ASTM D8259/D8259M-21

(Test Method)Standard Test Method for Rotary Wheel Testing (RWT) of Compacted Asphalt Mixtures

Standard Test Method for Rotary Wheel Testing (RWT) of Compacted Asphalt Mixtures

SIGNIFICANCE AND USE

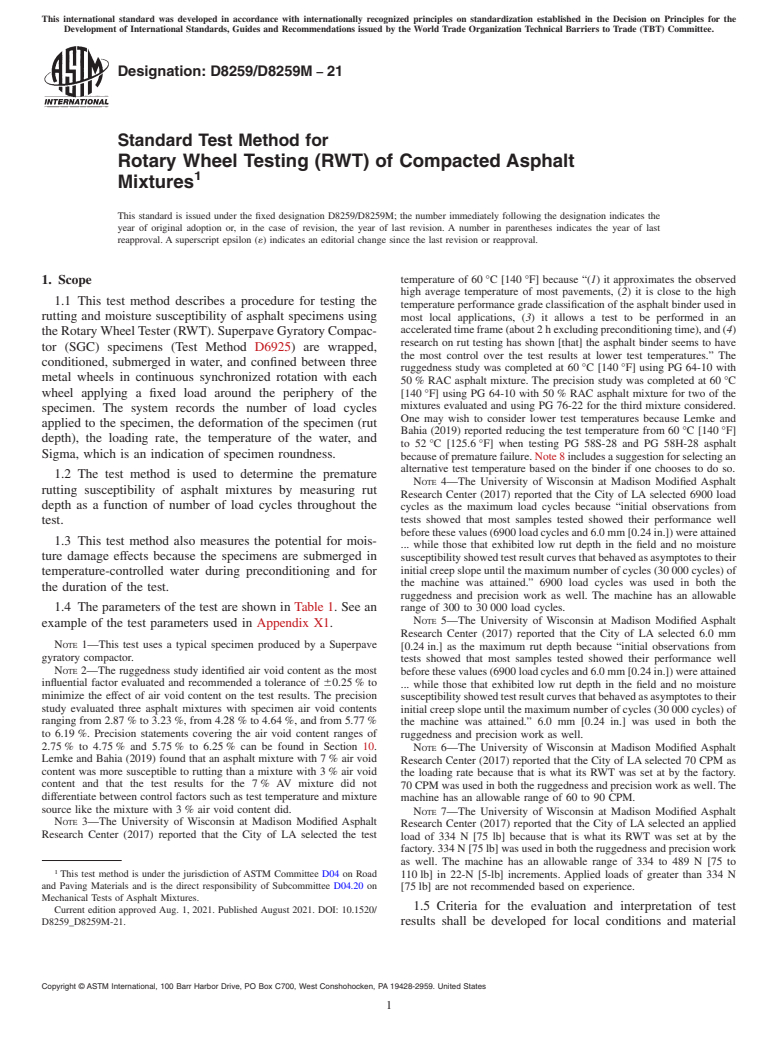

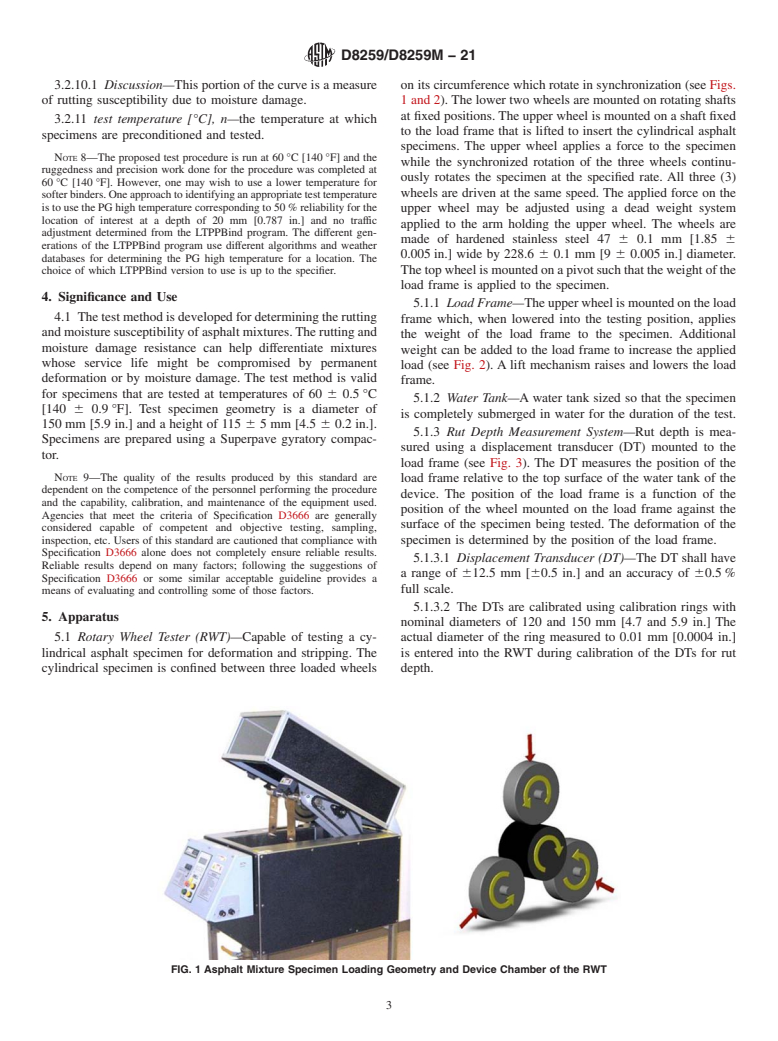

4.1 The test method is developed for determining the rutting and moisture susceptibility of asphalt mixtures. The rutting and moisture damage resistance can help differentiate mixtures whose service life might be compromised by permanent deformation or by moisture damage. The test method is valid for specimens that are tested at temperatures of 60 ± 0.5 °C [140 ± 0.9 °F]. Test specimen geometry is a diameter of 150 mm [5.9 in.] and a height of 115 ± 5 mm [4.5 ± 0.2 in.]. Specimens are prepared using a Superpave gyratory compactor.

Note 9: The quality of the results produced by this standard are dependent on the competence of the personnel performing the procedure and the capability, calibration, and maintenance of the equipment used. Agencies that meet the criteria of Specification D3666 are generally considered capable of competent and objective testing, sampling, inspection, etc. Users of this standard are cautioned that compliance with Specification D3666 alone does not completely ensure reliable results. Reliable results depend on many factors; following the suggestions of Specification D3666 or some similar acceptable guideline provides a means of evaluating and controlling some of those factors.

SCOPE

1.1 This test method describes a procedure for testing the rutting and moisture susceptibility of asphalt specimens using the Rotary Wheel Tester (RWT). Superpave Gyratory Compactor (SGC) specimens (Test Method D6925) are wrapped, conditioned, submerged in water, and confined between three metal wheels in continuous synchronized rotation with each wheel applying a fixed load around the periphery of the specimen. The system records the number of load cycles applied to the specimen, the deformation of the specimen (rut depth), the loading rate, the temperature of the water, and Sigma, which is an indication of specimen roundness.

1.2 The test method is used to determine the premature rutting susceptibility of asphalt mixtures by measuring rut depth as a function of number of load cycles throughout the test.

1.3 This test method also measures the potential for moisture damage effects because the specimens are submerged in temperature-controlled water during preconditioning and for the duration of the test.

1.4 The parameters of the test are shown in Table 1. See an example of the test parameters used in Appendix X1.

Note 1: This test uses a typical specimen produced by a Superpave gyratory compactor.

Note 2: The ruggedness study identified air void content as the most influential factor evaluated and recommended a tolerance of ±0.25 % to minimize the effect of air void content on the test results. The precision study evaluated three asphalt mixtures with specimen air void contents ranging from 2.87 % to 3.23 %, from 4.28 % to 4.64 %, and from 5.77 % to 6.19 %. Precision statements covering the air void content ranges of 2.75 % to 4.75 % and 5.75 % to 6.25 % can be found in Section 10. Lemke and Bahia (2019) found that an asphalt mixture with 7 % air void content was more susceptible to rutting than a mixture with 3 % air void content and that the test results for the 7 % AV mixture did not differentiate between control factors such as test temperature and mixture source like the mixture with 3 % air void content did.

Note 3: The University of Wisconsin at Madison Modified Asphalt Research Center (2017) reported that the City of LA selected the test temperature of 60 °C [140 °F] because “(1) it approximates the observed high average temperature of most pavements, (2) it is close to the high temperature performance grade classification of the asphalt binder used in most local applications, (3) it allows a test to be performed in an accelerated time frame (about 2 h excluding preconditioning time), and (4) research on rut testing has shown [that] the asphalt binder seems to have the most control over the test results at lower test temperatures.” The ruggedness study was comple...

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8259/D8259M − 21

Standard Test Method for

Rotary Wheel Testing (RWT) of Compacted Asphalt

1

Mixtures

This standard is issued under the fixed designation D8259/D8259M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

temperature of 60 °C [140 °F] because “(1) it approximates the observed

1. Scope

high average temperature of most pavements, (2) it is close to the high

1.1 This test method describes a procedure for testing the

temperature performance grade classification of the asphalt binder used in

rutting and moisture susceptibility of asphalt specimens using most local applications, (3) it allows a test to be performed in an

acceleratedtimeframe(about2 hexcludingpreconditioningtime),and(4)

the RotaryWheelTester (RWT). Superpave Gyratory Compac-

research on rut testing has shown [that] the asphalt binder seems to have

tor (SGC) specimens (Test Method D6925) are wrapped,

the most control over the test results at lower test temperatures.” The

conditioned, submerged in water, and confined between three

ruggedness study was completed at 60 °C [140 °F] using PG 64-10 with

metal wheels in continuous synchronized rotation with each

50 % RAC asphalt mixture. The precision study was completed at 60 °C

wheel applying a fixed load around the periphery of the [140 °F] using PG 64-10 with 50 % RAC asphalt mixture for two of the

mixtures evaluated and using PG 76-22 for the third mixture considered.

specimen. The system records the number of load cycles

One may wish to consider lower test temperatures because Lemke and

applied to the specimen, the deformation of the specimen (rut

Bahia (2019) reported reducing the test temperature from 60 °C [140 °F]

depth), the loading rate, the temperature of the water, and

to 52 °C [125.6 °F] when testing PG 58S-28 and PG 58H-28 asphalt

Sigma, which is an indication of specimen roundness.

becauseofprematurefailure.Note8includesasuggestionforselectingan

alternative test temperature based on the binder if one chooses to do so.

1.2 The test method is used to determine the premature

NOTE 4—The University of Wisconsin at Madison Modified Asphalt

rutting susceptibility of asphalt mixtures by measuring rut

Research Center (2017) reported that the City of LA selected 6900 load

depth as a function of number of load cycles throughout the

cycles as the maximum load cycles because “initial observations from

tests showed that most samples tested showed their performance well

test.

beforethesevalues(6900loadcyclesand6.0mm[0.24in.])wereattained

1.3 This test method also measures the potential for mois-

... while those that exhibited low rut depth in the field and no moisture

ture damage effects because the specimens are submerged in

susceptibilityshowedtestresultcurvesthatbehavedasasymptotestotheir

initial creep slope until the maximum number of cycles (30 000 cycles) of

temperature-controlled water during preconditioning and for

the machine was attained.” 6900 load cycles was used in both the

the duration of the test.

ruggedness and precision work as well. The machine has an allowable

1.4 The parameters of the test are shown in Table 1. See an

range of 300 to 30 000 load cycles.

NOTE 5—The University of Wisconsin at Madison Modified Asphalt

example of the test parameters used in Appendix X1.

Research Center (2017) reported that the City of LA selected 6.0 mm

NOTE 1—This test uses a typical specimen produced by a Superpave

[0.24 in.] as the maximum rut depth because “initial observations from

gyratory compactor.

tests showed that most samples tested showed their performance well

NOTE 2—The ruggedness study identified air void content as the most

beforethesevalues(6900loadcyclesand6.0mm[0.24in.])wereattained

influential factor evaluated and recommended a tolerance of 60.25 % to

... while those that exhibited low rut depth in the field and no moisture

minimize the effect of air void content on the test results. The precision

susceptibilityshowedtestresultcurvesthatbehavedasasymptotestotheir

study evaluated three asphalt mixtures with specimen air void contents

initial creep slope until the maximum number of cycles (30 000 cycles) of

ranging from 2.87 % to 3.23 %, from 4.28 % to 4.64 %, and from 5.77 %

the machine was attained.” 6.0 mm [0.24 in.] was used in both the

to 6.19 %. Precision statements covering the air void content ranges of

ruggedness and precision work as well.

2.75 % to 4.75 % and 5.75 % to 6.25 % can be found in Sectio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.