ASTM F1430-98

(Test Method)Standard Test Method for Acoustic Emission Testing of Insulated Aerial Personnel Devices with Supplemental Load Handling Attachments

Standard Test Method for Acoustic Emission Testing of Insulated Aerial Personnel Devices with Supplemental Load Handling Attachments

SCOPE

1.1 This test method describes a procedure for acoustic emission (AE) testing of insulated aerial personnel devices (IAPDs) with supplemental load handling attachments.

1.1.1 Equipment Covered -This test method covers the following types of vehicle-mounted insulated aerial personnel devices with supplemental load handling attachments:

1.1.1.1 Extensible-boom IAPDs,

1.1.1.2 Articulating-boom IAPDs, and

1.1.1.3 Any combination of 1.1.1.1 and 1.1.1.2.

1.1.2 Equipment Not Covered -This test method does not cover any of the following equipment:

1.1.2.1 Noninsulated aerial devices,

1.1.2.2 Insulated aerial personnel devices without supplemental load handling attachments,

1.1.2.3 Digger-derricks with platform,

1.1.2.4 Cranes with platform, and

1.1.2.5 Aerial devices with load-lifting capabilities located anywhere other than adjacent to the platform.

1.2 The AE test method is used to detect and area-locate emission sources. Verification of emission sources may require the use of other nondestructive test (NDT) methods, such as radiography, ultrasonics, magnetic particle, liquid penetrant, and visual inspection. Note 1-This test method requires that external loads be applied to the superstructure of the vehicle under test. During the test, caution must be taken to safeguard personnel and equipment against unexpected failure or instability of the vehicle or components.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1430 – 98

Standard Test Method for

Acoustic Emission Testing of Insulated Aerial Personnel

Devices with Supplemental Load Handling Attachments

This standard is issued under the fixed designation F 1430; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope tures During Controlled Stimulation

E 650 Guide for Mounting Piezoelectric Acoustic Emission

1.1 This test method describes a procedure for acoustic

Sensors

emission (AE) testing of insulated aerial personnel devices

E 750 Practice for Characterizing Acoustic Emission Instru-

(IAPDs) with supplemental load handling attachments.

mentation

1.1.1 Equipment Covered—This test method covers the

E 976 Guide for Determining the Reproducibility of Acous-

following types of vehicle-mounted insulated aerial personnel

tic Emission Sensor Response

devices with supplemental load handling attachments:

E 1067 Practice for Acoustic Emission Testing of Fiberglass

1.1.1.1 Extensible-boom IAPDs,

Reinforced Plastic Resin (FRP) Tanks/Vessels

1.1.1.2 Articulating-boom IAPDs, and

E 1316 Terminology for Nondestructive Examinations

1.1.1.3 Any combination of 1.1.1.1 and 1.1.1.2.

F 914 Test Method for Acoustic Emission for Insulated

1.1.2 Equipment Not Covered—This test method does not

Aerial Personnel Devices

cover any of the following equipment:

2.2 Other Standards:

1.1.2.1 Noninsulated aerial devices,

ANSI A92.2 Standard for Vehicle-Mounted Elevating and

1.1.2.2 Insulated aerial personnel devices without supple-

Rotating Aerial Devices

mental load handling attachments,

ASNT SNT-TC-1A Recommended Practice for Personnel

1.1.2.3 Digger-derricks with platform,

Qualification and Certification in Nondestructive Testing

1.1.2.4 Cranes with platform, and

Equipment Manufacturer’s Institute, Manufacturers of

1.1.2.5 Aerial devices with load-lifting capabilities located

Aerial Devices and Digger-Derricks Council (EMI/

anywhere other than adjacent to the platform.

MADDDC), Nomenclature and Specifications for Truck-

1.2 The AE test method is used to detect and area-locate

Mounted:

emission sources. Verification of emission sources may require

(a) Extensible Aerial Devices,

the use of other nondestructive test (NDT) methods, such as

(b) Articulating Aerial Devices, and

radiography, ultrasonics, magnetic particle, liquid penetrant,

(c) Digger-Derricks

and visual inspection.

NOTE 1—Warning: This test method requires that external loads be 3. Terminology

applied to the superstructure of the vehicle under test. During the test,

3.1 Definitions:

caution must be taken to safeguard personnel and equipment against

3.1.1 acoustic emission (AE)—the class of phenomena

unexpected failure or instability of the vehicle or components.

whereby elastic waves are generated by the rapid release of

1.3 This standard does not purport to address all of the

energy from a localized source or sources within a material, or

safety problems, if any, associated with its use. It is the

the transient elastic wave(s) so generated. Acoustic emission is

responsibility of the user of this standard to establish appro-

the recommended term for general use. Other terms that have

priate safety and health practices and determine the applica-

been used in AE literature include (1) stress wave emission, (2)

bility of regulatory limitations prior to use.

microseismic activity, and (3) emission or acoustic emission

with other qualifying modifiers.

2. Referenced Documents

3.1.2 amplitude (acoustic emission signal amplitude)—the

2.1 ASTM Standards:

peak voltage of the largest excursion attained by the signal

E 569 Practice for Acoustic Emission Monitoring of Struc-

Annual Book of ASTM Standards, Vol 03.03.

Annual Book of ASTM Standards, Vol 10.03.

Available from the American National Standards Institute, 11 West 42nd Street,

This test method is under the jurisdiction of ASTM Committee F-18 on

13th Floor, New York, NY 10036.

Electrical Protective Equipment for Workers and is the direct responsibility of

Available from American Society of Nondestructive Testing, 4153 Arlingate

Subcommittee F18.55 on Acoustic Emission.

Plaza, Caller #28518, Columbus, OH 43228.

Current edition approved Nov. 10, 1998. Published February 1999. Originally

Available from the Equipment Manufacturer’s Institute, 410 N. Michigan Ave.,

published as F 1430–92. Last previous edition F 1430–92.

Chicago, IL 60611.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1430

waveform from an emission event. usually FRP or the equivalent.

3.1.17 noise—any undesired signal that tends to interfere

3.1.3 amplitude distribution—a display of the number of

acoustic emission events with signals that exceed an arbitrary with the normal reception or processing of the desired signal.

amplitude as a function of amplitude.

3.1.18 non-overcenter—the feature of an aerial device is

such that the upper boom cannot travel past vertical orientation

3.1.4 articulating-boom aerial device—an aerial device

with two or more hinged boom sections. with respect to the ground.

3.1.5 attenuation—the loss of energy per unit distance, 3.1.19 overcenter—the feature of an aerial device is such

that the upper boom travels past vertical orientation with

typically measured as loss of signal peak amplitude with unit

respect to the ground.

distance from the source of emission.

3.1.20 qualified personnel—personnel who, by possession

3.1.6 channel—an input to the main AE instrument that

of a recognized degree, certificate, professional standing, or

accepts a preamplifier output.

skill, and who, by knowledge, training, and experience, have

3.1.7 commoned—two or more sensors interconnected such

demonstrated the ability to deal with problems relating to the

that the sensor outputs are electronically processed by a single

subject matter, the work, or the project.

channel without differentiation of sensor origin.

3.1.21 rated load capacity (RLC)—the maximum allowable

3.1.8 count also acoustic emission count,, n—the number of

load as stated by the aerial device manufacturer which by

times the acoustic emission signal amplitude exceeds a preset

combination of the platform load and supplemental load, may

threshold during any selected portion of a test.

be placed on the aerial device at a designated boom position

3.1.9 decibel (dB)—the logarithmic expression of a ratio of

and a designated SLHA orientation.

two single peak amplitudes. A reference scale expresses the

3.1.22 signal (emission signal)—a signal obtained by detec-

logarithmic ratio of a single peak amplitude to a fixed reference

tion of one or more acoustic emission events.

amplitude.

3.1.23 supplemental load—a load which may be affixed to a

Signal peak amplitude ~dB! 5 20 log ~A /A !

10 1 0

supplemental load-handling attachment on an insulated aerial

personnel device.

where:

3.1.24 supplemental load attachment capacity (SLAC)—the

A = 1 uV at the sensor output (before amplification), and

0 maximum allowable load, as stated by the aerial device

A = peak voltage of the measured acoustic emission

1 manufacturer, which may be affixed to the supplemental

signal.

load-handling attachment at specified positions of the attach-

Acoustic Emission Reference Scale

ments.

dB Value Voltage At Voltage At Integral Preamp Sen-

3.1.25 For definitions of other terms in this test method,

Sensor Output sor Output (40-dB Gain)

refer to Terminology E 1316 and EMI/MADDDC.

0 1 μV 100 μV

20 10 μV 1 mV

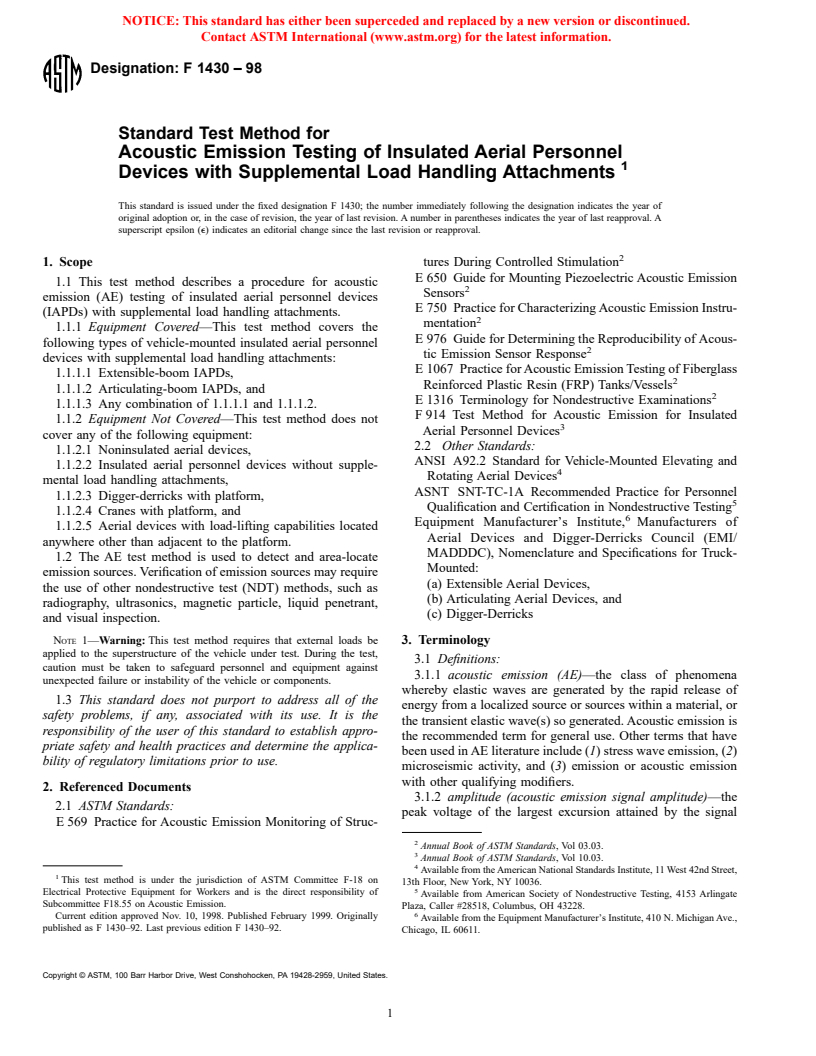

3.2 Definitions of Terms Specific to This Standard: (see Fig.

40 100 μV 10 mV

1 and Fig. 2):

60 1 mV 100 mV

80 10 mV 1 V

3.2.1 elbow—the structure connecting the upper boom to

100 100 mV 10 V

the lower boom, about which one boom articulates relative to

the other.

3.1.10 insulated aerial personnel device (IAPD)—any de-

3.2.2 elbow pin—the horizontal pin about which the upper

vice (extensible or articulating) which is designed primarily to

boom rotates relative to the lower boom.

position personnel and may be equipped with a supplemental

3.2.3 lift cylinder—the hydraulic cylinder that lifts the

load handling attachment.

lower boom and the extensible boom(s).

3.1.11 event (acoustic emission event)—a local material

change giving rise to acoustic emission. 3.2.4 lower boom—the structural member, attached to a

turntable or base, that supports the upper boom.

3.1.12 event count (N )—the number obtained by counting

e

3.2.5 lower-boom cylinder—the hydraulic cylinder that ar-

each discerned acoustic emission event once.

ticulates the lower boom.

3.1.13 extensible-boom aerial device—an aerial device, ex-

cept the aerial ladder type, with a telescopic or extensible 3.2.6 lower-boom insulator—the part of the lower boom

made of high-dielectric strength material (usually fiberglass

boom.

reinforced plastic or equivalent).

3.1.14 first-hit—a mode of operation of AE monitoring

equipment in which an event occurring on one channel will 3.2.7 lower-boom pin—the horizontal pin about which the

lower boom is raised and lowered relative to the turntable.

prevent all other channels from processing data for a specified

period of time. The channel with a sensor closest to the 3.2.8 outriggers—the structural members that, when prop-

erly extended or deployed on firm ground, assist in stabilizing

physical location of the emission source will then be the only

channel processing data from that source. the vehicle on which the aerial device is mounted.

3.1.15 insulated aerial device—an aerial device designed 3.2.9 pedestal—the stationary base of the aerial device that

supports the turntable.

with dielectric components to meet a specific electrical insu-

lation rating. 3.2.10 platform—the personnel-carrying component of an

3.1.16 insulator—any part of an aerial device such as, but aerial device, such as a bucket, basket, stand, or equivalent.

not limited to, the upper boom, lower boom or supporting 3.2.11 platform pin—the horizontal pin about which the

structure, made of a material having a high dielectric strength, platform rotates relative to the upper boom.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1430

1. Upper Controls 8. Elbow 15. Pedestal

2. Platform 9. Elbow Pin 16. Lower Controls

3. Platform Pin 10. Lower Boom 17. Outriggers

4. Upper Boom Tip 11. Lower Boom Insulator 18. Outrigger Controls

5. Upper Boom 12. Lower Boom Cylinder 19. Stabilizers

6. Upper Boom Cylinder 13. Lower Boom Pin 20. Supplemental Load Handling Attachment Arm

7. Upper Boom Drive Mechanism 14. Turntable 21. Supplemental Load Handling Attachment Bracket

FIG. 1 Articulating-Boom IAPD Nomenclature Diagram

3.2.12 rated platform capacity (RPC)—the maximum load 3.3 Abbreviations:

as stated by the manufacturer for which an aerial device is 3.3.1 AE—Acoustic Emission

designed to operate, consisting of the combined weight of the 3.3.2 FRP—Fiberglass Reinforced Plastic

personnel and all items carried on or in the platform. 3.3.3 IAPD—Insulated Aerial Personnel Device(s)

3.2.13 stabilizers—a means to assist in stabilizing the ve- 3.3.4 NDT—Nondestructive Testing

hicle, such as outriggers, torsion bars, and spring lockouts. 3.3.5 RLC—Rated Load Capacity

3.2.14 supplemental load-handling attachment (SLHA)—a 3.3.6 RPC—Rated Platform Capacity

device(s) affixed to the upper-boom tip area which is designed 3.3.7 SLHA—Supplemental Load Handling Attachment

to lift and or position materials. 3.3.8 SLAC—Supplemental Load Attachment Capacity

3.2.15 supplemental load-handling attachment bracket—

4. Summary of Test Method

the apparatus which affixes the supplemental load handling

attachment to the IAPD. 4.1 This test method consists of applying a predetermined

3.2.16 turntable—the rotating base of the aerial device that load to an IAPD while it is being monitored by sensors that are

supports the boom(s). sensitive to acoustic emissions (AE) caused by active defects.

3.2.17 upper boom—the structural member, attached to the These acoustic emissions can be generated by, but are not

lower boom, that supports the platform. limited to, the following: crack nucleation movement or

3.2.18 upper-boom cylinder—the hydraulic cylinder that propagation in the metal components; or matrix crazing,

articulates the upper boom. delamination or fiber breakage of the fiberglass reinforced

3.2.19 upper-boom drive mechanism—means, such as link- plastic (FRP) material; or both.

age, cables, sheaves, and gears, used to produce upper-boom 4.2 The IAPD is loaded at a uniform rate until a predeter-

articulation. mined load is reached, which is held for a period of time. The

3.2.20 upper-boom tip—the end of the upper boom to which load is removed and the cycle is repeated. Acoustic emissions

the platform is attached. are monitored during both cycles and the data is evaluated.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1430

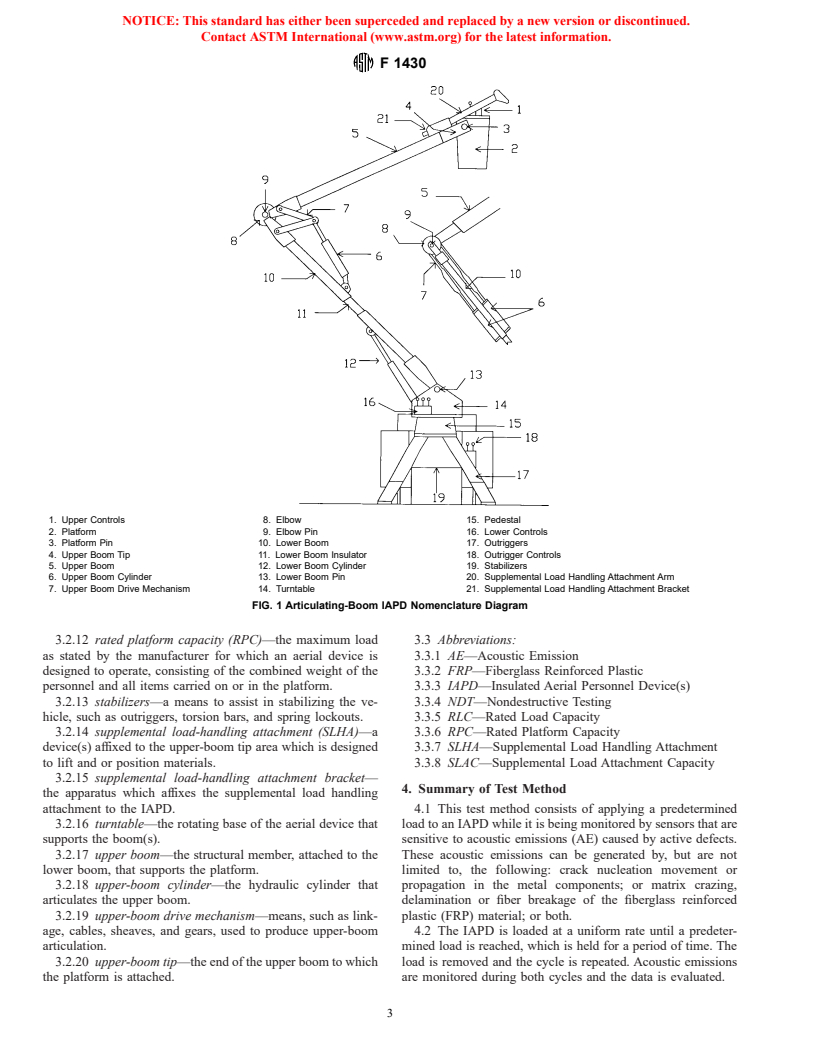

1. Upper Controls 10. Lift Cylinder

2. Platform 11. Turntable

3. Platform Pin 12. Pedestal

4. Upper Boom Tip 13. Lower Controls

5. Upper Boom 14. Outriggers

6. Intermediate Boom 15. Outrigger Controls

7. Lower Boom 16. Stabilizers

8. Extension Cylinder 17. Supplemental Load Handling Attachment Arm

9. Lower Boom Pin 18. Supplemental Load Handling Attachment Bracket

FIG. 2 Extensible-Boom IAPD Nomenclature Diagram

5. Significance and Use (visual, liquid penetrant, radiography, ultrasonics, magnetic

particle, etc.). Other nondestructive tests may be required to

5.1 This test method provides a means of evaluating acous-

locate defects present in IAPDs.

tic emissions generated by the rapid release of energy from

5.5 Defective areas found in aerial devices by this test

localized sources within an IAPD under controlled loading.

method should be repaired and retested as appropriate. Repair

The resultant energy releases occur during intentional applica-

procedure recommendations are outside the scope of this test

tion of a controlled predetermined load. These energy releases

method.

can be monitored and interpreted by qualified individuals.

5.2 This test method permits testing of the major compo-

6. Personnel Qualificati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.