ASTM C1579-13

(Test Method)Standard Test Method for Evaluating Plastic Shrinkage Cracking of Restrained Fiber Reinforced Concrete (Using a Steel Form Insert)

Standard Test Method for Evaluating Plastic Shrinkage Cracking of Restrained Fiber Reinforced Concrete (Using a Steel Form Insert)

SIGNIFICANCE AND USE

4.1 The test method is intended to evaluate the effects of evaporation, settlement, and early autogenous shrinkage on the plastic shrinkage cracking performance of fiber reinforced concrete up to and for some hours beyond the time of final setting (See Terminology C125).

4.2 The measured values obtained from this test may be used to compare the performance of concretes with different mixture proportions, concretes with and without fibers, concretes containing various amounts of different types of fibers, and concretes containing various amounts and types of admixtures. For meaningful comparisons, the evaporative conditions during test shall be sufficient to produce an average crack width of at least 0.5 mm in the control specimens (2, 5) (See Note 2). In addition, the evaporation rate from a free surface of water shall be within ± 5 % for each test.Note 2—To achieve evaporation rates that result in a crack of at least 0.5 mm in the control specimens, it may be necessary to use an evaporation rate higher than that discussed in Note 1.

4.3 This method attempts to control atmospheric variables to quantify the relative performance of a given fresh concrete mixture. Since many other variables such as cement fineness, aggregate gradation, aggregate volume, mixing procedures, slump, air content, concrete temperature and surface finish can also influence potential cracking, attention shall be paid to keep these as consistent as possible from mixture to mixture.

SCOPE

1.1 This test method compares the surface cracking of fiber reinforced concrete panels with the surface cracking of control concrete panels subjected to prescribed conditions of restraint and moisture loss that are severe enough to produce cracking before final setting of the concrete.

1.2 This test method can be used to compare the plastic shrinkage cracking behavior of different concrete mixtures containing fiber reinforcement.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (Warning— fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure.)2

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1579 − 13

Standard Test Method for

Evaluating Plastic Shrinkage Cracking of Restrained Fiber

1

Reinforced Concrete (Using a Steel Form Insert)

This standard is issued under the fixed designation C1579; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* C670 Practice for Preparing Precision and Bias Statements

for Test Methods for Construction Materials

1.1 This test method compares the surface cracking of fiber

reinforced concrete panels with the surface cracking of control

3. Summary of Test Method

concrete panels subjected to prescribed conditions of restraint

3.1 Panels of control concrete and fiber reinforced concrete

and moisture loss that are severe enough to produce cracking

are prepared in a prescribed manner and are exposed to

before final setting of the concrete.

controlled drying conditions after finishing. The drying condi-

1.2 This test method can be used to compare the plastic

tions (see Note 1) are intended to be severe enough to induce

shrinkage cracking behavior of different concrete mixtures

plastic shrinkage cracking in test panels made of control

containing fiber reinforcement.

concrete. The evaporation rate from a free water surface is

1.3 The values stated in SI units are to be regarded as

monitored by pans placed next to the panels in the environ-

standard. No other units of measurement are included in this

mental chamber.

standard. NOTE 1—An important parameter in this method is the rate of

evaporative water loss, which is controlled by the atmospheric conditions

1.4 This standard does not purport to address all of the

surrounding the test specimens. Since the concrete specimens will not

safety concerns, if any, associated with its use. It is the

always have the same rate of water evaporation as the pan of water (due

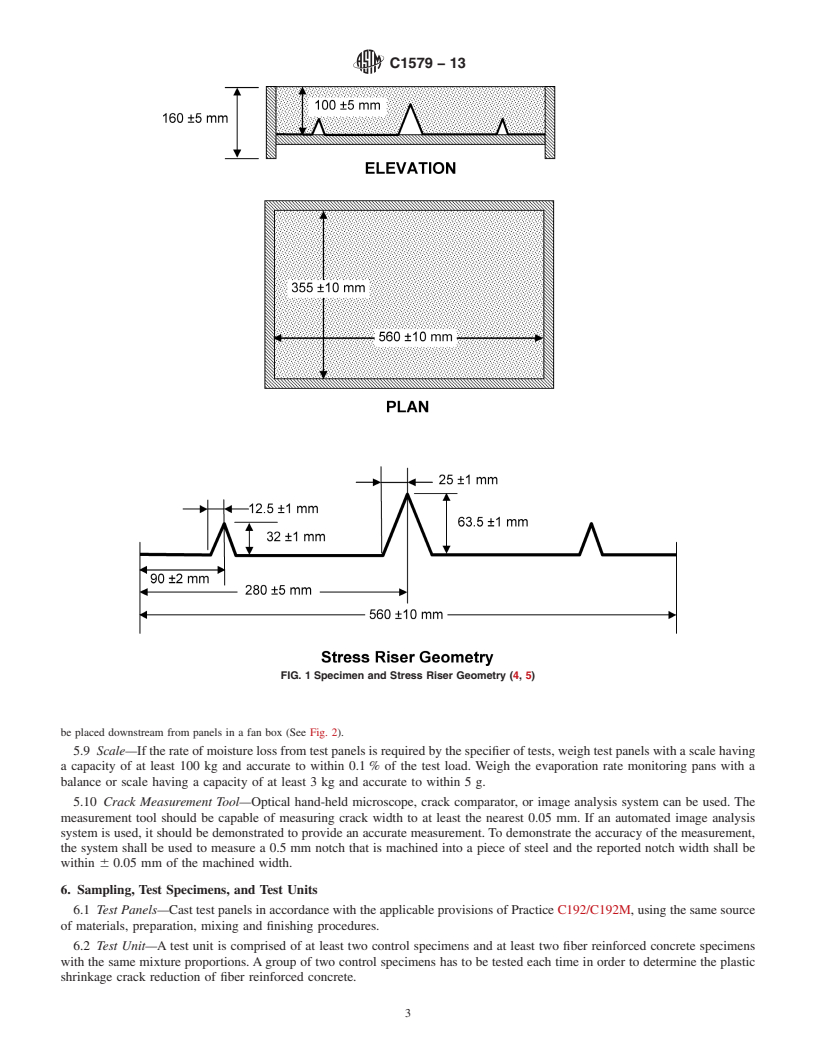

2

responsibility of the user of this standard to establish appro- toevaporativeandbleedingeffects),therateofevaporationof1.0kg/m ·h

from the pan of water represents the minimum evaporation rate that must

priate safety and health practices and determine the applica-

4

be attained for this test (1). The moisture loss from the concrete test

bility of regulatory limitations prior to use. (Warning—fresh

panels can also be monitored and reported, however, the rate of evapora-

hydraulic cementitious mixtures are caustic and may cause

tion from the free surface of the water in the pan is the parameter that

2

chemical burns to skin and tissue upon prolonged exposure. )

should be used to quantify the drying environment.

3.2 The test is terminated at the time of final setting of the

2. Referenced Documents

concrete determined in accordance with Test Method C403/

3

2.1 ASTM Standards:

C403M. At 24 h from initial mixing, the average crack width

C125 Terminology Relating to Concrete and Concrete Ag-

is determined.

gregates

3.3 A cracking reduction ratio (CRR) is computed from the

C143/C143M Test Method for Slump of Hydraulic-Cement

average crack width for the fiber-reinforced concrete panels

Concrete

and the average crack width for the control concrete panels.

C192/C192M Practice for Making and Curing Concrete Test

Specimens in the Laboratory

4. Significance and Use

C403/C403M Test Method for Time of Setting of Concrete

4.1 The test method is intended to evaluate the effects of

Mixtures by Penetration Resistance

evaporation, settlement, and early autogenous shrinkage on the

plastic shrinkage cracking performance of fiber reinforced

1

concrete up to and for some hours beyond the time of final

This test method is under the jurisdiction of ASTM Committee C09 on

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

setting (see Terminology C125).

C09.42 on Fiber-Reinforced Concrete.

4.2 The measured values obtained from this test may be

Current edition approved April 1, 2013. Published May 2013. Originally

published in 2006. Last previous edition approved in 2012 as C1579 – 06 (2012).

used to compare the performance of concretes with different

DOI: 10.1520/C1579-13.

mixture proportions, concretes with and without fibers, con-

2

Section on Safety Precautions, Manual of Aggregate and Concrete Testing,

cretes containing various amounts of different types of fibers,

Annual Book of ASTM Standards, Vol 04.02.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to the list of references at the end of

the ASTM website. this standard.

*A

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1579 − 06 (Reapproved 2012) C1579 − 13

Standard Test Method for

Evaluating Plastic Shrinkage Cracking of Restrained Fiber

1

Reinforced Concrete (Using a Steel Form Insert)

This standard is issued under the fixed designation C1579; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method compares the surface cracking of fiber reinforced concrete panels with the surface cracking of control

concrete panels subjected to prescribed conditions of restraint and moisture loss that are severe enough to produce cracking before

final setting of the concrete.

1.2 This test method can be used to compare the plastic shrinkage cracking behavior of different concrete mixtures containing

fiber reinforcement.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. (Warning— fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and

2

tissue upon prolonged exposure.)

2. Referenced Documents

3

2.1 ASTM Standards:

C125 Terminology Relating to Concrete and Concrete Aggregates

C143/C143M Test Method for Slump of Hydraulic-Cement Concrete

C192/C192M Practice for Making and Curing Concrete Test Specimens in the Laboratory

C403/C403M Test Method for Time of Setting of Concrete Mixtures by Penetration Resistance

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

4

C995 Test Method for Time of Flow of Fiber-Reinforced Concrete Through Inverted Slump Cone (Withdrawn 2009)

3. Summary of Test Method

3.1 Panels of control concrete and fiber reinforced concrete are prepared in a prescribed manner and are exposed to controlled

drying conditions after finishing. The drying conditions (See Note 1) are intended to be severe enough to induce plastic shrinkage

cracking in test panels made of control concrete. The evaporation rate from a free water surface is monitored by pans placed next

to the panels in the environmental chamber.

NOTE 1—An important parameter in this method is the rate of evaporative water loss, which is controlled by the atmospheric conditions surrounding

the test specimens. Since the concrete specimens will not always have the same rate of water evaporation as the pan of water (due to evaporative and

2

bleeding effects), the rate of evaporation of 1.0 kg/m ·h from the pan of water represents the minimum evaporation rate that must be attained for this test

4

(1). The moisture loss from the concrete test panels can also be monitored and reported, however, the rate of evaporation from the free surface of the

water in the pan is the parameter that should be used to quantify the drying environment.

3.2 The test is terminated at the time of final setting of the concrete determined in accordance with Test Method C403/C403M.

At 24 h from initial mixing, the average crack width is determined.

1

This test method is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.42 on

Fiber-Reinforced Concrete.

Current edition approved April 1, 2012April 1, 2013. Published October 2012May 2013. Originally published in 2006. Last previous edition approved in 2012 as

C1579–06(2012). DOI: 10.1520/C1579-06R12.10.1520/C1579-13.

2

Section on Safety Precautions, Manual of Aggregate and Concrete Testing, Annual Book of ASTM Standards, Vol. 04.02.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

The last approved version of this historical standard is referenced on www.astm.org.

4

The boldface numbers in parentheses refer to the list of references at the end of this standard.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 194

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.