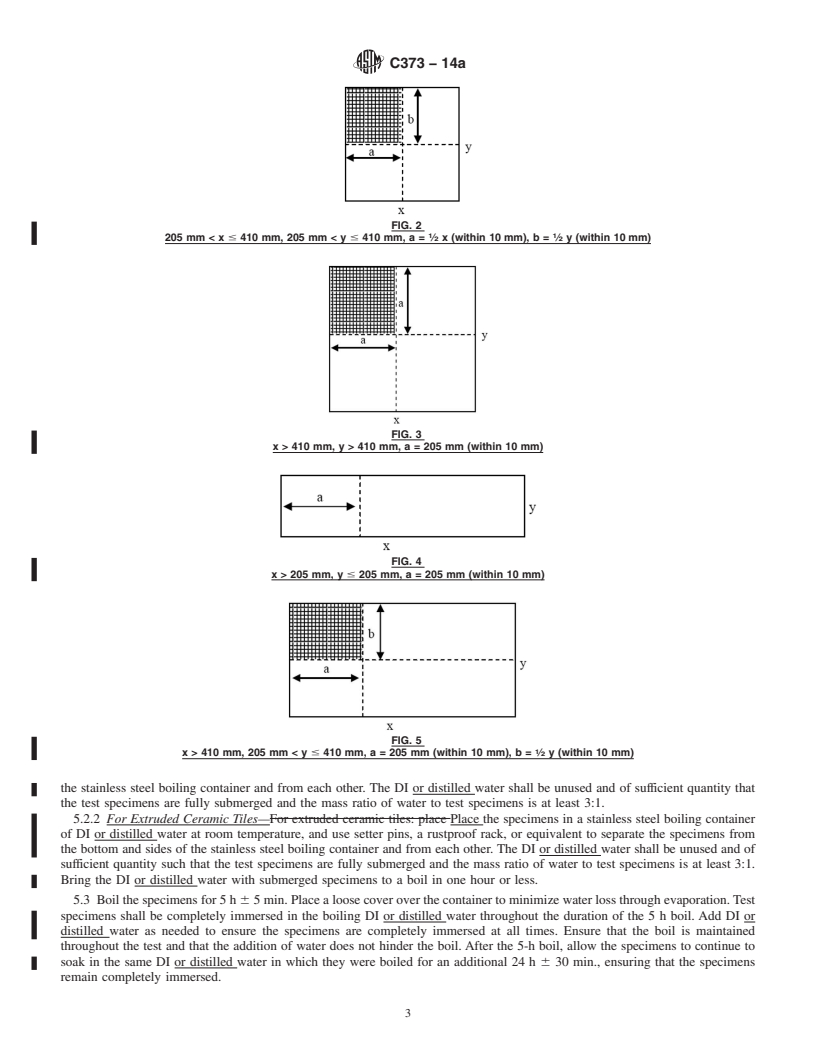

4.2.3 Fortilesgreaterthan205×205mm(8×8in.)andless

than or equal to 410 × 410 mm (16 × 16 in.), each specimen

shall be cut into four equal quadrants, within 10 mm (0.4 in).

Select one quadrant at random from each specimen for testing

(see Fig. 2).

4.2.4 For tiles greater than 410 × 410 mm (16 × 16 in.), a

205 × 205 mm (8 × 8 in.) portion, within 10 mm (0.4 in), shall

be cut from one corner of each specimen for testing (see Fig.

3.

4.2.5 For non-square tiles which have a side less than or

equalto205mm(8in.)andasidegreaterthan205mm(8in.), FIG. 5

x > 410 mm, 205 mm < y# 410 mm, a = 205 mm (within 10 mm),

each specimen shall be cut once perpendicular to the longest

b= ⁄2 y (within 10 mm)

side,suchthata205mm(8in.)portion,within10mm(0.4in),

from the end remains for testing (see Fig. 4).

4.2.6 For non-square tiles which have a side greater than

5. Procedure

205 mm (8 in.) and less than or equal to 410 mm (16 in.), and

5.1 Dry the test specimens to constant mass (Note 2)by

asidegreaterthan410mm(16in.),eachspecimenshallbecut

heating in an oven at 150 6 5°C (302 6 9°F) for a minimum

once perpendicular to the longest side, such that a 205 mm (8

of24h(orsuchothertimeashasbeenestablishedfortheoven

in.) portion, within 10 mm (0.4 in.), from the end remains.The

in use and the mass of the tiles being dried), followed by

205 mm (8in.) portion shall be cut a second time, in half,

cooling in a desiccator. Determine the dry mass, D,tothe

within10mm(0.4in.)perpendiculartothefirstcut.Selectone

nearest 0.01 g (0.00002 lb) (see Note 1).

half at random from each specimen for testing (see Fig. 5).

4.2.7 If a tile does not weigh at least 50 g (0.11 lb) prior to

NOTE1—Specimensbeingtesteddirectlyfollowingtheirmanufacture

may be considered fully dried so long as they have not been subjected to

cutting, then multiple whole pieces may be used to equal one

anyprocessthatwetsthespecimenpostfiring(suchascanoccurincutting

test specimen with a mass of at least 50 g (0.11 lb).

and polishing operations) and are placed in a desiccator sufficiently

quickly (usually within no more than 30 min of exiting the kiln) that no

moisture has been absorbed from ambient air.

NOTE 2—The drying of the specimens and the determination of their

masses may be done either before or after the specimens have been

impregnated with water. Usually the dry mass is determined before

impregnation. However, if the specimens are friable or evidence indicates

that particles have broken loose during the impregnation, the specimens

shall be dried and weighe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C373 − 14 C373 − 14a

Standard Test Method for

Water Absorption, Bulk Density, Apparent Porosity, and

Apparent Specific Gravity of Fired Whiteware Products,

Ceramic Tiles, and Glass Tiles

This standard is issued under the fixed designation C373; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method covers procedures for determining water absorption, bulk density, apparent porosity, and apparent specific

gravity of fired unglazed whiteware products, glazed or unglazed ceramic tiles, and glass tiles.

1.2 The values stated in metric units are normative. The values given in parentheses are mathematical conversions to inch-pound

units that are provided for information only and are not normative.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Significance and Use

2.1 Measurement of density, porosity, and specific gravity is a tool for determining the degree of maturation of a ceramic body,

or for determining structural properties that may be required for a given application.

3. Apparatus and Materials

3.1 Balance, of adequate capacity, suitable to weigh accurately to 0.01 g (0.00002 lb).

3.2 Oven, capable of maintaining a temperature of 150 6 5°C (302 6 9°F).

3.3 Wire Loop, Halter, or Basket, capable of supporting specimens under water for making suspended mass measurements.

3.4 Suspended Mass Container (If(if Determination of Suspended Mass is Desired)—A glass beaker or similar container of such

size and shape that the sample, when suspended from the balance by the wire loop, specified in 3.3, is completely immersed in

water with the sample and the wire loop completely free of contact with any part of the container.

3.5 Stainless Steel Boiling Container, suitable for boiling water and with sufficient capacity to hold the test specimens and

quantity of water specified in 5.2. The container shall be equipped with a loose removable cover which does not allow pressure

to build.

3.6 Deionized (DI) or Distilled Water.

3.7 Leather Chamois.

3.8 Heat Source, such as a hot plate, burner, or equivalent to heat the water to boiling.

3.9 Desiccator, Desiccator—a sealed chamber containing desiccants which is of sufficient size and capacity to allow specimens

to cool while preventing the specimens from absorbing moisture from ambient air.

4. Test SpecimensSpecimens:

4.1 Ceramic WhitewaresWhitewares:

4.1.1 At least five representative test specimens shall be selected that have not been previously tested. The specimens shall be

unglazed and shall have as much of the surface freshly fractured as is practical. Sharp edges or corners shall be removed. The

specimens shall contain no cracks. The individual test specimens shall weigh at least 50 g.

This test method is under the jurisdiction of ASTM Committee C21 on Ceramic Whitewares and Related Products and is the direct responsibility of Subcommittee C21.03

on Methods for Whitewares and Environmental Concerns.

Current edition approved March 1, 2014Dec. 1, 2014. Published March 2014December 2014. Originally approved in 1955. Last previous edition approved in 20062014

as C373 – 88 (2006).C373 – 2014. DOI: 10.1520/C0373-14.10.1520/C0373-14A.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C373 − 14a

4.2 Ceramic Tiles and Glass TilesTiles:

4.2.1 The specimens shall contain no visible damage or cracks prior to testing. At least five representative test specimens shall

be selected that have not been previously tested. Cutting of specimens, as described in the following sections, shall consist of

scoring and snapping, or sawing when impossible to score and snap with conventional tile scoring equipment (as can be the case

with some glass tiles and highly textured and structured porcelain tiles).

4.2.2 For tiles less than or equal to 205 × 205 mm (8 × 8 in.), 8 in.), specimens shall be cut in half, within 10 mm (0.4 in).

Specimens shall be cut perpendicular to the longest side if the specimen has unequal sides. Select one half at random from each

specimen for testing.testing (see Fig. 1a and Fig. 1b).

4.2.3 For tiles greater than 205 × 205 mm (8 × 8 in.) and less than or equal to 410 × 410 mm (16 × 16 in.), each specimen shall

be cut into four equal quadrants, within 10 mm (0.4 in). Select one quadrant at random from each specimen for testing. testing

(see Fig. 2).

4.2.4 For tiles greater than 410 × 410 mm (16 × 16 in.), a 205 × 205 mm (8 × 8 in.) portion, within 10 mm (0.4 in), shall be

cut from one corner of each specimen for testing.testing (see Fig. 3.

4.2.5 For non-square tiles which have a side less than or equal to 205 mm (8 in.) and a side greater than 205 mm (8 in.), each

specimen shall be cut once perpendicular to the longest side, such that a 205 mm (8 in.) portion, within 10 mm (0.4 in), from the

end remains. remains for testing (see Fig. 4).

4.2.6 For non-square tiles which have a side greater than 205 mm (8 in.) and less than or equal to 410 mm (16 in.), and a side

greater than 410 mm (16 in.), each specimen shall be cut once perpendicular to the longest side, such that a 205 mm (8 in.) portion,

within 10 mm (0.4 in.), from the end remains. The 205 mm (8 in.) portion shall be cut a second time, in half, within 10 mm (0.4

in.) perpendicular to the first cut. Select one half at random from each specimen for testing (see Fig. 5).

4.2.7 If a tile does not weigh at least 50 g (0.11 lb) prior to cutting, then multiple whole pieces may be used to equal one test

specimen with a mass of at least 50 g (0.11 lb).

5. Procedure

5.1 Dry the test specimens to constant mass (Note 2) by heating in an oven at 150 6 5°C (302 6 9°F) for a minimum of 24

h (or such other time as has been established for the oven in use and the mass of the tiles being dried), followed by cooling in a

desiccator. Determine the dry mass, D, to the nearest 0.01 g (0.00002 lb) (see Note 1).

NOTE 1—Specimens being tested directly following their manufacture may be considered fully dried so long as they have not been subjected to any

process that wets the specimen post firing (such as can occur in cutting and polishing operations) and are placed in a desiccator sufficiently quickly

(usually within no more than 30 minutesmin of exiting the kiln) that no moisture has been absorbed from ambient air.

NOTE 2—The drying of the specimens and the determination of their masses may be done either before or after the specimens have been impregnated

with water. Usually the dry mass is determined before impregnation. However, if the specimens are friable or evidence indicates that particles have broken

loose during the impregnation, the specimens shall be dried and weighed after the suspended mass and the saturated mass have been determined, in

accordance with 5.45.4 and 5.5 and 5.5. In this case, the second dry mass shall be used in all appropriate calculations.

5.2 Addition

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.