ASTM D5709-95(2000)e1

(Test Method)Standard Test Method for Sieve Analysis of Petroleum Coke

Standard Test Method for Sieve Analysis of Petroleum Coke

SCOPE

1.1 This test method details a procedure for performing particle size distribution analysis by dry sieve testing on green petroleum coke with a topsize of no more than 75 mm and calcined petroleum coke with a topsize of no more than 25 mm. Size fractions go down to and include 4.75 mm for green petroleum coke and 75 [mu]m for calcined petroleum coke. Note 1-To convert units see Table 1 from Specification E11. For example, 75 mm is approximately equivalent to a nominal sieve opening of 3 in. and 25 mm to a nominal sieve opening of 1 in. Likewise, 4.75 mm can be converted to approximately 0.187 in. and 75 microns to 0.0029 in.

1.2 Although the values stated in SI units are to be regarded as the standard, the sieve size is reported as U.S.A. standard test series in any units listed in Table 1 of Specification E11, or their commercial size equivalents.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation:D5709–95 (Reapproved 2000)

Standard Test Method for

Sieve Analysis of Petroleum Coke

This standard is issued under the fixed designation D 5709; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Warning note was placed in the text in April 2000.

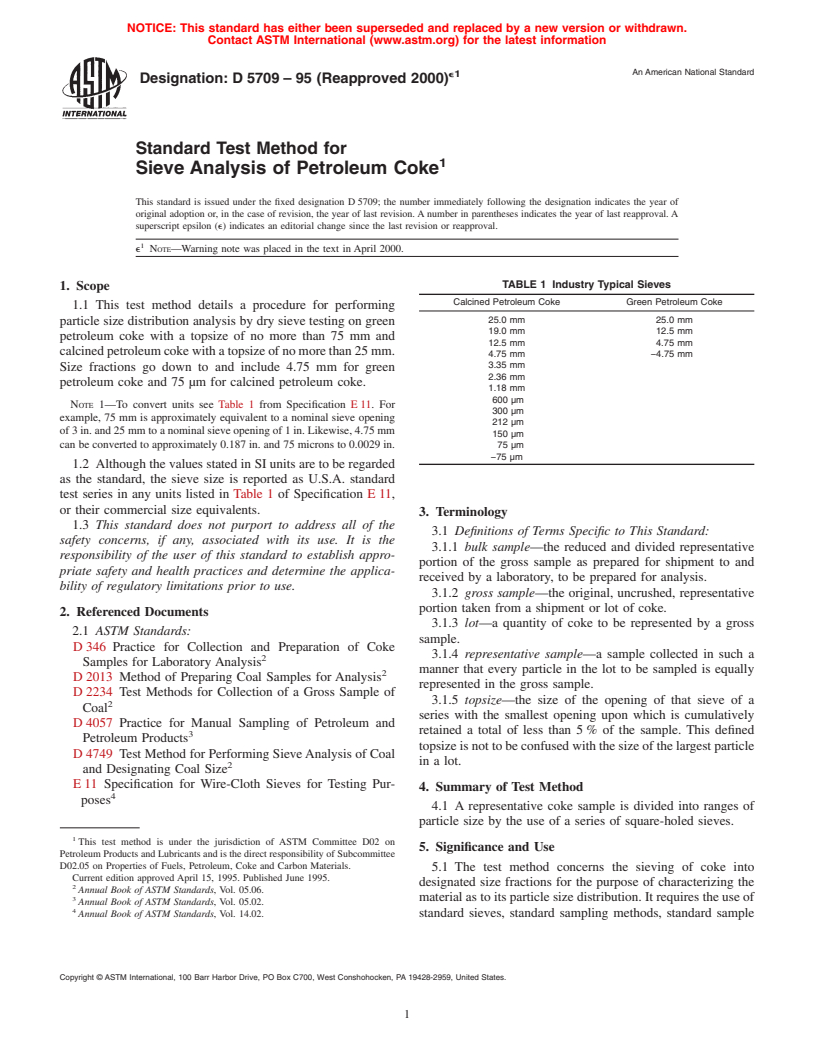

TABLE 1 Industry Typical Sieves

1. Scope

Calcined Petroleum Coke Green Petroleum Coke

1.1 This test method details a procedure for performing

25.0 mm 25.0 mm

particle size distribution analysis by dry sieve testing on green

19.0 mm 12.5 mm

petroleum coke with a topsize of no more than 75 mm and

12.5mm 4.75mm

calcinedpetroleumcokewithatopsizeofnomorethan25mm.

4.75 mm −4.75 mm

3.35 mm

Size fractions go down to and include 4.75 mm for green

2.36 mm

petroleum coke and 75 µm for calcined petroleum coke.

1.18 mm

600 µm

NOTE 1—To convert units see Table 1 from Specification E11. For

300 µm

example, 75 mm is approximately equivalent to a nominal sieve opening

212 µm

of 3 in. and 25 mm to a nominal sieve opening of 1 in. Likewise, 4.75 mm

150 µm

can be converted to approximately 0.187 in. and 75 microns to 0.0029 in.

75 µm

−75 µm

1.2 Although the values stated in SI units are to be regarded

as the standard, the sieve size is reported as U.S.A. standard

test series in any units listed in Table 1 of SpecificationE11,

or their commercial size equivalents.

3. Terminology

1.3 This standard does not purport to address all of the

3.1 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

3.1.1 bulk sample—the reduced and divided representative

responsibility of the user of this standard to establish appro-

portion of the gross sample as prepared for shipment to and

priate safety and health practices and determine the applica-

received by a laboratory, to be prepared for analysis.

bility of regulatory limitations prior to use.

3.1.2 gross sample—the original, uncrushed, representative

portion taken from a shipment or lot of coke.

2. Referenced Documents

3.1.3 lot—a quantity of coke to be represented by a gross

2.1 ASTM Standards:

sample.

D 346 Practice for Collection and Preparation of Coke

3.1.4 representative sample—a sample collected in such a

Samples for Laboratory Analysis

manner that every particle in the lot to be sampled is equally

D 2013 Method of Preparing Coal Samples for Analysis

represented in the gross sample.

D 2234 Test Methods for Collection of a Gross Sample of

3.1.5 topsize—the size of the opening of that sieve of a

Coal

series with the smallest opening upon which is cumulatively

D 4057 Practice for Manual Sampling of Petroleum and

retained a total of less than 5 % of the sample. This defined

Petroleum Products

topsizeisnottobeconfusedwiththesizeofthelargestparticle

D 4749 Test Method for Performing SieveAnalysis of Coal

in a lot.

and Designating Coal Size

E11 Specification for Wire-Cloth Sieves for Testing Pur-

4. Summary of Test Method

poses

4.1 A representative coke sample is divided into ranges of

particle size by the use of a series of square-holed sieves.

This test method is under the jurisdiction of ASTM Committee D02 on

5. Significance and Use

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.05 on Properties of Fuels, Petroleum, Coke and Carbon Materials.

5.1 The test method concerns the sieving of coke into

Current edition approved April 15, 1995. Published June 1995.

designated size fractions for the purpose of characterizing the

Annual Book of ASTM Standards, Vol. 05.06.

3 material as to its particle size distribution. It requires the use of

Annual Book of ASTM Standards, Vol. 05.02.

Annual Book of ASTM Standards, Vol. 14.02. standard sieves, standard sampling methods, standard sample

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D5709–95 (2000)

preparationmethods,andaminimuminitialsamplemassbased 7.2.2 For sieving small quantities of coke or very fine coke

on lot topsize. Suggestions are given for industry typical sieve (below 70 mesh), use a laboratory type sieving machine.

stacks for both green and calcined petroleum coke.

5.2 Particle size distribution is significant in that many

TABLE 2 Initial Minimum Test Sample Mass Requirements for

physical characteristics of a coke are related to such a

Sieve Analysis

distribution including bulk density and surface area. Nuisance

Initial Sample Expected

characteristics, such as excessive fines in a lot, can also be

Topsize Type of Coke Mass Requirement, Relative

g Error, %

controlled.

75 mm Green 50,000 6

5.3 Results from this test method are useful in determining

50 mm Green 30,000 6

whether a coke lot meets purchase specifications, for classifi-

25 mm Green/Calcined 1,500 3

cation purposes, and for quality control. The results of this test

19 mm Green/Calcined 1,300 1

12.5 mm Green/Calcined 1,000 1

method can also be used to predict the performance of a

4.75 mm Green/Calcined 800 1

particular lot of coke in a process.

2.36 mm Green/Calcined 700 1

1.18 mm Green/Calcined 500 1

600 µm Green/Calcined 300 1

6. Interferences

300 µm Green/Calcined 100 1

A

6.1 A sieve analysis is very sensitive to the sieve cloth and 150 µm Green/Calcined 50 1

A

sievecloth-frameintegrity.Minorseparationsofthesievecloth

For topsize less than 150 µm, use an initial sample mass requirement of 50 g.

from the frame such as one broken sieve wire, and slight

distortions of sieve wires, can cause serious inaccuracies in the

8. Sample Preparation

final results of a sieve analysis.

6.2 Blinding of or a reduction in the number of openings in

8.1 A representative gross sample of the coke lot must be

a sieve due to a collection of particles caught in the mesh can

collected using appropriate procedures from Practice D 346,

introduce errors.

Test Methods D 2234, or Practice D 4057 (Warning—The

6.3 Flooding or overloading of any sieve with particles gross sample must not be crushed or reduced in topsize during

reduces the probability of any given particle encountering an the gross sample collection process or during subsequent

opening in the sieve. divisions of the sample.).

8.2 The gross sample is divided into a smaller bulk sample

7. Apparatus following guidelines inTest Methods D 2234.The bulk sample

must remain representative including no loss in topsize. Keep-

7.1 Sieves:

ing in mind the initial sample mass requirements (see Table 2),

7.1.1 Sieves will be used in a descending size opening

the bulk sample must be at least twice the largest minimum

sequence, larger mesh openings above smaller.

mass that you estimate will be required for the analysis.

7.1.1.1 TypicalsetsofsievestobeusedarelistedinTable1.

8.3 Upon delivery of the bulk sample to the laboratory, the

sample shall be stored in a safe, dry location. Prevent any size

NOTE 2—Sets of sieves are often modified. Typically, specifications on

sets of sieves are negotiated between the buyer and the seller. The actual degradation, loss of mass, or contamination of the sample until

sequence used by the operator performing the analysis can vary. For

needed for the sieve analysis.

example, intermediate sieves can be chosen to avoid sieve flooding and to

8.4 Immediately prior to the sieve analysis, examine the

make the sieving operation more efficient.Table 1 from SpecificationE11

bulk sample determining whether it is dry and free flowing. If

is to be used as a guide.

not, use the air drying apparatus and drying procedure of

7.1.2 A topsize sieve must be used. Method D 2013.

8.5 Determine the initial minimum test sample mass re-

7.1.3 Wire sieve cloth and frames used will conform to

quired for the analysis from Table 2.

SpecificationE11.

8.6 Reduce the bulk sample to the recommended minimum

7.1.4 Wire composition and types of frames must be sized

test sample mass required using the division methods outlined

properly for potential sieving operations. Stainless steel sieve

in Test Methods D 2234 or D 4749.

cloth is very resistant to distortion and preferred over softer

metals.

9. Procedure

7.1.5 Collecting pans and sieve covers designed to fit the

9.1 Accurately weigh the minimum test sample mass (see

sieves are required.

8.6) before sieving with a precision equal to or better than

7.1.6 Check SpecificationE11 for more details on standard

0.5 %ofthefractionbeingweighed.Thismassis M(initialtest

i

sieves, service checks, and calibration.

sample mass).

7.2 Sieve Shaker:

9.2 Start with the sieve having the largest required opening.

7.2.1 Use a batch type sieve shaker.

9.3 All sieving is to be done using a batch type sieve shaker.

5 6

A model number TS-1 Gils

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.