ASTM D6630/D6630M-16(2022)

(Guide)Standard Guide for Low-Slope Insulated Roof Membrane Assembly Performance

Standard Guide for Low-Slope Insulated Roof Membrane Assembly Performance

SIGNIFICANCE AND USE

4.1 A roof assembly must work as a system. Any component of the roof assembly demonstrating an inherent weakness or inability to perform will diminish the roof system performance and service life expected. This guide lists minimum performance attributes required of low-slope roof assemblies. Products not previously used as roof membrane materials require additional tests beyond the scope of this document. This guide is not intended for use on in-service roofing materials. Roof membranes and other components should conform to ASTM product standards, if available.

SCOPE

1.1 This guide lists test methods intended to establish a minimum level of performance for insulated roof membrane assemblies, and lists pertinent design guidelines and installation methods in a unified manner. Material tests and evaluations are included with and without roof insulation.

1.2 It is not possible to establish a precise correlation between laboratory tests on roof assemblies and natural weathering due to variations in geographical climate, design, material, and installation.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6630/D6630M − 16 (Reapproved 2022)

Standard Guide for

Low-Slope Insulated Roof Membrane Assembly

Performance

This standard is issued under the fixed designation D6630/D6630M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D450/D450M Specification for Coal-Tar Pitch Used in

Roofing, Dampproofing, and Waterproofing

1.1 This guide lists test methods intended to establish a

D1079 Terminology Relating to Roofing and Waterproofing

minimum level of performance for insulated roof membrane

D2523/D2523M Practice for Testing Load-Strain Properties

assemblies, and lists pertinent design guidelines and installa-

of Roofing Membranes

tion methods in a unified manner. Material tests and evalua-

D4434/D4434M Specification for Poly(Vinyl Chloride)

tions are included with and without roof insulation.

Sheet Roofing

1.2 It is not possible to establish a precise correlation

D4637/D4637M Specification for EPDM Sheet Used in

between laboratory tests on roof assemblies and natural weath-

Single-Ply Roof Membrane

ering due to variations in geographical climate, design,

D4798/D4798M Practice for Accelerated Weathering Test

material, and installation.

Conditions and Procedures for Bituminous Materials

1.3 The values stated in either SI units or inch-pound units

(Xenon-Arc Method)

are to be regarded separately as standard. The values stated in

D4799/D4799M Practice for Accelerated Weathering Test

each system may not be exact equivalents; therefore, each

Conditions and Procedures for Bituminous Materials

system shall be used independently of the other. Combining

(Fluorescent UV,Water Spray, and Condensation Method)

values from the two systems may result in nonconformance

D5019 Specification for Reinforced CSM (Chlorosulfonated

with the standard.

Polyethylene) Sheet Used in Single-Ply Roof Membrane

1.4 This standard does not purport to address all of the

(Withdrawn 2011)

safety concerns, if any, associated with its use. It is the

D5147/D5147M Test Methods for Sampling and Testing

responsibility of the user of this standard to establish appro-

Modified Bituminous Sheet Material

priate safety, health, and environmental practices and deter-

D5601 Test Method for Tearing Resistance of Roofing and

mine the applicability of regulatory limitations prior to use.

Waterproofing Materials and Membranes (Withdrawn

1.5 This international standard was developed in accor-

2002)

dance with internationally recognized principles on standard-

D5602/D5602M Test Method for Static Puncture Resistance

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- of Roofing Membrane Specimens

mendations issued by the World Trade Organization Technical D5635/D5635M Test Method for Dynamic Puncture Resis-

Barriers to Trade (TBT) Committee.

tance of Roofing Membrane Specimens

D5849/D5849M Test Method for Evaluating Resistance of

2. Referenced Documents

Modified Bituminous Roofing Membrane to Cyclic Fa-

2.1 ASTM Standards:

tigue (Joint Displacement)

D95 Test Method for Water in Petroleum Products and

D6754/D6754M Specification for Ketone Ethylene Ester

Bituminous Materials by Distillation

Based Sheet Roofing

D6878/D6878M Specification for Thermoplastic Polyolefin-

Based Sheet Roofing

This guide is under the jurisdiction of ASTM Committee D08 on Roofing and

Waterproofing and is the direct responsibility of Subcommittee D08.20 on Roofing E96/E96M Test Methods for Gravimetric Determination of

Membrane Systems.

Water Vapor Transmission Rate of Materials

Current edition approved July 1, 2022. Published July 2022. Originally approved

E631 Terminology of Building Constructions

in 2001. Last previous edition approved in 2016 as D6630/D6630M – 16. DOI:

10.1520/D6630_D6630M-16R22.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6630/D6630M − 16 (2022)

2.2 ASCE Standard:

Roof Membrane Configuration Method of Attachment

ASCE-7 Minimum Design Loads for Buildings and Other

Method LD Loose laid air Uses air pressure equalization

pressure equalization valves valve with loose laid membrane

Structures

tightly sealed at edge. Needs

2.3 ANSI/SPRI Standard:

airtight deck.

ANSI/SPRI RP-4 Wind Design Guide for Ballasted Single

Method M Partially attached/ Uses a variety of fasteners and

Ply Roof Systems

mechanically fastened attachment schemes that anchor

membrane to roof deck for uplift

3. Terminology

resistance.

3.1 For terminology used in this standard, refer to Termi-

Method P Protected membrane Uses aggregate ballast, pavers, or

nologies D1079 and E631.

other dead load devices for wind

uplift resistance of extruded

3.2 roof assemblies—the weathering or waterproofing

polystyrene.

material, whether film, flexible membrane, semi-flexible

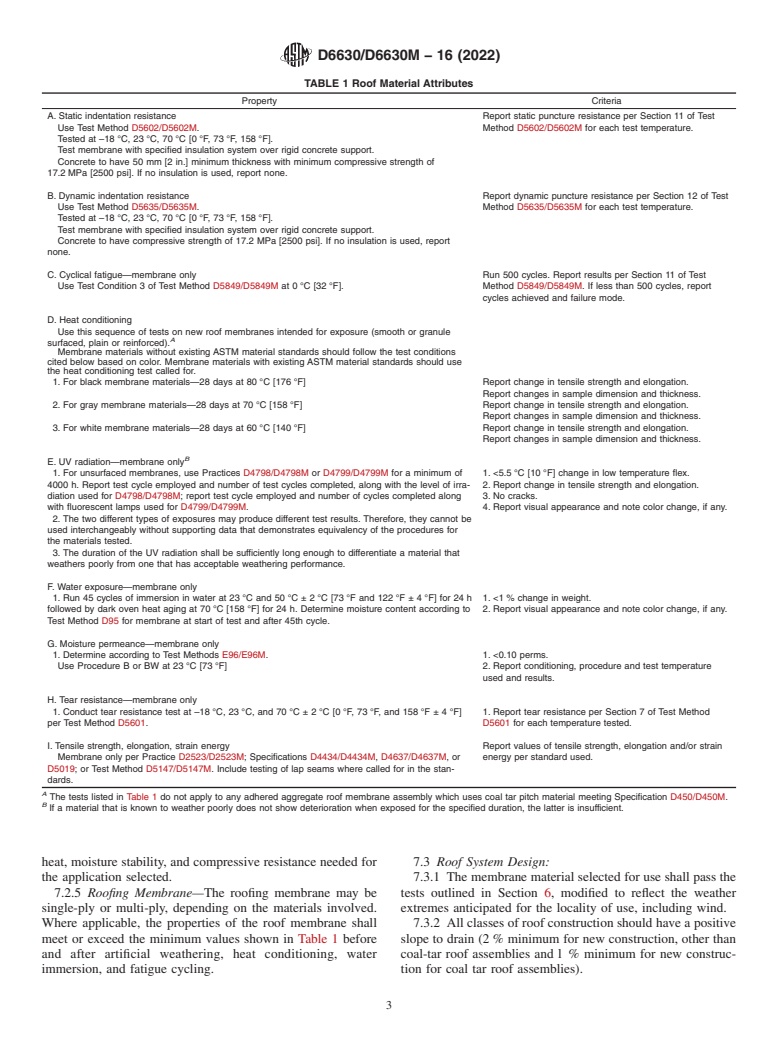

6. Roof Material Attributes

membrane, factory or field manufactured; the underlying

substrate including insulation (if used) above or below the

6.1 The roof membrane and insulated roof system shall be

membrane, or both; supporting deck structure and method of tested according to the procedures in Table 1. In addition, the

attachment of the entire assembly. Low-slope roof assemblies

roof membrane shall meet specific test requirements where

may be up to 25 % slope. Some roof assemblies may accom- identified.

modate higher slopes.

7. Design of Roofing Assembly

3.3 performance—theabilityoftheroofsystemasdesigned,

7.1 The roofing system may consist of the following func-

manufactured, and installed to provide adequate levels of

tional layers from the bottom to the top:

expected service life in terms of watertightness, thermal

7.1.1 Structural deck;

protection, and condensation control, while being maintain-

7.1.2 Air retarder;

able. Live loading of the roof system may also occur.

7.1.3 Vapor retarder;

7.1.4 Thermal insulation; and

4. Significance and Use

7.1.5 Roofing membrane

4.1 Aroofassemblymustworkasasystem.Anycomponent

7.2 The following paragraphs list the minimum design

of the roof assembly demonstrating an inherent weakness or

requirements for each functional layer of the roof assembly.

inability to perform will diminish the roof system performance

These may exceed the requirements of the local building code.

and service life expected. This guide lists minimum perfor-

7.2.1 Structural Deck—The structural deck shall have the

mance attributes required of low-slope roof assemblies. Prod-

capacity to support the full design load, including dead load,

ucts not previously used as roof membrane materials require

live loads, and environmental loads anticipated or mandated by

additional tests beyond the scope of this document. This guide

code.Thedeadloadoftheroofsystemshallbeincludedaspart

is not intended for use on in-service roofing materials. Roof

of the design load. Deck deflection should be limited to L/240

membranes and other components should conform to ASTM

under full design load. Ponding due to deck deflection should

product standards, if available.

not occur. Provide overflow drains or scuppers when interior

5. Roof Design Classifications

drains are used. The live load capacity shall not be less than

98 Kg⁄m [20 psf] and should have adequate capacity to resist

5.1 Type of Construction:

construction loads.

Class Construction

7.2.2 Air Retarder—Air retarders are used to retard the flow

I New New

of air from the interior into the roof system. When air retarders

II Replace Remove existing roof membrane (and existing

are used properly, they reduce the effects from wind on some

insulation, if necessary) and replace

roofing systems. With care, the vapor retarder and air retarder

functions may be provided by the same materials.

III Re-cover Re-cover existing roof membrane

7.2.3 Vapor Retarder—The vapor retarder retards the trans-

fer of the moist-warm interior vapor into the roofing system.A

5.2 Methods of Attachment:

vapor retarder should be used on the warm side of the system

Roof Membrane Configuration Method of Attachment

over moist occupancies, and at locations where the quantity of

Method A Adhered Uses a variety of adhesives

including hot and cold applied. moisture accumulated in the winter exceeds the moisture

capacity of the materials in the system.

Method B Loose laid ballasted Uses aggregate ballast or pavers.

7.2.4 Thermal Insulation—Thermal insulation must be used

Structure needs capacity to carry

ballast dead load. wherever a building is heated or cooled, except industrial

facilities where excess process heat needs to be dissipated.

Where used, it should be installed in two or more layers with

offsetjoints.Taperedinsulationcanbeusedwherenecessaryto

Available from American Society of Civil Engineers (ASCE), 1801 Alexander

provide a positive slope to the drains. Provide sump areas at all

Bell Dr., Reston, VA 20191, http://www.asce.org.

roof drains to assist drainage. The insulation selected must b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.