ASTM D5968-06(2013)

(Test Method)Standard Test Method for Evaluation of Corrosiveness of Diesel Engine Oil at 121 °C

Standard Test Method for Evaluation of Corrosiveness of Diesel Engine Oil at 121 °C

SIGNIFICANCE AND USE

4.1 This test method is intended to simulate the corrosion process of non-ferrous metals in diesel lubricants. The corrosion process under investigation is that believed to be induced primarily by inappropriate lubricant chemistry rather than lubricant degradation or contamination. This test method has been found to correlate with an extensive fleet database containing corrosion-induced cam and bearing failures.

SCOPE

1.1 This test method is used to test diesel engine lubricants to determine their tendency to corrode various metals, specifically alloys of lead and copper commonly used in cam followers and bearings. Correlation with field experience has been established.4

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in 5.3.1, 6.6, 6.7, 6.8, 6.9, 6.10, 6.11, 7.1.1, 7.1.2, 7.1.5, and 7.4.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5968 − 06(Reapproved 2013)

Standard Test Method for

Evaluation of Corrosiveness of Diesel Engine Oil at 121 °C

This standard is issued under the fixed designation D5968; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The method described in this test method is based on the gas turbine lubricant corrosion and

oxidation test described in FederalTest Method Standard 791, Method 5308. Because this test method

relates to corrosion in diesel engines rather than in gas turbines, temperatures, metal coupons, and

certain parts of the test procedure were modified to be more appropriate for heavy duty diesel engines.

The method described in this test method can be used by any properly equipped laboratory, without

outside assistance. However, the ASTM Test Monitoring Center (TMC) provides reference oils and

an assessment of the test results obtained on those oils by the laboratory (see Annex A1). By these

means, the laboratory will know whether their use of the test method gives results statistically similar

to those obtained by other laboratories. Furthermore, various agencies require that a laboratory utilize

the TMC services in seeking qualification of oils against specifications. For example, the U.S. Army

imposes such a requirement in connection with several Army engine lubricating oil specifications.

Accordingly, this test method is written for use by laboratories that utilize the TMC services.

Laboratories that choose not to use those services may simply ignore those portions of the test method

that refer to the TMC.

This test method may be modified by means of Information Letters issued by theTMC. In addition,

the TMC may issue supplementary memoranda related to the method (see Annex A1). For other

information, refer to the research report on the Cummins Bench Corrosion Test.

1. Scope 1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method is used to test diesel engine lubricants

responsibility of the user of this standard to establish appro-

to determine their tendency to corrode various metals, specifi-

priate safety and health practices and determine the applica-

cally alloys of lead and copper commonly used in cam

bility of regulatory limitations prior to use. Specific hazard

followers and bearings. Correlation with field experience has

statements are given in 5.3.1, 6.6, 6.7, 6.8, 6.9, 6.10, 6.11,

been established.

7.1.1, 7.1.2, 7.1.5, and 7.4.1.

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

2. Referenced Documents

standard.

2.1 ASTM Standards:

D130 Test Method for Corrosiveness to Copper from Petro-

This test method is under the jurisdiction of ASTM Committee D02 on leum Products by Copper Strip Test

Petroleum Products, Liquid Fuels, and Lubricantsand is the direct responsibility of

D5185 Test Method for Multielement Determination of

Subcommittee D02.B0.02 on Heavy Duty Engine Oils.

Used and Unused Lubricating Oils and Base Oils by

Current edition approved Oct. 1, 2013. Published October 2013. Originally

Inductively Coupled Plasma Atomic Emission Spectrom-

approved in 1998. Last previous edition approved in 2006 as D5968 – 06. DOI:

10.1520/D5968-06R13.

etry (ICP-AES)

ASTM Test Monitoring Center, 6555 Penn Ave., Pittsburgh, PA 15206-4489.

E691 Practice for Conducting an Interlaboratory Study to

(http://www.astmtmc.cmu.edu/)

Determine the Precision of a Test Method

Supporting data have been filed at ASTM International Headquarters and may

be obtained by requesting Research Report RR:D02-1322. The research report and

this test method are supplemented by Information Letters and Memoranda issued by

theASTM Test Monitoring Center. This edition incorporates revisions contained in

all information letters through No. 05–1. Users of this test method shall contact the For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ASTM Test Monitoring Center to obtain the most recent of these. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Wang, J. C., and Cusano, C. M., “Development ofABench Test to Detect Oils Standards volume information, refer to the standard’s Document Summary page on

Corrosive to Engine Components,” SAE Technical Paper No. 940790, 1994. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5968 − 06 (2013)

FIG. 2 Sample Tube Head

FIG. 1 Sample Tube

2.2 U.S. Federal Test Method Standards:

Federal Test Method Standard 791, Method 5308.7 Corro-

siveness and Oxidation Stability of Light Oils (Metal

Squares)

3. Summary of Test Method

3.1 Four metal coupons of copper, lead, tin, and phosphor

bronze are immersed in a measured amount of engine oil. The

oil,atanelevatedtemperature,isblownwithairforaperiodof

time. When the test is completed, the coupons and the stressed

oil are examined to detect corrosion.

3.2 An industrial reference oil is tested with each group of

tests to verify test acceptability.

4. Significance and Use

4.1 This test method is intended to simulate the corrosion

process of non-ferrous metals in diesel lubricants. The corro-

sion process under investigation is that believed to be induced

primarily by inappropriate lubricant chemistry rather than

lubricant degradation or contamination. This test method has

been found to correlate with an extensive fleet database

FIG. 3 Air Tube

containing corrosion-induced cam and bearing failures.

5. Apparatus

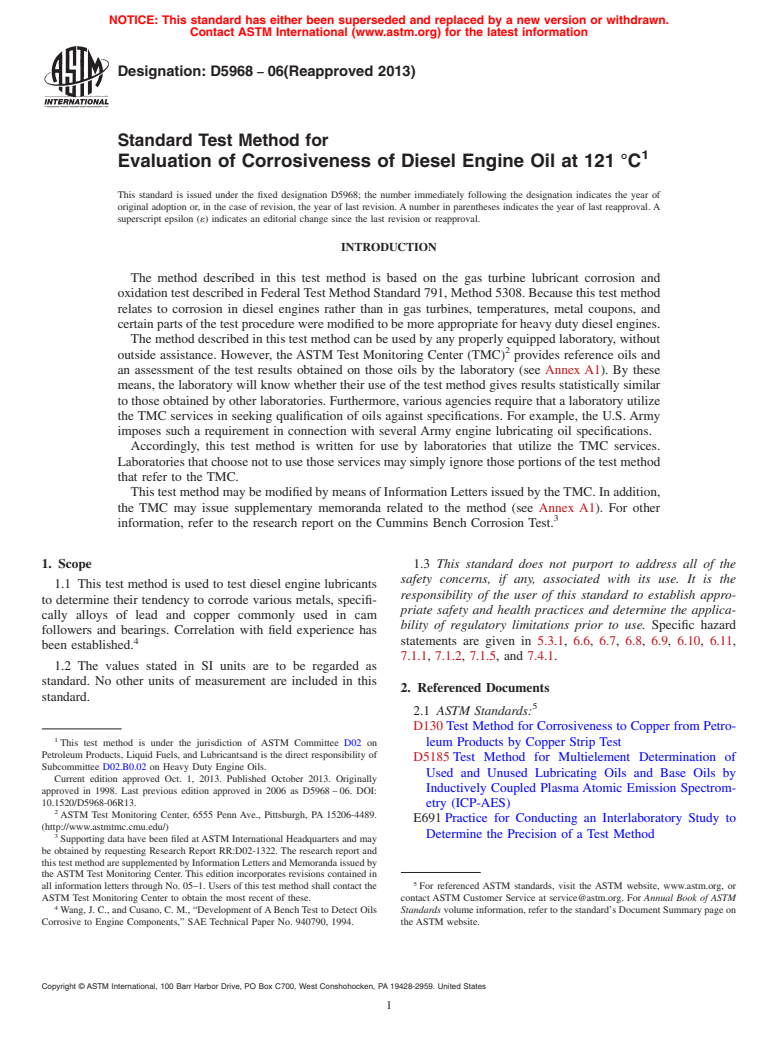

5.1.4 Thermocouple Tube, Fig. 4.

5.1.5 Condenser, Allihn Type, Fig. 5.

5.1 The main apparatus consists of the following items of

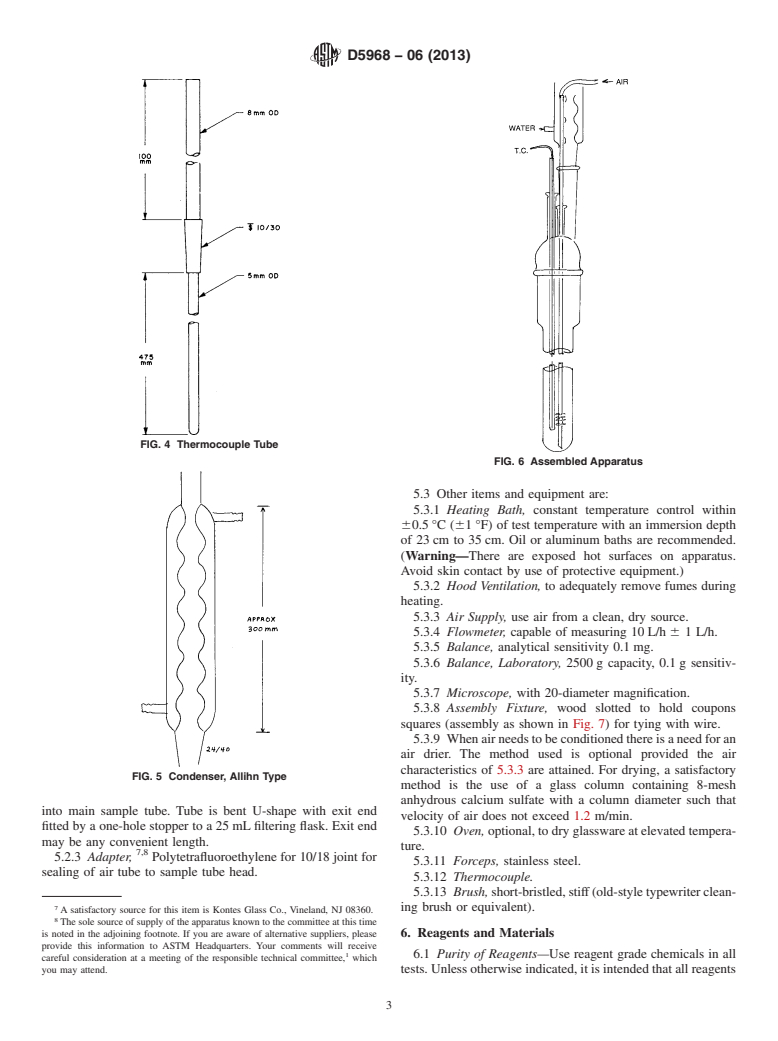

5.1.6 Assembled Apparatus, Fig. 6.

standard wall borosilicate glassware as shown in Figs. 1-6.

5.1.1 Main Sample Tube, Fig. 1.

5.2 Additional glassware items and assembly accessories

5.1.2 Sample Tube Head, Fig. 2.

needed are:

5.1.3 Air Tube, Fig. 3.

5.2.1 Spacers (for metal specimen), of borosilicate glass,

standard wall, 9 mm outside diameter, 6 mm length.

5.2.2 Oil Sampling Tube, Borosilicate Glass, 4 mm outside

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098. diameter, with sampling end approximately 600 mm to reach

D5968 − 06 (2013)

FIG. 4 Thermocouple Tube

FIG. 6 Assembled Apparatus

5.3 Other items and equipment are:

5.3.1 Heating Bath, constant temperature control within

60.5 °C (61 °F) of test temperature with an immersion depth

of 23 cm to 35 cm. Oil or aluminum baths are recommended.

(Warning—There are exposed hot surfaces on apparatus.

Avoid skin contact by use of protective equipment.)

5.3.2 Hood Ventilation, to adequately remove fumes during

heating.

5.3.3 Air Supply, use air from a clean, dry source.

5.3.4 Flowmeter, capable of measuring 10 L/h 6 1 L/h.

5.3.5 Balance, analytical sensitivity 0.1 mg.

5.3.6 Balance, Laboratory, 2500 g capacity, 0.1 g sensitiv-

ity.

5.3.7 Microscope, with 20-diameter magnification.

5.3.8 Assembly Fixture, wood slotted to hold coupons

squares (assembly as shown in Fig. 7) for tying with wire.

5.3.9 Whenairneedstobeconditionedthereisaneedforan

air drier. The method used is optional provided the air

characteristics of 5.3.3 are attained. For drying, a satisfactory

FIG. 5 Condenser, Allihn Type

method is the use of a glass column containing 8-mesh

anhydrous calcium sulfate with a column diameter such that

into main sample tube. Tube is bent U-shape with exit end

velocity of air does not exceed 1.2 m/min.

fitted by a one-hole stopper to a 25 mLfiltering flask. Exit end

5.3.10 Oven, optional, to dry glassware at elevated tempera-

may be any convenient length.

ture.

7,8

5.2.3 Adapter, Polytetrafluoroethylene for 10/18 joint for

5.3.11 Forceps, stainless steel.

sealing of air tube to sample tube head.

5.3.12 Thermocouple.

5.3.13 Brush,short-bristled,stiff(old-styletypewriterclean-

ing brush or equivalent).

A satisfactory source for this item is Kontes Glass Co., Vineland, NJ 08360.

The sole source of supply of the apparatus known to the committee at this time

is noted in the adjoining footnote. If you are aware of alternative suppliers, please 6. Reagents and Materials

provide this information to ASTM Headquarters. Your comments will receive

6.1 Purity of Reagents—Use reagent grade chemicals in all

careful consideration at a meeting of the responsible technical committee, which

you may attend. tests.Unlessotherwiseindicated,itisintendedthatallreagents

D5968 − 06 (2013)

6.7 Degreasing Solvents, Trichlorotrifluorethane or 1,1,1-

trichloroethane. (Warning—Harmful if inhaled.)

6.8 Glassware Cleaning Solution, mix 35 mL of saturated

sodium dichromate (aqueous) solution and 1000 mL of con-

centrated sulfuric acid. (Warning—Causes severe burns.)

12,8

6.9 Carbon Remover for Glassware , Oakite Stripper

R-8. (Warning—Corrosive, causes severe burns.)

6.10 Tetrahydrofuran. (Warning—Toxic and flammable.

Health hazard.)

6.11 Naphtha, Aromatic. (Warning—Flammable. Health

hazard.)

6.12 Filter Paper.

6.13 Kimwipe Tissues, or similar.

6.14 Industrial Reference Oil.

7. Preparation of Apparatus

7.1 Cleaning of Glassware from Previous Run:

7.1.1 Rinse all glassware items and the air tube adapter with

degreasing solvent to remove residual oil, and air dry.

(Warning—Harmful if inhaled.)

7.1.2 Fill or immerse the sample tube, air tube, and the

9 mm glass spacers in carbon remover at room temperature

until carbonaceous deposits are removed. Water rinse after

removal. (Warning—Corrosive, causes severe burns.)

FIG. 7 Arrangement of Metal Coupons

7.1.3 Wash all glassware items and the air tube adapter with

13,8

detergent. Rinse with water to remove detergent, and dry.

7.1.4 Store all items in a dust free cabinet until needed for

conform to the specifications of the Committee on Analytical

test. If stored longer than one week, rinse again with distilled

Reagents of the American Chemical Society where such

water before use, and dry.

specifications are available.

7.1.5 A more elaborate glass cleaning procedure can be

10,8

used, if it is for a given situation. This cleaning procedure is

6.2 Metal Specimens:

necessary in a referee situation unless a cleaning solution can

6.2.1 Coupons, 0.081 cm thick by 2.5 cm square, one each,

be used which is satisfactory to all parties involved. Fill and

with two drilled holes (as shown in Fig. 7), as follows:

immerse all glassware items with glassware cleaning solution

6.2.1.1 Copper (R401-A),

and soak for 3 h to 16 h. (Warning—Corrosive, causes severe

6.2.1.2 Lead (R401-lead),

burns.)

6.2.1.3 Tin (R401-tin), and

7.1.6 Remove glassware from cleaning solution, rinse sev-

6.2.1.4 Phosphor Bronze (R401-LEADz).

eral times with tap water, followed by distilled water, and oven

6.3 Nichrome Wire, clean (for tying coupons together).

dry.

6.4 Abrasive Paper, 240 grit aluminum oxide and 400 grit

7.2 Cleaning of Glassware (New):

silicon-carbide. Do not use iron-containing abrasives such as

7.2.1 Proceed as in 7.1.3 and 7.1.6 in that order (omit 7.1.1,

natural emery.

7.1.2, 7.1.4, and 7.1.5).

6.5 Cotton, absorbent.

7.3 Assembly—Assemble as shown in Fig. 6 using only the

6.6 Acetone (ACS), sulfur-free. (Warning—Flammable.

test oil to lubricate glass joints during assembly.

Health hazard.

7.4 Preparation of Metal Specimens:

7.4.1 Wash a length of the metal tying wire with tetrahy-

drofuran and acetone and allow to dry. (Warning—This and

Reagent Chemicals, American Chemical Society Specifications, American

thefollowingpreparationprocessesshouldbeperformedunder

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

listed by the American Chemical Society, see Annual Standards for Laboratory

a fume hood.)

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

7.4.2 The metal squares are prepared as follows:

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD.

Satisfactory metal specimens may be obtained from: Test Engineering, Inc.

(TEI), 12718 Cimarron Path, SanAntonio,TX 78249-3423.This is the only coupon Oakite Stripper R-8 is available from Oakite Products, Inc., 50 Valley Rd.,

source to be used for obtaining a valid reference run and data for certification. Berkeley Heights, NJ 07922. It has been found satisfactory for this purpose.

11 13

Suitable abrasive paper meeting these specifications is included with the metal A detergent found satisfactory is Alconox made by Alconox, Inc., 215 Park

coupons from the source indicated in 6.2. Ave. S., New York, NY 10003.

D5968 − 06 (2013)

7.4.2.1 Usingthe240gritabrasivepaper,removeallsurface Correct the leak, and repeat the determination, using fresh oil

blemishes from both sides and all four edges of each square, sample and new coupons.

and any burrs from the drilled holes. Finish polishing with 400

8.3.4 Using forceps, withdraw the coupons from the test

grit paper wetted by acetone to remove marks from previous tube, and remove the wire holding them together. (Retain the

polishing.Agood technique is to place abrasive paper on a flat

test tube and sample for further examination).

surface, then rub the specimen with longitudinal strokes in a

8.4 Preparing Squares for Examination:

direction perpendicular to that used with 240 grit paper. Use a

8.4.1 Using forceps, wash each square individually in tet-

different sheet of paper for each metal type.

rahydrofuran.

7.4.2.2 In all succeeding steps, handle the squares only with

8.4.2 Repeat the washing, using fresh tetrahydrofuran,

tongs or filter paper until the final weighing. If large defects or

scrubbing the squares with the short-bristled brush until the

particles are present on the metal coupons, course sand paper

tetrahydrofuran shows no additional discoloration. Use a piece

should be used first to remove them; this is followed by

of Kimwipe, dampened with acetone, to rub and wipe the

polishing with the 240 and 400 grit abrasive paper.

coupons repeatedly until the tissue remains clean after wiping.

(1) Store the polished metal coupon in tetrahydrofuran and

Allow the squares to air-dry. The reaction products that are to

proceed until all coupons are polished.

be removed by this cleaning process may tend to have a

(2) Remove each square from the tetrahydrofuran, clean all

stronger affinity to the br

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.