ASTM E96/E96M-23

(Test Method)Standard Test Methods for Gravimetric Determination of Water Vapor Transmission Rate of Materials

Standard Test Methods for Gravimetric Determination of Water Vapor Transmission Rate of Materials

SIGNIFICANCE AND USE

5.1 The purpose of these tests is to determine water vapor transmission rate of materials by means of a simple gravimetric procedure.

5.2 Test Conditions:

5.2.1 A WVTR result obtained in one method under one set of test conditions cannot be used to predict the result that would be obtained using the same method with a different set of conditions, or using the other method. See Appendix X3 for discussion of determining dependency of WVTR on different relative humidity (at a given temperature).

5.2.2 Test conditions that are commonly used or are considered standard in various industries or research applications are listed as Procedures A-E in Appendix X1, but use of these conditions is not mandatory in the methods herein.

5.2.3 Given the caution in 5.2.1, the selection of test conditions that closely approach exposure conditions of material in actual use is advised when possible.

5.2.4 Where tests are conducted for classification or compliance purposes, test conditions are typically defined in codes, specifications, and manufacturer’s technical literature.

SCOPE

1.1 These test methods cover the determination of water vapor transmission rate (WVTR) of materials, such as, but not limited to, paper, plastic films, other sheet materials, coatings, foams, fiberboards, gypsum and plaster products, wood products, and plastics. Two basic methods, the Desiccant Method and the Water Method, are provided for the measurement of WVTR. In these tests, the desired temperature and side-to-side humidity conditions, with resultant vapor drive through the specimen, are used. The test conditions employed are at the discretion of the user, but in all cases, are reported with the results.

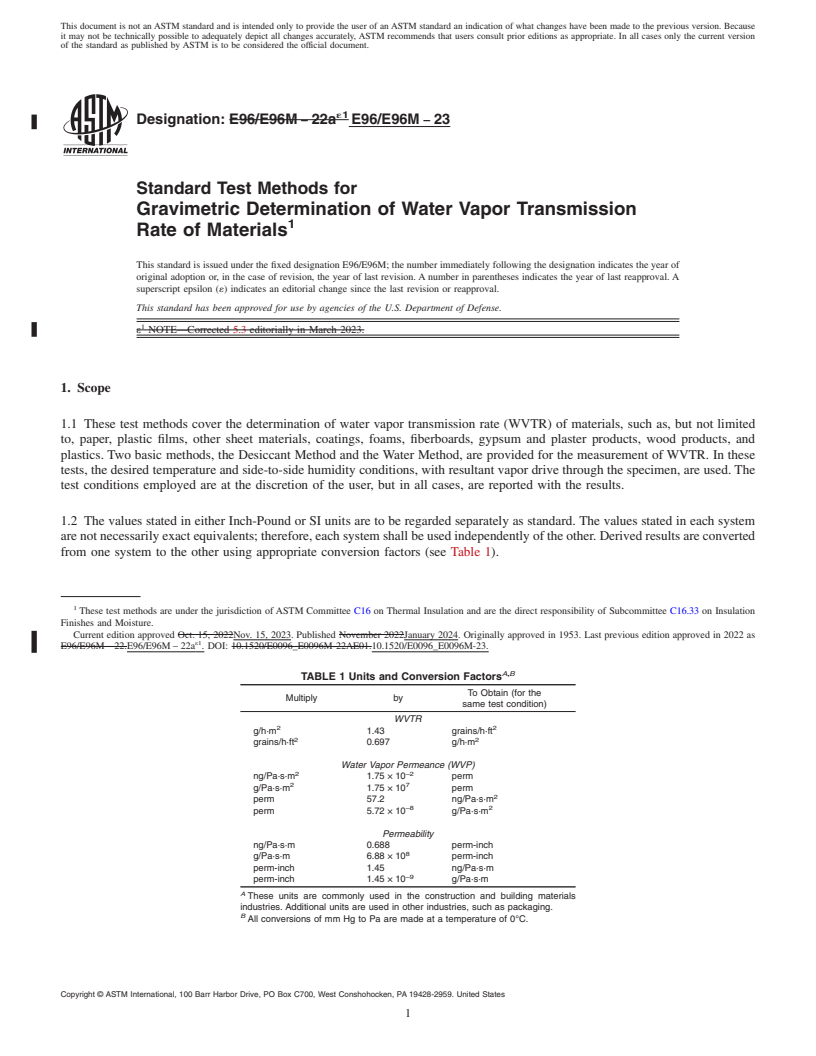

1.2 The values stated in either Inch-Pound or SI units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, each system shall be used independently of the other. Derived results are converted from one system to the other using appropriate conversion factors (see Table 1).

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E96/E96M − 23

Standard Test Methods for

Gravimetric Determination of Water Vapor Transmission

1

Rate of Materials

This standard is issued under the fixed designation E96/E96M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 These test methods cover the determination of water

C168 Terminology Relating to Thermal Insulation

vapor transmission rate (WVTR) of materials, such as, but not

C1809 Practice for Preparation of Specimens and Reporting

limited to, paper, plastic films, other sheet materials, coatings,

of Results for Permeance Testing of Pressure Sensitive

foams, fiberboards, gypsum and plaster products, wood

Adhesive Sealed Joints in Insulation Vapor Retarders

products, and plastics. Two basic methods, the Desiccant

D449/D449M Specification for Asphalt Used in Dampproof-

Method and the Water Method, are provided for the measure-

ing and Waterproofing

ment of WVTR. In these tests, the desired temperature and

D2301 Specification for Vinyl Chloride Plastic Pressure-

side-to-side humidity conditions, with resultant vapor drive

Sensitive Electrical Insulating Tape

through the specimen, are used. The test conditions employed

E177 Practice for Use of the Terms Precision and Bias in

are at the discretion of the user, but in all cases, are reported

ASTM Test Methods

with the results.

E691 Practice for Conducting an Interlaboratory Study to

1.2 The values stated in either Inch-Pound or SI units are to Determine the Precision of a Test Method

be regarded separately as standard. The values stated in each

3. Terminology

system are not necessarily exact equivalents; therefore, each

3.1 Definitions of terms used in this standard will be found

system shall be used independently of the other. Derived

in Terminology C168, from which the following is quoted:

results are converted from one system to the other using

“water vapor permeability—the time rate of water vapor

appropriate conversion factors (see Table 1).

transmission through unit area of flat material of unit thickness

1.3 This standard does not purport to address all of the

induced by unit vapor pressure difference between two specific

safety concerns, if any, associated with its use. It is the

surfaces, under specified temperature and humidity conditions.

responsibility of the user of this standard to establish appro-

Discussion—Permeability is a property of a material, but the

priate safety, health, and environmental practices and deter-

permeability of a body that performs like a material may be

mine the applicability of regulatory limitations prior to use.

used. Permeability is the arithmetic product of permeance and

1.4 This international standard was developed in accor- thickness.

dance with internationally recognized principles on standard- water vapor permeance—the time rate of water vapor

ization established in the Decision on Principles for the transmission through unit area of flat material or construction

induced by unit vapor pressure difference between two specific

Development of International Standards, Guides and Recom-

surfaces, under specified temperature and humidity conditions.

mendations issued by the World Trade Organization Technical

Discussion—Permeance is a performance evaluation and not

Barriers to Trade (TBT) Committee.

a property of a material.

water vapor transmission rate—the steady water vapor flow

in unit time through unit area of a body, normal to specific

1

These test methods are under the jurisdiction of ASTM Committee C16 on

Thermal Insulation and are the direct responsibility of Subcommittee C16.33 on

2

Insulation Finishes and Moisture. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 15, 2023. Published January 2024. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ε1

approved in 1953. Last previous edition approved in 2022 as E96/E96M – 22a . Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/E0096_E0096M-23. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E96/E96M − 23

A,B

TABLE 1 Units and Conversion Factors

5.2.4 Where tests are conducted for c

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E96/E96M − 22a E96/E96M − 23

Standard Test Methods for

Gravimetric Determination of Water Vapor Transmission

1

Rate of Materials

This standard is issued under the fixed designation E96/E96M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—Corrected 5.3 editorially in March 2023.

1. Scope

1.1 These test methods cover the determination of water vapor transmission rate (WVTR) of materials, such as, but not limited

to, paper, plastic films, other sheet materials, coatings, foams, fiberboards, gypsum and plaster products, wood products, and

plastics. Two basic methods, the Desiccant Method and the Water Method, are provided for the measurement of WVTR. In these

tests, the desired temperature and side-to-side humidity conditions, with resultant vapor drive through the specimen, are used. The

test conditions employed are at the discretion of the user, but in all cases, are reported with the results.

1.2 The values stated in either Inch-Pound or SI units are to be regarded separately as standard. The values stated in each system

are not necessarily exact equivalents; therefore, each system shall be used independently of the other. Derived results are converted

from one system to the other using appropriate conversion factors (see Table 1).

1

These test methods are under the jurisdiction of ASTM Committee C16 on Thermal Insulation and are the direct responsibility of Subcommittee C16.33 on Insulation

Finishes and Moisture.

Current edition approved Oct. 15, 2022Nov. 15, 2023. Published November 2022January 2024. Originally approved in 1953. Last previous edition approved in 2022 as

ε1

E96/E96M – 22.E96/E96M – 22a . DOI: 10.1520/E0096_E0096M-22AE01.10.1520/E0096_E0096M-23.

A,B

TABLE 1 Units and Conversion Factors

To Obtain (for the

Multiply by

same test condition)

WVTR

2 2

g/h·m 1.43 grains/h·ft

2 2

grains/h·ft 0.697 g/h·m

Water Vapor Permeance (WVP)

2 –2

ng/Pa·s·m 1.75 × 10 perm

2 7

g/Pa·s·m 1.75 × 10 perm

2

perm 57.2 ng/Pa·s·m

–8 2

perm 5.72 × 10 g/Pa·s·m

Permeability

ng/Pa·s·m 0.688 perm-inch

8

g/Pa·s·m 6.88 × 10 perm-inch

perm-inch 1.45 ng/Pa·s·m

–9

perm-inch 1.45 × 10 g/Pa·s·m

A

These units are commonly used in the construction and building materials

industries. Additional units are used in other industries, such as packaging.

B

All conversions of mm Hg to Pa are made at a temperature of 0°C.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E96/E96M − 23

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C168 Terminology Relating to Thermal Insulation

C1809 Practice for Preparation of Specimens and Reporting of Results for Permeance Testing of Pressure Sensitive Adhesive

Sealed Joints in Insulation Vapor Retarders

D449/D449M Specification for Asphalt Used in Dampproofing and Waterproofing

D2301 Specification for Vinyl Chloride Plastic Pressure-Sensitive Electrical Insulating Tape

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions of terms used in this standard will be found in Terminology C168, from which the following is quoted:

“water vapor permeability—the time rate of water vapor transmission through unit area of flat material of unit thickness induced

by unit vapor pressure difference between two specific surfaces, under specified temperature and humidity conditions.

Discussion—Permeability is a property of a material, but the permeability of

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E96/E96M − 23

Standard Test Methods for

Gravimetric Determination of Water Vapor Transmission

1

Rate of Materials

This standard is issued under the fixed designation E96/E96M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 These test methods cover the determination of water

C168 Terminology Relating to Thermal Insulation

vapor transmission rate (WVTR) of materials, such as, but not

C1809 Practice for Preparation of Specimens and Reporting

limited to, paper, plastic films, other sheet materials, coatings,

of Results for Permeance Testing of Pressure Sensitive

foams, fiberboards, gypsum and plaster products, wood

Adhesive Sealed Joints in Insulation Vapor Retarders

products, and plastics. Two basic methods, the Desiccant

D449/D449M Specification for Asphalt Used in Dampproof-

Method and the Water Method, are provided for the measure-

ing and Waterproofing

ment of WVTR. In these tests, the desired temperature and

D2301 Specification for Vinyl Chloride Plastic Pressure-

side-to-side humidity conditions, with resultant vapor drive

Sensitive Electrical Insulating Tape

through the specimen, are used. The test conditions employed

E177 Practice for Use of the Terms Precision and Bias in

are at the discretion of the user, but in all cases, are reported

ASTM Test Methods

with the results.

E691 Practice for Conducting an Interlaboratory Study to

1.2 The values stated in either Inch-Pound or SI units are to

Determine the Precision of a Test Method

be regarded separately as standard. The values stated in each

3. Terminology

system are not necessarily exact equivalents; therefore, each

3.1 Definitions of terms used in this standard will be found

system shall be used independently of the other. Derived

in Terminology C168, from which the following is quoted:

results are converted from one system to the other using

“water vapor permeability—the time rate of water vapor

appropriate conversion factors (see Table 1).

transmission through unit area of flat material of unit thickness

1.3 This standard does not purport to address all of the

induced by unit vapor pressure difference between two specific

safety concerns, if any, associated with its use. It is the

surfaces, under specified temperature and humidity conditions.

responsibility of the user of this standard to establish appro-

Discussion—Permeability is a property of a material, but the

priate safety, health, and environmental practices and deter-

permeability of a body that performs like a material may be

mine the applicability of regulatory limitations prior to use.

used. Permeability is the arithmetic product of permeance and

1.4 This international standard was developed in accor- thickness.

dance with internationally recognized principles on standard- water vapor permeance—the time rate of water vapor

ization established in the Decision on Principles for the transmission through unit area of flat material or construction

induced by unit vapor pressure difference between two specific

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical surfaces, under specified temperature and humidity conditions.

Discussion—Permeance is a performance evaluation and not

Barriers to Trade (TBT) Committee.

a property of a material.

water vapor transmission rate—the steady water vapor flow

in unit time through unit area of a body, normal to specific

1

These test methods are under the jurisdiction of ASTM Committee C16 on

Thermal Insulation and are the direct responsibility of Subcommittee C16.33 on

2

Insulation Finishes and Moisture. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 15, 2023. Published January 2024. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ε1

approved in 1953. Last previous edition approved in 2022 as E96/E96M – 22a . Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/E0096_E0096M-23. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E96/E96M − 23

A,B

TABLE 1 Units and Conversion Factors

5.2.4 Where tests are conducted for classification or com-

To Obtain (for the

pliance purposes, test conditions are typically defined in codes,

Multiply by

same test condition)

sp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.