ASTM B796-00

(Test Method)Standard Test Method for Nonmetallic Inclusion Content of Powders Intended for Powder Forging (P/F) Applications

Standard Test Method for Nonmetallic Inclusion Content of Powders Intended for Powder Forging (P/F) Applications

SCOPE

1.1 This test method covers a metallographic method for determining the nonmetallic inclusion level of powders intended for powder forging (P/F) applications.

1.2 The test method covers repress powder forged test specimens in which there has been minimal lateral material flow (

1.3 This test method is not suitable for determining the nonmetallic inclusion level of powder forged test specimens that have been forged such that the core region contains porosity. At the magnification used for this test method residual porosity is hard to distinguish from oxide inclusions. Too much residual porosity makes a meaningful assessment of the inclusion population impossible.

1.4 The test method may be applied to materials that contain manganese sulfide (admixed or prealloyed) provided the near neighbor separation distance is changed from 30 μm to 15 μm.

Note 1—The test method may be applied to powder forged parts where there has been a greater amount of material flow provided:

The near neighbor separation distance is changed, or The inclusion sizes agreed between the parties are adjusted for the amount of material flow.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 796 – 00

Standard Test Method for

Nonmetallic Inclusion Level of Powder Forged (P/F) Steel

Parts

This standard is issued under the fixed designation B 796; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a recognized metallographic

method for determining the nonmetallic inclusion level of

powder forged steel parts.

1.2 This test method also may be used to determine the

nonmetallic inclusion content of powders intended for powder

forging applications after they have been consolidated in a

prescribed manner so that the core region where the assessment

is to be carried out contains no porosity.

1.3 This test method is not suitable for determining the

nonmetallic inclusion level of powder forged parts that have

been forged such that the core region contains porosity or of

those parts that contain additions of manganese sulphide. At

the magnification used for this test method residual porosity is

hard to distinguish from oxide inclusions. Too much residual

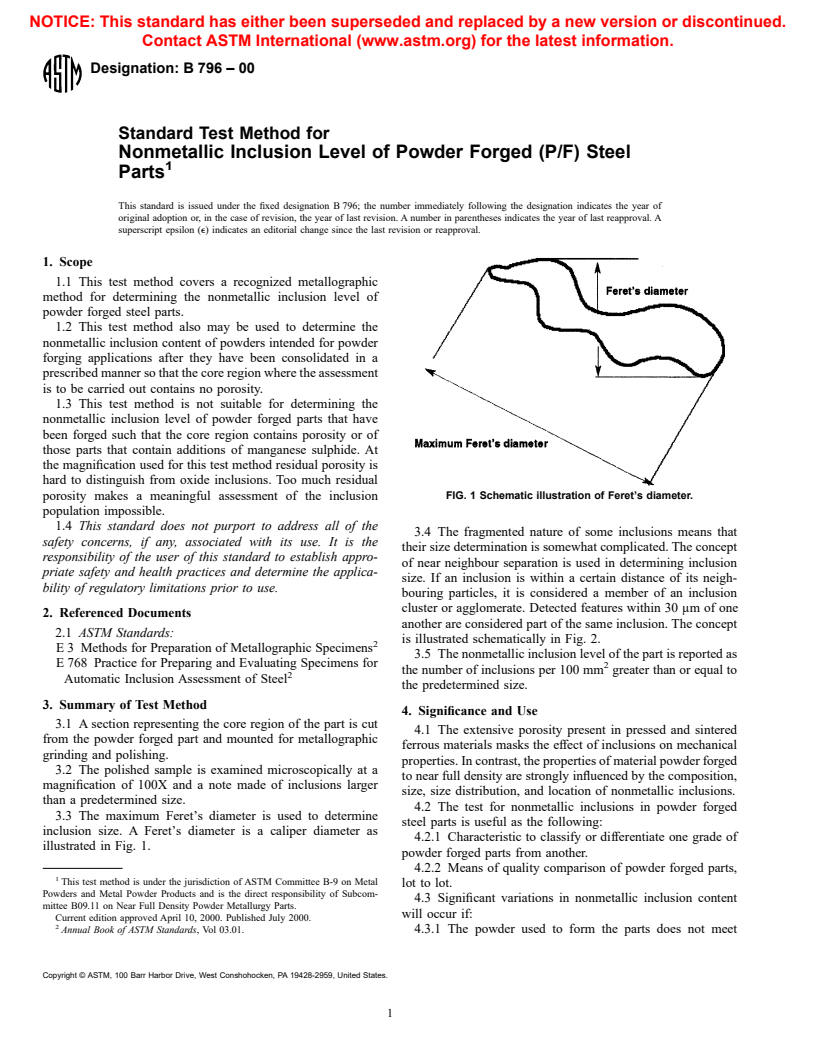

porosity makes a meaningful assessment of the inclusion FIG. 1 Schematic illustration of Feret’s diameter.

population impossible.

1.4 This standard does not purport to address all of the

3.4 The fragmented nature of some inclusions means that

safety concerns, if any, associated with its use. It is the

their size determination is somewhat complicated. The concept

responsibility of the user of this standard to establish appro-

of near neighbour separation is used in determining inclusion

priate safety and health practices and determine the applica-

size. If an inclusion is within a certain distance of its neigh-

bility of regulatory limitations prior to use.

bouring particles, it is considered a member of an inclusion

cluster or agglomerate. Detected features within 30 μm of one

2. Referenced Documents

another are considered part of the same inclusion. The concept

2.1 ASTM Standards:

is illustrated schematically in Fig. 2.

E 3 Methods for Preparation of Metallographic Specimens

3.5 The nonmetallic inclusion level of the part is reported as

E 768 Practice for Preparing and Evaluating Specimens for 2

the number of inclusions per 100 mm greater than or equal to

Automatic Inclusion Assessment of Steel

the predetermined size.

3. Summary of Test Method

4. Significance and Use

3.1 A section representing the core region of the part is cut

4.1 The extensive porosity present in pressed and sintered

from the powder forged part and mounted for metallographic

ferrous materials masks the effect of inclusions on mechanical

grinding and polishing.

properties. In contrast, the properties of material powder forged

3.2 The polished sample is examined microscopically at a

to near full density are strongly influenced by the composition,

magnification of 100X and a note made of inclusions larger

size, size distribution, and location of nonmetallic inclusions.

than a predetermined size.

4.2 The test for nonmetallic inclusions in powder forged

3.3 The maximum Feret’s diameter is used to determine

steel parts is useful as the following:

inclusion size. A Feret’s diameter is a caliper diameter as

4.2.1 Characteristic to classify or differentiate one grade of

illustrated in Fig. 1.

powder forged parts from another.

4.2.2 Means of quality comparison of powder forged parts,

This test method is under the jurisdiction of ASTM Committee B-9 on Metal

lot to lot.

Powders and Metal Powder Products and is the direct responsibility of Subcom-

4.3 Significant variations in nonmetallic inclusion content

mittee B09.11 on Near Full Density Powder Metallurgy Parts.

will occur if:

Current edition approved April 10, 2000. Published July 2000.

Annual Book of ASTM Standards, Vol 03.01. 4.3.1 The powder used to form the parts does not meet

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

B 796

a wavelength of 544 nm (green filter), an objective lens with a

magnification of from 8X to 12.5X, and a numerical aperture

between 0.16 and 0.20.

7.2.2 Size detected inclusions on the basis of near neighbor

separation. Features within 30 μm of one another are consid-

ered to be part of the same inclusion.

7.2.3 For individual features less than 30 μm in size, three

such features

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.