ASTM B571-97(2013)

(Practice)Standard Practice for Qualitative Adhesion Testing of Metallic Coatings

Standard Practice for Qualitative Adhesion Testing of Metallic Coatings

SIGNIFICANCE AND USE

2.1 These tests are useful for production control and for acceptance testing of products.

2.2 Interpreting the results of qualitative methods for determining the adhesion of metallic coatings is often a controversial subject. If more than one test is used, failure to pass any one test is considered unsatisfactory. In many instances, the end use of the coated article or its method of fabrication will suggest the technique that best represents functional requirements. For example, an article that is to be subsequently formed would suggest a draw or a bend test; an article that is to be soldered or otherwise exposed to heat would suggest a heat-quench test. If a part requires baking or heat treating after plating, adhesion tests should be carried out after such posttreatment as well.

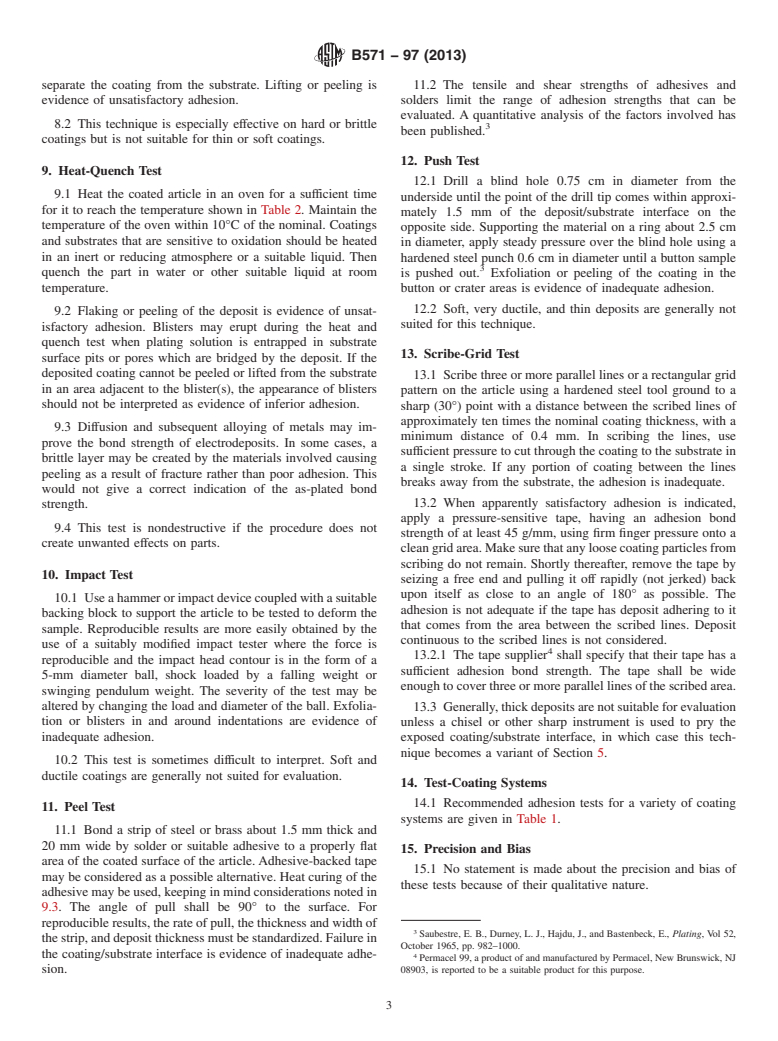

2.3 Several of the tests are limited to specific types of coatings, thickness ranges, ductilities, or compositions of the substrate. These limitations are noted generally in the test descriptions and are summarized in Table 1 for certain metallic coatings.TABLE 1 Adhesion Tests Appropriate for Various Coatings

Adhesion Test

Coating MaterialA

Cadmium

Chromium

Copper

Lead and

Lead/Tin

Alloy

Nickel

Nickel and

Chromium

Palladium

Rhodium

Silver

Tin and

Tin/Lead

Alloy

Zinc

Gold

Bend

+

−

+

+

+

+

+

+

+

+

+

+

Burnish

−

+

+

−

+

+

−

−

+

−

+

−

Chisel/knife

+

+

+

+

+

−

+

−

+

+

−

+

Draw

−

−

+

−

+

+

−

−

−

−

+

−

File

−

+

+

+

+

+

−

+

+

+

−

+

Grind and

saw

+

+

−

−

+

+

+

−

−

+

+

−

Heat/quench

−

+

+

+

+

+

−

−

+

+

−

+

Impact

+

−

+

−

+

+

−

−

−

−

+

−

Peel

−

+

+

−

+

−

−

−

+

+

−

+ ...

SCOPE

1.1 This practice covers simple, qualitative tests for evaluating the adhesion of metallic coatings on various substances.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B571 − 97 (Reapproved 2013)

Standard Practice for

Qualitative Adhesion Testing of Metallic Coatings

This standard is issued under the fixed designation B571; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope of either. Such adhesion is usually obtained if good electro-

plating practices are followed.

1.1 This practice covers simple, qualitative tests for evalu-

ating the adhesion of metallic coatings on various substances. 2.5 For many purposes, the adhesion test has the objective

of detecting any adhesion less than “perfect.” For such a test,

1.2 The values stated in SI units are to be regarded as

oneusesanymeansavailabletoattempttoseparatethecoating

standard. No other units of measurement are included in this

from the substrate. This may be prying, hammering, bending,

standard.

beating, heating, sawing, grinding, pulling, scribing, chiseling,

1.3 This standard does not purport to address all of the

or a combination of such treatments. If the coating peels,

safety concerns, if any, associated with its use. It is the

flakes, or lifts from the substrate, the adhesion is less than

responsibility of the user of this standard to establish appro-

perfect.

priate safety and health practices and determine the applica-

2.6 Ifevaluationofadhesionisrequired,itmaybedesirable

bility of regulatory limitations prior to use.

to use one or more of the following tests. These tests have

2. Significance and Use varying degrees of severity; and one might serve to distinguish

between satisfactory and unsatisfactory adhesion in a specific

2.1 These tests are useful for production control and for

application. The choice for each situation must be determined.

acceptance testing of products.

2.7 When this guideline is used for acceptance inspection,

2.2 Interpreting the results of qualitative methods for deter-

the method or methods to be used must be specified. Because

mining the adhesion of metallic coatings is often a controver-

the results of tests in cases of marginal adhesion are subject to

sial subject. If more than one test is used, failure to pass any

interpretation, agreement shall be reached on what is accept-

one test is considered unsatisfactory. In many instances, the

able.

end use of the coated article or its method of fabrication will

suggest the technique that best represents functional require-

2.8 If the size and shape of the item to be tested precludes

ments. For example, an article that is to be subsequently

use of the designated test, equivalent test panels may be

formed would suggest a draw or a bend test; an article that is

appropriate. If permitted, test panels shall be of the same

to be soldered or otherwise exposed to heat would suggest a

material and have the same surface finish as the item to be

heat-quench test. If a part requires baking or heat treating after tested and shall be processed through the same preplating,

plating, adhesion tests should be carried out after such post-

electroplating, and postplating cycle with the parts they repre-

treatment as well. sent.

2.3 Several of the tests are limited to specific types of

3. Bend Tests

coatings, thickness ranges, ductilities, or compositions of the

substrate. These limitations are noted generally in the test

3.1 Bend the part with the coated surface away over a

descriptionsandaresummarizedinTable1forcertainmetallic

mandrel until its two legs are parallel. The mandrel diameter

coatings.

should be four times the thickness of the sample. Examine the

deformed area visually under low magnification, for example,

2.4 “Perfect” adhesion exists if the bonding between the

4×, for peeling or flaking of the coating from the substrate,

coating and the substrate is greater than the cohesive strength

which is evidence of poor adhesion. If the coating fractures or

blisters, a sharp blade may be used to attempt to lift off the

coating. With hard or brittle coatings, cracking usually occurs

This practice is under the jurisdiction of ASTM Committee B08 on Metallic

and Inorganic Coatings and is the direct responsibility of Subcommittee B08.10 on

in the bend area. Such cracks may or may not propagate into

Test Methods.

the substrate. In either case, cracks are not indicative of poor

Current edition approved Dec. 1, 2013. Published December 2013. Originally

ε1

adhesion unless the coating can be peeled back with a sharp

approved in 1979. Last previous edition approved in 2008 as B571–97(2008) .

DOI: 10.1520/B0571-97R13. instrument.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B571 − 97 (2013)

TABLE 1 Adhesion Tests Appropriate for Various Coatings

A

Coating Material

Lead and Tin and

Adhesion Test

Nickel and

Cadmium Chromium Copper Lead/Tin Nickel Palladium Rhodium Silver Tin/Lead Zinc Gold

Chromium

Alloy Alloy

Bend +−+++ + + + + + + +

Burnish −++−+ + − − + − + −

Chisel/knife +++++ − + − + + − +

Draw −−+−+ + − − − − + −

File −++++ + − + + + − +

Grind and ++−−+ + + − − + + −

saw

Heat/quench −++++ + − − + + − +

Impact +−+−+ + − − − − + −

Peel −++−+ − − − + + − +

Push −−−−+ + − − − − + −

Scribe −−+−+ − − − − − − −

A

+ Appropriate; − not appropriate.

TABLE 2 Temperature Test Guide

Coating Material

Chromium,

Lead, Gold and

Nickel, Nickel + Tin, Zinc, Palladium, Rhodium,

Substrate

Tin/Lead, Silver,

Chromium, Temperature, Temperature, Temperature, Temperature,

Temperature, Temperature,

Copper, °C °C °C °C

°C °C

Temperature, °C

Steel 250 150 150 150 250 350 185

Zinc alloys 150 150 150 150 150 150 150

Copper and 250 150 150 150 250 350 185

copper alloys

Aluminum and 220 150 150 150 220 220 185

aluminum alloys

3.2 Bend the part repeatedly, back and forth, through an ordinary punch press. Penetration of the male die may be

angle of 180° until failure of the basis metal occurs. Examine continued until the cap fractures. The adhesion of the coating

the region at low magnification, for example, 10×, for separa- may be observed directly or evaluated further by techniques

tion or peeling of the coating. Prying with a sharp blade will described in Section 5 for detachment from the substrate. If

indicate unsatisfactory adhesion by lift off of the coating. there is peeling or flaking of the coating or if it can be

detached, the adhesion is not satisfactory.

4. Burnishing Test

6.2 Results from this technique must be interpreted

4.1 Rub a coated area of about 5 cm with a smooth-ended

cautiously, because the ductilities of both the coating and

tool for approximately 15 s.Asuitable tool is a steel rod 6 mm

substrate are involved.

in diameter with a smooth hemispherical end. The pressure

shall be sufficient to burnish the coating at each stroke but not 7. File Test

so great as to dig into it. Blisters, lifting, or peeling should not

7.1 Sawoffapieceofthecoatedspecimenandinspectitfor

develop. Generally, thick deposits cannot be evaluated satis-

detachmentatthedeposit/substrateinterface.Applycoarsemill

factorily.

file across the sawed edge from the substrate toward the

coating so as to raise it, using an approach angle of approxi-

5. Chisel-Knife Test

mately45°tothecoatingsurface.Liftingorpeelingisevidence

5.1 Use a sharp cold chisel to penetrate the coating on the

of unsatisfactory adhesion.

article being evaluated.Alternatively the chisel may be placed

7.2 This technique is not suitable for thin or soft coatings.

in back of an overhang area of the coating or at a coating-

substrateinterfaceexposedbysectioningthearticlewithasaw.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.