ASTM D7336/D7336M-07

(Test Method)Standard Test Method for Static Energy Absorption Properties of Honeycomb Sandwich Core Materials

Standard Test Method for Static Energy Absorption Properties of Honeycomb Sandwich Core Materials

SIGNIFICANCE AND USE

Sandwich honeycomb core materials are used extensively in energy absorption applications, due to their ability to sustain compressive loading while being crushed. Proper design of energy absorption devices utilizing sandwich honeycomb core materials requires knowledge of the compressive crush stress and crush stroke properties of the honeycomb core material.

The procedures contained within this standard are intended to assess the crush stress and crush stroke properties of the sandwich honeycomb core material under static compressive loading. The dynamic crush stress of the honeycomb core material may vary from that measured under static loading, depending upon factors such as honeycomb core material thickness, core material density, impact velocity, etc.

This test method provides a standard method of obtaining the compressive crush stress and crush stroke for sandwich honeycomb core material structural design properties, material specifications, research and development applications, and quality assurance.

This test method is not intended for use in crush testing of stabilized honeycomb core materials (for which the edges of the honeycomb core material are dipped in resin to resist local crushing) or sandwich specimens (for which facings are bonded to the honeycomb core material).

Factors that influence the compressive crush stress and crush stroke and shall therefore be reported include the following: honeycomb core material, methods of material fabrication, core material geometry (nominal cell size), core material density, specimen geometry, specimen preparation, specimen conditioning, environment of testing, specimen alignment, pre-crush procedure, pre-crush depth, loading procedure, and speed of testing.

SCOPE

1.1 This test method determines the static energy absorption properties (compressive crush stress and crush stroke) of honeycomb sandwich core materials. These properties are usually determined for design purposes in a direction normal to the plane of facings as the honeycomb core material would be placed in a structural sandwich construction.

1.2 Permissible core materials are limited to those in honeycomb form.

1.3 This test method is not intended for use in crush testing of stabilized honeycomb core materials (for which the edges of the honeycomb core material are dipped in resin to resist local crushing) or sandwich specimens (for which facings are bonded to the honeycomb core material).

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7336/D7336M – 07

Standard Test Method for

Static Energy Absorption Properties of Honeycomb

Sandwich Core Materials

This standard is issued under the fixed designation D7336/D7336M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C271/C271M Test Method for Density of Sandwich Core

Materials

1.1 This test method determines the static energy absorption

C274 Terminology of Structural Sandwich Constructions

properties (compressive crush stress and crush stroke) of

D883 Terminology Relating to Plastics

honeycomb sandwich core materials. These properties are

D3878 Terminology for Composite Materials

usuallydeterminedfordesignpurposesinadirectionnormalto

D5229/D5229M Test Method for Moisture Absorption

the plane of facings as the honeycomb core material would be

Properties and Equilibrium Conditioning of Polymer Ma-

placed in a structural sandwich construction.

trix Composite Materials

1.2 Permissible core materials are limited to those in hon-

E4 Practices for Force Verification of Testing Machines

eycomb form.

E6 TerminologyRelatingtoMethodsofMechanicalTesting

1.3 This test method is not intended for use in crush testing

E18 Test Methods for Rockwell Hardness of Metallic Ma-

of stabilized honeycomb core materials (for which the edges of

terials

the honeycomb core material are dipped in resin to resist local

E122 Practice for Calculating Sample Size to Estimate,

crushing) or sandwich specimens (for which facings are

With Specified Precision, the Average for a Characteristic

bonded to the honeycomb core material).

of a Lot or Process

1.4 The values stated in either SI units or inch-pound units

E177 Practice for Use of the Terms Precision and Bias in

are to be regarded separately as standard. Within the text the

ASTM Test Methods

inch-pound units are shown in brackets. The values stated in

E456 Terminology Relating to Quality and Statistics

each system are not exact equivalents; therefore, each system

E1309 Guide for Identification of Fiber-Reinforced

must be used independently of the other. Combining values

Polymer-Matrix Composite Materials in Databases

from the two systems may result in nonconformance with the

E1434 Guide for Recording Mechanical Test Data of Fiber-

standard.

Reinforced Composite Materials in Databases

1.5 This standard does not purport to address all of the

E1471 Guide for Identification of Fibers, Fillers, and Core

safety concerns, if any, associated with its use. It is the

Materials in Computerized Material Property Databases

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3. Terminology

bility of regulatory limitations prior to use.

3.1 Definitions—Terminology D3878 defines terms relating

2. Referenced Documents to high-modulus fibers and their composites. Terminology

C274 defines terms relating to structural sandwich construc-

2.1 ASTM Standards:

tions. Terminology D883 defines terms relating to plastics.

Terminology E6 defines terms relating to mechanical testing.

Terminology E456 and Practice E177 define terms relating to

This test method is under the jurisdiction of ASTM Committee D30 on

statistics.Intheeventofaconflictbetweenterms,Terminology

Composite Materials and is the direct responsibility of Subcommittee D30.09 on

D3878 shall have precedence over the other terminologies.

Sandwich Construction.

Current edition approved May 1, 2007. Published May 2007. DOI: 10.1520/

NOTE 1—If the term represents a physical quantity, its analytical

D7336_D7336M-07.

2 dimensionsarestatedimmediatelyfollowingtheterm(orlettersymbol)in

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

fundamental dimension form, using the following ASTM standard sym-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

bology for fundamental dimensions, shown within square brackets: [M]

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. for mass, [L] for length, [T] for time, [u] for thermodynamic temperature,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7336/D7336M – 07

and[nd]fornon-dimensionalquantities.Useofthesesymbolsisrestricted

comb core materials requires knowledge of the compressive

to analytical dimensions when used with square brackets, as the symbols

crush stress and crush stroke properties of the honeycomb core

may have other definitions when used without the brackets.

material.

5.2 The procedures contained within this standard are in-

3.2 Definitions of Terms Specific to This Standard:

tended to assess the crush stress and crush stroke properties of

3.2.1 cell size [L], n—in a honeycomb core, the distance

the sandwich honeycomb core material under static compres-

between two parallel and opposite cell walls at node bond

sive loading. The dynamic crush stress of the honeycomb core

areas, measured transverse to the ribbon direction.

material may vary from that measured under static loading,

3.2.2 node bond area, n—in a honeycomb core, the area

depending upon factors such as honeycomb core material

betweentwocellsatwhichthecomponentwallsofthecellsare

thickness, core material density, impact velocity, etc.

bonded or attached.

5.3 This test method provides a standard method of obtain-

3.3 Symbols:

ing the compressive crush stress and crush stroke for sandwich

honeycomb core material structural design properties, material

A = cross-sectional area of a test specimen prior to specifications, research and development applications, and

compressive crush testing quality assurance.

CV = coefficient of variation statistic of a sample popula- 5.4 This test method is not intended for use in crush testing

tion for a given property (in percent)

of stabilized honeycomb core materials (for which the edges of

K = initial chord slope of the force versus displacement/

the honeycomb core material are dipped in resin to resist local

A

deformation curve

crushing) or sandwich specimens (for which facings are

K = post-crush slope of the force versus displacement/

bonded to the honeycomb core material).

B

deformation curve

5.5 Factors that influence the compressive crush stress and

P = average force carried by test specimen during com-

cr crush stroke and shall therefore be reported include the

pressive crushing

following: honeycomb core material, methods of material

s = crush stroke in percent

cr

fabrication, core material geometry (nominal cell size), core

S = standard deviation statistic of a sample population

n-1

material density, specimen geometry, specimen preparation,

for a given property

specimen conditioning, environment of testing, specimen

t = thickness of a test specimen prior to compressive

i

alignment, pre-crush procedure, pre-crush depth, loading pro-

crush testing

cedure, and speed of testing.

x = test result for an individual specimen from the

sample population for a given property

6. Interferences

x = mean or average (estimate of mean) of a sample

6.1 Material and Specimen Preparation—Poor material

population for a given property

fabrication practices and damage induced by improper speci-

d = recorded displacement/deflection

men machining are known causes of high data scatter in

d = displacement/deflection at which the initial chord

A

composites and sandwich structures in general. Important

slope intersects the displacement/deformation axis

aspects of sandwich core material specimen preparation that

d = displacement/deflection at which the post-crushing

B

contribute to data scatter include the existence of joints, voids

slope equals the initial chord slope

or other core material discontinuities, out-of-plane curvature/

d = crush stroke

cr

warpage, and surface roughness.

D = normalized displacement/deflection

6.2 System Alignment—Non-uniform loading over the sur-

s = average compressive crush stress

cr

face of the test specimen may cause premature or uneven

crushing. This may occur as a result from non-uniform

4. Summary of Test Method

thickness, failing to locate the specimen concentrically in the

4.1 This test method consists of subjecting a sandwich

fixture, or system or fixture misalignment.

honeycomb core material to a uniaxial compressive force

6.3 Geometry—Specific geometric factors that affect com-

normal to the plane of the facings as the honeycomb core

pressive crush stress and crush stroke include honeycomb core

materialwouldbeplacedinastructuralsandwichconstruction.

material cell geometry, core material thickness, and specimen

The force is transmitted to the sandwich honeycomb core

shape (square or circular). Thicker specimens are generally

material using loading platens attached to the testing machine.

desirable, as the crush stroke is greater for thick specimens

Compressive force is applied past the initial failure force, such

compared to thin specimens.

that the honeycomb core material is crushed under continuous

6.4 Pre-Crushing—It is recommended to pre-crush honey-

displacement of the loading platens. Force versus loading

comb core material specimens prior to test, as historical crush

platen displacement data are recorded and used to determine

force versus displacement data for pre-crushed specimens have

the crush stress and crush stroke.

displayed greater uniformity (consistency of the crush force

level for varying crush stroke) than have similar data for non

5. Significance and Use

pre-crushed specimens. If tests are performed using analog

5.1 Sandwich honeycomb core materials are used exten- equipment to record force versus displacement data, pre-

sively in energy absorption applications, due to their ability to crushingmaybenecessarytoensurethecrushforceisrecorded

sustain compressive loading while being crushed. Proper on a high sensitivity force scale (if not pre-crushed, the peak

design of energy absorption devices utilizing sandwich honey- force to initially fail the specimen may be substantially higher

D7336/D7336M – 07

than the crush force). Pre-crushing also aids interpretation of

force versus displacement data and calculation of crush stroke

values. Results are affected by the pre-crush depth and unifor-

mity of pre-crushing.

6.5 Environment—Results are affected by the environmen-

tal conditions under which specimens are conditioned, as well

as the conditions under which the tests are conducted. Speci-

mens tested in various environments can exhibit significant

differences in both crush stress and crush stroke. Critical

environments must be assessed independently for each honey-

comb core material tested.

7. Apparatus

7.1 Micrometers and Calipers—A micrometer having a flat

anvil interface, or a caliper of suitable size, shall be used. The

accuracy of the instrument(s) shall be suitable for reading to

within 1 % of the sample length and width (or diameter) and

thickness. For typical specimen geometries, an instrument with

an accuracy of 6250 µm [60.010 in.] is desirable for thick-

ness, length and width (or diameter) measurement.

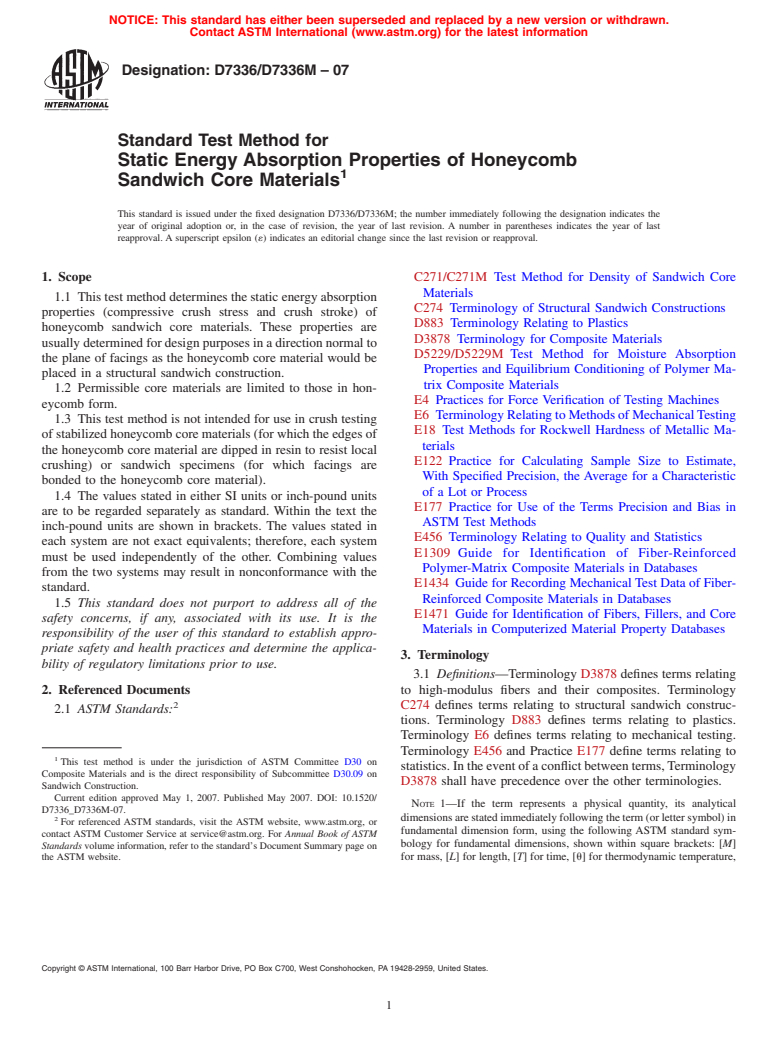

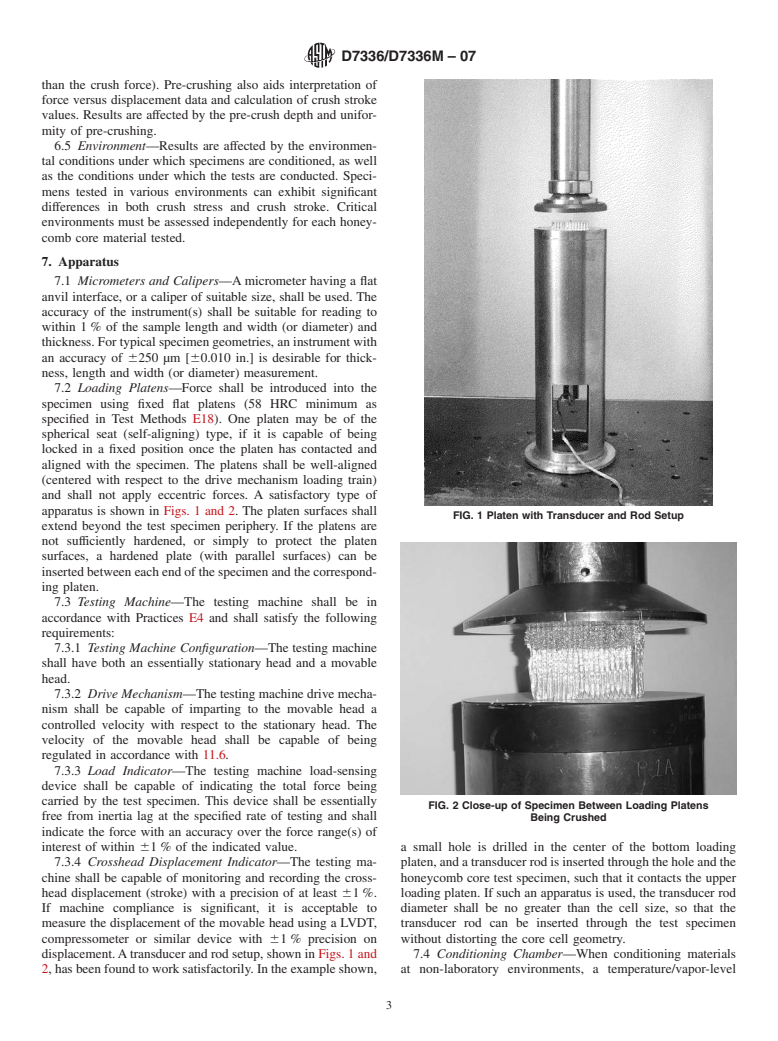

7.2 Loading Platens—Force shall be introduced into the

specimen using fixed flat platens (58 HRC minimum as

specified in Test Methods E18). One platen may be of the

spherical seat (self-aligning) type, if it is capable of being

locked in a fixed position once the platen has contacted and

aligned with the specimen. The platens shall be well-aligned

(centered with respect to the drive mechanism loading train)

and shall not apply eccentric forces. A satisfactory type of

apparatus is shown in Figs. 1 and 2. The platen surfaces shall

FIG. 1 Platen with Transducer and Rod Setup

extend beyond the test specimen periphery. If the platens are

not sufficiently hardened, or simply to protect the platen

surfaces, a hardened plate (with parallel surfaces) can be

inserted between each end of the specimen and the correspond-

ing platen.

7.3 Testing Machine—The testing machine shall be in

accordance with Practices E4 and shall satisfy the following

requirements:

7.3.1 Testing Machine Configuration—The testing machine

shall have both an essentially stationary head and a movable

head.

7.3.2 Drive Mechanism—The testing machine drive mecha-

nism shall be capable of imparting to the movable head a

controlled velocity with respect to the stationary head. The

velocity of the movable head shall be capable of being

regulated in accordance with 11.6.

7.3.3 Load Indicator—The testing machine load-sensing

device shall be capable of indicating the total force being

carried by the test specimen. This device shall be essentially

FIG. 2 Close-up of Specimen Between Loading Platens

free from inertia lag at the specified rate of testing and shall

Being Crushed

indicate the force with an accuracy over the force range(s) of

interest of within 61 % of the indicated value. a small hole is drilled in the center of the bottom loading

7.3.4 Crosshead Displacement Indicator—The testing ma- platen,andatransducerrodisinsertedthroughtheholeandthe

chine shall be capable of monitoring and recording the cross- honeycomb core test specimen, such that it contacts the upper

head displacement (stroke) with a precision of at least 61%. loading platen. If such an apparatus is used, the transducer rod

If machine compliance is significant, it is acceptable to diameter shall be no greater than the cell size, so that the

measure the displacement of the movable head using a LVDT, transducer rod can be inserted through the test specimen

compressometer or similar device with 61 % precision on without distorting the core cell geometry.

displacement.Atransducer and rod setup, shown in Figs. 1 and 7.4 Conditioning Chamber—When conditioning materials

2, has been found to work satisfactorily. In the example shown, at non-laboratory environments, a temperature/vapor-level

D7336/D7336M – 07

controlledenvironmentalconditioningchamberisrequiredthat [1.0 in.].Therequiredfacingareaofthespecimenisdependent

shall be capable of maintaining the required temperature to upon the cell size, to ensure a minimum number of cells are

within 63°C [65°F] and the required relative humidity level

tested. Minimum facing areas are recommended in Table 1 for

to within 63 %. Chamber conditions shall be monitored either

the more common cell sizes. These are intended to provide

on an automated continuous basis or on a manual basis at

approximately 60 cells minimum in the test specimen. The

2 2

regular intervals.

largest facing area listed in th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.