ASTM E1424-91(2008)

(Test Method)Standard Test Method for Determining the Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors Under Specified Pressure and Temperature Differences Across the Specimen

Standard Test Method for Determining the Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors Under Specified Pressure and Temperature Differences Across the Specimen

SIGNIFICANCE AND USE

The exterior building envelope and its components (for example, windows and doors) separate the interior conditioned spaces from exterior environmental factors such as heat, cold, rain, wind, noise dust, etc. Building materials and components can expand or contract to varying degrees, depending on seasonal and diurnal exterior ambient air temperatures. Fluctuations in the ambient air temperatures can alter the sealing characteristics of windows, curtain walls, and doors by changing weather seal compression ratios. Thermal expansion or contraction of framing materials coupled with thermal blowing due to temperature gradients through the product, and alterations in the effective leakage areas due to weather seal shrinkage and compression set, can also significantly alter the air leakage rates of these products in field service applications. Air leakage tests performed using Test Method E 283 (a laboratory air leakage test performed at ambient temperature conditions) will not account accurately for changes in air leakage rates that may occur from dimensional changes in fenestration systems, materials, and components.

It is recommended that test specifiers consult the manufacturer for recommended test temperature extremes.

This procedure provides a means for evaluating air leakage rates of fenestration systems under various temperature and pressure conditions and air flow directions. It is also applicable for use in evaluating the efficiency of weather sealing products in fenestration systems. All air flow rates are converted to standard conditions to provide a means of comparison between measurements made at different ambient air temperature and pressure conditions.

Air leakage rates are sometimes used for comparison purposes. Such comparisons may not be valid unless the components being tested and compared are of essentially the same size, configuration, and design.

SCOPE

1.1 This test method provides a standard laboratory procedure for determining the air leakage rates of exterior windows, curtain walls, and doors under specified differential air temperature and pressure conditions across the specimen.

1.2 Specified temperature and pressure conditions are representative of those that may be encountered at the exterior thermal envelope of buildings, excluding the effects of heat buildup due to solar radiation.

1.3 This laboratory procedure is applicable to exterior windows, curtain walls, and doors and is intended to measure only such leakage associated with the assembly and not the installation; however, the test method can be adapted for the latter purpose.

1.4 This is a laboratory procedure for testing at differential temperature conditions. Persons interested in a laboratory test at ambient conditions should reference Test Method E 283. Persons interested in a field test on installed windows and doors should reference Test Method E 783.

1.5 Persons using this procedure should be knowledgeable in the areas of heat transfer, fluid mechanics, and instrumentation practices, and shall have a general understanding of fenestration products and components.

1.6 The values stated in SI units are to be regarded as standard. The inch-pound units given in parenthesis are provided for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1424 −91(Reapproved 2008)

Standard Test Method for

Determining the Rate of Air Leakage Through Exterior

Windows, Curtain Walls, and Doors Under Specified

Pressure and Temperature Differences Across the

Specimen

This standard is issued under the fixed designation E1424; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope bility of regulatory limitations prior to use. For specific hazard

statements, see Section 7.

1.1 This test method provides a standard laboratory proce-

dure for determining the air leakage rates of exterior windows,

2. Referenced Documents

curtain walls, and doors under specified differential air tem-

perature and pressure conditions across the specimen. 2.1 ASTM Standards:

E283Test Method for Determining Rate of Air Leakage

1.2 Specified temperature and pressure conditions are rep-

Through Exterior Windows, Curtain Walls, and Doors

resentative of those that may be encountered at the exterior

Under Specified Pressure Differences Across the Speci-

thermal envelope of buildings, excluding the effects of heat

men

buildup due to solar radiation.

E631Terminology of Building Constructions

1.3 This laboratory procedure is applicable to exterior

E783Test Method for Field Measurement of Air Leakage

windows, curtain walls, and doors and is intended to measure

Through Installed Exterior Windows and Doors

only such leakage associated with the assembly and not the

installation; however, the test method can be adapted for the

3. Terminology

latter purpose.

3.1 Definitions—Terms used in this test method are defined

1.4 This is a laboratory procedure for testing at differential

in Terminology E631.

temperature conditions. Persons interested in a laboratory test

3.2 Definitions of Terms Specific to This Standard:

at ambient conditions should reference Test Method E283.

3.2.1 air leakage rate (q or q )—theairleakageperunitof

A L

Persons interested in a field test on installed windows and

specimen area (A) or per unit length of operable crack

3 2 3 2 3

doors should reference Test Method E783.

perimeter (L), expressed as m /s-m (ft /min-ft)orm /s-m

(ft /min-ft).

1.5 Persons using this procedure should be knowledgeable

in the areas of heat transfer, fluid mechanics, and instrumen-

3.2.2 extraneous air leakage (Q)—the volume of air

e

tation practices, and shall have a general understanding of flowing per unit of time through the test chamber and test

fenestration products and components. apparatus, exclusive of the air flowing through the test

specimen, under a test pressure difference and test temperature

1.6 The values stated in SI units are to be regarded as

difference, converted to standard conditions, expressed in m /s

standard. The inch-pound units given in parenthesis are pro-

(ft /min).

vided for information only.

3.2.2.1 Discussion—Extraneous leakage is the sum of all

1.7 This standard does not purport to address all of the

leakage other than that intended to be measured by the test.

safety concerns, if any, associated with its use. It is the

3.2.3 specimen air leakage (Q )—the volume of air flowing

s

responsibility of the user of this standard to establish appro-

per unit of time through the specimen under a test pressure

priate safety and health practices and determine the applica-

difference and test temperature difference, converted to stan-

3 3

dard conditions, expressed in m /s (ft /min).

This test method is under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.51

on Performance of Windows, Doors, Skylights and Curtain Walls. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2008. Published October 2008. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1991. Last previous edition approved in 2000 as E1424–91(2000). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/E1424-91R08. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1424−91 (2008)

3.2.4 specimen area (A)—theareadeterminedbytheoverall and pressure conditions and air flow directions. It is also

dimensions of the frame that fits into the rough opening, applicable for use in evaluating the efficiency of weather

2 2

expressed as m (ft ). sealing products in fenestration systems. All air flow rates are

converted to standard conditions to provide a means of

3.2.5 test mask assembly—a wall construction that sur-

comparison between measurements made at different ambient

rounds and supports the test specimen.

air temperature and pressure conditions.

3.2.6 test pressure differences—the specified differential

5.4 Air leakage rates are sometimes used for comparison

static air pressure across the specimen, expressed in PA

purposes. Such comparisons may not be valid unless the

(lbf/ft ).

components being tested and compared are of essentially the

3.2.7 test temperature difference—thespecifieddifferencein

same size, configuration, and design.

temperature across the test specimen, expressed as a set of

room-side and weather-side temperatures, in °C (°F).

6. Apparatus

3.2.8 total air flow (Q)—the volume of air flowing per unit

t

6.1 The description of the apparatus in this section is

of time through the test chamber and test apparatus, inclusive

general. Any suitable arrangement of equipment capable of

of the air flowing through the test specimen, under a test

maintaining the required test tolerances is permitted.

pressure difference and test temperature difference, converted

6.1.1 Test Chamber—A well sealed box, wall, or other

3 3

to standard conditions, expressed in m /s (ft /min).

apparatus into or against which the specimen is mounted and

3.2.9 unit length of operable crack perimeter (L)—the sum

secured for testing.An air supply shall be provided to allow a

of all perimeters of operable ventilators, sash, or doors con-

positive or negative pressure differential to be applied across

tained in the test specimen, based on the overall dimensions of

the specimen without significant extraneous losses. The cham-

such parts, expressed as m (ft).Where two such operable parts

ber should also be constructed of materials that have good

meet,thetwoadjacentlengthsofperimetershallbecountedas

resistance to heat flow. The chamber shall be capable of

only one length.

withstanding the differential test pressures and temperatures

that may be encountered in this procedure. At least one static

4. Summary of Test Method

air pressure tap shall be provided on each side of the specimen

4.1 The procedure consists of sealing a specimen into or

to measure the test pressure differences. The pressure tap shall

against a chamber capable of maintaining a specified air

belocatedinanareaofthechamberinwhichpressurereadings

temperature differential across the specimen. When the speci-

will not be affected by any supply air or air conditioning fans.

men has been conditioned for a specified period of time, air is

The air supply to the chamber shall be located in an area in

supplied to, or exhausted from, the chamber at a rate required

which it does not directly impinge upon the test specimen. A

to maintain the specified test pressure difference across the

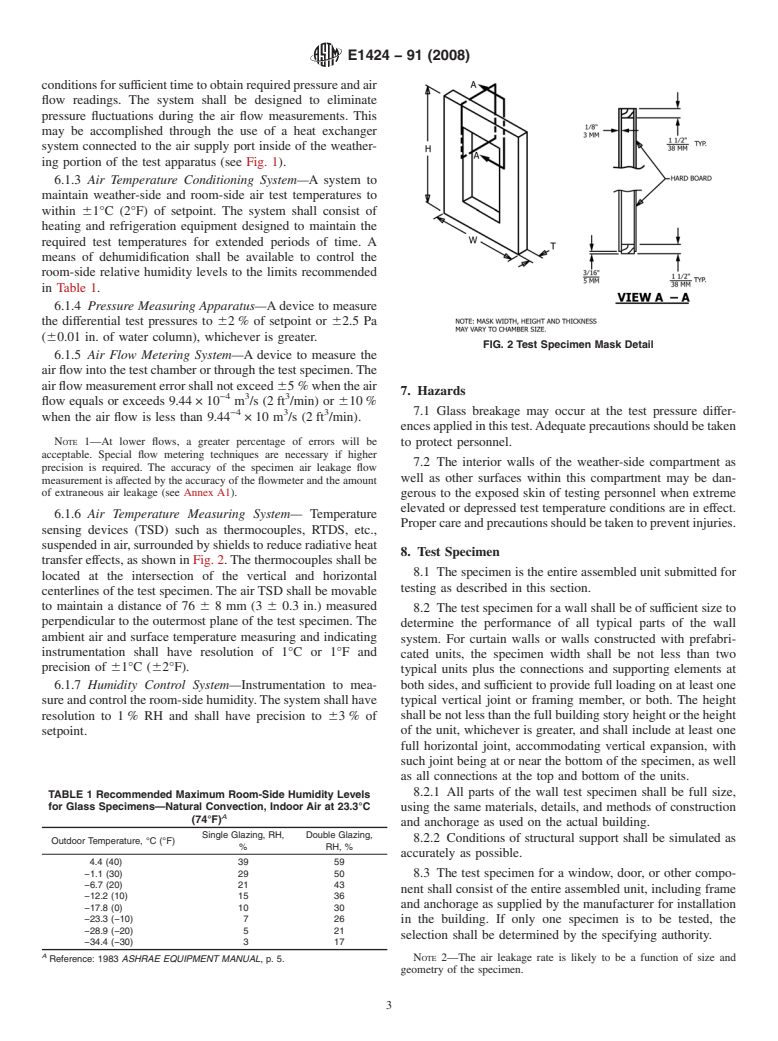

schematic is given in Fig. 1.

specimen. The resultant air flow through the specimen is then

6.1.2 Supply Air System—A controllable dry air supply or

measured.

exhaust system designed to provide conditioned air flow

through the test specimen at constant pressure and temperature

5. Significance and Use

5.1 The exterior building envelope and its components (for

example,windowsanddoors)separatetheinteriorconditioned

spaces from exterior environmental factors such as heat, cold,

rain, wind, noise dust, etc. Building materials and components

can expand or contract to varying degrees, depending on

seasonal and diurnal exterior ambient air temperatures. Fluc-

tuations in the ambient air temperatures can alter the sealing

characteristics of windows, curtain walls, and doors by chang-

ing weather seal compression ratios. Thermal expansion or

contractionofframingmaterialscoupledwiththermalblowing

due to temperature gradients through the product, and altera-

tions in the effective leakage areas due to weather seal

shrinkage and compression set, can also significantly alter the

air leakage rates of these products in field service applications.

Air leakage tests performed using Test Method E283 (a

laboratory air leakage test performed at ambient temperature

conditions) will not account accurately for changes in air

leakage rates that may occur from dimensional changes in

fenestration systems, materials, and components.

5.2 It is recommended that test specifiers consult the manu-

facturer for recommended test temperature extremes.

5.3 This procedure provides a means for evaluating air

leakageratesoffenestrationsystemsundervarioustemperature FIG. 1Environmental Chamber, Schematic

E1424−91 (2008)

conditionsforsufficienttimetoobtainrequiredpressureandair

flow readings. The system shall be designed to eliminate

pressure fluctuations during the air flow measurements. This

may be accomplished through the use of a heat exchanger

system connected to the air supply port inside of the weather-

ing portion of the test apparatus (see Fig. 1).

6.1.3 Air Temperature Conditioning System—A system to

maintain weather-side and room-side air test temperatures to

within 61°C (2°F) of setpoint. The system shall consist of

heating and refrigeration equipment designed to maintain the

required test temperatures for extended periods of time. A

means of dehumidification shall be available to control the

room-side relative humidity levels to the limits recommended

in Table 1.

6.1.4 Pressure Measuring Apparatus—Adevice to measure

the differential test pressures to 62% of setpoint or 62.5 Pa

(60.01 in. of water column), whichever is greater.

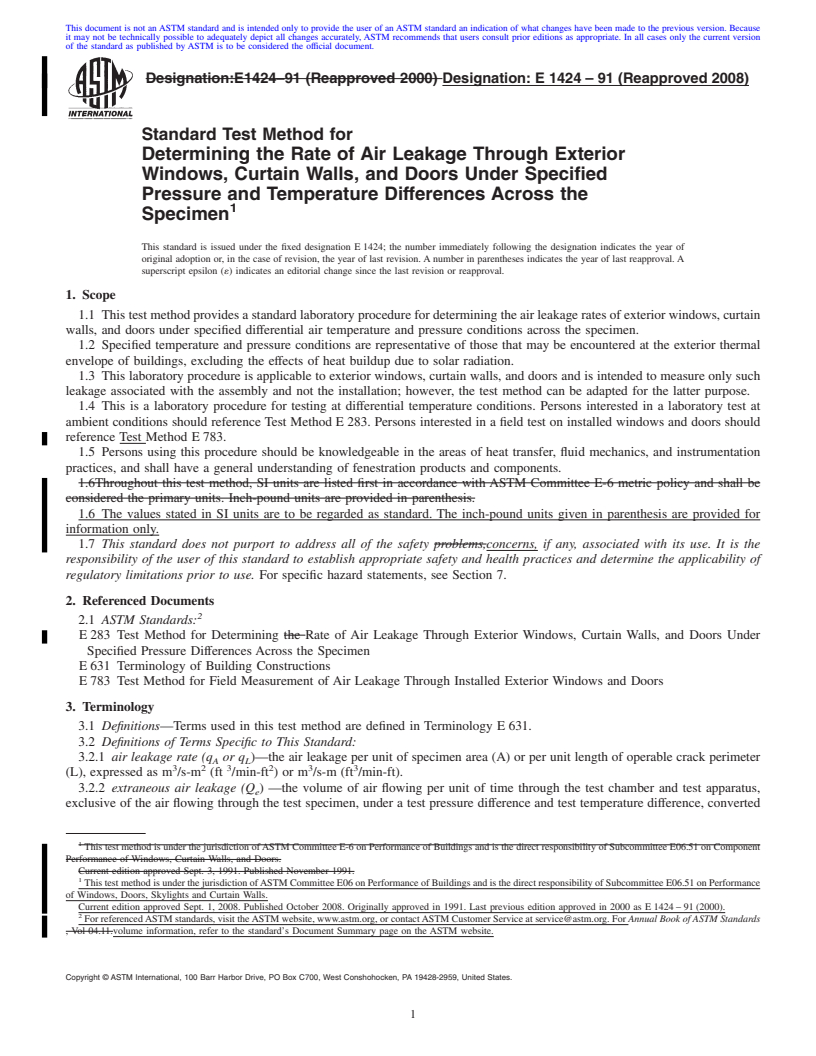

FIG. 2Test Specimen Mask Detail

6.1.5 Air Flow Metering System—A device to measure the

airflowintothetestchamberorthroughthetestspecimen.The

airflowmeasurementerrorshallnotexceed 65%whentheair

7. Hazards

−4 3 3

flow equals or exceeds 9.44×10 m /s (2ft /min) or 610%

−4 3 3 7.1 Glass breakage may occur at the test pressure differ-

when the air flow is less than 9.44 ×10m /s (2ft /min).

encesappliedinthistest.Adequateprecautionsshouldbetaken

NOTE 1—At lower flows, a greater percentage of errors will be to protect personnel.

acceptable. Special flow metering techniques are necessary if higher

7.2 The interior walls of the weather-side compartment as

precision is required. The accuracy of the specimen air leakage flow

well as other surfaces within this compartment may be dan-

measurement is affected by the accuracy of the flowmeter and the amount

of extraneous air leakage (see Annex A1).

gerous to the exposed skin of testing personnel when extreme

elevated or depressed test temperature conditions are in effect.

6.1.6 Air Temperature Measuring System— Temperature

Propercareandprecautionsshouldbetakentopreventinjuries.

sensing devices (TSD) such as thermocouples, RTDS, etc.,

suspendedinair,surroundedbyshieldstoreduceradiativeheat

8. Test Specimen

transfereffects,asshowninFig.2.Thethermocouplesshallbe

8.1 The specimen is the entire assembled unit submitted for

located at the intersection of the vertical and horizontal

testing as described in this section.

centerlines of the test specimen.The airTSD shall be movable

to maintain a distance of 76 68mm(3 6 0.3 in.) measured

8.2 Thetestspecimenforawallshallbeofsufficientsizeto

perpendicular to the outermost plane of the test specimen. The

determine the performance of all typical parts of the wall

ambient air and surface temperature measuring and indicating

system. For curtain walls or walls constructed with prefabri-

instrumentation shall have resolution of 1°C or 1°F and

cated units, the specimen width shall be not less than two

precision of 61°C (62°F).

typical units plus the connections and supporting elements at

6.1.7 Humidity Control System—Instrumentation to mea- both sides, and sufficient to provide full loading on at least one

sureandcontroltheroom-sidehumidity.Thesystemshallhave typical vertical joint or framing member, or both. The height

shallbenotlessthanthefullbuildingstoryheightortheheight

resolution to 1% RH and shall have precision to 63% of

setpoint. of the unit, whichever is greater, and shall include at least one

full horizontal joint, accommodating vertical expansion, with

such joint being at or near the bottom of the specimen, as well

as all connections at the top and bottom of the units.

8.2.1 All parts of the wall test specimen shall be full size,

TABLE 1 Recommended Maximum Room-Side Humidity Levels

for Glass Specimens—Natural Convection, Indoor Air at 23.3°C using the same materials, details, and methods of construction

A

(74°F)

and anchorage as used on the actual building.

Single Glazing, RH, Double Glazing,

8.2.2 Conditions of structural support shall be simulated as

Outdoor Temperature, °C (°F)

% RH, %

accurately as possible.

4.4 (40) 39 59

−1.1 (30) 29 50 8.3 The test specimen for a window, door, or other compo-

−6.7 (20) 21 43

nent shall consist of the entire assembled unit, including frame

−12.2 (10) 15 36

and anchorage as supplied by the manufacturer for installation

−17.8 (0) 10 30

−23.3 (−10) 7 26

in the building. If only one specimen is to be tested, the

−28.9 (−20) 5 21

selection shall be determined by the specifying authority.

−34.4 (−30) 3 17

A

NOTE 2—The air leakage rate is likely to be a function of size and

Reference: 1983 ASHRAE EQUIPMENT MANUAL,p.5.

geometry of the specimen.

E1424−91 (2008)

9. Preparation of Test Specimen

9.1 The location of surface temperature measuring devices

shall conform to the configurations shown in Figs. 3-6.

9.2 A test mask assembly shall be provided for the instal-

lationofthespecimentothetestapparatus.Atypicaltestmask

assembly is shown in Fig. 7. The thickness of the test mask

assembly shall not be less than the test specimen. Mount the

test specimen to the test mask assembly to simulate, as closely

as possible, the actual installation conditions anticipated. Seal

perimeter joints between the test specimen and the test mask

assembly to eliminate extraneous air leakage.

10. Calibration

10.1 Specific procedures for calibration of the total air flow

measurement system are being

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E1424–91 (Reapproved 2000) Designation: E 1424 – 91 (Reapproved 2008)

Standard Test Method for

Determining the Rate of Air Leakage Through Exterior

Windows, Curtain Walls, and Doors Under Specified

Pressure and Temperature Differences Across the

Specimen

This standard is issued under the fixed designation E1424; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thistestmethodprovidesastandardlaboratoryprocedurefordeterminingtheairleakageratesofexteriorwindows,curtain

walls, and doors under specified differential air temperature and pressure conditions across the specimen.

1.2 Specified temperature and pressure conditions are representative of those that may be encountered at the exterior thermal

envelope of buildings, excluding the effects of heat buildup due to solar radiation.

1.3 This laboratory procedure is applicable to exterior windows, curtain walls, and doors and is intended to measure only such

leakage associated with the assembly and not the installation; however, the test method can be adapted for the latter purpose.

1.4 This is a laboratory procedure for testing at differential temperature conditions. Persons interested in a laboratory test at

ambient conditions should reference Test Method E283. Persons interested in a field test on installed windows and doors should

reference Test Method E783.

1.5 Persons using this procedure should be knowledgeable in the areas of heat transfer, fluid mechanics, and instrumentation

practices, and shall have a general understanding of fenestration products and components.

1.6Throughout this test method, SI units are listed first in accordance with ASTM Committee E-6 metric policy and shall be

considered the primary units. Inch-pound units are provided in parenthesis.

1.6 The values stated in SI units are to be regarded as standard. The inch-pound units given in parenthesis are provided for

information only.

1.7 This standard does not purport to address all of the safety problems,concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of

regulatory limitations prior to use. For specific hazard statements, see Section 7.

2. Referenced Documents

2.1 ASTM Standards:

E283 Test Method for Determining the Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors Under

Specified Pressure Differences Across the Specimen

E631 Terminology of Building Constructions

E783 Test Method for Field Measurement of Air Leakage Through Installed Exterior Windows and Doors

3. Terminology

3.1 Definitions—Terms used in this test method are defined in Terminology E631.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 air leakage rate (q or q )—the air leakage per unit of specimen area (A) or per unit length of operable crack perimeter

A L

3 2 3 2 3 3

(L), expressed as m /s-m (ft /min-ft)orm /s-m (ft /min-ft).

3.2.2 extraneous air leakage (Q ) —the volume of air flowing per unit of time through the test chamber and test apparatus,

e

exclusive of the air flowing through the test specimen, under a test pressure difference and test temperature difference, converted

This test method is under the jurisdiction ofASTM Committee E-6 on Performance of Buildings and is the direct responsibility of Subcommittee E06.51 on Component

Performance of Windows, Curtain Walls, and Doors.

Current edition approved Sept. 3, 1991. Published November 1991.

ThistestmethodisunderthejurisdictionofASTMCommitteeE06onPerformanceofBuildingsandisthedirectresponsibilityofSubcommitteeE06.51onPerformance

of Windows, Doors, Skylights and Curtain Walls.

Current edition approved Sept. 1, 2008. Published October 2008. Originally approved in 1991. Last previous edition approved in 2000 as E1424–91(2000).

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 04.11.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 1424 – 91 (2008)

3 3

to standard conditions, expressed in m /s (ft /min).

3.2.2.1 Discussion—Extraneous leakage is the sum of all leakage other than that intended to be measured by the test.

3.2.3 specimen air leakage (Q )—the volume of air flowing per unit of time through the specimen under a test pressure

s

3 3

difference and test temperature difference, converted to standard conditions, expressed in m /s (ft /min).

3.2.4 specimen area (A)—theareadeterminedbytheoveralldimensionsoftheframethatfitsintotheroughopening,expressed

2 2

as m (ft ).

3.2.5 test mask assembly—a wall construction that surrounds and supports the test specimen.

3.2.6 test pressure differences—the specified differential static air pressure across the specimen, expressed in PA (lbf/ft ).

3.2.7 test temperature difference—the specified difference in temperature across the test specimen, expressed as a set of

room-side and weather-side temperatures, in °C (°F).

3.2.8 total air flow (Q)—the volume of air flowing per unit of time through the test chamber and test apparatus, inclusive of

t

the air flowing through the test specimen, under a test pressure difference and test temperature difference, converted to standard

3 3

conditions, expressed in m /s (ft /min).

3.2.9 unit length of operable crack perimeter (L)—the sum of all perimeters of operable ventilators, sash, or doors contained

in the test specimen, based on the overall dimensions of such parts, expressed as m (ft). Where two such operable parts meet, the

two adjacent lengths of perimeter shall be counted as only one length.

4. Summary of Test Method

4.1 The procedure consists of sealing a specimen into or against a chamber capable of maintaining a specified air temperature

differential across the specimen. When the specimen has been conditioned for a specified period of time, air is supplied to, or

exhaustedfrom,thechamberataraterequiredtomaintainthespecifiedtestpressuredifferenceacrossthespecimen.Theresultant

air flow through the specimen is then measured.

5. Significance and Use

5.1 The exterior building envelope and its components (for example, windows and doors) separate the interior conditioned

spaces from exterior environmental factors such as heat, cold, rain, wind, noise dust, etc. Building materials and components can

expand or contract to varying degrees, depending on seasonal and diurnal exterior ambient air temperatures. Fluctuations in the

ambient air temperatures can alter the sealing characteristics of windows, curtain walls, and doors by changing weather seal

compression ratios. Thermal expansion or contraction of framing materials coupled with thermal blowing due to temperature

gradientsthroughtheproduct,andalterationsintheeffectiveleakageareasduetoweathersealshrinkageandcompressionset,can

also significantly alter the air leakage rates of these products in field service applications.Air leakage tests performed using Test

Method E283 (a laboratory air leakage test performed at ambient temperature conditions) will not account accurately for changes

in air leakage rates that may occur from dimensional changes in fenestration systems, materials, and components.

5.2It5.2 It is recommended that test specifiers consult the manufacturer for recommended test temperature extremes.

5.3 This procedure provides a means for evaluating air leakage rates of fenestration systems under various temperature and

pressure conditions and air flow directions. It is also applicable for use in evaluating the efficiency of weather sealing products in

fenestration systems. All air flow rates are converted to standard conditions to provide a means of comparison between

measurements made at different ambient air temperature and pressure conditions.

5.4 Air leakage rates are sometimes used for comparison purposes. Such comparisons may not be valid unless the components

being tested and compared are of essentially the same size, configuration, and design.

6. Apparatus

6.1 The description of the apparatus in this section is general.Any suitable arrangement of equipment capable of maintaining

the required test tolerances is permitted.

6.1.1 Test Chamber—A well sealed box, wall, or other apparatus into or against which the specimen is mounted and secured

for testing.An air supply shall be provided to allow a positive or negative pressure differential to be applied across the specimen

without significant extraneous losses.The chamber should also be constructed of materials that have good resistance to heat flow.

The chamber shall be capable of withstanding the differential test pressures and temperatures that may be encountered in this

procedure. At least one static air pressure tap shall be provided on each side of the specimen to measure the test pressure

differences. The pressure tap shall be located in an area of the chamber in which pressure readings will not be affected by any

supply air or air conditioning fans.The air supply to the chamber shall be located in an area in which it does not directly impinge

upon the test specimen. A schematic is given in Fig. 1.

6.1.2 Supply Air System—Acontrollable dry air supply or exhaust system designed to provide conditioned air flow through the

test specimen at constant pressure and temperature conditions for sufficient time to obtain required pressure and air flow readings.

The system shall be designed to eliminate pressure fluctuations during the air flow measurements. This may be accomplished

through the use of a heat exchanger system connected to the air supply port inside of the weathering portion of the test apparatus

(see Fig. 1).

6.1.3 Air Temperature Conditioning System—Asystem to maintain weather-side and room-side air test temperatures to within

61°C (2°F) of setpoint. The system shall consist of heating and refrigeration equipment designed to maintain the required test

E 1424 – 91 (2008)

FIG. 1 Environmental Chamber, Schematic

temperatures for extended periods of time. A means of dehumidification shall be available to control the room-side relative

humidity levels to the limits recommended in Table 1.

6.1.4 Pressure Measuring Apparatus—A device to measure the differential test pressures to 62% of setpoint or 62.5 Pa

(60.01 in. of water column), whichever is greater.

6.1.5 Air Flow Metering System—Adevice to measure the air flow into the test chamber or through the test specimen. The air

−4 3 3

flowmeasurementerrorshallnotexceed 65%whentheairflowequalsorexceeds9.44 310 m /s(2ft /min)or 610%when

−4 3 3

the air flow is less than 9.44 310 m /s (2ft /min).

NOTE 1—At lower flows, a greater percentage of errors will be acceptable. Special flow metering techniques are necessary if higher precision is

required. The accuracy of the specimen air leakage flow measurement is affected by the accuracy of the flowmeter and the amount of extraneous air

leakage (see Annex A1).

6.1.6 Air Temperature Measuring System—Temperature sensing devices (TSD) such as thermocouples, RTDS, etc., suspended

in air, surrounded by shields to reduce radiative heat transfer effects, as shown in Fig. 2. The thermocouples shall be located at

theintersectionoftheverticalandhorizontalcenterlinesofthetestspecimen.TheairTSDshallbemovabletomaintainadistance

of 76 68mm(3 6 0.3 in.) measured perpendicular to the outermost plane of the test specimen. The ambient air and surface

temperature measuring and indicating instrumentation shall have resolution of 1°C or 1°F and precision of 61°C (62°F).

6.1.7 Humidity Control System—Instrumentation to measure and control the room-side humidity. The system shall have

resolution to 1% RH and shall have precision to 63% of setpoint.

7. Hazards

7.1 Glass breakage may occur at the test pressure differences applied in this test. Adequate precautions should be taken to

protect personnel.

TABLE 1 Recommended Maximum Room-Side Humidity Levels

for Glass Specimens—Natural Convection, Indoor Air at 23.3°C

A

(74°F)

Single Glazing, RH, Double Glazing,

Outdoor Temperature, °C (°F)

% RH, %

4.4 (40) 39 59

−1.1 (30) 29 50

−6.7 (20) 21 43

−12.2 (10) 15 36

−17.8 (0) 10 30

−23.3 (−10) 7 26

−28.9 (−20) 5 21

−34.4 (−30) 3 17

A

Reference: 1983 ASHRAE EQUIPMENT MANUAL, page 5.2 5.

E 1424 – 91 (2008)

FIG. 2 Test Specimen Mask Detail

7.2 The interior walls of the weather-side compartment as well as other surfaces within this compartment may be dangerous to

theexposedskinoftestingpersonnelwhenextremeelevatedordepressedtesttemperatureconditionsareineffect.Propercareand

precautions should be taken to prevent injuries.

8. Test Specimen

8.1 The specimen is the entire assembled unit submitted for testing as described in this section.

8.2 The test specimen for a wall shall be of sufficient size to determine the performance of all typical parts of the wall system.

For curtain walls or walls constructed with prefabricated units, the specimen width shall be not less than two typical units plus the

connections and supporting elements at both sides, and sufficient to provide full loading on at least one typical vertical joint or

framing member, or both. The height shall be not less than the full building story height or the height of the unit, whichever is

greater, and shall include at least one full horizontal joint, accommodating vertical expansion, with such joint being at or near the

bottom of the specimen, as well as all connections at the top and bottom of the units.

8.2.1 All parts of the wall test specimen shall be full size, using the same materials, details, and methods of construction and

anchorage as used on the actual building.

8.2.2 Conditions of structural support shall be simulated as accurately as possible.

8.3 The test specimen for a window, door, or other component shall consist of the entire assembled unit, including frame and

anchorage as supplied by the manufacturer for installation in the building. If only one specimen is to be tested, the selection shall

be determined by the specifying authority.

NOTE 2—The air leakage rate is likely to be a functio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.