ASTM D4803-24

(Test Method)Standard Test Method for Predicting Heat Buildup in PVC Building Products

Standard Test Method for Predicting Heat Buildup in PVC Building Products

SIGNIFICANCE AND USE

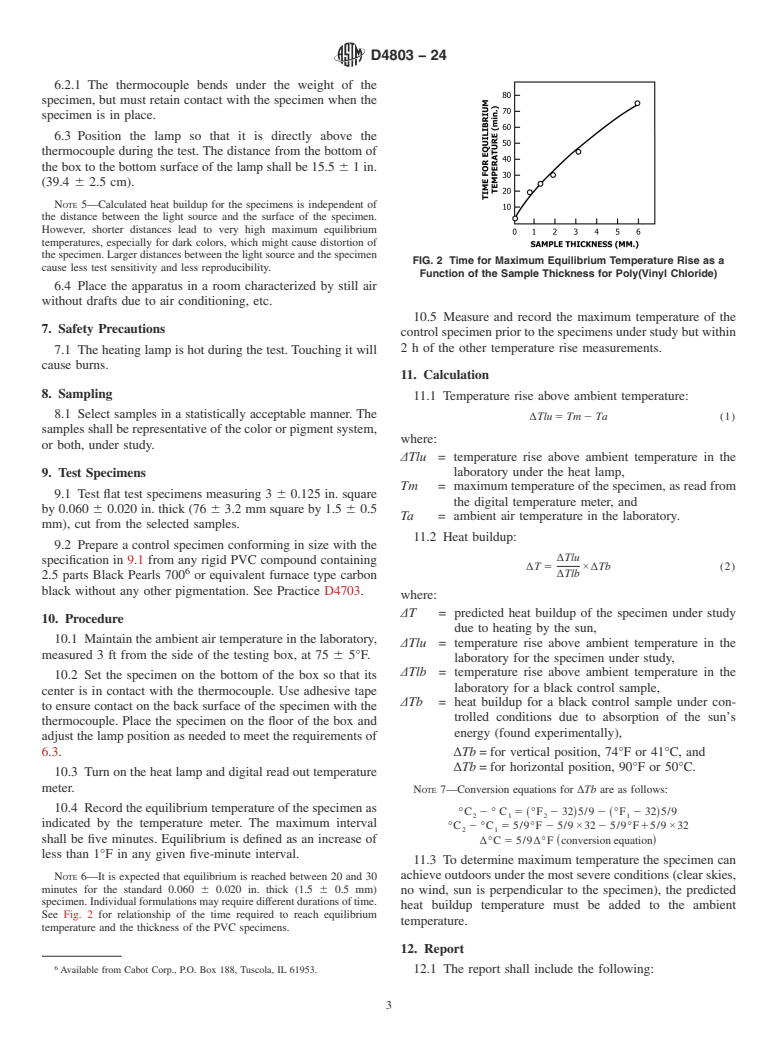

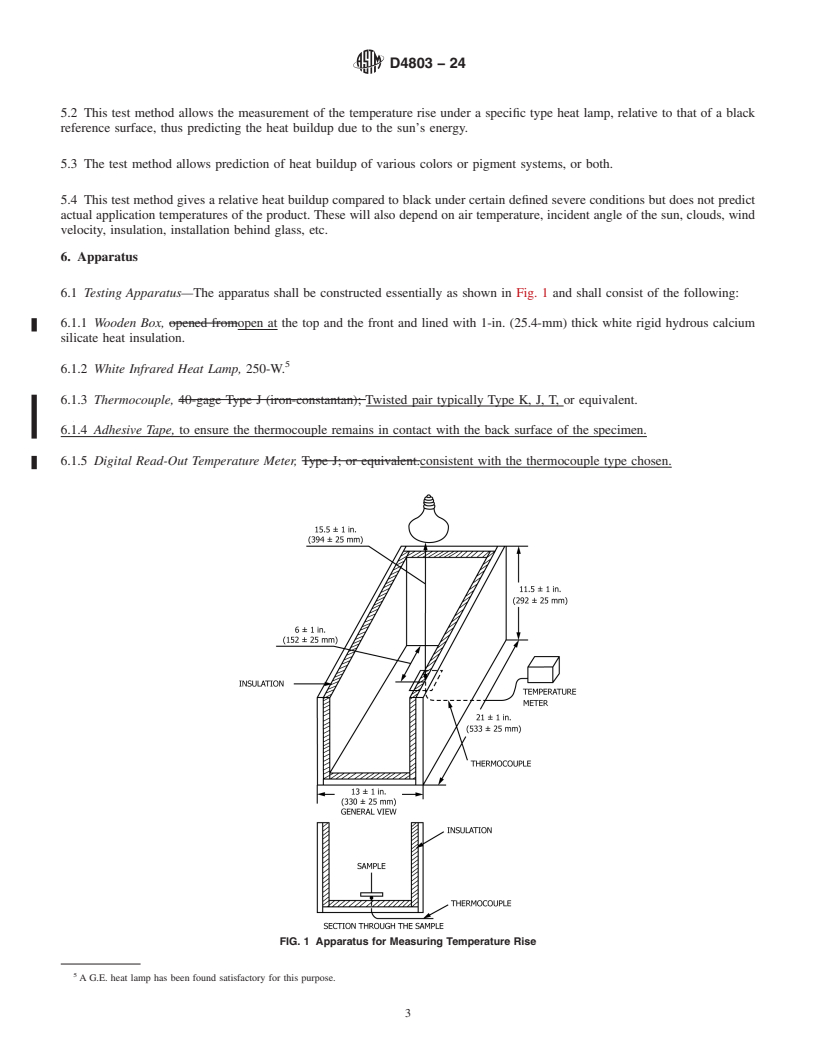

5.1 Heat buildup in PVC exterior building products due to absorption of the energy from the sun may lead to distortion problems. Heat buildup is affected by the color, emittance, absorptance, and reflectance of a product. Generally, the darker the color of the product, the more energy is absorbed and the greater is the heat buildup. However, even with the same apparent color, the heat buildup may vary due to the specific pigment system involved. The greatest heat buildup generally occurs in the color black containing carbon black pigment. The black control sample used in this test method contains 2.5 parts of furnace black per 100 parts of PVC suspension resin. The maximum temperature rise above ambient temperature for this black is 90°F (50°C) for a 45° or horizontal surface when the sun is perpendicular to the surface and 74°F (41°C) for a vertical surface assuming that the measurements were done on a cloudless day with no wind and heavy insulation on the back of the specimen.4

5.2 This test method allows the measurement of the temperature rise under a specific type heat lamp, relative to that of a black reference surface, thus predicting the heat buildup due to the sun's energy.

5.3 The test method allows prediction of heat buildup of various colors or pigment systems, or both.

5.4 This test method gives a relative heat buildup compared to black under certain defined severe conditions but does not predict actual application temperatures of the product. These will also depend on air temperature, incident angle of the sun, clouds, wind velocity, insulation, installation behind glass, etc.

SCOPE

1.1 This test method covers prediction of the heat buildup in rigid and flexible PVC building products above ambient air temperature, relative to black, which occurs due to absorption of the sun's energy.

Note 1: This test method is expected to be applicable to all types of colored plastics. The responsible subcommittee intends to broaden the scope beyond PVC when data on other materials is submitted for review.

Note 2: There are no ISO standards covering the primary subject matter of this test method.

1.2 Rigid PVC exterior profile extrusions for assembled windows and doors are covered in Specification D4726.

1.3 Rigid PVC exterior profiles for fencing are covered in Specification F964.

1.4 Rigid PVC siding profiles are covered in Specification D3679.

1.5 Rigid PVC soffit profiles are covered in Specification D4477.

1.6 Rigid PVC and Rigid CPVC plastic building products compounds are covered in Specification D4216.

1.7 The text of this test method references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of this test method.

1.8 Units—The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific safety hazard statements are given in Section 7.

1.10 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4803 − 24 An American National Standard

Standard Test Method for

1

Predicting Heat Buildup in PVC Building Products

This standard is issued under the fixed designation D4803; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.10 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This test method covers prediction of the heat buildup in

ization established in the Decision on Principles for the

rigid and flexible PVC building products above ambient air

Development of International Standards, Guides and Recom-

temperature, relative to black, which occurs due to absorption

mendations issued by the World Trade Organization Technical

of the sun’s energy.

Barriers to Trade (TBT) Committee.

NOTE 1—This test method is expected to be applicable to all types of

colored plastics. The responsible subcommittee intends to broaden the

2. Referenced Documents

scope beyond PVC when data on other materials is submitted for review.

2

2.1 ASTM Standards:

NOTE 2—There are no ISO standards covering the primary subject

D883 Terminology Relating to Plastics

matter of this test method.

D1600 Terminology for Abbreviated Terms Relating to Plas-

1.2 Rigid PVC exterior profile extrusions for assembled

3

tics (Withdrawn 2024)

windows and doors are covered in Specification D4726.

D3679 Specification for Rigid Poly(Vinyl Chloride) (PVC)

1.3 Rigid PVC exterior profiles for fencing are covered in

Siding

Specification F964.

D4216 Specification for Rigid Poly(Vinyl Chloride) (PVC)

and Related PVC and Chlorinated Poly(Vinyl Chloride)

1.4 Rigid PVC siding profiles are covered in Specification

(CPVC) Building Products Compounds

D3679.

D4477 Specification for Rigid (Unplasticized) Poly(Vinyl

1.5 Rigid PVC soffit profiles are covered in Specification

Chloride) (PVC) Soffit

D4477.

D4703 Practice for Compression Molding Thermoplastic

1.6 Rigid PVC and Rigid CPVC plastic building products

Materials into Test Specimens, Plaques, or Sheets

compounds are covered in Specification D4216.

D4726 Specification for Rigid Poly(Vinyl Chloride) (PVC)

Exterior-Profile Extrusions Used for Assembled Windows

1.7 The text of this test method references notes and

and Doors

footnotes which provide explanatory material. These notes and

E456 Terminology Relating to Quality and Statistics

footnotes (excluding those in tables and figures) shall not be

E631 Terminology of Building Constructions

considered as requirements of this test method.

F964 Specification for Rigid Poly (Vinyl Chloride) (PVC)

1.8 Units—The values stated in inch-pound units are to be

Exterior Profiles Used for Fencing and Railing

regarded as the standard. The values given in parentheses are

mathematical conversions to SI units that are provided for

3. Terminology

information only and are not considered standard.

3.1 Definitions—Terms used in this standard are defined in

1.9 This standard does not purport to address all of the

accordance with Terminology D883, unless otherwise speci-

safety concerns, if any, associated with its use. It is the

fied. For terms relating to precision and bias and associated

responsibility of the user of this standard to establish appro-

issues, the terms used in this standard are defined in accordance

priate safety, health, and environmental practices and deter-

with Terminology E456. Any abbreviations used in this stan-

mine the applicability of regulatory limitations prior to use.

dard are in accordance with Terminology D1600.

Specific safety hazard statements are given in Section 7.

3.2 Definitions of Terms Specific to This Standard:

1 2

This test method is under the jurisdiction of ASTM Committee D20 on Plastics For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and is the direct responsibility of Subcommittee D20.24 on Plastic Building contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Products. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Feb. 1, 2024. Published February 2024. Originally the ASTM website.

3

approved in 1989. Last previous edition approved in 2018 as D4803 - 18. DOI: The last approved version of this historical standard is referenced on

10.1520/D4803-24. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 1942

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4803 − 18 D4803 − 24 An American National Standard

Standard Test Method for

1

Predicting Heat Buildup in PVC Building Products

This standard is issued under the fixed designation D4803; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers prediction of the heat buildup in rigid and flexible PVC building products above ambient air

temperature, relative to black, which occurs due to absorption of the sun’s energy.

NOTE 1—This test method is expected to be applicable to all types of colored plastics. The responsible subcommittee intends to broaden the scope beyond

PVC when data on other materials is submitted for review.

NOTE 2—There are no ISO standards covering the primary subject matter of this test method.

1.2 Rigid PVC exterior profile extrusions for assembled windows and doors are covered in Specification D4726.

1.3 Rigid PVC exterior profiles for fencing are covered in Specification F964.

1.4 Rigid PVC siding profiles are covered in Specification D3679.

1.5 Rigid PVC soffit profiles are covered in Specification D4477.

1.6 Rigid PVC and Rigid CPVC plastic building products compounds are covered in Specification D4216.

1.7 The text of this test method references notes and footnotes which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of this test method.

1.8 Units—The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are

mathematical conversions to SI units that are provided for information only and are not considered standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. Specific safety hazard statements are given in Section 7.

1.10 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.24 on Plastic Building Products.

Current edition approved Oct. 1, 2018Feb. 1, 2024. Published October 2018February 2024. Originally approved in 1989. Last previous edition approved in 2018 as

ɛ1

D4803 - 10D4803 - 18.(2018) . DOI: 10.1520/D4803-18.10.1520/D4803-24.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4803 − 24

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

3

D1600 Terminology for Abbreviated Terms Relating to Plastics (Withdrawn 2024)

D4703 Practice for Compression Molding Thermoplastic Materials into Test Specimens, Plaques, or Sheets

D3679 Specification for Rigid Poly(Vinyl Chloride) (PVC) Siding

D4216 Specification for Rigid Poly(Vinyl Chloride) (PVC) and Related PVC and Chlorinated Poly(Vinyl Chloride) (CPVC)

Building Products Compounds

D4477 Specification for Rigid (Unplasticized) Poly(Vinyl Chloride) (PVC) Soffit

D4703 Practice for Compression Molding Thermoplastic Materials into Test Specimens, Plaques, or Sheets

D4726 Specification for Rigid Poly(Vinyl Chloride) (PVC) Exterior-Profile Extrusions Used for Assembled Windows and Doors

E456 Terminology Relating to Quality and Statistics

E631 Terminology of Building Constructions

F964 Specification for Rigid Poly (Vinyl Chloride) (PVC) Exterior Profiles Used for Fencing and Railing

3. Terminology

3.1 Definitions—Definitions are Terms used in this standard are defined in accordance with TerminologiesTerminology D883 or

, unless otherwise specified. For terms relating to precision and bias and associated issues, the terms used in this standard are

defined in accordance with Terminology E631E456 and abbreviations . Any abbreviations used in this stan

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.