ASTM B832-93(2018)

(Guide)Standard Guide for Electroforming with Nickel and Copper

Standard Guide for Electroforming with Nickel and Copper

SIGNIFICANCE AND USE

4.1 The specialized use of the electroplating process for electroforming results in the manufacture of tools and products that are unique and often impossible to make economically by traditional methods of fabrication. Current applications of nickel electroforming include: textile printing screens; components of rocket thrust chambers, nozzles, and motor cases; molds and dies for making automotive arm-rests and instrument panels; stampers for making phonograph records, video-discs, and audio compact discs; mesh products for making porous battery electrodes, filters, and razor screens; and optical parts, bellows, and radar wave guides (1-3).3

4.2 Copper is extensively used for electroforming thin foil for the printed circuit industry. Copper foil is formed continuously by electrodeposition onto rotating drums. Copper is often used as a backing material for electroformed nickel shells and in other applications where its high thermal and electrical conductivities are required. Other metals including gold are electroformed on a smaller scale.

4.3 Electroforming is used whenever the difficulty and cost of producing the object by mechanical means is unusually high; unusual mechanical and physical properties are required in the finished piece; extremely close dimensional tolerances must be held on internal dimensions and on surfaces of irregular contour; very fine reproduction of detail and complex combinations of surface finish are required; and the part cannot be made by other available methods.

SCOPE

1.1 This guide covers electroforming practice and describes the processing of mandrels, the design of electroformed articles, and the use of copper and nickel electroplating solutions for electroforming.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B832 − 93 (Reapproved 2018)

Standard Guide for

Electroforming with Nickel and Copper

This standard is issued under the fixed designation B832; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B343 Practice for Preparation of Nickel for Electroplating

with Nickel

1.1 This guide covers electroforming practice and describes

B374 Terminology Relating to Electroplating

the processing of mandrels, the design of electroformed

B489 Practice for Bend Test for Ductility of Electrodepos-

articles, and the use of copper and nickel electroplating

ited and Autocatalytically Deposited Metal Coatings on

solutions for electroforming.

Metals

1.2 This standard does not purport to address all of the

B490 Practice for Micrometer Bend Test for Ductility of

safety concerns, if any, associated with its use. It is the

Electrodeposits

responsibility of the user of this standard to establish appro-

B558 Practice for Preparation of Nickel Alloys for Electro-

priate safety, health, and environmental practices and deter-

plating

mine the applicability of regulatory limitations prior to use.

B571 Practice for Qualitative Adhesion Testing of Metallic

1.3 This international standard was developed in accor-

Coatings

dance with internationally recognized principles on standard-

B578 Test Method for Microhardness of Electroplated Coat-

ization established in the Decision on Principles for the

ings

Development of International Standards, Guides and Recom-

B636 Test Method for Measurement of Internal Stress of

mendations issued by the World Trade Organization Technical

Plated Metallic Coatings with the Spiral Contractometer

Barriers to Trade (TBT) Committee.

B659 Guide for Measuring Thickness of Metallic and Inor-

ganic Coatings

2. Referenced Documents

B849 Specification for Pre-Treatments of Iron or Steel for

2.1 ASTM Standards: Reducing Risk of Hydrogen Embrittlement

B183 Practice for Preparation of Low-Carbon Steel for

E8 Test Methods for Tension Testing of Metallic Materials

Electroplating E384 Test Method for Microindentation Hardness of Mate-

B242 Guide for Preparation of High-Carbon Steel for Elec- rials

troplating

3. Summary of Electroforming Practice

B252 Guide for Preparation of Zinc Alloy Die Castings for

Electroplating and Conversion Coatings 3.1 Electroforming is defined (see Terminology B374)as

B253 Guide for Preparation of Aluminum Alloys for Elec- the production or reproduction of articles by electrodeposition

troplating uponamandrelormoldthatissubsequentlyseparatedfromthe

B254 Practice for Preparation of and Electroplating on deposit.

Stainless Steel

3.2 The basic fabrication steps are as follows: a suitable

B281 Practice for Preparation of Copper and Copper-Base

mandrel is fabricated and prepared for electroplating; the

Alloys for Electroplating and Conversion Coatings

mandrel is placed in an appropriate electroplating solution and

B311 Test Method for Density of Powder Metallurgy (PM)

metal is deposited upon the mandrel by electrolysis; when the

Materials Containing Less Than Two Percent Porosity

required thickness of metal has been applied, the metal-

coveredmandrelisremovedfromthesolution;andthemandrel

is separated from the electrodeposited metal. The electroform

This guide is under the jurisdiction of ASTM Committee B08 on Metallic and

is a separate, free-standing entity composed entirely of elec-

Inorganic Coatings and is the direct responsibility of Subcommittee B08.03 on

trodeposited metal. Electroforming is concerned with the

Engineering Coatings.

fabrication of articles of various kinds.

Current edition approved June 1, 2018. Published June 2018. Originally

approvedin1993.Lastpreviouseditionapprovedin2013asB832 – 93(2013).DOI:

4. Significance and Use

10.1520/B0832-93R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1 The specialized use of the electroplating process for

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

electroforming results in the manufacture of tools and products

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. that are unique and often impossible to make economically by

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B832 − 93 (2018)

traditional methods of fabrication. Current applications of the electroform from the mandrel (unless the mandrel is

nickel electroforming include: textile printing screens; compo- removed by melting or chemical dissolution).

nents of rocket thrust chambers, nozzles, and motor cases;

5.1.3 Whether or not a permanent or expendable mandrel

molds and dies for making automotive arm-rests and instru- should be used is largely dependent on the particular article

ment panels; stampers for making phonograph records, video-

that is to be electroformed. If no reentrant shapes or angles are

discs, and audio compact discs; mesh products for making involved, it is possible to use permanent, rigid mandrels that

porous battery electrodes, filters, and razor screens; and optical

can be separated from the finished electroform mechanically

parts, bellows, and radar wave guides (1-3). and reused. If reentrant angles and shapes are involved, it is

necessary to use mandrel materials that can be removed by

4.2 Copper is extensively used for electroforming thin foil

melting or by chemical dissolution, or materials that are

for the printed circuit industry. Copper foil is formed continu-

collapsible, such as polyvinyl chloride and other plastics. In

ouslybyelectrodepositionontorotatingdrums.Copperisoften

some cases, multiple piece mandrels are used that can be

used as a backing material for electroformed nickel shells and

removed even with reentrant features.

in other applications where its high thermal and electrical

5.1.4 Many solid materials can be used to fabricate man-

conductivities are required. Other metals including gold are

drels for electroforming, but the following generalizations may

electroformed on a smaller scale.

help in selecting a suitable material: permanent mandrels are

4.3 Electroforming is used whenever the difficulty and cost

preferred for accuracy and for large production runs; expend-

of producing the object by mechanical means is unusually

able mandrels must be used whenever the part is so designed

high; unusual mechanical and physical properties are required

that a permanent mandrel cannot be withdrawn; and it is

in the finished piece; extremely close dimensional tolerances

important that the mandrel retain its dimensional stability in

must be held on internal dimensions and on surfaces of

warm plating baths. Wax and most plastics expand when

irregular contour; very fine reproduction of detail and complex

exposed to electroplating solutions operated at elevated tem-

combinationsofsurfacefinisharerequired;andthepartcannot

peratures.Insuchcases,itmaybenecessarytouseacidcopper,

be made by other available methods.

nickel sulfamate, and other electroplating solutions that func-

tion at room temperature.

5. Processing of Mandrels for Electroforming

5.2 Mandrel Design:

5.1 General Considerations:

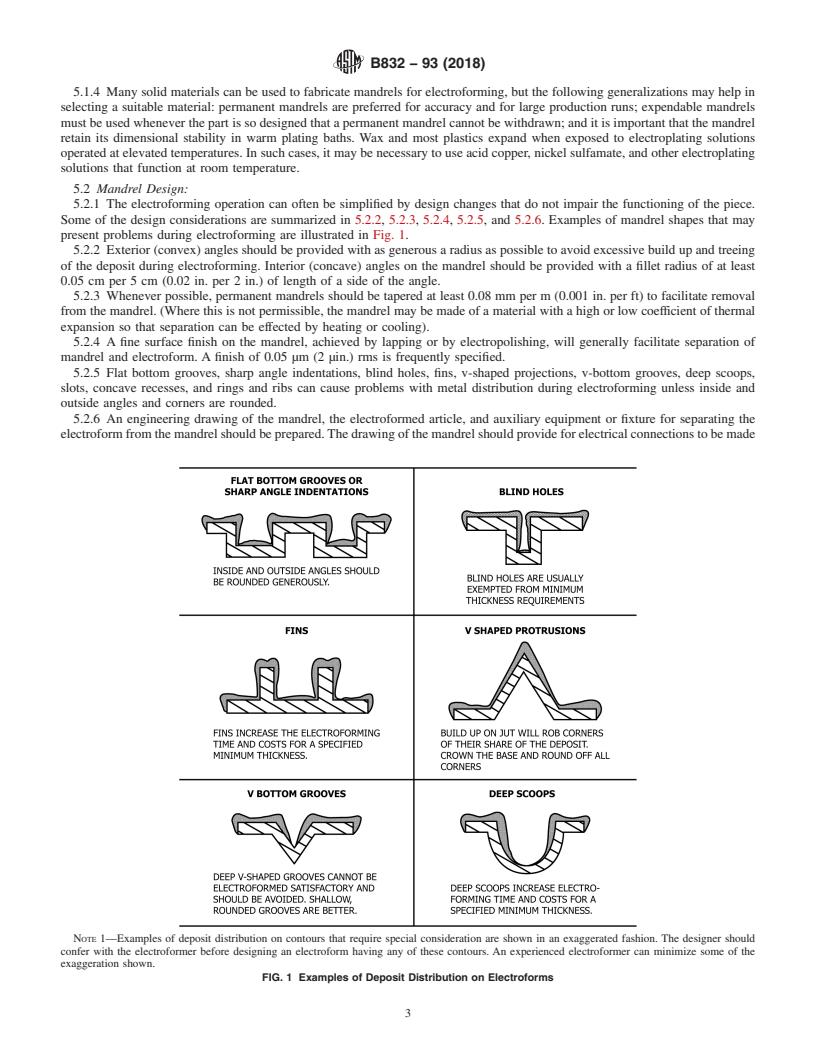

5.2.1 The electroforming operation can often be simplified

5.1.1 Mandrels may be classified as conductors or noncon-

by design changes that do not impair the functioning of the

ductors of electricity, and each of these may be permanent,

piece. Some of the design considerations are summarized in

semipermanent, or expendable (Table 1).

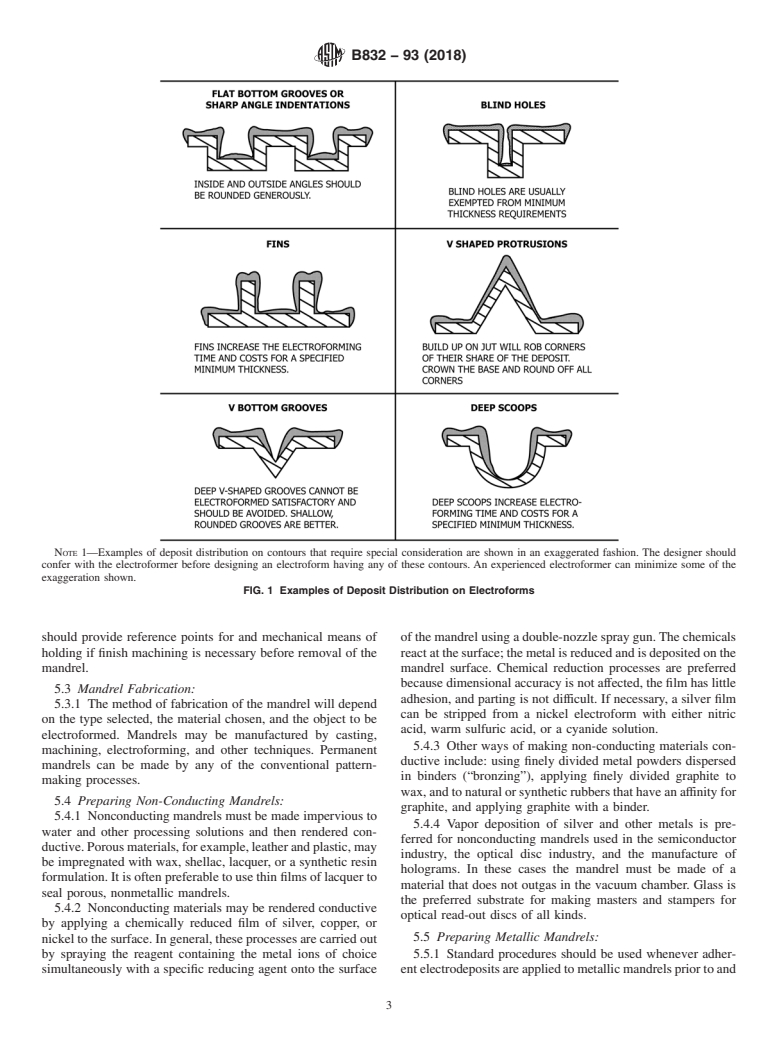

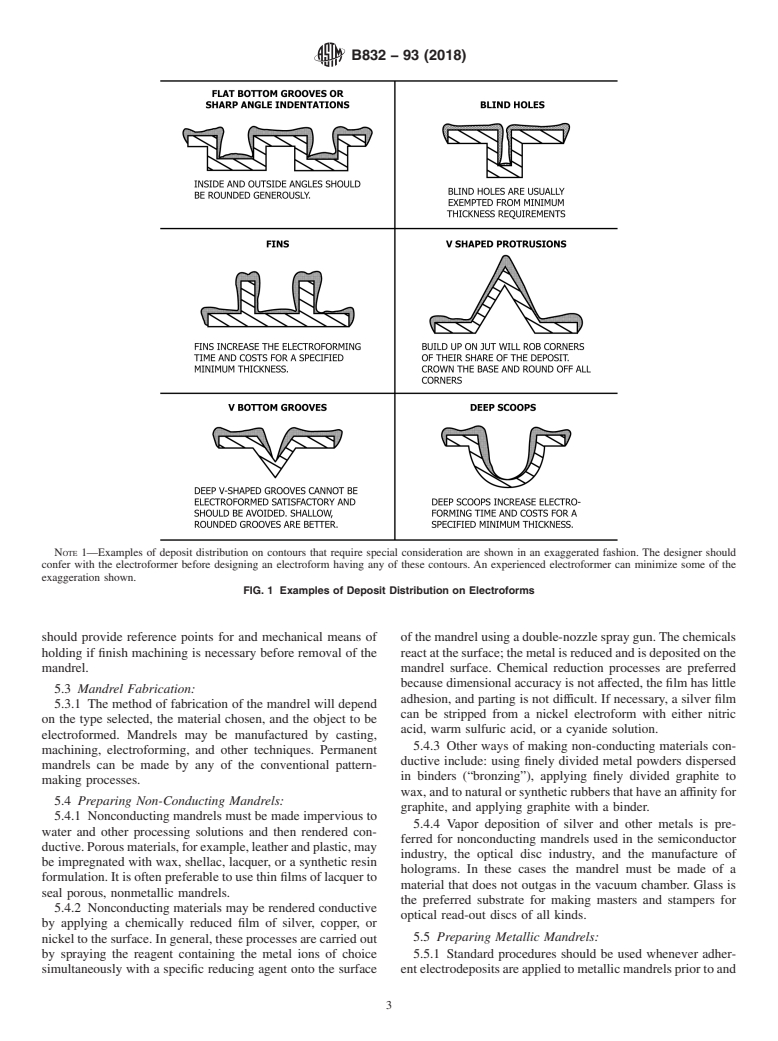

5.2.2, 5.2.3, 5.2.4, 5.2.5, and 5.2.6. Examples of mandrel

shapes that may present problems during electroforming are

TABLE 1 Types of Mandrel Materials

illustrated in Fig. 1.

Types Typical Materials

5.2.2 Exterior (convex) angles should be provided with as

Conductors

generous a radius as possible to avoid excessive build up and

Expendable Low-melting point alloys; for example,

treeing of the deposit during electroforming. Interior (concave)

bismuth-free 92 % tin and 8 % zinc

anglesonthemandrelshouldbeprovidedwithafilletradiusof

Aluminum alloys

at least 0.05 cm per 5 cm (0.02 in. per 2 in.) of length of a side

Zinc alloys

Permanent Nickel

of the angle.

Austenitic Stainless

5.2.3 Whenever possible, permanent mandrels should be

Invar, Kovar

Copper and brass tapered at least 0.08 mm per m (0.001 in. per ft) to facilitate

Nickel-plated steel

removal from the mandrel. (Where this is not permissible, the

Nickel/chromium-plated aluminum

mandrel may be made of a material with a high or low

Nonconductors

coefficient of thermal expansion so that separation can be

effected by heating or cooling).

Expendable Wax

5.2.4 A fine surface finish on the mandrel, achieved by

Glass

Permanent (or Semi-Permanent) Rigid and collapsible plastic; for

lapping or by electropolishing, will generally facilitate separa-

example, epoxy resins and polyvinyl

tion of mandrel and electroform. A finish of 0.05 µm (2 µin.)

chloride

rms is frequently specified.

Wood

5.2.5 Flat bottom grooves, sharp angle indentations, blind

holes, fins, v-shaped projections, v-bottom grooves, deep

5.1.2 Whether or not a mandrel is a conductor will deter-

scoops, slots, concave recesses, and rings and ribs can cause

mine the procedures required to prepare it for electroforming. problems with metal distribution during electroforming unless

Conductive mandrels are usually pure metals or alloys of

inside and outside angles and corners are rounded.

metals and are prepared by standard procedures but may

5.2.6 An engineering drawing of the mandrel, the electro-

require an additional thin parting film to facilitate separation of

formed article, and auxiliary equipment or fixture for separat-

ing the electroform from the mandrel should be prepared. The

drawing of the mandrel should provide for electrical connec-

The boldface numbers in parentheses refer to the list of references at the end of

this standard. tions to be made in nonfunctional areas of the electroform. It

B832 − 93 (2018)

NOTE 1—Examples of deposit distribution on contours that require special consideration are shown in an exaggerated fashion. The designer should

confer with the electroformer before designing an electroform having any of these contours. An experienced electroformer can minimize some of the

exaggeration shown.

FIG. 1 Examples of Deposit Distribution on Electroforms

should provide reference points for and mechanical means of ofthemandrelusingadouble-nozzlespraygun.Thechemicals

holding if finish machining is necessary before removal of the reactatthesurface;themetalisreducedandisdepositedonthe

mandrel. mandrel surface. Chemical reduction processes are preferred

because dimensional accuracy is not affected, the film has little

5.3 Mandrel Fabrication:

adhesion, and parting is not difficult. If necessary, a silver film

5.3.1 The method of fabrication of the mandrel will depend

can be stripped from a nickel electroform with either nitric

on the type selected, the material chosen, and the object to be

acid, warm sulfuric acid, or a cyanide solution.

electroformed. Mandrels may be manufactured by casting,

5.4.3 Other ways of making non-conducting materials con-

machining, electroforming, and other techniques. Permanent

ductive include: using finely divided metal powders dispersed

mandrels can be made by any of the conventional pattern-

in binders (“bronzing”), applying finely divided graphite to

making processes.

wax,andtonaturalorsyntheticrubbersthathaveanaffinityfor

5.4 Preparing Non-Conducting Mandrels:

graphite, and applying graphite with a binder.

5.4.1 Nonconducting mandrels must be made impervious to

5.4.4 Vapor deposition of silver and other metals is pre-

water and other processing solutions and then rendered con-

ferred for nonconducting mandrels used in the semiconductor

ductive.Porousmaterials,forexample,leatherandplastic,may

industry, the optical disc industry, and the manufacture of

be impregnated with wax, shellac, lacquer, or a synthetic resin

holograms. In these cases the mandrel must be made of a

formulation.Itisoftenpreferabletousethinfilmsoflacquerto

material that does not outgas in the vacuum chamber. Glass is

seal porous, nonmetallic mandrels.

the preferred substrate for making masters and stampers for

5.4.2 Nonconducting materials may be rendered conductive

optical read-out discs of all kinds.

by applying a chemically reduced film of silver, copper, or

5.5 Preparing Metallic Mandrels:

nickel to the surface. In general, these processes are carried out

by spraying the reagent containing the metal ions of choice 5.5.1 Standard procedures should be used whenever adher-

simultaneously with a specific reducing agent onto the surface entelectrodepositsareappliedtometallicmandrelspriortoand

B832 − 93 (2018)

FIG. 1 (continued)

in preparation for electroforming. See Practices B183, B242, 5.5.7 The low-melting point alloys included in Table 1

B254, B281, and B558, for example. employed to make expendable mandrels that can be melted

5.5.2 With most metallic mandrels an additional chemical away have a tendency to leave a residue of tin on the surface

treatment that forms a parting film on the surface is required to oftheelectroform.Themandrelcanbeplatedwithcopperprior

separate the electroform from the mandrel. After removing all to electroforming to prevent this.

traces of grease and oil by means of solvents, various metallic

mandrels are given different treatments for this purpose (see 6. Nickel and Copper Electroforming Solutions

5.5.3, 5.5.4, 5.5.5, 5.5.6, and 5.5.7).

6.1 The choice of metal selected for the electroform will

5.5.3 Stainless steel, nickel, and nickel- or chromium-plated

depend on the mechanical and physical properties required in

steel are cleaned using standard procedures, rinsed, and passi-

the finished article as related to function. The two metals

vatedbyimmersionina2 %solutionofsodiumdichromatefor

selected most frequently are nickel and copper. The operation

30 to 60 s at room temperature. The mandrel must then be

and control of nickel and copper electroforming solutions are

rinsed to remove all traces of the dichromate solution.

described in this section.

5.5.4 Copper and brass mandrels that have been nickel

6.2 The nickel electroplating solutions commonly used for

and/orchromium-platedmaybetreatedasd

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B832 − 93 (Reapproved 2018)

Standard Guide for

Electroforming with Nickel and Copper

This standard is issued under the fixed designation B832; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B343 Practice for Preparation of Nickel for Electroplating

with Nickel

1.1 This guide covers electroforming practice and describes

B374 Terminology Relating to Electroplating

the processing of mandrels, the design of electroformed

B489 Practice for Bend Test for Ductility of Electrodepos-

articles, and the use of copper and nickel electroplating

ited and Autocatalytically Deposited Metal Coatings on

solutions for electroforming.

Metals

1.2 This standard does not purport to address all of the

B490 Practice for Micrometer Bend Test for Ductility of

safety concerns, if any, associated with its use. It is the

Electrodeposits

responsibility of the user of this standard to establish appro-

B558 Practice for Preparation of Nickel Alloys for Electro-

priate safety, health, and environmental practices and deter-

plating

mine the applicability of regulatory limitations prior to use.

B571 Practice for Qualitative Adhesion Testing of Metallic

1.3 This international standard was developed in accor-

Coatings

dance with internationally recognized principles on standard-

B578 Test Method for Microhardness of Electroplated Coat-

ization established in the Decision on Principles for the

ings

Development of International Standards, Guides and Recom-

B636 Test Method for Measurement of Internal Stress of

mendations issued by the World Trade Organization Technical

Plated Metallic Coatings with the Spiral Contractometer

Barriers to Trade (TBT) Committee.

B659 Guide for Measuring Thickness of Metallic and Inor-

ganic Coatings

2. Referenced Documents

B849 Specification for Pre-Treatments of Iron or Steel for

2.1 ASTM Standards:

Reducing Risk of Hydrogen Embrittlement

B183 Practice for Preparation of Low-Carbon Steel for E8 Test Methods for Tension Testing of Metallic Materials

Electroplating

E384 Test Method for Microindentation Hardness of Mate-

B242 Guide for Preparation of High-Carbon Steel for Elec- rials

troplating

3. Summary of Electroforming Practice

B252 Guide for Preparation of Zinc Alloy Die Castings for

Electroplating and Conversion Coatings 3.1 Electroforming is defined (see Terminology B374) as

B253 Guide for Preparation of Aluminum Alloys for Elec- the production or reproduction of articles by electrodeposition

troplating upon a mandrel or mold that is subsequently separated from the

B254 Practice for Preparation of and Electroplating on deposit.

Stainless Steel

3.2 The basic fabrication steps are as follows: a suitable

B281 Practice for Preparation of Copper and Copper-Base

mandrel is fabricated and prepared for electroplating; the

Alloys for Electroplating and Conversion Coatings

mandrel is placed in an appropriate electroplating solution and

B311 Test Method for Density of Powder Metallurgy (PM)

metal is deposited upon the mandrel by electrolysis; when the

Materials Containing Less Than Two Percent Porosity

required thickness of metal has been applied, the metal-

covered mandrel is removed from the solution; and the mandrel

is separated from the electrodeposited metal. The electroform

This guide is under the jurisdiction of ASTM Committee B08 on Metallic and

is a separate, free-standing entity composed entirely of elec-

Inorganic Coatings and is the direct responsibility of Subcommittee B08.03 on

trodeposited metal. Electroforming is concerned with the

Engineering Coatings.

fabrication of articles of various kinds.

Current edition approved June 1, 2018. Published June 2018. Originally

approved in 1993. Last previous edition approved in 2013 as B832 – 93(2013). DOI:

4. Significance and Use

10.1520/B0832-93R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1 The specialized use of the electroplating process for

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

electroforming results in the manufacture of tools and products

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. that are unique and often impossible to make economically by

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B832 − 93 (2018)

traditional methods of fabrication. Current applications of the electroform from the mandrel (unless the mandrel is

nickel electroforming include: textile printing screens; compo- removed by melting or chemical dissolution).

nents of rocket thrust chambers, nozzles, and motor cases; 5.1.3 Whether or not a permanent or expendable mandrel

molds and dies for making automotive arm-rests and instru-

should be used is largely dependent on the particular article

ment panels; stampers for making phonograph records, video- that is to be electroformed. If no reentrant shapes or angles are

discs, and audio compact discs; mesh products for making

involved, it is possible to use permanent, rigid mandrels that

porous battery electrodes, filters, and razor screens; and optical can be separated from the finished electroform mechanically

parts, bellows, and radar wave guides (1-3).

and reused. If reentrant angles and shapes are involved, it is

necessary to use mandrel materials that can be removed by

4.2 Copper is extensively used for electroforming thin foil

melting or by chemical dissolution, or materials that are

for the printed circuit industry. Copper foil is formed continu-

collapsible, such as polyvinyl chloride and other plastics. In

ously by electrodeposition onto rotating drums. Copper is often

some cases, multiple piece mandrels are used that can be

used as a backing material for electroformed nickel shells and

removed even with reentrant features.

in other applications where its high thermal and electrical

5.1.4 Many solid materials can be used to fabricate man-

conductivities are required. Other metals including gold are

drels for electroforming, but the following generalizations may

electroformed on a smaller scale.

help in selecting a suitable material: permanent mandrels are

4.3 Electroforming is used whenever the difficulty and cost

preferred for accuracy and for large production runs; expend-

of producing the object by mechanical means is unusually

able mandrels must be used whenever the part is so designed

high; unusual mechanical and physical properties are required

that a permanent mandrel cannot be withdrawn; and it is

in the finished piece; extremely close dimensional tolerances

important that the mandrel retain its dimensional stability in

must be held on internal dimensions and on surfaces of

warm plating baths. Wax and most plastics expand when

irregular contour; very fine reproduction of detail and complex

exposed to electroplating solutions operated at elevated tem-

combinations of surface finish are required; and the part cannot

peratures. In such cases, it may be necessary to use acid copper,

be made by other available methods.

nickel sulfamate, and other electroplating solutions that func-

tion at room temperature.

5. Processing of Mandrels for Electroforming

5.2 Mandrel Design:

5.1 General Considerations:

5.2.1 The electroforming operation can often be simplified

5.1.1 Mandrels may be classified as conductors or noncon-

by design changes that do not impair the functioning of the

ductors of electricity, and each of these may be permanent,

piece. Some of the design considerations are summarized in

semipermanent, or expendable (Table 1).

5.2.2, 5.2.3, 5.2.4, 5.2.5, and 5.2.6. Examples of mandrel

shapes that may present problems during electroforming are

TABLE 1 Types of Mandrel Materials

illustrated in Fig. 1.

Types Typical Materials

5.2.2 Exterior (convex) angles should be provided with as

Conductors

generous a radius as possible to avoid excessive build up and

Expendable Low-melting point alloys; for example,

treeing of the deposit during electroforming. Interior (concave)

bismuth-free 92 % tin and 8 % zinc

angles on the mandrel should be provided with a fillet radius of

Aluminum alloys

Zinc alloys at least 0.05 cm per 5 cm (0.02 in. per 2 in.) of length of a side

Permanent Nickel

of the angle.

Austenitic Stainless

5.2.3 Whenever possible, permanent mandrels should be

Invar, Kovar

Copper and brass

tapered at least 0.08 mm per m (0.001 in. per ft) to facilitate

Nickel-plated steel

removal from the mandrel. (Where this is not permissible, the

Nickel/chromium-plated aluminum

mandrel may be made of a material with a high or low

Nonconductors coefficient of thermal expansion so that separation can be

effected by heating or cooling).

Expendable Wax

5.2.4 A fine surface finish on the mandrel, achieved by

Glass

Permanent (or Semi-Permanent) Rigid and collapsible plastic; for

lapping or by electropolishing, will generally facilitate separa-

example, epoxy resins and polyvinyl

tion of mandrel and electroform. A finish of 0.05 µm (2 µin.)

chloride

rms is frequently specified.

Wood

5.2.5 Flat bottom grooves, sharp angle indentations, blind

holes, fins, v-shaped projections, v-bottom grooves, deep

5.1.2 Whether or not a mandrel is a conductor will deter-

scoops, slots, concave recesses, and rings and ribs can cause

mine the procedures required to prepare it for electroforming.

problems with metal distribution during electroforming unless

Conductive mandrels are usually pure metals or alloys of inside and outside angles and corners are rounded.

metals and are prepared by standard procedures but may

5.2.6 An engineering drawing of the mandrel, the electro-

require an additional thin parting film to facilitate separation of

formed article, and auxiliary equipment or fixture for separat-

ing the electroform from the mandrel should be prepared. The

3 drawing of the mandrel should provide for electrical connec-

The boldface numbers in parentheses refer to the list of references at the end of

this standard. tions to be made in nonfunctional areas of the electroform. It

B832 − 93 (2018)

NOTE 1—Examples of deposit distribution on contours that require special consideration are shown in an exaggerated fashion. The designer should

confer with the electroformer before designing an electroform having any of these contours. An experienced electroformer can minimize some of the

exaggeration shown.

FIG. 1 Examples of Deposit Distribution on Electroforms

should provide reference points for and mechanical means of of the mandrel using a double-nozzle spray gun. The chemicals

holding if finish machining is necessary before removal of the react at the surface; the metal is reduced and is deposited on the

mandrel. mandrel surface. Chemical reduction processes are preferred

because dimensional accuracy is not affected, the film has little

5.3 Mandrel Fabrication:

adhesion, and parting is not difficult. If necessary, a silver film

5.3.1 The method of fabrication of the mandrel will depend

can be stripped from a nickel electroform with either nitric

on the type selected, the material chosen, and the object to be

acid, warm sulfuric acid, or a cyanide solution.

electroformed. Mandrels may be manufactured by casting,

5.4.3 Other ways of making non-conducting materials con-

machining, electroforming, and other techniques. Permanent

ductive include: using finely divided metal powders dispersed

mandrels can be made by any of the conventional pattern-

in binders (“bronzing”), applying finely divided graphite to

making processes.

wax, and to natural or synthetic rubbers that have an affinity for

5.4 Preparing Non-Conducting Mandrels:

graphite, and applying graphite with a binder.

5.4.1 Nonconducting mandrels must be made impervious to

5.4.4 Vapor deposition of silver and other metals is pre-

water and other processing solutions and then rendered con-

ferred for nonconducting mandrels used in the semiconductor

ductive. Porous materials, for example, leather and plastic, may

industry, the optical disc industry, and the manufacture of

be impregnated with wax, shellac, lacquer, or a synthetic resin

holograms. In these cases the mandrel must be made of a

formulation. It is often preferable to use thin films of lacquer to

material that does not outgas in the vacuum chamber. Glass is

seal porous, nonmetallic mandrels.

the preferred substrate for making masters and stampers for

5.4.2 Nonconducting materials may be rendered conductive

optical read-out discs of all kinds.

by applying a chemically reduced film of silver, copper, or

5.5 Preparing Metallic Mandrels:

nickel to the surface. In general, these processes are carried out

by spraying the reagent containing the metal ions of choice 5.5.1 Standard procedures should be used whenever adher-

simultaneously with a specific reducing agent onto the surface ent electrodeposits are applied to metallic mandrels prior to and

B832 − 93 (2018)

FIG. 1 (continued)

in preparation for electroforming. See Practices B183, B242, 5.5.7 The low-melting point alloys included in Table 1

B254, B281, and B558, for example. employed to make expendable mandrels that can be melted

5.5.2 With most metallic mandrels an additional chemical away have a tendency to leave a residue of tin on the surface

treatment that forms a parting film on the surface is required to of the electroform. The mandrel can be plated with copper prior

separate the electroform from the mandrel. After removing all to electroforming to prevent this.

traces of grease and oil by means of solvents, various metallic

6. Nickel and Copper Electroforming Solutions

mandrels are given different treatments for this purpose (see

5.5.3, 5.5.4, 5.5.5, 5.5.6, and 5.5.7).

6.1 The choice of metal selected for the electroform will

5.5.3 Stainless steel, nickel, and nickel- or chromium-plated

depend on the mechanical and physical properties required in

steel are cleaned using standard procedures, rinsed, and passi-

the finished article as related to function. The two metals

vated by immersion in a 2 % solution of sodium dichromate for

selected most frequently are nickel and copper. The operation

30 to 60 s at room temperature. The mandrel must then be

and control of nickel and copper electroforming solutions are

rinsed to remove all traces of the dichromate solution.

described in this section.

5.5.4 Copper and brass mandrels that have been nickel

6.2 The nickel electroplating solutions commonly used for

and/or chromiu

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B832 − 93 (Reapproved 2013) B832 − 93 (Reapproved 2018)

Standard Guide for

Electroforming with Nickel and Copper

This standard is issued under the fixed designation B832; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide covers electroforming practice and describes the processing of mandrels, the design of electroformed articles,

and the use of copper and nickel electroplating solutions for electroforming.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

B183 Practice for Preparation of Low-Carbon Steel for Electroplating

B242 Guide for Preparation of High-Carbon Steel for Electroplating

B252 Guide for Preparation of Zinc Alloy Die Castings for Electroplating and Conversion Coatings

B253 Guide for Preparation of Aluminum Alloys for Electroplating

B254 Practice for Preparation of and Electroplating on Stainless Steel

B281 Practice for Preparation of Copper and Copper-Base Alloys for Electroplating and Conversion Coatings

B311 Test Method for Density of Powder Metallurgy (PM) Materials Containing Less Than Two Percent Porosity

B343 Practice for Preparation of Nickel for Electroplating with Nickel

B374 Terminology Relating to Electroplating

B489 Practice for Bend Test for Ductility of Electrodeposited and Autocatalytically Deposited Metal Coatings on Metals

B490 Practice for Micrometer Bend Test for Ductility of Electrodeposits

B558 Practice for Preparation of Nickel Alloys for Electroplating

B571 Practice for Qualitative Adhesion Testing of Metallic Coatings

B578 Test Method for Microhardness of Electroplated Coatings

B636 Test Method for Measurement of Internal Stress of Plated Metallic Coatings with the Spiral Contractometer

B659 Guide for Measuring Thickness of Metallic and Inorganic Coatings

B849 Specification for Pre-Treatments of Iron or Steel for Reducing Risk of Hydrogen Embrittlement

E8 Test Methods for Tension Testing of Metallic Materials

E384 Test Method for Microindentation Hardness of Materials

3. Summary of Electroforming Practice

3.1 Electroforming is defined (see Terminology B374) as the production or reproduction of articles by electrodeposition upon

a mandrel or mold that is subsequently separated from the deposit.

3.2 The basic fabrication steps are as follows: a suitable mandrel is fabricated and prepared for electroplating; the mandrel is

placed in an appropriate electroplating solution and metal is deposited upon the mandrel by electrolysis; when the required

thickness of metal has been applied, the metal-covered mandrel is removed from the solution; and the mandrel is separated from

This guide is under the jurisdiction of ASTM Committee B08 on Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee B08.03 on Engineering

Coatings.

Current edition approved Dec. 1, 2013June 1, 2018. Published December 2013June 2018. Originally approved in 1993. Last previous edition approved in 20082013 as

B832 – 93(2008).(2013). DOI: 10.1520/B0832-93R13.10.1520/B0832-93R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B832 − 93 (2018)

the electrodeposited metal. The electroform is a separate, free-standing entity composed entirely of electrodeposited metal.

Electroforming is concerned with the fabrication of articles of various kinds.

4. Significance and Use

4.1 The specialized use of the electroplating process for electroforming results in the manufacture of tools and products that are

unique and often impossible to make economically by traditional methods of fabrication. Current applications of nickel

electroforming include: textile printing screens; components of rocket thrust chambers, nozzles, and motor cases; molds and dies

for making automotive arm-rests and instrument panels; stampers for making phonograph records, video-discs, and audio compact

discs; mesh products for making porous battery electrodes, filters, and razor screens; and optical parts, bellows, and radar wave

guides (1-3).

4.2 Copper is extensively used for electroforming thin foil for the printed circuit industry. Copper foil is formed continuously

by electrodeposition onto rotating drums. Copper is often used as a backing material for electroformed nickel shells and in other

applications where its high thermal and electrical conductivities are required. Other metals including gold are electroformed on a

smaller scale.

4.3 Electroforming is used whenever the difficulty and cost of producing the object by mechanical means is unusually high;

unusual mechanical and physical properties are required in the finished piece; extremely close dimensional tolerances must be held

on internal dimensions and on surfaces of irregular contour; very fine reproduction of detail and complex combinations of surface

finish are required; and the part cannot be made by other available methods.

5. Processing of Mandrels for Electroforming

5.1 General Considerations:

5.1.1 Mandrels may be classified as conductors or nonconductors of electricity, and each of these may be permanent,

semipermanent, or expendable (Table 1).

TABLE 1 Types of Mandrel Materials

Types Typical Materials

Conductors

Expendable Low-melting point alloys; for example,

bismuth-free 92 % tin and 8 % zinc

Aluminum alloys

Zinc alloys

Permanent Nickel

Austenitic Stainless

Invar, Kovar

Copper and brass

Nickel-plated steel

Nickel/chromium-plated aluminum

Nonconductors

Expendable Wax

Glass

Permanent (or Semi-Permanent) Rigid and collapsible plastic; for

example, epoxy resins and polyvinyl

chloride

Wood

5.1.2 Whether or not a mandrel is a conductor will determine the procedures required to prepare it for electroforming.

Conductive mandrels are usually pure metals or alloys of metals and are prepared by standard procedures but may require an

additional thin parting film to facilitate separation of the electroform from the mandrel (unless the mandrel is removed by melting

or chemical dissolution).

5.1.3 Whether or not a permanent or expendable mandrel should be used is largely dependent on the particular article that is

to be electroformed. If no reentrant shapes or angles are involved, it is possible to use permanent, rigid mandrels that can be

separated from the finished electroform mechanically and reused. If reentrant angles and shapes are involved, it is necessary to use

mandrel materials that can be removed by melting or by chemical dissolution, or materials that are collapsible, such as polyvinyl

chloride and other plastics. In some cases, multiple piece mandrels are used that can be removed even with reentrant features.

The boldface numbers in parentheses refer to the list of references at the end of this standard.

B832 − 93 (2018)

5.1.4 Many solid materials can be used to fabricate mandrels for electroforming, but the following generalizations may help in

selecting a suitable material: permanent mandrels are preferred for accuracy and for large production runs; expendable mandrels

must be used whenever the part is so designed that a permanent mandrel cannot be withdrawn; and it is important that the mandrel

retain its dimensional stability in warm plating baths. Wax and most plastics expand when exposed to electroplating solutions

operated at elevated temperatures. In such cases, it may be necessary to use acid copper, nickel sulfamate, and other electroplating

solutions that function at room temperature.

5.2 Mandrel Design:

5.2.1 The electroforming operation can often be simplified by design changes that do not impair the functioning of the piece.

Some of the design considerations are summarized in 5.2.2, 5.2.3, 5.2.4, 5.2.5, and 5.2.6. Examples of mandrel shapes that may

present problems during electroforming are illustrated in Fig. 1.

5.2.2 Exterior (convex) angles should be provided with as generous a radius as possible to avoid excessive build up and treeing

of the deposit during electroforming. Interior (concave) angles on the mandrel should be provided with a fillet radius of at least

0.05 cm per 5 cm (0.02 in. per 2 in.) of length of a side of the angle.

5.2.3 Whenever possible, permanent mandrels should be tapered at least 0.08 mm per m (0.001 in. per ft) to facilitate removal

from the mandrel. (Where this is not permissible, the mandrel may be made of a material with a high or low coefficient of thermal

expansion so that separation can be effected by heating or cooling).

5.2.4 A fine surface finish on the mandrel, achieved by lapping or by electropolishing, will generally facilitate separation of

mandrel and electroform. A finish of 0.05 μm (2 μin.) rms is frequently specified.

5.2.5 Flat bottom grooves, sharp angle indentations, blind holes, fins, v-shaped projections, v-bottom grooves, deep scoops,

slots, concave recesses, and rings and ribs can cause problems with metal distribution during electroforming unless inside and

outside angles and corners are rounded.

5.2.6 An engineering drawing of the mandrel, the electroformed article, and auxiliary equipment or fixture for separating the

electroform from the mandrel should be prepared. The drawing of the mandrel should provide for electrical connections to be made

NOTE 1—Examples of deposit distribution on contours that require special consideration are shown in an exaggerated fashion. The designer should

confer with the electroformer before designing an electroform having any of these contours. An experienced electroformer can minimize some of the

exaggeration shown.

FIG. 1 Examples of Deposit Distribution on Electroforms

B832 − 93 (2018)

FIG. 1 (continued)

in nonfunctional areas of the electroform. It should provide reference points for and mechanical means of holding if finish

machining is necessary before removal of the mandrel.

5.3 Mandrel Fabrication:

5.3.1 The method of fabrication of the mandrel will depend on the type selected, the material chosen, and the object to be

electroformed. Mandrels may be manufactured by casting, machining, electroforming, and other techniques. Permanent mandrels

can be made by any of the conventional pattern-making processes.

5.4 Preparing Non-Conducting Mandrels:

5.4.1 Nonconducting mandrels must be made impervious to water and other processing solutions and then rendered conductive.

Porous materials, for example, leather and plastic, may be impregnated with wax, shellac, lacquer, or a synthetic resin formulation.

It is often preferable to use thin films of lacquer to seal porous, nonmetallic mandrels.

5.4.2 Nonconducting materials may be rendered conductive by applying a chemically reduced film of silver, copper, or nickel

to the surface. In general, these processes are carried out by spraying the reagent containing the metal ions of choice simultaneously

with a specific reducing agent onto the surface of the mandrel using a double-nozzle spray gun. The chemicals react at the surface;

the metal is reduced and is deposited on the mandrel surface. Chemical reduction processes are preferred because dimensional

accuracy is not affected, the film has little adhesion, and parting is not difficult. If necessary, a silver film can be stripped from a

nickel electroform with either nitric acid, warm sulfuric acid, or a cyanide solution.

5.4.3 Other ways of making non-conducting materials conductive include: using finely divided metal powders dispersed in

binders (“bronzing”), applying finely divided graphite to wax, and to natural or synthetic rubbers that have an affinity for graphite,

and applying graphite with a binder.

5.4.4 Vapor deposition of silver and other metals is preferred for nonconducting mandrels used in the semiconductor industry,

the optical disc industry, and the manufacture of holograms. In these cases the mandrel must be made of a material that does not

outgas in the vacuum chamber. Glass is the preferred substrate for making masters and stampers for optical read-out discs of all

kinds.

5.5 Preparing Metallic Mandrels:

5.5.1 Standard procedures should be used whenever adherent electrodeposits are applied to metallic mandrels prior to and in

preparation for electroforming. See Practices B183, B242, B254, B281, and B558, for example.

5.5.2 With most metallic mandrels an additional chemical treatment that forms a parting film on the surface is required to

separate the electroform from the mandrel. After removing all traces of grease and oil by means of solvents, various metallic

mandrels are given different treatments for this purpose (see 5.5.3, 5.5.4, 5.5.5, 5.5.6, and 5.5.7).

B832 − 93 (2018)

5.5.3 Stainless steel, nickel, and nickel- or chromium-plated steel are cleaned using standard procedures, rinsed, and passivated

by immersion in a 2 % solution of sodium dichromate for 30 to 60 s at room temperature. The mandrel must then be rinsed to

remove all traces of the dichromate solution.

5.5.4 Copper and brass mandrels that have been nickel and/or chromium-plated may be treated as described in 5.5.3. If not

electroplated, the surface can be made passive by immersion in a solution containing 8 g/L sodium sulfide.

5.5.5 Aluminum alloys may require special treatments even when they are used as expendable mandrels to be separated by

chemical dissolution. If the deposits are highly stressed, it may b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.