ASTM D4828-94(2008)

(Test Method)Standard Test Methods for Practical Washability of Organic Coatings

Standard Test Methods for Practical Washability of Organic Coatings

SIGNIFICANCE AND USE

Interior architectural paints are subjected in use to soiling by dirt or other stains. This test method provides a way to assess relative ease of soil or stain removal from a paint film using materials common to households. This test method includes a way to evaluate the film for washability properties and changes in appearance. Thus, a formulator may evaluate the effects of composition on the washability properties of a paint. Users may also compare the ease of soil removal from different paints that are tested, preferably at the same time.

SCOPE

1.1 These test methods cover the determination of the relative ease of removal of common soil and stains from interior coatings by manual or mechanical washing with a sponge and a liquid or powder cleanser.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4828 − 94 (Reapproved 2008)

Standard Test Methods for

Practical Washability of Organic Coatings

This standard is issued under the fixed designation D4828; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope to assess relative ease of soil or stain removal from a paint film

using materials common to households. This test method

1.1 These test methods cover the determination of the

includes a way to evaluate the film for washability properties

relative ease of removal of common soil and stains from

and changes in appearance. Thus, a formulator may evaluate

interior coatings by manual or mechanical washing with a

the effects of composition on the washability properties of a

sponge and a liquid or powder cleanser.

paint. Users may also compare the ease of soil removal from

1.2 The values stated in SI units are to be regarded as the

different paints that are tested, preferably at the same time.

standard. The values given in parentheses are for information

only.

5. Apparatus

1.3 This standard does not purport to address all of the

5.1 Sponge and Holder.

safety concerns, if any, associated with its use. It is the

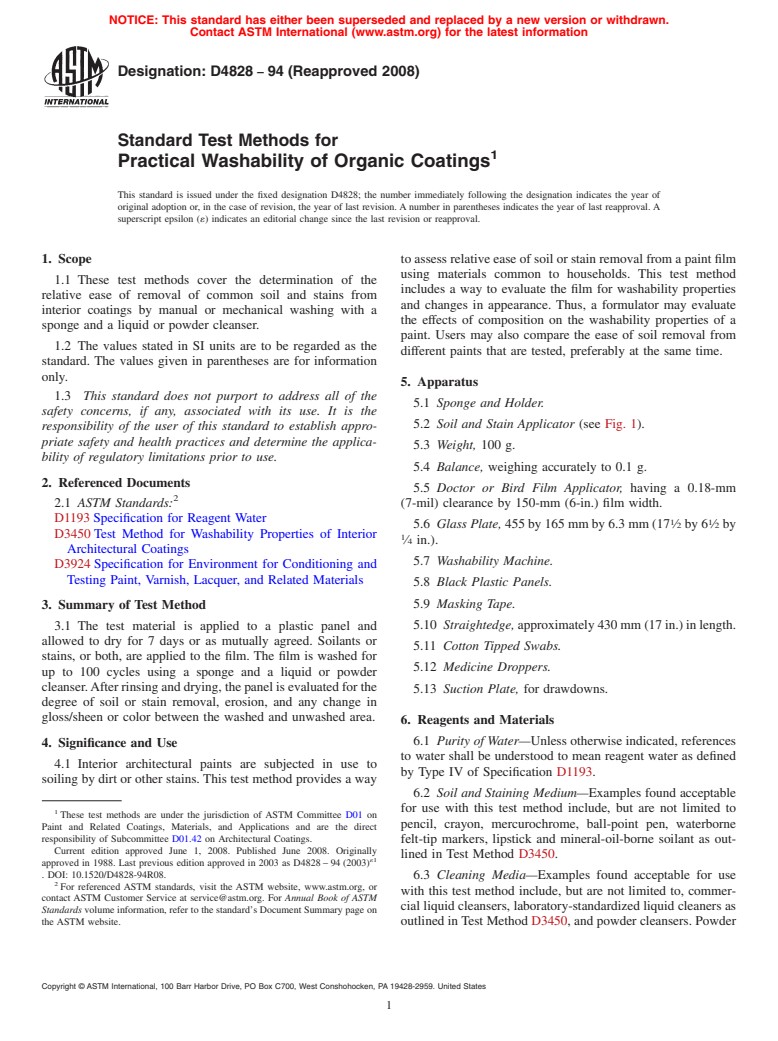

5.2 Soil and Stain Applicator (see Fig. 1).

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5.3 Weight, 100 g.

bility of regulatory limitations prior to use.

5.4 Balance, weighing accurately to 0.1 g.

2. Referenced Documents

5.5 Doctor or Bird Film Applicator, having a 0.18-mm

2.1 ASTM Standards: (7-mil) clearance by 150-mm (6-in.) film width.

D1193 Specification for Reagent Water

1 1

5.6 GlassPlate, 455 by 165 mm by 6.3 mm (17 ⁄2 by 6 ⁄2 by

D3450 Test Method for Washability Properties of Interior

⁄4 in.).

Architectural Coatings

5.7 Washability Machine.

D3924 Specification for Environment for Conditioning and

Testing Paint, Varnish, Lacquer, and Related Materials

5.8 Black Plastic Panels.

5.9 Masking Tape.

3. Summary of Test Method

3.1 The test material is applied to a plastic panel and 5.10 Straightedge,approximately430mm(17in.)inlength.

allowed to dry for 7 days or as mutually agreed. Soilants or

5.11 Cotton Tipped Swabs.

stains, or both, are applied to the film. The film is washed for

5.12 Medicine Droppers.

up to 100 cycles using a sponge and a liquid or powder

cleanser.Afterrinsinganddrying,thepanelisevaluatedforthe

5.13 Suction Plate, for drawdowns.

degree of soil or stain removal, erosion, and any change in

gloss/sheen or color between the washed and unwashed area.

6. Reagents and Materials

6.1 Purity of Water—Unless otherwise indicated, references

4. Significance and Use

to water shall be understood to mean reagent water as defined

4.1 Interior architectural paints are subjected in use to

by Type IV of Specification D1193.

soiling by dirt or other stains. This test method provides a way

6.2 Soil and Staining Medium—Examples found acceptable

for use with this test method include, but are not limited to

These test methods are under the jurisdiction of ASTM Committee D01 on

pencil, crayon, mercurochrome, ball-point pen, waterborne

Paint and Related Coatings, Materials, and Applications and are the direct

responsibility of Subcommittee D01.42 on Architectural Coatings.

felt-tip markers, lipstick and mineral-oil-borne soilant as out-

Current edition approved June 1, 2008. Published June 2008. Originally

lined in Test Method D3450.

´1

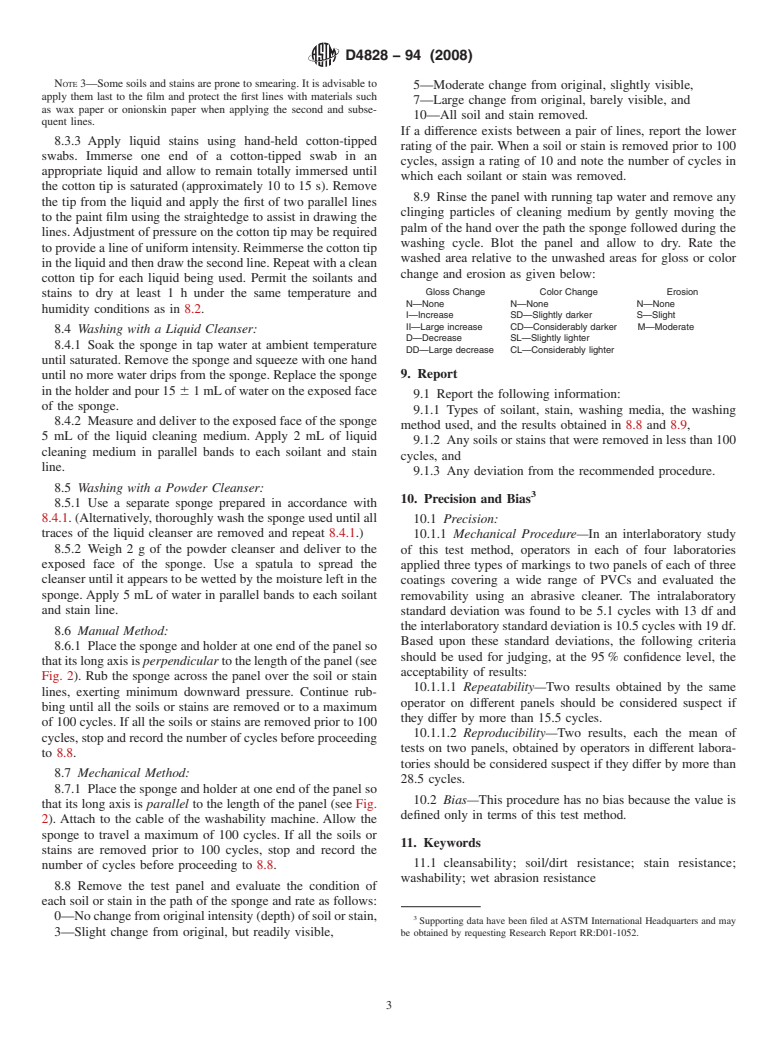

approved in 1988. Last previous edition approved in 2003 as D4828 – 94 (2003)

. DOI: 10.1520/D4828-94R08.

6.3 Cleaning Media—Examples found acceptable for use

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

with this test method include, but are not limited to, commer-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

cial liquid cleansers, laboratory-standardized liquid cleaners as

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. outlined in Test Method D3450, and powder cleansers. Powder

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

D4828 − 94 (2008)

FIG. 1 Solid Soil and Stain Application

cleansers containing chlorine may affect the color of the 2°C (73 6 3.5°F) and 50 6 5 % relative humidity as described

washed portion of the test panel. in Specification D3924, or under conditions specifically appli-

cable to the material under test.

7. Preparation of Apparatus

NOTE 2—If desired, an extra panel of each paint may be prepared to

7.1 Washability Machine—Level the apparatus before use

serve as its unwashed control.

and operate at 37 6 1 cpm. (A cycle consists of a complete

8.3 Application of Soilants and Stains:

forward and reverse stroke.)

8.3.1 Atthecompletionofthedryingperiod,tapethecoated

7.2 SpongeandHolder—Add sufficient weight to the holder

panel to the glass plate, as directed in 8.1, to ensure uniform

in the form of metal sheets or other flat weights to give a

application of the soilants and stains. Apply the selected

combined weight of 1000 g, including the dry sponge.

soilants or stains, or both, to the coating film in straight pairs

of lines parallel to the length of the panel for the manual

NOTE 1—Check the compression of the damp sponge under the 1000-g

weight to ensure that the holder does not drag along the panel and tear the

method of cleaning, or perpendicular to the length of the panel

film.

for the mechanical method of cleaning.

8.3.2 Apply solid soilants or stains using the apparatus

8. Procedure

showninFig.1.Insertpencil,crayon,pen,orsimilaritemsinto

8.1 Clean the top of the glass plate and both sides of the

theappropriatelysizedholeandsecureitspositionsoitextends

black plastic panel to be sure they are free of specks. Place the

40 mm (1 ⁄2 in.) beyond the panel (see Fig. 1(a)). Secure the

black panel on the glass plate and tape one end to the plate.

medium in position with a piece of masking tape (see Fig.

Smooth the panel along the plate to ensure a close fit.

1(b)). Put the applicator at one end of the coated plastic panel

8.2 Stir the material thoroughly and strain, if necessary, to and place the 100-g weight on the top face of the wooden panel

remove all skins and particles. Draw down the coating on the at the end nearest to the marking device, as shown in Fig. 1(b),

panel.Apply the coating in 3 to 4 s from end to end to prevent securing it with a piece of tape.Allow the nonweighted end of

pin holes or holidays in the film. Prepare enough panels with the applicator to rest on the surface of the film, then hold it by

each paint for all the projected tests. Air dry all panels in a the outer edges and pull it along the entire length of the film

horizontal position for 7 day

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.